Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Epoxy Coating Systems Guide for Atmospheric & Immersion Applications

Caricato da

nasirDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Epoxy Coating Systems Guide for Atmospheric & Immersion Applications

Caricato da

nasirCopyright:

Formati disponibili

APCS 1A – epoxy coating system for atmospheric service (inorganic zinc primer)

• severe atmospheric exposure, particularly for offshore construction.

APCS 1B – epoxy coating system for atmospheric service (epoxy primer)

• severe atmospheric exposure including exposure to many acid and alkalis.

APCS 1C – epoxy coating system for atmospheric service (zinc rich epoxy primer)

• maintenance painting for severe atmospheric exposure.

APCS 1D – epoxy/polyurethanes coating system for atmospheric service (inorganic zinc primer)

• severe atmospheric exposure, when added gloss retention, color retention and abrasion resistance are required

(usually outdoors)

APCS 1E – epoxy/polyurethanes coating system for atmospheric service (epoxy primer)

• severe atmospheric exposure including exposure to many acid and alkalis, when added gloss retention, color

retention and abrasion resistance are required (usually outdoors)

APCS 1F – epoxy/polyurethanes coating system for atmospheric service (zinc rich epoxy primer)

• maintenance painting for severe atmospheric exposure when added gloss retention and abrasion resistance

are required. (usually outdoors)

APCS 2A – epoxy coating system for general immersion service (self priming)

• immersion service particularly for raw or treated waters for GOSP traps handling hot crude oil/brine solutions.

Not for potable water.

APCS 2B – epoxy coating system for potable water immersion service (self priming)

• immersion service for potable water.

APCS 2C – epoxy coating system for immersion service, at temperature up to 120ºC

• immersion service for demineralized water and boiler skim tanks.

APCS 2D – epoxy coating system for interior of steel aviation fuel storage tanks and piping.

• immersion service for aviation fuel, turbine fuel and kerosene.

APCS 3 - coal tar epoxy coating system for immersion services (self priming)

• immersion service in tankage containing hydrocarbons, seawater, fresh water ang most alkalis; intermittent contact

with acids and solvents.

APCS 4 - aluminum pigmented coating system.

• Structural steelwork, tanks, vessels, pipes and equipment subject to moderate industrial atmospheres including H 2S fumes and high humidity. Not generally recommended for shop

applications or when handling is required after coating.

APCS 4 - alkyd enamel coating system

• Structural steels, machinery and equipment in marine and industrial environments including intermittent exposure to H 2S fumes and high humidity. Not recommended for shop application or

when handling is required after coating. (See APCS - 26/26T).

APCS 7 - Rust Conversion Primer/Alkyd Topcoat System for Use on Slightly Rusted Steel

• Maintenance coating system for APCS - 4 and APCS - 6. Applied directly to bare, slightly rusted steel surfaces. Not intended as an intermediate or tie coat over sound coatings.

APCS 9 - Chlorinated Rubber Coating System

• Metallic and concrete surfaces exposed to salts, high humidity, and spillage of acids and alkalis.

APCS 10 - Metallic and c Bituminous Paint for Moderate Temperature, Buried or Immersion Service (Self-Priming)

• Buried and immersed steel. Resistant to water and acidic fumes.

APCS 11A - High Temperature Coating System for Atmospheric Service between 150°C-400°C (with Inorganic Zinc Primer)

• Steel in atmospheric service at elevated temperature.

APCS 11B - Very High Temperature Coating System for Atmospheric Service Between 400°C and 540°C

• Steel in atmospheric service at elevated temperatures.

APCS 12 - Nonskid Epoxy Coating System for Floors and Decks

• Nonskid surface on interior and exterior floors and walkways.

