Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Scania DC16 650 Tech - Tier 4

Caricato da

Dave WallaceTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Scania DC16 650 Tech - Tier 4

Caricato da

Dave WallaceCopyright:

Formati disponibili

SCANIA industrial engines

DC16 70A. 478 kW (650 hp)

US Tier 4i, EU Stage IIIB

Standard equipment

• Scania Engine Management System, EMS

• Extra high pressure fuel injection system, XPI

• Turbo charger

• Fuel filter and extra pre-filter with water

separator

• Oil filter, full flow

• Centrifugal oil cleaner

• Oil cooler, integrated in block

• Oil filler, in valve cover

• Deep front oil sump

• Oil dipstick, in block

• Magnetic drain plug for oil draining

• Starter, 1-pole 7.0 kW

• Alternator, 1-pole 100A

• Flywheel, for use with friction clutch

• Silumin flywheel housing, SAE 1 flange

• Front mounted engine brackets

The industrial engines from Scania are based on a robust design with a strength • SCR system

optimised cylinder block containing wet cylinder liners that can easiliy be exchanged. • Open crankcase ventilation

• Operator’s manual

Individual cylinder heads with 4 valves per cylinder promotes repairability and fuel

economy.

The engine is equipped with a Scania developed Engine Management System, Optional equipment

• Prepared for cooling package

EMS, in order to ensure the control of all aspects related to engine performance.

• Puller and pusher fans

The injection system is Scania’s XPI (Extra High Pressure Injection), a common rail • Fan ring with sealing

system that in combination with SCR (Selective Catalytic Reduction) gives low exhaust • Hydraulic pump

emissions with good fuel economy and a high torque. The engine can be fitted with • Air compressor

• AC compressor

many accessories such as air cleaners, silencers, PTO:s and flywheels in order to suit

• Side mounted PTO

a variety of installations. • Front mounted PTO

• Exhaust connections

• Electrical base system

• Control and instrument panels

Engine speed (rpm) • Accelerator position sensor

• Engine heater

Rating 1200 1500 1800 2100

• Flywheel: SAE14”

Gross power (kW) ICFN 356 478 478 478 • Stiff rubber engine suspension

Gross power (hp) ICFN 484 650 650 650 • Air cleaner

• Closed crankcase ventilation

Gross torque (Nm) ICFN 2830 3043 2536 2174

• Studs in flywheel housing

Spec fuel consumption. Full load (g/kWh) 192 194 200 212 • External thermostat for extra oil cooler

Spec fuel consumption. 3/4 load (g/kWh) 194 196 198 217 • Low coolant level reaction

Spec fuel consumption. 1/2 load (g/kWh) 196 196 203 226 • Variable idle speed setting

• Low oil sump

AdBlue consumption. Full load (g/kWh) 21 20 20 24

• Oil level sensor

Heat rejection to cooling water (kW) 144 165 168 188

ICFN – Continous service: Rated output available 1/1 h.

Unlimited h/year service time at a load factor of 100%

This specification is preliminary and may be revised

without notice.

SCANIA industrial engines

DC16 70A. 478 kW (650 hp)

