Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

K-MAX Unmanned Aircraft System. Optionally Piloted Cargo Lift Helicopter For The Warfighter

Caricato da

cenkj0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

81 visualizzazioni4 paginekmax uav

Titolo originale

- K-MAX Unmanned Aircraft System. Optionally Piloted Cargo Lift Helicopter for the Warfighter

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentokmax uav

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

81 visualizzazioni4 pagineK-MAX Unmanned Aircraft System. Optionally Piloted Cargo Lift Helicopter For The Warfighter

Caricato da

cenkjkmax uav

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

About the K-MAX

UAS Team

Lockheed Martin’s Mission Systems

and Sensors facility in Owego, NY is

the Corporation’s rotary wing center of

excellence. The company has more than

35 years of experience as a leading mission

systems integrator of rotary wing aircraft,

including the British Royal Navy’s Merlin

Mk 1 helicopter fleet and two generations

of U.S. Navy helicopters, the SH-60B and

MH-60R.

In keeping with its world-class systems

integration status, the Owego site has

K-MAX® Unmanned Aircraft System

achieved CMMI® Level 5 for systems

engineering, software engineering, integrated

product and process development, and

supplier sourcing. Optionally Piloted Cargo Lift Helicopter for the Warfighter

Kaman Aerospace Corporation is a division

of Kaman Corporation, located in Bloomfield,

CT and does business as a prime helicopter

manufacturer; a subcontractor for aircraft

structures and components; designs and

manufactures safe, arm and fuzing devices

for bombs and missile systems; and is a

leading manufacturer of specialty bearings

for commercial and military aircraft.

Kaman Helicopters, a division within

Kaman Aerospace, conducts business

in the engineering, manufacturing, and

support business for their K-MAX and

SH-2G helicopters, as well as designing and

manufacturing of components for other prime

helicopter manufacturers.

Lockheed Martin MS2 Kaman Aerospace Corporation

300 M Street, SE Helicopters Division

Washington, DC 20003 Old Windsor Road

www.lockheedmartin.com/ms2/ Bloomfield, CT 06002

860-242-4461

Copyright ©2010 Lockheed Martin Corporation www.kamanaero.com

All rights reserved

PIRA# OWG201008002 K-MAX is a registered trademark of Kaman Aerospace Corporation

P07542001 11/2010

Capability Maturity Model, CMM, CMMI and Carnegie Mellon are registered

in the U.S. Patent and Trademark Office by Carnegie Mellon University U.S. Marine Corps Photo

The K-MAX® Unmanned Aircraft System – Servo control — The K-MAX generates

rotor pitch control via a mechanical servo flap

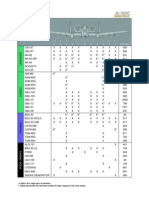

Weights and Measurements

Max gross weight (with external load) 12,000 lb 5,443 kg

A Power Lifter Transformed positioned along each of the four rotor blades. Max take-off weight 7,000 lb 3,175 kg

Servo flap control eliminates the need for a Empty weight 5,145 lb 2,334 kg

Useful load 6,855 lb 3,109 kg

Kaman Aerospace and Lockheed Martin have successfully complex, redundant, high-pressure hydraulic Cargo hook capacity 6,000 lb 2,722 kg

transformed Kaman’s proven K-MAX power lift helicopter into system.

Lift Performance — ISA +15°C (59°F)

an unmanned aircraft system (UAS). Its mission: battlefield cargo Safer by design — No tail rotor and minimal Sea Level 6,000 lb 2,722 kg

re-supply. downwash mean safer ground and flight 5,000 feet 5,663 lb 2,574 kg

operations. 10,000 feet 5,163 lb 2,347 kg

15,000 feet 4,313 lb 1,960 kg

As a UAS, the unmanned K-MAX can lift and deliver a full Low noise — No tail rotor yields a low

noise signature collectively that will give the Hover Performance — 4,000 feet, 35°C (95°F)

6,000 lb of cargo at sea level, or more than 4,000 lb at 15,000 ft Hover IGE 12,000 lb 5,443 kg

K-MAX UAS and the warfighter a tactical

density altitude. And it does so with autonomous flight capability. Hover OGE 11,500 lb 5,216 kg

advantage during cargo delivery.

