Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Friction Coefficients PDF

Caricato da

desc82Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Friction Coefficients PDF

Caricato da

desc82Copyright:

Formati disponibili

Friction and friction coefficients Information Site

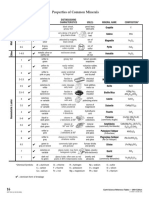

Assignment of friction classes with guide values to various materials / surfaces and lubrication conditions for threaded

connections according to VDI 2230 (the table applies for room temperature).

Friction coefficient range for Selection of typical examples for

class µG and µK Material / surfaces Lubricants

metallic, bare Solid lubricants like

black coating MoS2, Graphite, PTFE, PA, PE, Pl

phosphated in anti-friction paints as top coats

A 0,04–0,10

galvanic coverings like or in pastes

Zn, Zn/Fe, Zn/Ni Wax melts,

zinc flake coatings Wax dispersions

metallic, bare Solid lubricants like

black coating MoS2, Graphite, PTFE, PA, PE, Pl

phosphated in anti-friction paints as top coats

galvanic coverings like or in pastes

Zn, Zn/Fe, Zn/Ni Wax melts,

zinc flake coatings Wax dispersions, greases

B 0,08–0,16 aluminium and magnesium alloys oils, delivery condition

hot-dip galvanised MoS2; Graphite

Wax dispersions

organic coatings with integrated solid lubricant

or wax dispersion

austentitic steel Solid lubricants or waxes;

pastes

austentitic steel Wax dispersions, pastes

metallic, bare Delivery condition (slightly oiled)

phosphated

C 0,14–0,24 galvanic coverings like without

Zn, Zn/Fe, Zn/Ni

zinc flake coatings

Adhesive

austentitic steel Oil

galvanic coverings like without

D 0,20–0,35

Zn, Zn/Fe

hot-dip galvanised

galvanic coverings like without

Zn/Fe, Zn/Ni

E ≥ 0,30

austentitic steel

aluminium and magnesium alloys

Précontrainte FM [kN]

Good to know

in.

µm

Rp

0,2

0,9 min

Rp .

0,2

The friction values µGes, µG, µK show dispersion It is important for reliable assembly to precise- FM max. min

.

.

ax

m

µ

as they depend on many factors, such as, e.g. ly define the friction conditions and to keep

the material pairings, the surface quality (sur- their dispersion as narrow as possible.

face roughness), the surface treatment (bare

metal, blackened, galvanised, Dacromet® coat- In the case of large dispersion, the preload

ing, etc.) and the type of the lubrication (with/ force achieved will fluctuate very strongly. In

FM min.

without oil, molybdenum sulphide, Molykote® contrast, the usual tolerance of the tightening

paste, anti-friction coating, etc.). The follow- torque only has a small influence.

MA max.

MA min.

ing tables show friction coefficients for thread

and contact surfaces.

Couple de serrage MA [Nm]

Approximate values for static friction Material pairing Static friction coefficient in the condition

coefficients µT in the joint according to dry lubricated

VDI 2230 Steel – steel / cast steel 0,1 – 0,23 0,07 – 0,12

Steel – GG (cast iron) 0,12 – 0,24 0,06 – 0,1

GG – GG 0,15 – 0,3 0,2

Bronze – steel 0,12 – 0,28 0,18

GG – Bronze 0,28 0,15 – 0,2

Steel – copper alloy 0,07

Steel – aluminium alloy 0,1 – 0,28 0,05 – 0,18

Aluminium – Aluminium 0,21

Potrebbero piacerti anche

- Welding Inspection CSWIP (ANSWER)Documento131 pagineWelding Inspection CSWIP (ANSWER)Manoj PaudelNessuna valutazione finora

- Material GradesDocumento32 pagineMaterial GradesMarius PopaNessuna valutazione finora

- АК туториалDocumento63 pagineАК туториалLucas Gabriel100% (2)

- Sheet Metal Design-Handbook-Rev3 PDFDocumento12 pagineSheet Metal Design-Handbook-Rev3 PDFtnchsg100% (1)

- Bolt Tightening HandbookDocumento44 pagineBolt Tightening HandbookShekhar V Madhavi100% (1)

- Bolt Tightening HandbookDocumento44 pagineBolt Tightening HandbookShekhar V Madhavi100% (1)

- BendWorks PDFDocumento9 pagineBendWorks PDFLiam Choon SengNessuna valutazione finora

- BendWorks PDFDocumento9 pagineBendWorks PDFLiam Choon SengNessuna valutazione finora

- SS Surface FinishesDocumento1 paginaSS Surface FinishesWendyNessuna valutazione finora

