Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Worksafe Bulletin: Lifting Concrete Locking Blocks Safely

Caricato da

Abdulkerim A.Abdi0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni2 paginerisk assessment

Titolo originale

Other-1321566

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentorisk assessment

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

23 visualizzazioni2 pagineWorksafe Bulletin: Lifting Concrete Locking Blocks Safely

Caricato da

Abdulkerim A.Abdirisk assessment

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

WorkSafe Bulletin

Lifting concrete locking blocks safely

Concrete locking blocks are used, and often reused, in the construction of a wide range of structures,

such as silos, containment bunkers, barriers, and retaining walls. Many different manufacturers make

these blocks. There is a lot of variation in the design, manufacturing, quality of materials, strength,

durability, and age of blocks found at different worksites.

What is the hazard?

Concrete locking blocks are often moved from

one location to another on worksites or stacked

on top of other blocks. On many worksites, the

blocks are lifted using hooks through a “lifting

eye” on the top of each block. The lifting eye is

often made of wire but it may also be rebar, metal

rod, or steel. The eye can fail for various reasons,

including wear and corrosion, putting workers Lifting eyes,

and equipment at risk. such as this wire

eye, can fail as

In general, manufacturers only rate lifting eyes on a result of wear

blocks for three lifts: from mould to storage, from and corrosion.

storage to truck, and from truck to worksite. After

these three initial lifts, the eyes on most blocks are Reducing the risks

no longer considered safe points of attachment.

Make sure you have a safe lifting plan in place

Generally, there are no design requirements for

before moving concrete locking blocks on your

the block or lifting eye.

worksite. Instruct workers in the plan and provide

If a lifting eye fails during a lift and a block is adequate supervision.

dropped, there can be serious consequences.

Before every lift, do the following:

For example, if a crane lifts a locking block and

the block drops, the crane can be thrown off • Refer to industry best practices and assess the

balance and tip over. Both the falling block and risks. Consider the safest way to move the block.

the tipping crane can cause serious injury or • Ensure all workers are in a safe position during

death, and damage equipment and property. the lifting process.

WorkSafeBC Prevention Information Line: 604.276.3100

WS 2018-12 page 1 of 2

or toll-free 1.888.621.SAFE (7233)

Regulatory requirements The Act:

To help ensure your lifting plan is safe, refer to the • Sections 115 to 124, General duties

following sections of the Occupational Health and of employers, workers and others

Safety Regulation and the Workers Compensation

Act (available at worksafebc.com). For more information

Occupational Health and Safety Regulation: The following hazard alerts are available

on worksafebc.com:

• Section 4.1, Safe workplace

• Stay clear of concrete locking blocks

• Section 14.44, Loads over work areas

• Blocks alone do not make safe retaining walls

page 2 of 2

Potrebbero piacerti anche

- Risk Assessment: Pick & Carry CranesDocumento36 pagineRisk Assessment: Pick & Carry CranesAbd Ennacer100% (2)

- Risk Assessment: Pick & Carry CranesDocumento36 pagineRisk Assessment: Pick & Carry CranesAbd Ennacer100% (2)

- Risk Assessment: Pick & Carry CranesDocumento36 pagineRisk Assessment: Pick & Carry CranesAbd Ennacer100% (2)

- Industry Guide For Formwork: Construction Industry South Australia JUNE 2012Documento37 pagineIndustry Guide For Formwork: Construction Industry South Australia JUNE 2012tino3528100% (6)

- Load Dev Silo DesignDocumento0 pagineLoad Dev Silo Designuser 54Nessuna valutazione finora

- Structures Failures Reasons and MitigationDa EverandStructures Failures Reasons and MitigationNessuna valutazione finora

- Self-Locking & Self-Sealing Fasteners HandbookDocumento48 pagineSelf-Locking & Self-Sealing Fasteners Handbookkamy001Nessuna valutazione finora

- Safe Work Method Statement For Class 1, 2 & 10 Building Projects - B Grade Bricklayers Pty LTDDocumento3 pagineSafe Work Method Statement For Class 1, 2 & 10 Building Projects - B Grade Bricklayers Pty LTDsaqib85-999Nessuna valutazione finora