Powerplant

Low maintenance — Without need for

Flight autonomy allows the UAS to safely deliver sling loads to Model - Honeywell T53-17 gas turbine

high-maintenance hydraulics or tail rotor, Thermodynamic rating 1,800 shaft horsepower

multiple, beyond line-of-sight drop zones, and return to home the K-MAX UAS requires minimal daily

base — all during a single flight and with minimal ground maintenance and needs no special facilities Maximum Airspeed

Without external load 100 kt 185.2 kph

operator oversight. for maintenance work. With external load 80 kt 148.2 kph

Low operating costs — The K-MAX UAS

Fuel System

uses an average of 85 gallons of fuel per hour Total usable fuel 219.5 gal 831 liters

delivering the most efficient lift-to-fuel ratio Avg fuel consumption 85 gal/hr 321.7 l/hr

drop site, the system or receiving controller

can maneuver the aircraft to perform a

Optionally Piloted of any helicopter in its class. Jet A fuel

Maximum endurance

557.6 lb/hr 252.9 kg/hr

12+ hr

Cargo hook /trolley — The K-MAX UAS Maximum range 1,852km (est)

precision delivery. The Lockheed Martin and Kaman team have

is built around its cargo hook attached to a Maximum speed with external load 148.2km/h

retained the single seat cockpit in the K-MAX Maximum speed without external load 185.2km/h

curved trolley system. This configuration

Data links — Portable antennae for line-of- UAS, enabling piloted operation for maximum Internal fuel endurance 2 hr 41 min

allows the hook to track across the belly of the Range with external load 396.3km

sight and satellite-based beyond line-of-sight flexibility and lower risk to the platform.

airframe, enhancing aircraft maneuverability Range without external load 494.5km

data links maintain continuous connectivity

and load stability. Approved fuels Jet A/A-1, JP-5

with the unmanned K-MAX anywhere in the

world.

Better by Design Four-hook carousel — The carousel features

Jet B/JP-4

JP-8

When it comes to cargo lift, operational safety four hooks, each activated independently. The

The MMC downlinks aircraft status and flight and reliability, noise signature, maintenance ground controller can pre-program the UAS

parameters to a ground controller, who can and operating costs, no other rotary wing UAS to release a load at four separate destinations

upload new flight commands if required at can outperform the unmanned K-MAX. during a single flight.

any time during the mission.

Intermeshing rotors — Twin counter-rotating,

Managing the Mission Mission/Flight computers — The MMC intermeshing main rotors eliminate the need Logistics Support

Lockheed Martin brings advanced UAS communicates the ground controller’s for a tail rotor drive system. Without a tail

The Lockheed Martin-led team ensures

command, control and on-board intelligence objectives to the FCC (autopilot). FCC dual rotor, all engine power goes directly to the

high availability of the K-MAX UAS to the

to the unmanned K-MAX for truly redundancy provides high reliability. The main rotors for significantly improved lift

warfighter.

autonomous military operations. computers perform contingency management performance, critical to maintaining power

in an aircraft emergency or during a lost and performance at high altitudes and high The team will bring to bear Kaman’s logistics

UAS management consists of Mission communications link. temperatures. support experience established across

Management and redundant Flight Control 250,000+ worldwide flight hours serving the

Computers (FCC) connected via data links to a commercial K-MAX fleet.

ground controller.

During the past three years, Kaman has met a

Ground control — A ground controller uses 99 percent First Time Fill Rate for parts.

a ruggedized laptop with command and Lockheed Martin brings to the team

control software to develop and upload a exceptional supply chain management and

mission flight plan to the aircraft’s on-board global sustainment expertise.

Mission Management Computer (MMC) prior

to launch. The controller can upload new

A K-MAX UAS lifts 1,500 pounds during contractor flight

mission plans at any time during flight. At the tests at Yuma Proving Ground, AZ, in January 2010.

