Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Env Audit Feb

Caricato da

gkmlal100%(1)Il 100% ha trovato utile questo documento (1 voto)

70 visualizzazioni5 pagineThe document is an environmental audit report for the ABAN II facility located in KG BASIN. It finds that the facility is generally compliant with environmental policies and procedures, with a few exceptions. Hazardous waste is being properly tracked and stored, personnel are trained on environmental matters, and chemical inventories are maintained. However, the facility was not maintaining all required logs like the effluent monitoring and chemical inventory submission logs. It also lacks secondary containment in its hazardous waste accumulation area.

Descrizione originale:

environment Audit

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThe document is an environmental audit report for the ABAN II facility located in KG BASIN. It finds that the facility is generally compliant with environmental policies and procedures, with a few exceptions. Hazardous waste is being properly tracked and stored, personnel are trained on environmental matters, and chemical inventories are maintained. However, the facility was not maintaining all required logs like the effluent monitoring and chemical inventory submission logs. It also lacks secondary containment in its hazardous waste accumulation area.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

100%(1)Il 100% ha trovato utile questo documento (1 voto)

70 visualizzazioni5 pagineEnv Audit Feb

Caricato da

gkmlalThe document is an environmental audit report for the ABAN II facility located in KG BASIN. It finds that the facility is generally compliant with environmental policies and procedures, with a few exceptions. Hazardous waste is being properly tracked and stored, personnel are trained on environmental matters, and chemical inventories are maintained. However, the facility was not maintaining all required logs like the effluent monitoring and chemical inventory submission logs. It also lacks secondary containment in its hazardous waste accumulation area.

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

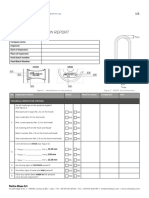

Environmental Audit – Worldwide Operations

Facility: ABAN II Inspection Date: 04/02/14

Location: KG BASIN Operating Condition: WELL TESTING

General Comments: ABAN Environmental Management system (EMS) to be referred and ensure that all

policies and procedure within the EMS are complied with.