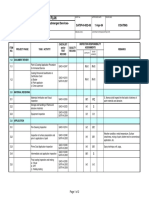

APCS - 1A Epoxy Coating System for Atmospheric Service (with Inorganic Zinc Primer)

APCS - 1B Epoxy Coating System for Atmospheric Service (with Epoxy Primer)

APCS - 1C Epoxy Coating System for Atmospheric Service (with Zinc-Rich Epoxy Primer)

APCS - 1D Epoxy/Polyurethane Coating System for Atmospheric Service (with Inorganic Zinc Primer)

APCS - 1E Epoxy/Polyurethane Coating System for Atmospheric Service (with Epoxy Primer)

APCS - 1F Epoxy/Polyurethane Coating System for Atmospheric Service (with Zinc-Rich Epoxy Primer)

APCS - 2A Epoxy Coating System for General Immersion Service (Self-Priming)

APCS - 2B Epoxy Coating System for Potable Water Immersion Service (Self-Priming)

APCS - 2C Epoxy Coating System for Immersion Service, at temperatures up to 120°C

APCS - 2D Epoxy Coating System for Interior of Steel Aviation Fuel Storage Tanks and Piping

APCS - 3 Coal Tar Epoxy Coating System for Immersion Service (Self-Priming)

APCS - 4 Aluminum-Pigmented Alkyd Coating System

APCS - 6 Alkyd Enamel Coating System

APCS - 7 Rust Conversion Primer/Alkyd Topcoat System for Use on Slightly Rusted Steel

APCS - 9 Chlorinated Rubber Coating System

APCS - 10 Bituminous Paint for Moderate Temperature, Buried or Immersion Service (Self-Priming)

APCS - 11A High Temperature Coating System for Atmospheric Service Between 150°C - 400°C

APCS - 11B Very High Temperature Coating System for Atmospheric Service Between 400°C - 540°C

APCS - 12 Nonskid Epoxy Coating System for Floors and Decks

APCS - 17A Inorganic Zinc Primer, Solvent Based

APCS - 17B Inorganic Zinc Primer, Water Based

APCS - 19A Splash Zone Compound, Hand Applied

APCS - 19B Splash Zone Compound, Spray Applied

APCS - 20A Fiberglass Reinforced Coatings, Hand Lay-Up

APCS - 20B Chopped Fiberglass Reinforced Epoxy Coatings, Spray Applied

APCS - 22 Epoxy Coating for Application onto Damp Steel Surfaces

APCS - 23 High Temperature Mastic Paint for Buried or Immersion Service (Self-Priming)

APCS - 26 Epoxy Mastic Coating (Self-Priming)

APCS - 26T Epoxy Mastic/Polyurethane Coating System

Potrebbero piacerti anche

- 09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFDocumento10 pagine09-SAMSS-069 - Epoxy Coating For Atmospheric Service PDFsuresh_viki100% (1)

- APCS DeatailsDocumento3 pagineAPCS DeatailsDandaman100% (3)

- 09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)Documento9 pagine09-SAMSS-071 - (2016) Qualification Requirements For Inorganic Zinc Primer (APCS-17A) and (APCS-17B)middlepermian100% (1)

- Materials System SpecificationDocumento6 pagineMaterials System SpecificationAjeetKumarNessuna valutazione finora

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocumento3 pagineSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNessuna valutazione finora

- Materials System SpecificationDocumento10 pagineMaterials System SpecificationAjeetKumar100% (1)

- 09 SAMSS 089 (Final Draft - 2018)Documento28 pagine09 SAMSS 089 (Final Draft - 2018)lhanx2Nessuna valutazione finora

- Saudi Aramco Typical Inspection PlanDocumento10 pagineSaudi Aramco Typical Inspection PlanMoghal AliNessuna valutazione finora

- Typical Inspection Plan (TIP) Index: Project Inspection Division / IAGDocumento5 pagineTypical Inspection Plan (TIP) Index: Project Inspection Division / IAGvajidqcNessuna valutazione finora

- SAUDI ARAMCO ID/PIEU-30-Nov-2018Documento2 pagineSAUDI ARAMCO ID/PIEU-30-Nov-2018Moghal AliNessuna valutazione finora

- Renovation Coating Inspection PlanDocumento10 pagineRenovation Coating Inspection PlanMoghal AliNessuna valutazione finora

