Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

The Design of Troughed Belt Conveyors

Caricato da

jonodo890 valutazioniIl 0% ha trovato utile questo documento (0 voti)

71 visualizzazioni44 pagineThe Design of Troughed Belt Conveyors

Copyright

© © All Rights Reserved

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documento0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

71 visualizzazioni44 pagineThe Design of Troughed Belt Conveyors

Caricato da

jonodo89Sei sulla pagina 1di 44

SISHEN SOUTH PROJECT

SPECIFICATION

@

ee

oo@

KUMBA

IRON ORE

THE DESIGN OF THROUGHED BELT CONVEYORS

K0001-A430-M-SPC-0003 REV A

APPROVED AND ACCEPTED BY

NAME POSITION DATE ‘SIGNATURE

LHaemse Project Manager: Sishen South Project

NAME ORIGINATOR DATE SIGNATURE

Theron Mechanical Engineer

SISHEN SOUTH PROJECT

SPECIFICATION Doc No: K0001-A430-M-SPC-0003 | Page 2 of 43

‘THE DESIGN OF THROUGHED BELT Rev No: A 19/10/2007

‘CONVEYORS.

TABLE OF CONTENTS

1 SCOPE

2 GENERAL ssn

24 2.1 SPECIFICATIONS, CODES OF PRACTICE AND DRAWINGS QUOTED IN PART 2 OF THIS

‘SPECIFICATION:

3 SOURCE OF AVAILABILITY OF SPECIFICATIONS QUOTED FROM:

3.1 BS, SABS AND AWS SPECIFICATIONS ARE OBTAINABLE FROM!

3.2 CORPORATE SPECIFICATIONS ARE OBTAINABLE FROM:

4 SPECIFICATION FOR CONVEYOR PULLEYS.....

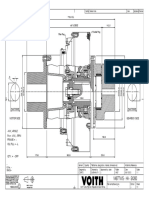

4.1 GENERAL CONDITIONS......

42 SHELLDETAILS...... rede

4.3 LAGGING DETAILS concen

4.4 ENDDISC DETAILS.

4.5 SHAFT AND LOCKING ELEMENT DETAILS.

48 WELDING DETAILS

4.7 WELD PROCESSES AND ELECTRODES ....

4.8 — QUALITY ASSURANCE...

5 SELECTION OF PULLEYS.

5.1 GENERAL CONDITIONS...

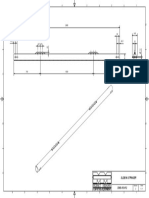

52 PULLEY FACE WIDTH........

53 PULLEY SHELL OUTSIDE DIAMETER

5.4 PULLEY SHAFT DIAMETER

5. PULLEY SHAFT LENGTH.

5.6 _ RESULTANT BELT FORCE ON PULLEY

57 PULLEY HUBDIAMETER :

58 PULLEY SHELL THICKNESS

5.9 RATIONALISATION OF PULLEYS

5.10 PREFERRED PULLEY SIZES.

5.11 PULLEY DESIGN AND SELECTION PROCEDURE...

5.12 STANDARD PULLEY DRAWINGS,

6 HOUSING, BEARING AND SEAL ASSEMBLIES...

6.1 GENERAL CONDITIONS...

62 SEALUNITS.

6.3 BEARING HOUSING END COVERS...

64 GREASE AND GREASE NIPPLES

65 6.5 BEARING HOUSING DETAILS

66 TYPE DESIGNATIONS

‘SISHEN SOUTH PROJECT

SPECIFICATION Doc No: K0001-A430-M-SPC-0003 | Page 3 of 43,

‘THE DESIGN OF THROUGHED BELT Rev No: A 19/10/2007

‘CONVEYORS,

1 SCOPE

34

This specification covers Kumba Resources requirements for all horizontal and inclined

troughed belt conveyors,

Part 2 covers the requirements for conveyor pulleys, the selection of pulleys,

plummerblocks, housings, bearings and seal assemblies.

GENERAL

24 SPECIFICATIONS, CODES OF PRACTICE AND DRAWINGS QUOTED IN PART

2 OF THIS SPECIFICATION:

SABS 044 Part Ill The fusion welding of steel (including stainless steel): Test

for the approval of welding procedures and production welds.

SABS 044 Part V._The fusion welding of steel (including stainless steel): Test

for the approval of welders working to approved welding procedures.

SABS 145 Solid filler wires for gas-shielded metal-arc welding of mild steel and

medium high tensile steel.

SABS 455 Covered electrodes for manual arc welding of mild steel and medium:

high tensile steel.

SABS 1033 Solid filler wires for the submerged are welding of mild steel and

medium high tensile steel.

BS 970 ‘Wrought steels in the form of blooms, billets, bars and forging,

Part 1 Carbon and carbon manganese steels including free cutting steels.

BS 1486 Heavy duty lubricating nipples.