US Tier 4i, EU Stage IIIB

Output

Engine description

kW 660 hp

480

470 640

No of cylinders 90º V8 460

620

450

Working principle 4-stroke kW 440

480

660

600 hp

430

470 640

Firing order 1-5-4-2-6-3-7-8 420

460

580

620

560

410

450

Displacement 16.4 litres kW

400

480

440

660 hp

600

540

390

470

430 640

Bore x stroke 130 x 154 mm 380

460

420

580

520

620

370

450

410 560

Compression ratio 16.7:1 360

440

400

500

600

540

480

350

430

390

Weight 1340 kg (excl oil and coolant) 340

420

380

580

520

460

330

410

370 560

Piston speed at 1500 rpm 7.7 m/s 320

400

360

500

440

540

310

390

350 480

420

Piston speed at 1800 rpm 9.24 m/s 300

380

340 520

460

400

290

370

330

Camshaft High position alloy steel 280

360

320

500

440

380

270

350

310 480

Pistons Steel pistons 420

360

260

340

300 460

250

330

290 400

340

Connection rods I-section press forgings of alloy steel 240

320

280 440

380

320

230

310

270 420

Crankshaft Alloy steel with hardened 220

300

260 360

300

400

and polished bearing surfaces 210

290

250 340

280

200

280

240 380

320

Oil capacity 35-45 dm3 190

270

230 260

360

180

260

220 300

240

Electrical system 1-pole 24V 170

250

210 340

280

160

240

200 220

230 320

190 260

220

Nm 3160

180 300 kpm

320

240

210

170

3060 310

280

200

160

2960 220

300

Torque

2860

190 260

290

2760

180

Nm 3160 280 kpm

2660 240

320

270

170

3060

2560 310

260

160

2960 220

300

2460 250

2860

2360 290

240

Nm 2760

2260

3160 280

230 kpm

2660 320

2160

3060 270

220

2560 310

2060

2960 260

210

2460 300

1960

2860 250

200

2360 290

1860

2760 240

190

2260 280

2660 230

270

2160 220

g/kWh2560

220

2060

260g/kWh

30

210

Fuel 2460

1960

250AdBlue

200

215

2360 240

1860 25

190

2260 230

210

2160 AdBlue

220

220

g/kWh2060 20

210g/kWh

30

205

Fuel 1960 200AdBlue

215

200

1860 15

190

25

Spec

210fuel and AdBlue consumptionAdBlue

Fuel

195

g/kWh 220 10

20 g/kWh

30

205

Fuel 190 AdBlue

Edition 01 © Scania CV AB, SE-151 87 Södertälje, Sweden

215

1288 200 5

25

15

185 Fuel

210 AdBlue

195

180 0

20

10

530 530 205

190800 1000 1200 1400 1600 1800 2000 2200 rpm

200 15

5

185 Fuel

195

180 10

0

190800 1000 1200 1400 1600 1800 2000 2200 rpm

5

185

180 0

735

800 1000 1200 1400 1600 1800 2000 2200 rpm

Test conditions Air temperature +25°C. Barometric pressure 100 kPa (750 mmHg). Humidity 30%. Diesel fuel

acc. to ECE R 24 Annex 6. Density of fuel 0.840 kg/dm3. Viscosity of fuel 3.0 cSt at 40°C. Energy value 42700 kJ/kg.

Power test code ISO 3046. Power and fuel values +/-3%.

445

SE 151 87 Södertälje, Sweden

Telephone +46 8 553 810 00

Telefax +46 8 553 829 93

www.scania.com

engines@scania.com

SCANIA industrial engines

sCr system

us tier 4i, eu stage iiiB

SCR (Selective Catalytic Reduction) technology is used on Scania’s engines

for Stage IIIB and Tier 4i to reduce the NOX content in the exhaust gases.

A chemical process is started by injecting AdBlue, a urea and water

mixture, into the exhaust gas stream. During injection the water evaporates

and the urea breaks down to form ammonia. The ammonia then reacts

with the nitrogen gases in the catalytic converter and forms harmless

products such as nitrogen gas and water. Through the use of SCR the

exhaust gases are purged of poisonous levels of NOX in the best possible

way. Scania is making use of a system that is carefully developed and

tested in our own laboratory.

The AdBlue tank holds 38 or 60 litres and is heated by the engine’s cooling

system in order to avoid freezing of the urea solution, urea freezes at

-11°C. The AdBlue tank and a pump module are delivered as a unit which

is fitted to brackets for an easy installation. The Scania system contains

all mechanical and electrical parts needed except from the exhaust piping

The principle for Scania SCR system which is to be adapted according to the customers installation.