- Saes H 204Documento34 pagineSaes H 204heartbreakkid132Nessuna valutazione finora

- Saep 1200Documento9 pagineSaep 1200Anonymous 4IpmN7On100% (1)

- Materials System SpecificationDocumento8 pagineMaterials System SpecificationAjeetKumarNessuna valutazione finora

- Paint System Recommendations PDFDocumento6 paginePaint System Recommendations PDFKumarNessuna valutazione finora

- Materials System SpecificationDocumento10 pagineMaterials System SpecificationAjeetKumar100% (1)

- SATIP H 002 08 Pipe Internal CoatingDocumento3 pagineSATIP H 002 08 Pipe Internal CoatinghossamalsherbinyNessuna valutazione finora

- 09 Samss 021Documento8 pagine09 Samss 021Kalanithi KasirajanNessuna valutazione finora

- SATIP-H-002-05 Epoxy For Atmospheric Up To 150CDocumento2 pagineSATIP-H-002-05 Epoxy For Atmospheric Up To 150ChossamalsherbinyNessuna valutazione finora

- Saudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilDocumento11 pagineSaudi Aramco Typical Inspection Plan: Fireproofing Concrete SATIP-B-006-01 14-May-18 CivilKhurram ShehzadNessuna valutazione finora

- Saudi Aramco Typical Inspection PlanDocumento10 pagineSaudi Aramco Typical Inspection PlanMoghal AliNessuna valutazione finora

- 09 Samss 060Documento4 pagine09 Samss 060asimazami69Nessuna valutazione finora

- Saes H 200Documento9 pagineSaes H 200راجہ شہزاد انورNessuna valutazione finora

- Satip H 002 02Documento10 pagineSatip H 002 02Rijwan MohammadNessuna valutazione finora

- SAES-H-102-Safety Requirements For Coating Applications2Documento12 pagineSAES-H-102-Safety Requirements For Coating Applications2محمد العيسوىNessuna valutazione finora

- SAIC-H-2001 Rev 7Documento3 pagineSAIC-H-2001 Rev 7Satheesh Rama SamyNessuna valutazione finora

- 09 Samss 068Documento7 pagine09 Samss 068AjeetKumarNessuna valutazione finora

- SATIP-H-002-06 Coating For Submerged Services-APCS 113 ABCDocumento2 pagineSATIP-H-002-06 Coating For Submerged Services-APCS 113 ABChossamalsherbinyNessuna valutazione finora

- Materials System SpecificationDocumento7 pagineMaterials System SpecificationAjeetKumarNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento8 pagineSaudi Aramco Inspection ChecklistAnantha PadmanabhanNessuna valutazione finora

- Pages From SAES-H-001-19Documento1 paginaPages From SAES-H-001-19mohammed s fawabNessuna valutazione finora

- Saep 119Documento11 pagineSaep 119Demac SaudNessuna valutazione finora

- Apcs 113a Rev 3 Pid ApprovalDocumento19 pagineApcs 113a Rev 3 Pid ApprovalMedel Cay De Castro50% (2)

- 01 Samss 012 2014Documento10 pagine01 Samss 012 2014lhanx2Nessuna valutazione finora

- Ipcoat Exam Test Paper 123Documento1 paginaIpcoat Exam Test Paper 123Senthil Kumar100% (1)

- Hempel'S Galvosil 15780: DescriptionDocumento2 pagineHempel'S Galvosil 15780: DescriptionEngTamer100% (1)

- Apcs 117Documento12 pagineApcs 117Ilyas AhmedNessuna valutazione finora

- SATR-H-2004 Rev 7Documento3 pagineSATR-H-2004 Rev 7josephNessuna valutazione finora

- Nitomortar TC2000Documento3 pagineNitomortar TC2000talatzahoorNessuna valutazione finora

- 175 091300Documento2 pagine175 091300Abu Anas M.SalaheldinNessuna valutazione finora

- 09 Samss 089-2016Documento26 pagine09 Samss 089-2016lhanx2Nessuna valutazione finora