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionDa EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNessuna valutazione finora

- 4001 Basic Erection GuideDocumento68 pagine4001 Basic Erection Guideak100% (1)

- RiggingDocumento97 pagineRiggingJonathan Lynch100% (3)

- SRISE - Rigging & Crane Safety TrainingDocumento68 pagineSRISE - Rigging & Crane Safety TrainingMohammed Sadruddin100% (1)

- Rigging Safety: GuideDocumento51 pagineRigging Safety: GuideJamal UddinNessuna valutazione finora

- Erecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373Documento32 pagineErecting Altering Dismantling Scaffolding Prefabricated Steel Modular Scaffolding Industry Safety Standard 2373madhav0303Nessuna valutazione finora

- Fall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public ConsultDocumento40 pagineFall Protection Systems Guidelines Part 1 - Anchorages Lifelines and Temporary Edge Protection Systems - Public Consultlwin_oo2435100% (4)

- BCSA - 43-07 Guide To Work at Height During The Loading and Unloading of SteelworkDocumento22 pagineBCSA - 43-07 Guide To Work at Height During The Loading and Unloading of Steelworkjunhe898Nessuna valutazione finora

- Locking Fasteners HandbookDocumento48 pagineLocking Fasteners HandbookMomchil YordanovNessuna valutazione finora

- Manual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateDocumento5 pagineManual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateMohamed IbrahimNessuna valutazione finora

- Slings Safety Use InspectionDocumento40 pagineSlings Safety Use InspectionajayNessuna valutazione finora

- HSE Management PlanDocumento35 pagineHSE Management PlanAbdulkerim A.Abdi100% (1)

- Mechanical HandbookDocumento48 pagineMechanical HandbookbenlandisNessuna valutazione finora

- Project Name: Submittal Cover SheetDocumento2 pagineProject Name: Submittal Cover SheetAbdulkerim A.Abdi100% (1)

- Anchorage GuidelinesDocumento26 pagineAnchorage GuidelinestatonyNessuna valutazione finora

- Bonney Forge Branch ConnectionsDocumento45 pagineBonney Forge Branch ConnectionsperoooNessuna valutazione finora

- Reinforced Concrete Buildings: Behavior and DesignDa EverandReinforced Concrete Buildings: Behavior and DesignValutazione: 5 su 5 stelle5/5 (1)

- Hydro Testing Spec For OnshoreDocumento19 pagineHydro Testing Spec For OnshoreSaut Maruli Tua Samosir67% (3)

- As 4906-2002 (Reference Use Only) Minor Works Contract Conditions (Principal Administered)Documento8 pagineAs 4906-2002 (Reference Use Only) Minor Works Contract Conditions (Principal Administered)SAI Global - APACNessuna valutazione finora

- 016 Procedure ScaffoldingDocumento13 pagine016 Procedure ScaffoldingHSE CERINessuna valutazione finora

- BS 6089 Core CuttingDocumento19 pagineBS 6089 Core Cuttingਸੁਖਬੀਰ ਸਿੰਘ ਮਾਂਗਟ100% (1)

- Scaffold Safety GuideDocumento17 pagineScaffold Safety Guideuserr29990100% (2)

- Tgn01 Guidance On The Selection Use Maintenance and Inspection of Retractable Type Fall ArrestorsDocumento8 pagineTgn01 Guidance On The Selection Use Maintenance and Inspection of Retractable Type Fall ArrestorsandrewhwNessuna valutazione finora

- Rolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsDa EverandRolling Bearing Tribology: Tribology and Failure Modes of Rolling Element BearingsNessuna valutazione finora

- Construction Safety ManagementDocumento16 pagineConstruction Safety ManagementNoman100% (3)

- ASME - Middle-East-Training-Brochure PDFDocumento32 pagineASME - Middle-East-Training-Brochure PDFMohamed F MorsyNessuna valutazione finora

- 2.2 2.3 Hydraulic and Structure DesignDocumento144 pagine2.2 2.3 Hydraulic and Structure DesignSriram Nambi100% (1)