Mechanical system Electric system

2 7 6

3 5

4

5

5 4

1

3

7 6

9

8

1

10

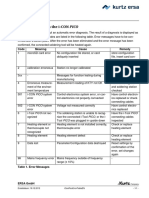

Mechanical system Standard Optional Electric system Standard Optional

1 AdBlue tank and pump module 38 l 60 l 1 Connection unit –

2 AdBlue fluid return line 3m 2 Cable harness between engine and

2m –

4m SCR control unit

3 Tank heater valve – 3 SCR control unit –

4 AdBlue pressure line 3m 4 Cable harness between SCR control

2m –

4m unit and components

5 Coolant hose for heating of tank 5 Extension cable – –

– –

and pump module

6 Cable to the tank heater valve –

6 Hydrolysis catalyst with AdBlue

– 7 Cable to the AdBlue tank level sensor –

dosage valve

7 NOX sensor with control unit –

8 SCR catalyst –

9 Temperature sensor –

10 Coolant return line from AdBlue

– –

tank and pump module

This specification is preliminary and may be revised

without notice.

SCANIA industrial engines

SCR system

US Tier 4i, EU Stage IIIB

AdBlue tank - 38 litres SCR catalyst

Total volume: 50 litres The SCR catalyst comes in four different models.

Filling volume: 38 litres

675 280

Engine Power (hp) Volume (litres) Measure A (mm)

DC9 200-400 24 765

DC13 350-450 26 790

DC13 500 30 830

DC16 650-700 33 880

570

A

304 646

AdBlue tank - 60 litres

ø 348,5

Total volume: 70 litres

Filling volume: 60 litres

675 280

304 649

700

SCR catalyst with silencer

Volume: 33 litres

Connection for exhaust pipes: Ø114 mm

(not for DC16 70A, 700 hp)

304 647

768

Hydrolysis catalyst

with reductant doser

450

Edition 01 © Scania CV AB, SE-151 87 Södertälje, Sweden

ø 597

ø 150

ø 190

304 651

304 650

SE 151 87 Södertälje, Sweden

This specification is preliminary and may be revised Telephone +46 8 553 810 00

Telefax +46 8 553 829 93

without notice.

www.scania.com

engines@scania.com

Potrebbero piacerti anche

- DC16 Engine 478kWDocumento4 pagineDC16 Engine 478kWmuniNessuna valutazione finora

- DC13 084A. 294 KW (400 HP) : EU Stage IV, US Tier 4fDocumento4 pagineDC13 084A. 294 KW (400 HP) : EU Stage IV, US Tier 4fJulio Cxar Sullayme VargasNessuna valutazione finora

- Electric Installation ManualDocumento47 pagineElectric Installation ManualAbuhurairah MunshiNessuna valutazione finora

- Scania RDocumento5 pagineScania Rnurul hidayatNessuna valutazione finora

- CALIBRACIONDocumento65 pagineCALIBRACIONNuñez JesusNessuna valutazione finora

- Scania P, G, R, T Series Workshop Manual - Removing The Reductant Main UnitDocumento1 paginaScania P, G, R, T Series Workshop Manual - Removing The Reductant Main Unitmusharrf100% (1)

- Engine Issue 8Documento39 pagineEngine Issue 8mustang460100% (1)

- dc16 SeriesDocumento77 paginedc16 SeriesRasheed SiddiquiNessuna valutazione finora

- Scania 12L - EMS - Operator - Manual - enDocumento60 pagineScania 12L - EMS - Operator - Manual - enАнатолий ЩербаковNessuna valutazione finora

- Electrical System Issue 7Documento38 pagineElectrical System Issue 7Charl Pietersen100% (1)

- Wartungsanweisungen Für Gruppe 1-3 P-, G-, R - Und T-SerieDocumento173 pagineWartungsanweisungen Für Gruppe 1-3 P-, G-, R - Und T-SerieWeber BennyNessuna valutazione finora

- Important Information: Operator's Manual DC9 EMS With S6/PDE Industrial EngineDocumento60 pagineImportant Information: Operator's Manual DC9 EMS With S6/PDE Industrial Enginemmmm100% (1)