- Stainless Steel Grade Composition ChartDocumento6 pagineStainless Steel Grade Composition Charteusufiqbal100% (1)

- Bolt Clamping Force vs Tightening Torque ChartDocumento1 paginaBolt Clamping Force vs Tightening Torque ChartphatmatNessuna valutazione finora

- Bolt Clamping Force vs Tightening Torque ChartDocumento1 paginaBolt Clamping Force vs Tightening Torque ChartphatmatNessuna valutazione finora

- Bolt Clamping Force vs Tightening Torque ChartDocumento1 paginaBolt Clamping Force vs Tightening Torque ChartphatmatNessuna valutazione finora

- Steel Material Table PDFDocumento1 paginaSteel Material Table PDFNathanNessuna valutazione finora

- (European Coatings TECH FILES) Et Al. - Sander, Jörg - Anticorrosive Coatings Fundamental and New Concepts-Vincentz Network (2014)Documento218 pagine(European Coatings TECH FILES) Et Al. - Sander, Jörg - Anticorrosive Coatings Fundamental and New Concepts-Vincentz Network (2014)Arthur ThiesenNessuna valutazione finora

- Effect of heat treatment on spring steel microstructures and propertiesDocumento7 pagineEffect of heat treatment on spring steel microstructures and propertiesMahmood KhanNessuna valutazione finora

- Copper, Bronze, IronDocumento15 pagineCopper, Bronze, IronDerick BrinNessuna valutazione finora

- Carbide GradesDocumento51 pagineCarbide GradesRicardo BravoNessuna valutazione finora

- C R R I C R S: ACI 364.6T-02Documento3 pagineC R R I C R S: ACI 364.6T-02Marco Flores ZuñigaNessuna valutazione finora

- F 1137 - 00 - RjexmzcDocumento2 pagineF 1137 - 00 - RjexmzckrutikNessuna valutazione finora

- CAN-ULC 1973 Ed.2-2018-En PDFDocumento107 pagineCAN-ULC 1973 Ed.2-2018-En PDFdesc82100% (1)

- Distributor List 24.02.2021Documento2 pagineDistributor List 24.02.2021Hoang TuNessuna valutazione finora

- Paint System (Table - 1)Documento2 paginePaint System (Table - 1)Imran AliNessuna valutazione finora

- Assembly: Friction coefficient Range for Selected typical examples for class μG and μK Materials/coatings LubricantsDocumento1 paginaAssembly: Friction coefficient Range for Selected typical examples for class μG and μK Materials/coatings LubricantspawkomNessuna valutazione finora

- 20050602014857.orion AlloysDocumento25 pagine20050602014857.orion AlloysdtweetyNessuna valutazione finora

- MENG 370 Poisson's Ratio and Young's ModulusDocumento69 pagineMENG 370 Poisson's Ratio and Young's ModuluscjonNessuna valutazione finora

- Week 1Documento22 pagineWeek 1JoRdAn HaNessuna valutazione finora

- CHIME POLYMER-Molykote Brochure PDFDocumento3 pagineCHIME POLYMER-Molykote Brochure PDFKrishna KumarNessuna valutazione finora

- M705-GRN360-MZ: High-Reliability, High-Preheat Resistance Lead-Free Solder PasteDocumento12 pagineM705-GRN360-MZ: High-Reliability, High-Preheat Resistance Lead-Free Solder PasteAlejandro Hernandez de DiosNessuna valutazione finora

- Selection Chart For Welding and Brazing Rods - Weldclass - 2021.08Documento2 pagineSelection Chart For Welding and Brazing Rods - Weldclass - 2021.08velan73Nessuna valutazione finora

- Chloride: Vapour Deposition Hard-Facing Miscellaneous TechniquesDocumento2 pagineChloride: Vapour Deposition Hard-Facing Miscellaneous TechniquessandeepNessuna valutazione finora

- EN Metallic Powder Coatings 1114Documento28 pagineEN Metallic Powder Coatings 1114Станислав ПодольскийNessuna valutazione finora

- Glassflake LTD: Moonshine® Effect Pigments: Product & Company OverviewDocumento32 pagineGlassflake LTD: Moonshine® Effect Pigments: Product & Company OverviewMani KandanNessuna valutazione finora

- Meterials: Non-Metallic Ceramic Ferrous Metallic Non-FerrousDocumento1 paginaMeterials: Non-Metallic Ceramic Ferrous Metallic Non-FerrousAli AhmedNessuna valutazione finora