- Saes H 201Documento9 pagineSaes H 201heartbreakkid132Nessuna valutazione finora

- Saes A 114Documento26 pagineSaes A 114abaanNessuna valutazione finora

- Paint Types - Important NotesDocumento3 paginePaint Types - Important Notesmushroom0320Nessuna valutazione finora

- 12 Samss 005 PDFDocumento6 pagine12 Samss 005 PDFfetihNessuna valutazione finora

- Removing Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncDocumento46 pagineRemoving Coatings and Cleaning Masonry Substrates: Kenneth A. Trimber KTA-Tator, IncMilagros MorantesNessuna valutazione finora

- Surface Prep StandardsDocumento25 pagineSurface Prep StandardsJahangir Khan100% (1)

- Saudi Aramco Field Coating Inspection ReportDocumento3 pagineSaudi Aramco Field Coating Inspection Reportravi ajith100% (1)

- Shop-Applied Internal FBE CoatingsDocumento18 pagineShop-Applied Internal FBE CoatingsFahad AhmadNessuna valutazione finora

- Gas QCP Pac 003 Apcs 113 CDocumento18 pagineGas QCP Pac 003 Apcs 113 Cfawad ali0% (1)

- SAEP-316 Latest RevisionDocumento25 pagineSAEP-316 Latest RevisionHabib RehmanNessuna valutazione finora

- Mini Gate Exam 2018 CBT-1 Solution ReportDocumento15 pagineMini Gate Exam 2018 CBT-1 Solution ReportamitNessuna valutazione finora

- Saudi Aramco Concrete Coating ProcedureDocumento10 pagineSaudi Aramco Concrete Coating Proceduremoytabura96100% (1)

- Coating Inspector ResumeDocumento4 pagineCoating Inspector Resumetulasirao.nammiNessuna valutazione finora

- Saes Q 001 Saes-Q-006Documento5 pagineSaes Q 001 Saes-Q-006Abdul Hannan100% (1)

- Saes 1bDocumento1 paginaSaes 1bIlyas AhmedNessuna valutazione finora

- Marine Coatings Systems Guide for Weathering, Heat and ImmersionDocumento8 pagineMarine Coatings Systems Guide for Weathering, Heat and ImmersionSyaiful Arif WicaksonoNessuna valutazione finora

- FHWA Bridge CoatingsDocumento2 pagineFHWA Bridge CoatingsAnonymous V92ZmILyQTNessuna valutazione finora

- Bro Pocket GuideDocumento8 pagineBro Pocket GuidepremNessuna valutazione finora

- Kanatpaints PipelineDocumento16 pagineKanatpaints PipelineMekineNessuna valutazione finora

- Carefull Interpretation To Reduce Disagreements & Unnecssary Reshoots - 8-Jan-2017Documento10 pagineCarefull Interpretation To Reduce Disagreements & Unnecssary Reshoots - 8-Jan-2017nasirNessuna valutazione finora

- Bench Testing Instruments (Control Valve, PT, TT) - 17.JAN.2017Documento10 pagineBench Testing Instruments (Control Valve, PT, TT) - 17.JAN.2017nasirNessuna valutazione finora

- SMEDA Barbecue Restaurant PDFDocumento18 pagineSMEDA Barbecue Restaurant PDFAifi ZafarNessuna valutazione finora

- SSPC-SP 11Documento5 pagineSSPC-SP 11topdrive100% (3)

- 04 PCI Sched 510Documento4 pagine04 PCI Sched 510Monday0% (1)

- 01 - PCI - Cov Page - 910 PDFDocumento1 pagina01 - PCI - Cov Page - 910 PDFnasirNessuna valutazione finora

- S Qa/Qc I "B " T I: Imulated Nspection of Ottomless Ank NstallationDocumento14 pagineS Qa/Qc I "B " T I: Imulated Nspection of Ottomless Ank NstallationnasirNessuna valutazione finora

- Welding Process ComparisonDocumento6 pagineWelding Process ComparisonHussain M.SukarNessuna valutazione finora