- enDocumento30 pagineenRegistr RegistrNessuna valutazione finora

- Inspection Instructions For Group 7-9Documento22 pagineInspection Instructions For Group 7-9pen 123Nessuna valutazione finora

- Scania: Pumpe Za Vodu I Ulje Water & Oil PumpsDocumento4 pagineScania: Pumpe Za Vodu I Ulje Water & Oil PumpsJasminM dooNessuna valutazione finora

- Cooling System - Industrial EnginesDocumento23 pagineCooling System - Industrial EnginesSyarifuddin RahmanNessuna valutazione finora

- Atc Fault Code List PDFDocumento10 pagineAtc Fault Code List PDFPutra PuguhNessuna valutazione finora

- Fuel system with EDC MS6 and unit injector PDE function descriptionDocumento55 pagineFuel system with EDC MS6 and unit injector PDE function descriptionMusharraf KhanNessuna valutazione finora

- Scania P, G, R, T Series Workshop Manual - Removing The AC CompressorDocumento4 pagineScania P, G, R, T Series Workshop Manual - Removing The AC CompressormusharrfNessuna valutazione finora

- Engine Data D12 PDFDocumento20 pagineEngine Data D12 PDFClaudesson Nascimento Rodrigues100% (1)

- How to optimize website content for search enginesDocumento3 pagineHow to optimize website content for search enginesHeri SuryoNessuna valutazione finora

- Fuel System Issue 6 1Documento20 pagineFuel System Issue 6 1Ririn Dwi100% (1)

- Damper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionDocumento8 pagineDamper For Range Gear Changing GR801-900, GRS890-900 Work DescriptionfugegaNessuna valutazione finora

- The Right Technology For The Right Application by Mr. Nick Leach, ScaniaDocumento39 pagineThe Right Technology For The Right Application by Mr. Nick Leach, ScaniaMichael Wild50% (4)

- Scania D9 Engine Manual RomanianDocumento67 pagineScania D9 Engine Manual RomanianRomica Ciornei100% (1)

- Scania Inter AxleDocumento14 pagineScania Inter AxleKharis Mahfudz100% (1)

- Basic Engine T4FDocumento39 pagineBasic Engine T4FDragan100% (1)

- Scania Workshop Manual - Removing InjectorsDocumento4 pagineScania Workshop Manual - Removing InjectorsocnogueiraNessuna valutazione finora

- Oil CoolerDocumento3 pagineOil CoolerCahyo UtomoNessuna valutazione finora

- DC16 Cylinder SequenceDocumento1 paginaDC16 Cylinder Sequencejengandxb100% (1)

- Cooling T4FDocumento19 pagineCooling T4FDragan100% (1)

- 19-20 Central Gear 1Documento80 pagine19-20 Central Gear 1Mamat salto100% (1)

- Catalogo Scania CromadosDocumento96 pagineCatalogo Scania CromadosDusanMasle100% (1)

- Scania dc12 Cylinder Head TestDocumento6 pagineScania dc12 Cylinder Head TestaliNessuna valutazione finora

- Texa Truck V 39 PDFDocumento14 pagineTexa Truck V 39 PDFscania100% (1)

- Scania P, G, R, T Series Workshop Manual - Removing The EngineDocumento16 pagineScania P, G, R, T Series Workshop Manual - Removing The EngineVictor SampaNessuna valutazione finora

- XCOM User GuideDocumento33 pagineXCOM User GuideAnonymous ljkiyqJt8MNessuna valutazione finora

- Use of Roller Brake Tester For Drum Brakes: en-GBDocumento78 pagineUse of Roller Brake Tester For Drum Brakes: en-GBruanNessuna valutazione finora

- enDocumento60 pagineenRegistr Registr100% (3)

- Scania DI9 Operator's ManualDocumento58 pagineScania DI9 Operator's ManualAmr HelalNessuna valutazione finora