The K-MAX® Unmanned Aircraft System – Servo control — The K-MAX generates

rotor pitch control via a mechanical servo flap

Weights and Measurements

Max gross weight (with external load) 12,000 lb 5,443 kg

A Power Lifter Transformed positioned along each of the four rotor blades. Max take-off weight 7,000 lb 3,175 kg

Servo flap control eliminates the need for a Empty weight 5,145 lb 2,334 kg

Useful load 6,855 lb 3,109 kg

Kaman Aerospace and Lockheed Martin have successfully complex, redundant, high-pressure hydraulic Cargo hook capacity 6,000 lb 2,722 kg

transformed Kaman’s proven K-MAX power lift helicopter into system.

Lift Performance — ISA +15°C (59°F)

an unmanned aircraft system (UAS). Its mission: battlefield cargo Safer by design — No tail rotor and minimal Sea Level 6,000 lb 2,722 kg

re-supply. downwash mean safer ground and flight 5,000 feet 5,663 lb 2,574 kg

operations. 10,000 feet 5,163 lb 2,347 kg

15,000 feet 4,313 lb 1,960 kg

As a UAS, the unmanned K-MAX can lift and deliver a full Low noise — No tail rotor yields a low

noise signature collectively that will give the Hover Performance — 4,000 feet, 35°C (95°F)

6,000 lb of cargo at sea level, or more than 4,000 lb at 15,000 ft Hover IGE 12,000 lb 5,443 kg

K-MAX UAS and the warfighter a tactical

density altitude. And it does so with autonomous flight capability. Hover OGE 11,500 lb 5,216 kg

advantage during cargo delivery.

Powerplant

Low maintenance — Without need for

Flight autonomy allows the UAS to safely deliver sling loads to Model - Honeywell T53-17 gas turbine

high-maintenance hydraulics or tail rotor, Thermodynamic rating 1,800 shaft horsepower

multiple, beyond line-of-sight drop zones, and return to home the K-MAX UAS requires minimal daily

base — all during a single flight and with minimal ground maintenance and needs no special facilities Maximum Airspeed

Without external load 100 kt 185.2 kph

operator oversight. for maintenance work. With external load 80 kt 148.2 kph

Low operating costs — The K-MAX UAS

Fuel System

uses an average of 85 gallons of fuel per hour Total usable fuel 219.5 gal 831 liters

delivering the most efficient lift-to-fuel ratio Avg fuel consumption 85 gal/hr 321.7 l/hr

drop site, the system or receiving controller

can maneuver the aircraft to perform a

Optionally Piloted of any helicopter in its class. Jet A fuel

Maximum endurance

557.6 lb/hr 252.9 kg/hr

12+ hr

Cargo hook /trolley — The K-MAX UAS Maximum range 1,852km (est)

precision delivery. The Lockheed Martin and Kaman team have

is built around its cargo hook attached to a Maximum speed with external load 148.2km/h

retained the single seat cockpit in the K-MAX Maximum speed without external load 185.2km/h

curved trolley system. This configuration

Data links — Portable antennae for line-of- UAS, enabling piloted operation for maximum Internal fuel endurance 2 hr 41 min

allows the hook to track across the belly of the Range with external load 396.3km

sight and satellite-based beyond line-of-sight flexibility and lower risk to the platform.

airframe, enhancing aircraft maneuverability Range without external load 494.5km

data links maintain continuous connectivity

and load stability. Approved fuels Jet A/A-1, JP-5

with the unmanned K-MAX anywhere in the

world.

Better by Design Four-hook carousel — The carousel features

Jet B/JP-4

JP-8

When it comes to cargo lift, operational safety four hooks, each activated independently. The

The MMC downlinks aircraft status and flight and reliability, noise signature, maintenance ground controller can pre-program the UAS

parameters to a ground controller, who can and operating costs, no other rotary wing UAS to release a load at four separate destinations

upload new flight commands if required at can outperform the unmanned K-MAX. during a single flight.

any time during the mission.