- 01 MS For Piling Testing (FINAL)Documento12 pagine01 MS For Piling Testing (FINAL)Joe PSNessuna valutazione finora

- Tower Crane ChecklistDocumento10 pagineTower Crane ChecklistumamNessuna valutazione finora

- SG29 - Internal Edge Protection On Scaffold PlatformsDocumento2 pagineSG29 - Internal Edge Protection On Scaffold PlatformsAnupam GhoshNessuna valutazione finora

- Edge Protection Code of PracticeDocumento37 pagineEdge Protection Code of PracticembranchteinNessuna valutazione finora

- APEGBC-Designing Guards For Buildings PDFDocumento26 pagineAPEGBC-Designing Guards For Buildings PDFhahaerNessuna valutazione finora

- TGN07 Guidance On The Sustainability of Abseil Rails. Design Selection Use Maintenance and InspectionDocumento6 pagineTGN07 Guidance On The Sustainability of Abseil Rails. Design Selection Use Maintenance and InspectionLeo LionNessuna valutazione finora

- 15 Aerial Lifts Tool Box TalkDocumento3 pagine15 Aerial Lifts Tool Box TalkMugilan SelvarajuNessuna valutazione finora

- Anti Two-Blocking Devices On CranesDocumento2 pagineAnti Two-Blocking Devices On CranesJan Francis Wilson MapacpacNessuna valutazione finora

- Avoid Outrigger FailureDocumento1 paginaAvoid Outrigger FailurehazopmanNessuna valutazione finora

- Basic Formwork & Concreting Checklist For Builders and Building Trades ContractorsDocumento2 pagineBasic Formwork & Concreting Checklist For Builders and Building Trades ContractorsAlphaNessuna valutazione finora

- HS-18-Hazards-Structural SteelworkDocumento1 paginaHS-18-Hazards-Structural SteelworktresspasseeNessuna valutazione finora

- Fall Protection Rule (OR-OSHA) Changes in Oregon: Competent PersonsDocumento11 pagineFall Protection Rule (OR-OSHA) Changes in Oregon: Competent PersonsEtibar AliyevNessuna valutazione finora

- DS Prestress HBDocumento28 pagineDS Prestress HBBrian James MarzanNessuna valutazione finora

- N N 36, O 2014 I: Ewsletter O Ctober NtroductionDocumento7 pagineN N 36, O 2014 I: Ewsletter O Ctober NtroductionponjoveNessuna valutazione finora

- UNIT 5 Scaffolds and LaddersDocumento87 pagineUNIT 5 Scaffolds and Laddersmohsin khanNessuna valutazione finora

- Bab 3 Keselamatan Konstruksi Dan PermesinanDocumento54 pagineBab 3 Keselamatan Konstruksi Dan Permesinanina emawati100% (1)

- Crane Safety PowerPoint PresentationDocumento30 pagineCrane Safety PowerPoint Presentationhamouda hediNessuna valutazione finora

- Concrete SafetyDocumento2 pagineConcrete SafetyStar StreamNessuna valutazione finora

- NCP 32Documento26 pagineNCP 32Mohammad Younus100% (1)

- Reviewer For HarnessDocumento6 pagineReviewer For HarnessJELLAH MAY LORENONessuna valutazione finora

- TW15.116 - Rebar Stability - Safety Bulletin - 16 Oct 2015Documento10 pagineTW15.116 - Rebar Stability - Safety Bulletin - 16 Oct 2015kamilrak2317Nessuna valutazione finora

- Operation and Maintenance of Pallet RackingDocumento6 pagineOperation and Maintenance of Pallet Rackingmbhanusagar.keynesNessuna valutazione finora

- FPS Extraction FinalDocumento27 pagineFPS Extraction Finalks_raghuveer100% (1)

- FPSExtractionFinal Jun2010Documento27 pagineFPSExtractionFinal Jun2010Salvatore MirandaNessuna valutazione finora