- Scania P, G, R, T Series Workshop Manual - Draining AxlesDocumento7 pagineScania P, G, R, T Series Workshop Manual - Draining AxlesBambang Mulyanto100% (1)

- Clucth ScaniaDocumento2 pagineClucth ScaniaNoeRtjahya Ahmad100% (1)

- Adjustable Parameters - EngineDocumento33 pagineAdjustable Parameters - EnginescaniaNessuna valutazione finora

- Turbo CompoundDocumento8 pagineTurbo CompoundJack PranNessuna valutazione finora

- enDocumento17 pagineenRegistr Registr60% (5)

- Bleeding Xpi Fuel System Scania XTDocumento3 pagineBleeding Xpi Fuel System Scania XTsam the fool100% (2)

- Remove Unit InjectorDocumento55 pagineRemove Unit InjectorГеоргий222Nessuna valutazione finora

- New Engine Range RecommendationsDocumento21 pagineNew Engine Range RecommendationsHariNessuna valutazione finora

- ZF As Tronic DescriptionDocumento24 pagineZF As Tronic DescriptionBienvenu MassouanguiNessuna valutazione finora

- Handbook - EngineDocumento230 pagineHandbook - EnginezeshanjamilNessuna valutazione finora

- Scania TerexDocumento126 pagineScania TerexzoeNessuna valutazione finora

- Scania P, G, R, T Series Workshop Manual - Removing The RetarderDocumento6 pagineScania P, G, R, T Series Workshop Manual - Removing The RetarderEdinson Ulloa100% (1)

- WSM 0000003 01Documento52 pagineWSM 0000003 01Anderson Bombista90% (10)

- Work Description 9 Litre Engine With 5 CylindersDocumento123 pagineWork Description 9 Litre Engine With 5 CylindersCharlie RebañoNessuna valutazione finora

- 12-Piece T-Star Bit Socket Set, Extra Short, T8 - T60: Item # 5098Documento22 pagine12-Piece T-Star Bit Socket Set, Extra Short, T8 - T60: Item # 5098HERRAPRONessuna valutazione finora

- Error Messages in The i-CON PICODocumento1 paginaError Messages in The i-CON PICOIvana Ika StankovicNessuna valutazione finora

- Scania Diagnos & Programmer 3 2.48.1Documento7 pagineScania Diagnos & Programmer 3 2.48.1Jaya Pranata50% (2)

- 01-05 Flywheel Housing: Fitting Flywheel Housing On 9, 11 and 12 Litre Engines With PDE or HPIDocumento4 pagine01-05 Flywheel Housing: Fitting Flywheel Housing On 9, 11 and 12 Litre Engines With PDE or HPIyordan baniaraNessuna valutazione finora

- Important Information: Operator's Manual D14 DC14 DI14Documento50 pagineImportant Information: Operator's Manual D14 DC14 DI14steynhen100% (2)

- Recloser NOJADocumento28 pagineRecloser NOJAPhan TiếnNessuna valutazione finora

- Perkins 2000 SeriesDocumento64 paginePerkins 2000 SeriesclarckNessuna valutazione finora

- Woodward L Series Application NoteDocumento17 pagineWoodward L Series Application NoteDave WallaceNessuna valutazione finora

- DCA13SPK Denyo SpecificationDocumento1 paginaDCA13SPK Denyo SpecificationDave WallaceNessuna valutazione finora

- Woodwide L Series ManualDocumento2 pagineWoodwide L Series ManualDave WallaceNessuna valutazione finora

- Woodward L Series Application NoteDocumento17 pagineWoodward L Series Application NoteDave WallaceNessuna valutazione finora

- Perkins 2000 SeriesDocumento64 paginePerkins 2000 SeriesclarckNessuna valutazione finora

- DeepSea E E-Series WebNet BulletinDocumento2 pagineDeepSea E E-Series WebNet BulletinDave WallaceNessuna valutazione finora

- Bianco 50mm High Head SubpumpDocumento1 paginaBianco 50mm High Head SubpumpDave WallaceNessuna valutazione finora