Part 2

BS 1503 _ Steel forging (including semi-finished forged products) for pressure

purposes.

BS 2789 ‘Spheroidal graphite or nodular graphite cast iron.

BS 4360 Specification for weldable structural steels.

BS 5996 Methods of testing and quality grading of ferritic steel plate by ultrasonic

methods.

SSS/SAZ/000 Specification for lubricants.

AWS A5.1-69 American Welding Society specification for welding electrodes.

SABS 1669-1996 — Conveyor Belt Pulleys

SOURCE OF AVAILABILITY OF SPECIFICATIONS QUOTED FROM:

BS, SABS AND AWS SPECIFICATIONS ARE OBTAINABLE FROM:

South African Bureau of Standards

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5795)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- M&T Risk & AssuranceDocumento39 pagineM&T Risk & Assurancejonodo89Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Screw Take UpsDocumento7 pagineScrew Take Upsjonodo89Nessuna valutazione finora

- Surface Preparation and Paint SpecificationDocumento63 pagineSurface Preparation and Paint Specificationjonodo89Nessuna valutazione finora

- Fire Protection Standard For Vehicles and Moving MachineryDocumento39 pagineFire Protection Standard For Vehicles and Moving Machineryjonodo89100% (1)

- Fire Protection Standard For Electrical Equipment and InstallationsDocumento27 pagineFire Protection Standard For Electrical Equipment and Installationsjonodo89100% (1)

- ENG ECI ELC SPC 004 Electrical InstallationDocumento68 pagineENG ECI ELC SPC 004 Electrical Installationjonodo89Nessuna valutazione finora

- Generic Geared ReducersDocumento12 pagineGeneric Geared Reducersjonodo89Nessuna valutazione finora

- BB Design ReportDocumento79 pagineBB Design Reportjonodo89Nessuna valutazione finora

- EXX-EME-STD-0008 - Wear Liners For Plate Work and ChutesDocumento22 pagineEXX-EME-STD-0008 - Wear Liners For Plate Work and Chutesjonodo89100% (1)

- Sole PlatesDocumento12 pagineSole Platesjonodo89Nessuna valutazione finora

- Aa Spec 114005Documento45 pagineAa Spec 114005jonodo8950% (2)

- AATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & StructuralDocumento68 pagineAATC000859 - AATC Design Criteria and Guidelines For Surface Infrastructure - Mechanical & Structuraljonodo89Nessuna valutazione finora

- Static Shaft Pulleys With Internal BearingsDocumento14 pagineStatic Shaft Pulleys With Internal Bearingsjonodo89100% (1)

- Macsteel VRN - Wear Abrasion Steels - Creusabro 8000Documento4 pagineMacsteel VRN - Wear Abrasion Steels - Creusabro 8000jonodo89Nessuna valutazione finora

- Fire Protection Standard For Use of Plastic PipesDocumento6 pagineFire Protection Standard For Use of Plastic Pipesjonodo89Nessuna valutazione finora

- SolidwovendatasheetDocumento1 paginaSolidwovendatasheetjonodo89Nessuna valutazione finora

- K0001 A430 M SPC 0011 Rev02 Metallic Wear LiningDocumento15 pagineK0001 A430 M SPC 0011 Rev02 Metallic Wear Liningjonodo89Nessuna valutazione finora

- Mechanical StandardsDocumento10 pagineMechanical Standardsjonodo890% (1)

- Belt Conveyor Idlers and RollsDocumento14 pagineBelt Conveyor Idlers and Rollsjonodo89Nessuna valutazione finora

- 2RVRETURNS25Documento1 pagina2RVRETURNS25jonodo89Nessuna valutazione finora

- New Doc 2018-04-24Documento6 pagineNew Doc 2018-04-24jonodo89Nessuna valutazione finora

- DWG 415-007 REV 0Documento1 paginaDWG 415-007 REV 0jonodo89Nessuna valutazione finora

- DWG 424-012 REV 1Documento1 paginaDWG 424-012 REV 1jonodo89Nessuna valutazione finora

- v487tvvs - Ha - Sx260Documento1 paginav487tvvs - Ha - Sx260jonodo89Nessuna valutazione finora

- New Doc 2018-04-24Documento6 pagineNew Doc 2018-04-24jonodo89Nessuna valutazione finora

- DWG 415-006 REV 0Documento1 paginaDWG 415-006 REV 0jonodo89Nessuna valutazione finora

- DWG 415-009 REV 0Documento1 paginaDWG 415-009 REV 0jonodo89Nessuna valutazione finora

- DWG 415-008 REV 0Documento1 paginaDWG 415-008 REV 0jonodo89Nessuna valutazione finora

- G - 1 - A1 General Arrangment DrawingDocumento1 paginaG - 1 - A1 General Arrangment Drawingjonodo89Nessuna valutazione finora

- DWG 415-012 REV 2Documento1 paginaDWG 415-012 REV 2jonodo89Nessuna valutazione finora