- vYMeuoP5WRyc8NIv - Jltnw0O1UgbBz9sp-OSHA 10 Construction - Module 11 - Study GuideDocumento7 paginevYMeuoP5WRyc8NIv - Jltnw0O1UgbBz9sp-OSHA 10 Construction - Module 11 - Study GuideBelkacem BouazzaNessuna valutazione finora

- LSD ConceptsDocumento19 pagineLSD Conceptsprabhu81Nessuna valutazione finora

- Working On Mobile Scaffolding Can Pose Various Hazards and RisksDocumento2 pagineWorking On Mobile Scaffolding Can Pose Various Hazards and RisksEjaz AhmadNessuna valutazione finora

- Civil Design Help2Documento4 pagineCivil Design Help2Ahsan RafiqNessuna valutazione finora

- Construction: Steel Components Bolting Site Welding AlignedDocumento21 pagineConstruction: Steel Components Bolting Site Welding AlignedRama Krishna Reddy DonthireddyNessuna valutazione finora

- Craneblock WulDocumento2 pagineCraneblock WulZachNessuna valutazione finora

- Tca Safety Guidelines Version13-1Documento11 pagineTca Safety Guidelines Version13-1engdireccionNessuna valutazione finora

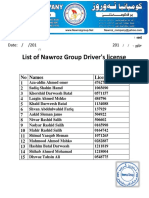

- List of Nawroz Group Driver's License: No Names License NoDocumento6 pagineList of Nawroz Group Driver's License: No Names License NoAbdulkerim A.AbdiNessuna valutazione finora

- Subcontractor Rating FormDocumento7 pagineSubcontractor Rating FormAbdulkerim A.AbdiNessuna valutazione finora

- D 2Documento1 paginaD 2Abdulkerim A.AbdiNessuna valutazione finora

- Empire Business Complex,: Building C2 - 3rd Floor Erbil, Iraq /provision of Crude Oil TransportationDocumento1 paginaEmpire Business Complex,: Building C2 - 3rd Floor Erbil, Iraq /provision of Crude Oil TransportationAbdulkerim A.AbdiNessuna valutazione finora

- 0-BOQ Out of Contract-Construction of R.C Floor For LSADocumento1 pagina0-BOQ Out of Contract-Construction of R.C Floor For LSAAbdulkerim A.AbdiNessuna valutazione finora

- Asphalt Facyory Memory of UndrstandingDocumento1 paginaAsphalt Facyory Memory of UndrstandingAbdulkerim A.AbdiNessuna valutazione finora

- Drug NameDocumento1 paginaDrug NameAbdulkerim A.AbdiNessuna valutazione finora

- Att.4 - NAWROZ H&S Induction Training PresentationDocumento76 pagineAtt.4 - NAWROZ H&S Induction Training PresentationAbdulkerim A.AbdiNessuna valutazione finora

- RFQ C-00015 BSQ - Attachment 1 - Due Diligence QuestionnaireDocumento8 pagineRFQ C-00015 BSQ - Attachment 1 - Due Diligence QuestionnaireAbdulkerim A.AbdiNessuna valutazione finora

- Lifting Plan Method Statement: (Include Weights, Lifting Radius, Dimensions, Lifting Points & Unusual Characteristics)Documento2 pagineLifting Plan Method Statement: (Include Weights, Lifting Radius, Dimensions, Lifting Points & Unusual Characteristics)Abdulkerim A.AbdiNessuna valutazione finora

- Concrete Risk PDFDocumento32 pagineConcrete Risk PDFkrissregionNessuna valutazione finora

- Pick Carry Cranes Risk Assessment 2Documento15 paginePick Carry Cranes Risk Assessment 2Abdulkerim A.AbdiNessuna valutazione finora

- Risk Assessment and Method Statement Beam and Block Installation From LorryDocumento16 pagineRisk Assessment and Method Statement Beam and Block Installation From LorryAbdulkerim A.AbdiNessuna valutazione finora

- Hunter Expressway Western Sec Cms 3Documento13 pagineHunter Expressway Western Sec Cms 3Abdulkerim A.AbdiNessuna valutazione finora