Intermeshing rotors — Twin counter-rotating,

Managing the Mission Mission/Flight computers — The MMC intermeshing main rotors eliminate the need Logistics Support

Lockheed Martin brings advanced UAS communicates the ground controller’s for a tail rotor drive system. Without a tail

The Lockheed Martin-led team ensures

command, control and on-board intelligence objectives to the FCC (autopilot). FCC dual rotor, all engine power goes directly to the

high availability of the K-MAX UAS to the

to the unmanned K-MAX for truly redundancy provides high reliability. The main rotors for significantly improved lift

warfighter.

autonomous military operations. computers perform contingency management performance, critical to maintaining power

in an aircraft emergency or during a lost and performance at high altitudes and high The team will bring to bear Kaman’s logistics

UAS management consists of Mission communications link. temperatures. support experience established across

Management and redundant Flight Control 250,000+ worldwide flight hours serving the

Computers (FCC) connected via data links to a commercial K-MAX fleet.

ground controller.

During the past three years, Kaman has met a

Ground control — A ground controller uses 99 percent First Time Fill Rate for parts.

a ruggedized laptop with command and Lockheed Martin brings to the team

control software to develop and upload a exceptional supply chain management and

mission flight plan to the aircraft’s on-board global sustainment expertise.

Mission Management Computer (MMC) prior

to launch. The controller can upload new

A K-MAX UAS lifts 1,500 pounds during contractor flight

mission plans at any time during flight. At the tests at Yuma Proving Ground, AZ, in January 2010.

About the K-MAX

UAS Team

Lockheed Martin’s Mission Systems

and Sensors facility in Owego, NY is

the Corporation’s rotary wing center of

excellence. The company has more than

35 years of experience as a leading mission

systems integrator of rotary wing aircraft,

including the British Royal Navy’s Merlin

Mk 1 helicopter fleet and two generations

of U.S. Navy helicopters, the SH-60B and

MH-60R.

In keeping with its world-class systems

integration status, the Owego site has

K-MAX® Unmanned Aircraft System

achieved CMMI® Level 5 for systems

engineering, software engineering, integrated

product and process development, and

supplier sourcing. Optionally Piloted Cargo Lift Helicopter for the Warfighter

Kaman Aerospace Corporation is a division

of Kaman Corporation, located in Bloomfield,

CT and does business as a prime helicopter

manufacturer; a subcontractor for aircraft

structures and components; designs and

manufactures safe, arm and fuzing devices

for bombs and missile systems; and is a

leading manufacturer of specialty bearings

for commercial and military aircraft.

Kaman Helicopters, a division within

Kaman Aerospace, conducts business

in the engineering, manufacturing, and

support business for their K-MAX and

SH-2G helicopters, as well as designing and

manufacturing of components for other prime

helicopter manufacturers.

Lockheed Martin MS2 Kaman Aerospace Corporation

300 M Street, SE Helicopters Division

Washington, DC 20003 Old Windsor Road

www.lockheedmartin.com/ms2/ Bloomfield, CT 06002

860-242-4461

Copyright ©2010 Lockheed Martin Corporation www.kamanaero.com

All rights reserved

PIRA# OWG201008002 K-MAX is a registered trademark of Kaman Aerospace Corporation

P07542001 11/2010

Capability Maturity Model, CMM, CMMI and Carnegie Mellon are registered

in the U.S. Patent and Trademark Office by Carnegie Mellon University U.S. Marine Corps Photo

Potrebbero piacerti anche

- Italian VSTOL Concepts of The Twentieth CenturyDocumento46 pagineItalian VSTOL Concepts of The Twentieth CenturyHarold_Godwinson100% (2)

- Kiss of The Spider Woman PDFDocumento290 pagineKiss of The Spider Woman PDFcenkj100% (6)

- 111759main DoD UAV Roadmap 2003Documento209 pagine111759main DoD UAV Roadmap 2003sharath_87Nessuna valutazione finora

- DCS Ka-50 GuideDocumento208 pagineDCS Ka-50 GuideKent MoralesNessuna valutazione finora

- ApacheDocumento18 pagineApacheKrishna Myakala100% (1)

- UAV OperationsDocumento183 pagineUAV OperationsGasMaskBobNessuna valutazione finora

- Helicopter Mi-28N-2011Documento5 pagineHelicopter Mi-28N-2011DefenceDog100% (1)

- 100117CDR MQ-9B SkyGuardian Readly To Deliver JUSTAS PDFDocumento5 pagine100117CDR MQ-9B SkyGuardian Readly To Deliver JUSTAS PDFMorgen GumpNessuna valutazione finora