- QC Responsibilities at Site/Shop Before Fit Up: Month Validity) )Documento1 paginaQC Responsibilities at Site/Shop Before Fit Up: Month Validity) )nasirNessuna valutazione finora

- 03 - Pci Toc - 910 PDFDocumento8 pagine03 - Pci Toc - 910 PDFMuhammad AsifNessuna valutazione finora

- 17 PCI Mod11 910Documento7 pagine17 PCI Mod11 910nasirNessuna valutazione finora

- Fractions and Decimals ConceptsDocumento29 pagineFractions and Decimals ConceptsnasirNessuna valutazione finora

- 02 - PCI Title Page - 910 PDFDocumento3 pagine02 - PCI Title Page - 910 PDFMuhammad AsifNessuna valutazione finora

- 04 PCI Sched 510Documento4 pagine04 PCI Sched 510Monday0% (1)

- Ntroduction: Welcome and Course IntroductionDocumento20 pagineNtroduction: Welcome and Course IntroductionAdnan RafiqNessuna valutazione finora

- Notification: Board of Revenue, PunjabDocumento2 pagineNotification: Board of Revenue, PunjabKhaqan MajeedNessuna valutazione finora

- Ausschreibung Helmut Schmidt Programm enDocumento5 pagineAusschreibung Helmut Schmidt Programm enSohaibRoomiNessuna valutazione finora

- J D Auditor TrainerDocumento2 pagineJ D Auditor TrainernasirNessuna valutazione finora

- Handy Calculations - Volume Solids and Spreading RateDocumento4 pagineHandy Calculations - Volume Solids and Spreading Ratevengadesh100% (1)

- APCS & SES coating standards for surface preparation and paintDocumento44 pagineAPCS & SES coating standards for surface preparation and paintnasir100% (1)

- SSPC-SP 11-2012 PDFDocumento4 pagineSSPC-SP 11-2012 PDFAhmad AshshiddieqyNessuna valutazione finora

- 16.07.18 - Daily Progress ReportDocumento1 pagina16.07.18 - Daily Progress ReportnasirNessuna valutazione finora

- TgbjhuDocumento5 pagineTgbjhunasirNessuna valutazione finora

- Element 2Documento15 pagineElement 2MahiBoumNessuna valutazione finora

- Imm5257e PDFDocumento1 paginaImm5257e PDFnasirNessuna valutazione finora

- Munch StudyDocumento1 paginaMunch StudynasirNessuna valutazione finora

- E Hinweise Zur Einordnung Der Kurse PDFDocumento9 pagineE Hinweise Zur Einordnung Der Kurse PDFnasirNessuna valutazione finora

- Munch StudyDocumento1 paginaMunch StudynasirNessuna valutazione finora

- 1 Scope: SAEP-302Documento8 pagine1 Scope: SAEP-302nasirNessuna valutazione finora

- Construction Questions PDFDocumento17 pagineConstruction Questions PDFAdeeb MalikNessuna valutazione finora

- Aavt S A0001209782 1Documento5 pagineAavt S A0001209782 1yokartikNessuna valutazione finora

- TDS RD103Documento2 pagineTDS RD103polypolyy100% (1)

- EASA ResinTreatmentTips 1021Documento3 pagineEASA ResinTreatmentTips 1021andres monederoNessuna valutazione finora

- Chemical Attack On Hardened Concrete - tcm45-345631Documento6 pagineChemical Attack On Hardened Concrete - tcm45-345631gosha93Nessuna valutazione finora

- Journal of Science: Advanced Materials and Devices: Original ArticleDocumento8 pagineJournal of Science: Advanced Materials and Devices: Original ArticleSamah SamahNessuna valutazione finora

- Fosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionDocumento4 pagineFosroc Conbextra EP150: Free Flow Epoxy Resin Grout Uses DescriptionVincent JavateNessuna valutazione finora

- DS - Epilux - 9 - HB - Phenolic - Coating F15Documento2 pagineDS - Epilux - 9 - HB - Phenolic - Coating F15parvez_ameenNessuna valutazione finora