- 1Documento33 pagine1Abdulkerim A.AbdiNessuna valutazione finora

- Shaban Booklet 13-9-2017 - 167 PagesDocumento167 pagineShaban Booklet 13-9-2017 - 167 PagesAbdulkerim A.AbdiNessuna valutazione finora

- 1d. MS 04 Earthworks PDFDocumento20 pagine1d. MS 04 Earthworks PDFAbdulkerim A.AbdiNessuna valutazione finora

- Design Project PCD 2020 Chapters 1 To 5 With Calculations 1Documento61 pagineDesign Project PCD 2020 Chapters 1 To 5 With Calculations 1Calvin BaraquiaNessuna valutazione finora

- 2020 ACEGrid GG (Biaxial)Documento1 pagina2020 ACEGrid GG (Biaxial)Raka BachtiaraNessuna valutazione finora

- Fosroc Egypt Company Profile 1646382455Documento12 pagineFosroc Egypt Company Profile 1646382455Mahmoud Akram AburidaNessuna valutazione finora

- Valve-Chamber ISO A3 Title BlockDocumento1 paginaValve-Chamber ISO A3 Title BlockAbNessuna valutazione finora

- Gemu DB FlareStar GBDocumento32 pagineGemu DB FlareStar GBejrfjxhjtntauuwtfcNessuna valutazione finora

- Chapter 2:-Reciprocating Pump 2.1: IntroducationDocumento7 pagineChapter 2:-Reciprocating Pump 2.1: IntroducationParth VyasNessuna valutazione finora

- Shopee E-Commerce Hub-Bogor Project: Inspection and Test PlanDocumento5 pagineShopee E-Commerce Hub-Bogor Project: Inspection and Test PlanANWAR PERANGINANGINNessuna valutazione finora

- Prediction of Movements For Braced Cuts in ClayDocumento19 paginePrediction of Movements For Braced Cuts in Clayvanness hoNessuna valutazione finora

- JMS - Snuffing Pipe Installation Rev 1Documento17 pagineJMS - Snuffing Pipe Installation Rev 1mohd as shahiddin jafriNessuna valutazione finora

- HT64-132 OWS Final Drawings150525Documento24 pagineHT64-132 OWS Final Drawings150525jamukanak padNessuna valutazione finora

- Standard Style Stuffing BoxDocumento4 pagineStandard Style Stuffing BoxAdelzon KinteroNessuna valutazione finora

- Piecharts WorksheetsDocumento5 paginePiecharts Worksheetssalbina arabiNessuna valutazione finora

- GFST200Documento7 pagineGFST200Arif andreas panjaitanNessuna valutazione finora

- Ned/Ac : Bs en 1992-1-1:2004 en 1992-1-1:2004 (E)Documento1 paginaNed/Ac : Bs en 1992-1-1:2004 en 1992-1-1:2004 (E)Arun PrakashNessuna valutazione finora

- Project Manager - Bridge Specialist UNOPSDocumento5 pagineProject Manager - Bridge Specialist UNOPSRonnie NdozirehoNessuna valutazione finora

- Aimsite Display Printing Cost - 10.02.2023Documento8 pagineAimsite Display Printing Cost - 10.02.2023sayli pNessuna valutazione finora

- Rain Bird Solenoid Valve (Reference)Documento7 pagineRain Bird Solenoid Valve (Reference)Syed Ali Abdullah RizviNessuna valutazione finora

- Forged FittingsDocumento9 pagineForged FittingsTran Anh TuanNessuna valutazione finora

- Product TKF CablesDocumento3 pagineProduct TKF CablesjoelNessuna valutazione finora

- SmartGrip-518 240718Documento2 pagineSmartGrip-518 240718Chiang LoongNessuna valutazione finora

- ME 112 - Mse Failure: Materials Science and EngineeringDocumento46 pagineME 112 - Mse Failure: Materials Science and EngineeringSundresh NNessuna valutazione finora

- An Introduction To Autoclaved Aerated Concrete (Aac) : Abhijitmangaraj, RojanilsenapatiDocumento7 pagineAn Introduction To Autoclaved Aerated Concrete (Aac) : Abhijitmangaraj, RojanilsenapatiRadhika KhandelwalNessuna valutazione finora