- Uav Roadmap2005Documento213 pagineUav Roadmap2005rwong1231Nessuna valutazione finora

- Subsonic Energy Maneuverability Diagrams For DCSDocumento29 pagineSubsonic Energy Maneuverability Diagrams For DCSLucasNessuna valutazione finora

- Kamov Ka-50Documento6 pagineKamov Ka-50jb2ookwormNessuna valutazione finora

- UuvmpDocumento127 pagineUuvmpmacon20000Nessuna valutazione finora

- FA 18 WeaponsDocumento1 paginaFA 18 Weaponsmandjare100% (1)

- Unmanned Aerial Vehicles Roadmap (2000-2025)Documento130 pagineUnmanned Aerial Vehicles Roadmap (2000-2025)Neto Custodio0% (1)

- Northrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Da EverandNorthrop N-63 Convoy Fighter: The Naval VTOL Turboprop Tailsitter Project of 1950Valutazione: 5 su 5 stelle5/5 (2)

- Jassm: The Best Value of Any Air-To-Surface Missile in Its ClassDocumento2 pagineJassm: The Best Value of Any Air-To-Surface Missile in Its ClassVictor PileggiNessuna valutazione finora

- Air and Space Power With Chinese Characteristics: China's Military RevolutionDocumento24 pagineAir and Space Power With Chinese Characteristics: China's Military RevolutionKyaw Gyii100% (1)

- A Perspective On The Requirements and Design For Advanced Cruise MissilesDocumento7 pagineA Perspective On The Requirements and Design For Advanced Cruise Missilesgrindormh53100% (1)

- Germanv Stol FightersDocumento54 pagineGermanv Stol FightersFahmi Abdillah100% (1)

- Unmanned Aircraft SystemDocumento123 pagineUnmanned Aircraft SystemedwardsilvaNessuna valutazione finora

- Methods of Radar Cross-section AnalysisDa EverandMethods of Radar Cross-section AnalysisJ.W. Jr. CrispinNessuna valutazione finora

- Army Aviation Digest - Jun 1968Documento68 pagineArmy Aviation Digest - Jun 1968Aviation/Space History LibraryNessuna valutazione finora

- Uav or DronesDocumento384 pagineUav or Dronescenkj100% (1)

- English Electric Lightning F1 Model KitDocumento16 pagineEnglish Electric Lightning F1 Model KitDonNessuna valutazione finora

- Lockheed Martin Service News Vol28 No2Documento15 pagineLockheed Martin Service News Vol28 No2Bobby ChippingNessuna valutazione finora

- L P - The Dear Departed-Drama-10thDocumento5 pagineL P - The Dear Departed-Drama-10thVritika Shorie100% (2)

- 3 Ekman SaabDocumento34 pagine3 Ekman SaabPanneer Selvam100% (1)

- Vision Based Systems For UAV Applications: Aleksander Nawrat Zygmunt KusDocumento348 pagineVision Based Systems For UAV Applications: Aleksander Nawrat Zygmunt KuscenkjNessuna valutazione finora

- Trip TicketDocumento2 pagineTrip TicketKynth Ochoa100% (2)

- EML3500 CH 8 SlidesDocumento134 pagineEML3500 CH 8 SlidesGanesh Dongre100% (1)

- Armada - June July 2014 DRONES CompendiumDocumento36 pagineArmada - June July 2014 DRONES CompendiumPillaChantas100% (1)

- Meggitt Defense Systems 20mm Linkless Feed System for Cobra HelicoptersDocumento2 pagineMeggitt Defense Systems 20mm Linkless Feed System for Cobra Helicoptersmelih100% (1)

- D956e0120 RWM SeaSnake 20Documento2 pagineD956e0120 RWM SeaSnake 20Panthep PattongNessuna valutazione finora

- Small But Mighty PowerfulDocumento4 pagineSmall But Mighty PowerfulMohammad LavasaniNessuna valutazione finora

- LSIS - Molded Case Circuit Breaker (MCCB) - CatalogDocumento140 pagineLSIS - Molded Case Circuit Breaker (MCCB) - CatalogNguyen LuongNessuna valutazione finora