- DSE E400 Data Sheet Control PDFDocumento2 pagineDSE E400 Data Sheet Control PDFDave WallaceNessuna valutazione finora

- Denyo DCA15 SPK2 SpecsDocumento1 paginaDenyo DCA15 SPK2 SpecsDave WallaceNessuna valutazione finora

- MTTC B10 Weighted Float SwitchDocumento1 paginaMTTC B10 Weighted Float SwitchDave WallaceNessuna valutazione finora

- DeepSea100 Data SheetDocumento2 pagineDeepSea100 Data SheetDave WallaceNessuna valutazione finora

- DSE E400 Data Sheet Control PDFDocumento2 pagineDSE E400 Data Sheet Control PDFDave WallaceNessuna valutazione finora

- Grindex Master Parts ListDocumento8 pagineGrindex Master Parts ListDave WallaceNessuna valutazione finora

- 1079 PDFDocumento7 pagine1079 PDFFahad MaqsoodNessuna valutazione finora

- Grindex Matador Brochure PDFDocumento1 paginaGrindex Matador Brochure PDFDave WallaceNessuna valutazione finora

- 5 Applications For RCDDocumento12 pagine5 Applications For RCDDave WallaceNessuna valutazione finora

- Engine N45 TM2A 96 kW (1500 rpm) - 107 kW (1800 rpmDocumento3 pagineEngine N45 TM2A 96 kW (1500 rpm) - 107 kW (1800 rpmDave Wallace100% (2)

- Product Specifications PDFDocumento8 pagineProduct Specifications PDFDave WallaceNessuna valutazione finora

- Simplex Load Bank DrawingsDocumento3 pagineSimplex Load Bank DrawingsDave WallaceNessuna valutazione finora

- FG Wilson Genset P20P2 SpecificationsDocumento1 paginaFG Wilson Genset P20P2 SpecificationsFiqi DzulfiqarNessuna valutazione finora

- Atlas Copco Genset DimensionsDocumento1 paginaAtlas Copco Genset DimensionsDave WallaceNessuna valutazione finora

- Atlas Copco QES RangeDocumento8 pagineAtlas Copco QES RangeDave WallaceNessuna valutazione finora

- Portable Compressors Full Line PDFDocumento8 paginePortable Compressors Full Line PDFADELALHTBANINessuna valutazione finora

- Portable Compressors Full Line PDFDocumento8 paginePortable Compressors Full Line PDFADELALHTBANINessuna valutazione finora

- Engine Number Guide: Engines 2 Litre/cylinderDocumento4 pagineEngine Number Guide: Engines 2 Litre/cylinderaney2002100% (4)

- Sakuragawa - U Series - High Head PumpDocumento2 pagineSakuragawa - U Series - High Head PumpDave WallaceNessuna valutazione finora

- Engine GENERATOR SDG series AIRMANDocumento12 pagineEngine GENERATOR SDG series AIRMANDave Wallace100% (1)

- Aprilia RSV4 RR SpecsDocumento11 pagineAprilia RSV4 RR SpecsMiguelKeenaNessuna valutazione finora

- Heavy Weight Drill Pipe With Welded Joints NS 1 A4 WatermarkedDocumento21 pagineHeavy Weight Drill Pipe With Welded Joints NS 1 A4 Watermarkedislam atifNessuna valutazione finora

- ARB Competence Guidelines - SustainabilityDocumento5 pagineARB Competence Guidelines - SustainabilitypatNessuna valutazione finora

- Understanding UL508A Combination Motor Controller DataDocumento4 pagineUnderstanding UL508A Combination Motor Controller DataNoneya BidnessNessuna valutazione finora

- UK 2666 Revision 2Documento7 pagineUK 2666 Revision 2boborg8792Nessuna valutazione finora

- OpenSAP Cst1 Week 1 Unit 3 Que PresentationDocumento11 pagineOpenSAP Cst1 Week 1 Unit 3 Que PresentationpatrickNessuna valutazione finora