- Spec PDFDocumento1 paginaSpec PDFcrysNessuna valutazione finora

- NTPC FGD Painting SPecificationDocumento3 pagineNTPC FGD Painting SPecificationanandakumar2810Nessuna valutazione finora

- Fluid AnalysisDocumento2 pagineFluid AnalysisAli WaqasNessuna valutazione finora

- CuSn6 Phosphor Bronze SpecificationDocumento1 paginaCuSn6 Phosphor Bronze SpecificationRemo StortiniNessuna valutazione finora

- Module 4b - Stainless SteelsDocumento11 pagineModule 4b - Stainless SteelsAnonymous 7yN43wjlNessuna valutazione finora

- Tool Steel MMDocumento3 pagineTool Steel MMBhushan UNessuna valutazione finora

- Corrosion Inhibitor Products by Kyoeisha ChemicalDocumento2 pagineCorrosion Inhibitor Products by Kyoeisha ChemicaldsyashankaNessuna valutazione finora

- SSDocumento10 pagineSSPrakash KaleNessuna valutazione finora

- PDS Poweroil Hone 7SDocumento1 paginaPDS Poweroil Hone 7SthenuamuNessuna valutazione finora

- Hot-Dip Galvanized Steel Sheet With Excellent Surface Quality For Automotive Outer PanelsDocumento6 pagineHot-Dip Galvanized Steel Sheet With Excellent Surface Quality For Automotive Outer PanelsHerdisNessuna valutazione finora

- Fluid Analysis Reference GuideDocumento2 pagineFluid Analysis Reference GuideLuizNessuna valutazione finora

- Paradiene - RangeDocumento4 pagineParadiene - RangemonetNessuna valutazione finora

- Zincalume G550 Steel: Metallic Coated - MC Structural - SDocumento1 paginaZincalume G550 Steel: Metallic Coated - MC Structural - SEwo50 New0% (1)

- Admina TableDocumento1 paginaAdmina TableNagi ReddyNessuna valutazione finora

- POSMAC Sales Promotion For CustomersDocumento45 paginePOSMAC Sales Promotion For CustomersLucio PereiraNessuna valutazione finora

- VW 50060-1 - 2007-11 - (Cold Rolled-DUAL Phase Steel)Documento5 pagineVW 50060-1 - 2007-11 - (Cold Rolled-DUAL Phase Steel)JORGE SOLISNessuna valutazione finora

- Properties of Soft Magnetic MaterialsDocumento57 pagineProperties of Soft Magnetic Materialsc_u_r_s_e_dNessuna valutazione finora

- Astm-A928-2005 Duplex Stailess Steel Pipe Electric Fusion WeldedDocumento6 pagineAstm-A928-2005 Duplex Stailess Steel Pipe Electric Fusion WeldedPablo PerdomoNessuna valutazione finora

- CCPDocumento4 pagineCCPganesh.patel37188Nessuna valutazione finora

- Approved Tier - 2 SupplierDocumento3 pagineApproved Tier - 2 SupplierMariyappanNessuna valutazione finora

- Catálogo de Eutalloy-Powder-Spray-FusingDocumento12 pagineCatálogo de Eutalloy-Powder-Spray-FusingEngenharia Gratt IndustriaNessuna valutazione finora

- Yg 1 Insert Highlight 2021Documento8 pagineYg 1 Insert Highlight 2021Mariano MoralesNessuna valutazione finora

- CV Flexible Body Filler, Light Grey: Technical InformationDocumento2 pagineCV Flexible Body Filler, Light Grey: Technical InformationGoodBoi EsberNessuna valutazione finora

- PV-ezRack Zn-Mg-Al Coating IntroductionDocumento4 paginePV-ezRack Zn-Mg-Al Coating Introduction郑秋Nessuna valutazione finora

- YG-1 Complete CatalogueDocumento1.156 pagineYG-1 Complete CatalogueMuchamad Fajar NugrohoNessuna valutazione finora

- Eur MT Gamma Isoparete Rev.03 170831 EngDocumento68 pagineEur MT Gamma Isoparete Rev.03 170831 Engscibduser001Nessuna valutazione finora

- OK Grain 21.85Documento1 paginaOK Grain 21.85brunizzaNessuna valutazione finora

- Design, engineering, supply, fabrication, installation, testing and commissioning of package A storage tanksDocumento1 paginaDesign, engineering, supply, fabrication, installation, testing and commissioning of package A storage tanksZuber KhanNessuna valutazione finora

- LKM Steel Rainbow Chart 2014 UpmoldDocumento1 paginaLKM Steel Rainbow Chart 2014 UpmoldsrinivasaNessuna valutazione finora