- Rq-4 Block 20 Global Hawk: Structural FeaturesDocumento5 pagineRq-4 Block 20 Global Hawk: Structural FeaturesTuğba BüyüktanırNessuna valutazione finora

- Agat New Generation of Active Radar Homing HeadsDocumento2 pagineAgat New Generation of Active Radar Homing HeadsWingexheroNessuna valutazione finora

- Jaguar HistoryDocumento14 pagineJaguar Historyjean linardNessuna valutazione finora

- Turn-to-Turn Fault Protection Schemes For Magnetically-Controlled Shunt Reactors (MCSR)Documento57 pagineTurn-to-Turn Fault Protection Schemes For Magnetically-Controlled Shunt Reactors (MCSR)Muhammad Asghar KhanNessuna valutazione finora

- Process Improvement and CMMI For Systems and SoftwareDocumento429 pagineProcess Improvement and CMMI For Systems and SoftwarecenkjNessuna valutazione finora

- Boris Mutafelija, Harvey Stromberg Process Improvement With CMMI® v1.2 and ISO StandardsDocumento426 pagineBoris Mutafelija, Harvey Stromberg Process Improvement With CMMI® v1.2 and ISO StandardsJuan Sebastián SánchezNessuna valutazione finora

- Bip 0072-2014 PDFDocumento94 pagineBip 0072-2014 PDFgrNessuna valutazione finora

- Analysis of G LEO Kinetic Bombardment AnDocumento28 pagineAnalysis of G LEO Kinetic Bombardment AnpsuedonymousNessuna valutazione finora

- Miniature UAVs & Future EW: Distributed SensingDocumento13 pagineMiniature UAVs & Future EW: Distributed Sensingl k100% (2)

- 4 WB Group Uav TechnologyDocumento48 pagine4 WB Group Uav Technologycroffle.inNessuna valutazione finora

- 2019 - Chasing Aphrodite - DefencegreeceDocumento18 pagine2019 - Chasing Aphrodite - Defencegreeceapeirotan100% (1)

- Lock On Flaming Cliffs 1.1 Flight ManualDocumento262 pagineLock On Flaming Cliffs 1.1 Flight ManualNidhogg100% (1)

- Surface To Air Missile - SA-15 (9K33 TOR) - Falcon LoungeDocumento6 pagineSurface To Air Missile - SA-15 (9K33 TOR) - Falcon Loungewizz33100% (2)

- History of The Talos MissileDocumento13 pagineHistory of The Talos Missileh_mahdi100% (2)

- 94sep Chang The IR Missle PDFDocumento87 pagine94sep Chang The IR Missle PDFfuckscribNessuna valutazione finora

- Process Control Valves TrainingDocumento12 pagineProcess Control Valves TrainingpptmnltNessuna valutazione finora

- EFT Stratguide GB 72dpiDocumento137 pagineEFT Stratguide GB 72dpic4c4100% (1)

- Difference Between Assessment and EvaluationDocumento5 pagineDifference Between Assessment and EvaluationcenkjNessuna valutazione finora

- Airborne Battlefield Command and Control Center - ABCCCDocumento4 pagineAirborne Battlefield Command and Control Center - ABCCCcicogna76100% (1)

- MD500 Proven PlatformDocumento25 pagineMD500 Proven PlatformrobbertmdNessuna valutazione finora

- SeascoutDocumento7 pagineSeascoutkevinlimyuanlinNessuna valutazione finora

- The World Largers AircraftDocumento64 pagineThe World Largers AircraftBobi PitropNessuna valutazione finora

- Aerodynamic Features of A Coaxial Rotor HelicopterDocumento19 pagineAerodynamic Features of A Coaxial Rotor HelicopterThomas MouraNessuna valutazione finora

- Matt Y B': The Trip 3Documento40 pagineMatt Y B': The Trip 3chunkyturtle1224100% (1)

- Saab Gripen Handbook PDFDocumento22 pagineSaab Gripen Handbook PDFJavi Moreno100% (2)

- The Rise of Aircraft Performance in the Early 20th CenturyDocumento188 pagineThe Rise of Aircraft Performance in the Early 20th CenturyRandal Marbury100% (1)