- MTech Mobile Pervasive Computing 2017Documento68 pagineMTech Mobile Pervasive Computing 2017ella palomaNessuna valutazione finora

- Tcs 7PA26 - 27 - 30 - Catalog - SIP-2008 - en PDFDocumento7 pagineTcs 7PA26 - 27 - 30 - Catalog - SIP-2008 - en PDFBagus Permadi100% (1)

- AAFA Webinar Intertek Jan 2012 V5Documento29 pagineAAFA Webinar Intertek Jan 2012 V5rabiulfNessuna valutazione finora

- Get A Lifecycle - Connecting Alarm Management and Safety Instrumented SystemsDocumento17 pagineGet A Lifecycle - Connecting Alarm Management and Safety Instrumented SystemsJulia Batista MéndezNessuna valutazione finora

- 03 ProfinetDocumento45 pagine03 Profinetnguyenanh.sale01Nessuna valutazione finora

- FSU-Secure Access Manager (FSU-SAM) 4.9 User Guide: Silver Spring Networks 555 Broadway Street Redwood City, CA 94063Documento27 pagineFSU-Secure Access Manager (FSU-SAM) 4.9 User Guide: Silver Spring Networks 555 Broadway Street Redwood City, CA 94063Elisa XuNessuna valutazione finora

- Media HubDocumento3 pagineMedia HubImran AliNessuna valutazione finora

- PHP Multiple Choice Questions and Answers: Ans: D and eDocumento11 paginePHP Multiple Choice Questions and Answers: Ans: D and eKannan SNessuna valutazione finora

- Cat Long Term StorageDocumento2 pagineCat Long Term Storagesimon60sNessuna valutazione finora

- Freescale MQX RTCS User GuideDocumento410 pagineFreescale MQX RTCS User GuideyoonghmNessuna valutazione finora

- Brochure P630 en 1663Documento8 pagineBrochure P630 en 1663anon_143821310Nessuna valutazione finora

- Absolute Rating vs. Nominal Rating For FiltersDocumento3 pagineAbsolute Rating vs. Nominal Rating For FiltersMukesh KangutkarNessuna valutazione finora

- Din en Iso 10360-9 - 2014-04Documento26 pagineDin en Iso 10360-9 - 2014-04gviola1405Nessuna valutazione finora

- Iso 16232 2018Documento15 pagineIso 16232 2018rp4391730Nessuna valutazione finora

- Whafis 4 DocDocumento7 pagineWhafis 4 DocsergioNessuna valutazione finora

- OPSS 903 - Nov09Documento28 pagineOPSS 903 - Nov09umerfr2Nessuna valutazione finora

- Long Radius Elbow 20.4.2020Documento2 pagineLong Radius Elbow 20.4.2020Sunil GurubaxaniNessuna valutazione finora

- SP 305Documento152 pagineSP 305Gebe András80% (5)

- ISO SymbolsDocumento49 pagineISO Symbolstarneem100% (1)

- OTN Interface Structure: Mapping, Multiplexing and Overhead FramesDocumento17 pagineOTN Interface Structure: Mapping, Multiplexing and Overhead FramesDerrick Senyo100% (1)

- Airlive Mfp-101u UDocumento113 pagineAirlive Mfp-101u UCorey AcevedoNessuna valutazione finora

- Thickness Design On Flexible Pavement - AASHTO 1993 MethodDocumento35 pagineThickness Design On Flexible Pavement - AASHTO 1993 MethodBenedictus YosiaNessuna valutazione finora

- KTS SEC BSDG ELE 009 Earthing Calculation R1Documento8 pagineKTS SEC BSDG ELE 009 Earthing Calculation R1mirzaNessuna valutazione finora

- ANSI ISEA Z89 1 2014 American National PDFDocumento41 pagineANSI ISEA Z89 1 2014 American National PDFTeam SHEQMS100% (3)