- 400150_PCB_Laminate_SpecificationDocumento2 pagine400150_PCB_Laminate_SpecificationmikeNessuna valutazione finora

- Properties of Common MineralsDocumento1 paginaProperties of Common MineralsRawan Ahmed ElbatrawyNessuna valutazione finora

- General - Fillers GBDocumento2 pagineGeneral - Fillers GBDraganNessuna valutazione finora

- Skema Modul 3 Blok 6Documento1 paginaSkema Modul 3 Blok 6Mifthahul KhoirNessuna valutazione finora

- Armowel 1Documento2 pagineArmowel 1Mahesh DeshmukhNessuna valutazione finora

- Hot Rolled HR Formable F HA3 Steel: General Description Typical UsesDocumento2 pagineHot Rolled HR Formable F HA3 Steel: General Description Typical UsesBaziNessuna valutazione finora

- Gasket ThicknessDocumento1 paginaGasket ThicknessPrabhakar KumarNessuna valutazione finora

- TDS Hardcarb 70 (#ET - EN - 20.1)Documento2 pagineTDS Hardcarb 70 (#ET - EN - 20.1)Jimit ShahNessuna valutazione finora

- Metal WareDocumento47 pagineMetal Waremukesh guptaNessuna valutazione finora

- Corrosion Control Methods: Modifying Metals and EnvironmentsDocumento1 paginaCorrosion Control Methods: Modifying Metals and EnvironmentssanthoshbrowsingNessuna valutazione finora

- Conductive Adhesive ComparisonTableDocumento1 paginaConductive Adhesive ComparisonTableAndréNessuna valutazione finora

- Zam-Brochure Nishin PDFDocumento6 pagineZam-Brochure Nishin PDFNguyễn Viết ĐạiNessuna valutazione finora

- 205 Tab-On TypeDocumento1 pagina205 Tab-On TypeNgoc NguyenNessuna valutazione finora

- Mylar® BP - UL Product IqDocumento2 pagineMylar® BP - UL Product Iqdesc82Nessuna valutazione finora

- Melinex 1311 - UL Product IqDocumento2 pagineMelinex 1311 - UL Product Iqdesc82Nessuna valutazione finora

- Mylar WC - UL Product IQDocumento2 pagineMylar WC - UL Product IQdesc82Nessuna valutazione finora

- Mylar 800 - UL Product IQDocumento2 pagineMylar 800 - UL Product IQdesc82Nessuna valutazione finora

- Mylar 209 - UL Product IQDocumento2 pagineMylar 209 - UL Product IQdesc82100% (1)

- General Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)Documento1 paginaGeneral Dimensional Tolerances For Sheet Metal Formed Parts. (Unless Otherwise Specified)murali036Nessuna valutazione finora

- Mylar 800 - UL Product IQDocumento2 pagineMylar 800 - UL Product IQdesc82Nessuna valutazione finora

- Suggested Tightening Torque1 Values To Produce Corresponding Bolt Clamping Loads PDFDocumento1 paginaSuggested Tightening Torque1 Values To Produce Corresponding Bolt Clamping Loads PDFdesc82Nessuna valutazione finora

- A Study On Anti-Loosening Characteristics of Different 3/8 BSW Threaded FastenersDocumento7 pagineA Study On Anti-Loosening Characteristics of Different 3/8 BSW Threaded Fastenersdesc82Nessuna valutazione finora

- Design Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyDocumento5 pagineDesign Guide For Bent Sheet Metal: Prepared by Gerald Davis D.S.M. Manufacturing CompanyVikram BorkhediyaNessuna valutazione finora

- 1 s2.0 S2212017314001054 Main PDFDocumento10 pagine1 s2.0 S2212017314001054 Main PDFdesc82Nessuna valutazione finora

- Sheet Metal BendingDocumento7 pagineSheet Metal Bendingdesc82Nessuna valutazione finora

- Analysing The Components of The Tightening TorqueDocumento1 paginaAnalysing The Components of The Tightening Torquedesc82Nessuna valutazione finora

- Aluminium Metal Galvanic CorrosionDocumento4 pagineAluminium Metal Galvanic CorrosionGnabBangNessuna valutazione finora

- Sheet Metal BendingDocumento7 pagineSheet Metal Bendingdesc82Nessuna valutazione finora

- Sli JT Age Coefficient enDocumento39 pagineSli JT Age Coefficient enalibambam1989Nessuna valutazione finora

- Sli JT Age Coefficient enDocumento39 pagineSli JT Age Coefficient enalibambam1989Nessuna valutazione finora