- Guidance and Control of Cannon Launched Guided Projectile-MorrisonDocumento7 pagineGuidance and Control of Cannon Launched Guided Projectile-MorrisonvaskarthikeyanNessuna valutazione finora

- Cruise Missile Technology Seminar ReportDocumento37 pagineCruise Missile Technology Seminar Reportshubham soniNessuna valutazione finora

- Yugoimport MagazineDocumento84 pagineYugoimport MagazineLUDICOVEK100% (1)

- 1988 - 2833Documento1 pagina1988 - 2833scorpion_l_810% (1)

- DCS A-10C External StoresDocumento1 paginaDCS A-10C External StoresAries0104Nessuna valutazione finora

- Picking The Right Airplane For The Job: by Leon "Badboy" SmithDocumento13 paginePicking The Right Airplane For The Job: by Leon "Badboy" SmithLeonMSmithNessuna valutazione finora

- Preliminary Design of Supersonic FighterDocumento28 paginePreliminary Design of Supersonic FighterSarangNessuna valutazione finora

- S-300 System Export Form RussiaDocumento26 pagineS-300 System Export Form Russiaveritas19871987Nessuna valutazione finora

- Army Aviation Digest - Mar 1991Documento68 pagineArmy Aviation Digest - Mar 1991Aviation/Space History LibraryNessuna valutazione finora

- Wilson-Dunham MissileThreat 20200826 0Documento27 pagineWilson-Dunham MissileThreat 20200826 0adnan gondžićNessuna valutazione finora

- HSM DatasheetDocumento2 pagineHSM DatasheetMrityunjoy MazumdarNessuna valutazione finora

- BR 57mmengDocumento4 pagineBR 57mmengLG GLNessuna valutazione finora

- Nevada Warbird Survivors 2002: A Handbook on Where to Find ThemDa EverandNevada Warbird Survivors 2002: A Handbook on Where to Find ThemNessuna valutazione finora

- SeaOtter. Unmanned VehiclesDocumento4 pagineSeaOtter. Unmanned VehiclescenkjNessuna valutazione finora

- Unmanned Vehicles Handbook 2008Documento72 pagineUnmanned Vehicles Handbook 2008itaiorrNessuna valutazione finora

- Air Force Unmanned Aerial System (UAS) Flight Plan 2009-2047Documento22 pagineAir Force Unmanned Aerial System (UAS) Flight Plan 2009-2047cenkj100% (1)

- UAV SystemsDocumento323 pagineUAV SystemscenkjNessuna valutazione finora

- SeaCat. Unmanned VehiclesDocumento2 pagineSeaCat. Unmanned VehiclescenkjNessuna valutazione finora

- Felipe Gonzalez Toro - Antonios Tsourdos - UAV or Drones For Remote Sensing Applications 2 (2018)Documento406 pagineFelipe Gonzalez Toro - Antonios Tsourdos - UAV or Drones For Remote Sensing Applications 2 (2018)cenkjNessuna valutazione finora

- UAV Cooperative Decision and ControlDocumento186 pagineUAV Cooperative Decision and ControlcenkjNessuna valutazione finora

- Skyflex Heli App Guide A4 SMDocumento2 pagineSkyflex Heli App Guide A4 SMcenkjNessuna valutazione finora

- FIZ101E 1vDocumento23 pagineFIZ101E 1vcenkjNessuna valutazione finora

- Advances in Composite ManufacturingDocumento34 pagineAdvances in Composite ManufacturingcenkjNessuna valutazione finora

- CGI Federal CMMI High Maturity ImplementationDocumento10 pagineCGI Federal CMMI High Maturity ImplementationcenkjNessuna valutazione finora

- Difference Between Quality Assurance and Quality Control (With Comparison Chart) - Key DifferencesDocumento5 pagineDifference Between Quality Assurance and Quality Control (With Comparison Chart) - Key Differencescenkj100% (1)

- Atwood C.P. - Huns and Xiongnu. New Thoughts On An Old ProblemDocumento26 pagineAtwood C.P. - Huns and Xiongnu. New Thoughts On An Old ProblemcenkjNessuna valutazione finora