- Epoxy HR: Technical Data SheetDocumento5 pagineEpoxy HR: Technical Data SheetOrgünOzarNessuna valutazione finora

- Chemical Tradename Dictionary (1993)Documento539 pagineChemical Tradename Dictionary (1993)phamthuyha63% (8)

- 02Y040A Yellow Epoxy Primer: Product DescriptionDocumento6 pagine02Y040A Yellow Epoxy Primer: Product DescriptionBoris KundačinaNessuna valutazione finora

- Use of Rapid Prototyping in Rapid ToolingDocumento11 pagineUse of Rapid Prototyping in Rapid ToolingSudhanwa KulkarniNessuna valutazione finora

- Rigid Polyisocyanurate Insulation Technical Data SheetDocumento12 pagineRigid Polyisocyanurate Insulation Technical Data Sheet최우혁Nessuna valutazione finora

- Resiflow FL2 PDFDocumento2 pagineResiflow FL2 PDFsriatul2006Nessuna valutazione finora

- A Review On Recycling and Reuse Methods For Carbon Fiber - Glass Fiber Composites Waste From Wind Turbine BladesDocumento15 pagineA Review On Recycling and Reuse Methods For Carbon Fiber - Glass Fiber Composites Waste From Wind Turbine BladesJhon Leyder Rodriguez OrtizNessuna valutazione finora

- Jotafloor: Traffic Deck SystemDocumento12 pagineJotafloor: Traffic Deck SystemUnited Construction Est. TechnicalNessuna valutazione finora

- Pentens - Spray Roofing SystemDocumento7 paginePentens - Spray Roofing SystemJun QuanNessuna valutazione finora

- Stycast Es 1000-EnDocumento2 pagineStycast Es 1000-EnIvan MarijanovićNessuna valutazione finora

- Paint system for above ground pipe field weldsDocumento2 paginePaint system for above ground pipe field weldsSam JoseNessuna valutazione finora

- The Corrosion ProtectionDocumento28 pagineThe Corrosion Protectionjewettwater100% (1)

- Duralprep A.C.: Bonding Agent and Anti-Corrosion CoatingDocumento2 pagineDuralprep A.C.: Bonding Agent and Anti-Corrosion Coatingaandueza_1Nessuna valutazione finora

- Filament Vs Convolute TubesDocumento1 paginaFilament Vs Convolute TubesGanesh.MahendraNessuna valutazione finora

- Corocrete Eng A4 20090807Documento3 pagineCorocrete Eng A4 20090807andriNessuna valutazione finora

- Boom Construction and Materials PDFDocumento1 paginaBoom Construction and Materials PDFFernandoNessuna valutazione finora

- Composites: Part A: Oleksandr G. Kravchenko, Chunyu Li, Alejandro Strachan, Sergii G. Kravchenko, R. Byron PipesDocumento9 pagineComposites: Part A: Oleksandr G. Kravchenko, Chunyu Li, Alejandro Strachan, Sergii G. Kravchenko, R. Byron Pipesmarco_ravelo_10Nessuna valutazione finora

- Polymers in Aerospace Applications - 1847350933 - Ismithers Rapra PublishingDocumento146 paginePolymers in Aerospace Applications - 1847350933 - Ismithers Rapra PublishingPrakash Vasudevan100% (1)

- Araldite PW 1036 Hardener HW 1036: Product Data SheetDocumento4 pagineAraldite PW 1036 Hardener HW 1036: Product Data SheetAhmed HusseinNessuna valutazione finora

- Rapid Coat Presentation - DomesticDocumento30 pagineRapid Coat Presentation - DomesticSudhir PatilNessuna valutazione finora

- MFG Technical Design Guide FRP Composite 0Documento25 pagineMFG Technical Design Guide FRP Composite 0thiyakiNessuna valutazione finora

- Publication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and AdhesivesDocumento56 paginePublication - Painting, Coating & Corrosion Protection - Aremco Inc - High Temperature Materials - Coatings and Adhesiveszinha_alNessuna valutazione finora