- Sli JT Age Coefficient enDocumento39 pagineSli JT Age Coefficient enalibambam1989Nessuna valutazione finora

- Effect of Normal Load and Sliding Velocity On Friction Coefficient PDFDocumento6 pagineEffect of Normal Load and Sliding Velocity On Friction Coefficient PDFdesc82Nessuna valutazione finora

- R100 R 2 eDocumento82 pagineR100 R 2 edesc82Nessuna valutazione finora

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01Documento1 paginaIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01subudhiprasannaNessuna valutazione finora

- Ashish Bhateja, Aditya Varma, Ashish Kashyap and Bhupinder Singh _ TheStudy the Effect on the Hardness of Three Sample Grades of Tool Steel i.e. En-31, En-8, And D3 After Heat Treatment Processes Such As Annealing, Normalizing, and Hardening & TemperingDocumento7 pagineAshish Bhateja, Aditya Varma, Ashish Kashyap and Bhupinder Singh _ TheStudy the Effect on the Hardness of Three Sample Grades of Tool Steel i.e. En-31, En-8, And D3 After Heat Treatment Processes Such As Annealing, Normalizing, and Hardening & TemperingProf.Bhateja AshishNessuna valutazione finora

- AMP Combined MCQsDocumento180 pagineAMP Combined MCQsBalaji JagalpureNessuna valutazione finora

- ME8793 Process Planning and Cost EStimation UNIT 5 NotesDocumento26 pagineME8793 Process Planning and Cost EStimation UNIT 5 NotesLEO PRAVIN PNessuna valutazione finora

- Sec 3 Welding Imperfections (Defects)Documento31 pagineSec 3 Welding Imperfections (Defects)Abdullah100% (1)

- Stainless and High Alloy Steel Valves: JIS 5K/10K/20K, ASME Class 150/300/600/900/1500, Gate, Globe and Check ValvesDocumento60 pagineStainless and High Alloy Steel Valves: JIS 5K/10K/20K, ASME Class 150/300/600/900/1500, Gate, Globe and Check ValvesSekson JunsukplukNessuna valutazione finora

- Roof Outlets BrochureDocumento32 pagineRoof Outlets BrochureKieran CondonNessuna valutazione finora

- A Study of Macrocrystalline Glazes: Provided by K-State Research ExchangeDocumento59 pagineA Study of Macrocrystalline Glazes: Provided by K-State Research ExchangemicochetoledoNessuna valutazione finora

- Kitchen Sink Catalogue-CombinedDocumento6 pagineKitchen Sink Catalogue-CombinedRathan_k11Nessuna valutazione finora

- Al7050 T7451Documento16 pagineAl7050 T7451Fatih HocaogluNessuna valutazione finora

- Knife Gate ValveDocumento2 pagineKnife Gate ValvePT TEMAN KARUNIA SEJAHTERANessuna valutazione finora

- Problemas Tamaño de Grano ASTMDocumento1 paginaProblemas Tamaño de Grano ASTMCristian MejiaNessuna valutazione finora

- WJ 1990 09 s362 PDFDocumento11 pagineWJ 1990 09 s362 PDFLaurentiu ZgripceaNessuna valutazione finora

- 3331901Documento9 pagine3331901Himanshu ChaudhariNessuna valutazione finora

- Monel Corrosion: Monel Strainer Corroded at The Seawater LineDocumento2 pagineMonel Corrosion: Monel Strainer Corroded at The Seawater LinePaul NeedhamNessuna valutazione finora

- Melting, Remelting, and Casting For Clean Steel: July 2016Documento14 pagineMelting, Remelting, and Casting For Clean Steel: July 2016tabibkarimNessuna valutazione finora

- Failure Analysis of Cracked Brass Turrets Used in Electronic CircuitsDocumento11 pagineFailure Analysis of Cracked Brass Turrets Used in Electronic CircuitsAJay LevantinoNessuna valutazione finora

- 316L Stainless Steel Technical Data SheetDocumento3 pagine316L Stainless Steel Technical Data Sheetchris calonzoNessuna valutazione finora

- ECO-FRIENDLY MACHINING OF SUPER DUPLEX STAINLESS STEELDocumento29 pagineECO-FRIENDLY MACHINING OF SUPER DUPLEX STAINLESS STEELNabil SalimNessuna valutazione finora

- Paint Spec CIEGO VOLTEODocumento3 paginePaint Spec CIEGO VOLTEOFreddy Carl FredricksenNessuna valutazione finora

- Selectivity in BioleachingDocumento8 pagineSelectivity in BioleachingemiaNessuna valutazione finora