- Achieving Maturity Levels 2 and 3 With LabviewDocumento8 pagineAchieving Maturity Levels 2 and 3 With LabviewcenkjNessuna valutazione finora

- Card&BEA Lvel6 Measurment&PSM102a 3Documento51 pagineCard&BEA Lvel6 Measurment&PSM102a 3cenkjNessuna valutazione finora

- 1 Measurement and AnalysisDocumento20 pagine1 Measurement and Analysiscris crisNessuna valutazione finora

- CMMI High Maturity Made PracticalDocumento62 pagineCMMI High Maturity Made PracticalcenkjNessuna valutazione finora

- Capability Maturity Model Integration (Cmmi) Version 1.1 OverviewDocumento58 pagineCapability Maturity Model Integration (Cmmi) Version 1.1 OverviewpicalaNessuna valutazione finora

- Anderson PDFDocumento7 pagineAnderson PDFChristian MavarezNessuna valutazione finora

- ExcelDocumento258 pagineExcelsusi herawatiNessuna valutazione finora

- MMP - Intro To ElectronicDocumento12 pagineMMP - Intro To ElectronicAye Chan OoNessuna valutazione finora

- Vibration Measuring Instrument: Assignment of Subject NVHDocumento28 pagineVibration Measuring Instrument: Assignment of Subject NVHSandeep Kadam60% (5)

- MS 2400 1 2010 P-TocDocumento7 pagineMS 2400 1 2010 P-Tocfauzirohani0% (1)

- PCBA MachineDocumento62 paginePCBA MachineSahara MalabananNessuna valutazione finora

- Document 1Documento14 pagineDocument 1Lê Quyên VõNessuna valutazione finora

- Chapter 8-Stringing and Miscellaneous WorksDocumento3 pagineChapter 8-Stringing and Miscellaneous Workschintan pandyaNessuna valutazione finora

- Rock Mechanics ASSGN 2Documento7 pagineRock Mechanics ASSGN 2ankeshNessuna valutazione finora

- C3Documento14 pagineC3mee myyNessuna valutazione finora

- Elektricna Sema KlimeDocumento58 pagineElektricna Sema Klimefrostssss0% (1)

- Schematic Diagrams: Compact Component SystemDocumento12 pagineSchematic Diagrams: Compact Component SystemGustavo DestruelNessuna valutazione finora

- Websphere Application Server Runtime Architecture: Welcome ToDocumento24 pagineWebsphere Application Server Runtime Architecture: Welcome ToluweinetNessuna valutazione finora

- 81/253/INF For IEC Use Only 2004-08-27 International Electrotechnical Commission Technical Committee No. 81: Lightning ProtectionDocumento3 pagine81/253/INF For IEC Use Only 2004-08-27 International Electrotechnical Commission Technical Committee No. 81: Lightning ProtectionAndres Felipe Muñoz ANessuna valutazione finora

- Alert Operators Transmission - Aot: Customer Services DirectorateDocumento8 pagineAlert Operators Transmission - Aot: Customer Services DirectorateIbrahim KhalilNessuna valutazione finora

- K2225 MosfetDocumento7 pagineK2225 MosfetDavid Eduardo Drew PerezNessuna valutazione finora

- BentleyDocumento27 pagineBentleycipele12Nessuna valutazione finora

- Owner's Manual Safety Instructions Operating InstructionsDocumento16 pagineOwner's Manual Safety Instructions Operating InstructionsKevin CharlesNessuna valutazione finora

- Masterseal Plus CatalogueDocumento8 pagineMasterseal Plus CataloguePeter ManNessuna valutazione finora

- Nitin FicoDocumento3 pagineNitin Ficoapi-3806547100% (1)

- Radio Amateur's Software GuideDocumento251 pagineRadio Amateur's Software GuideZdenko NagyNessuna valutazione finora

- Negotiation - Course Outline APR17Documento8 pagineNegotiation - Course Outline APR17ravindrarao_mNessuna valutazione finora

- Introduction To Data Analytics - AnnouncementsDocumento16 pagineIntroduction To Data Analytics - AnnouncementsAmit GuptaNessuna valutazione finora