A Administration Yes, No or N/A

1 Has an environmental audit been conducted at this work site? ENV 470.00 YES

2 Were a Hazardous Waste Generation, Disposal and Accumulation Log completed at this

YES

worksite and reported? ENV 470.00

3 Was a Refuse Discharge Log completed at this worksite?

YES

ENV 470.00

4 Was an Effluent Monitoring Log completed at this worksite? ENV 470.00 NO

B Environmental Testing Yes, No or N/A

1 Have all personnel onboard received Hazcom Training either before arriving or shortly

YES

after? TRA 200.40 - 5.1

2 Is employee Hazcom Refresher Training conducted annually? TRA 200.40 - 5.1 YES

3 Have all personnel onboard received Spill Response Training either before arriving or

YES

shortly after? TRA 200.40 - 5.1

4 Was the Environmental Management System (EMS) discussed and reviewed during the

YES

employee orientation process? TRA 200.40 - 3.1

5 Is Spill Refresher Training conducted annually? TRA 200.40 - 5.1 INPROGRESS

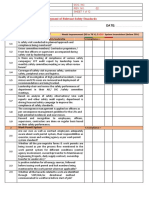

C Hazardous / Special Waste Minimization Yes, No or N/A

1 Are all wastes properly identified as either hazardous or non-hazardous (special or non-

YES

special)? ENV 140.00 - 5.1

2 Are hazardous wastes and non-hazardous wastes (special and non-special) segregated to

YES

prevent cross contamination and mixing? ENV 180.00 - 4.3, Table 1

3 When mixing paint, is the amount needed calculated to avoid over mixing? ENV 190.00 -

YES

5.7

4 Are recyclable materials segregated from other wastes? ENV 180.00 - 4.3, Table 1 YES

D Chemical Inventory Yes, No or N/A

1 Is a Chemical Inventory maintained and updated to reflect changes resulting from the

YES

arrival of new products, updated MSDSs and old MSDSs removed? ENV 140.00 - 5.2

2 Was the chemical inventory maintained electronically and submitted monthly as an

NO

attachment to the Monthly Environmental Audit Form? ENV 140.00 - 5.2

3 Does the Chemical Inventory accurately list items found in inventory? ENV 140.00 - 5.2 YES

E Non-Hazardous Waste Yes, No or N/A

1 Does the facility dispose of garbage per MARPOL 73/78 Annex V? ENV 170.00 - 4.2 YES

2 Are nonhazardous wastes stored separately from other wastes in a fixed designated area YES

Form No. ENV-005, 1 September 2009, Reference ENV 110.00 Page 1 of 5

Environmental Audit – Worldwide Operations

Facility: ABAN II Inspection Date: 04/02/14

Location: KG BASIN Operating Condition: WELL TESTING

which is clearly marked? ENV 170.00 4.2

3 Is food waste passed through a food grinder to ensure particles are less than 25 mm (1")

and output volumes are controlled from 10 to 250 liters (2.5 to 6.5 gallons) per minute?

YES

ENV 170.00- 4.5

4 Are one or more MARPOL compliant placard(s) displayed in prominent locations that can

YES

be read by all personnel onboard? ENV 170.00 - 4.7

5 Was an electronic record of non-hazardous waste disposal recorded and maintained on

NO

the Refuse Discharge Log? ENV 170.00 - 4.8

F Hazardous / Special waste Accumulation and Storage Yes, No or N/A

1 Is an area designated and properly marked as Hazardous Waste Accumulation Area? ENV

YES

180.00 - 4.6

2 Does the Hazardous Waste Accumulation Area have secondary containment? ENV 180.00 - NO

4.6

3 Do waste containers meet regulatory standards? ENV 180.00 - 4.8 YES

4 Are waste containers compatible with the waste material they contain? ENV 180.00 - 4.8 YES

5 Are containers in good physical condition (i.e.: rust free, dent free, etc.)? ENV 180.00 - 4.8 YES

6 Are all containers sealed when not being utilized? ENV 180.00 - 4.10 YES

7 Are all containers stowed off deck, e.g. on pallets? ENV 180.00 - 4.8 YES

8 Are waste containers identified and labeled as hazardous or non-hazardous? ENV 180.00 - YES

4.15

9 Are labels on containers identifying their contents? ENV 180.00 - 4.15. YES

10 Are containers marked to indicate whether they are Ignitable, Reactive, Corrosive, Toxic, YES

etc.?ENV 180.00 - 4.15

11 Are all hazardous wastes generated onboard the rig stored in the Hazardous Waste YES

Accumulation Area? ENV 180.00 - 4.6

12 Are hazardous wastes and non-hazardous wastes stored apart from each other in their YES

designated areas? ENV 180.00 - 4.6, 4.7

13 Are visual inspections of Hazardous Waste Accumulation Areas conducted by OIM/MIC or YES

designee on at least a weekly basis? Please provide dates of inspection in Corrective

Action. ENV 180.00 - 4.11

14 Is the hazardous waste accumulation area maintained to ensure no free standing liquids YES

are present? ENV 180.00 - 4.6

G Hazardous / Special Waste Log Yes, No or N/A

1 Are all wastes stored in the Hazardous Waste Accumulation Area recorded in the

YES

Hazardous Waste Generation, Disposal and Accumulation Log? ENV 180.00 - 4.3, Table 1

2 Is the total weight of accumulated hazardous wastes recorded in the Hazardous Waste

YES

Generation, Disposal and Accumulation Log? ENV 180.00 - 4.3, Table 1

3 Was a Hazardous Waste Generation, Disposal and Accumulation Log submitted on a

YES

monthly basis? ENV 110.00 - 4.3, Table 1

Form No. ENV-005, 1 September 2009, Reference ENV 110.00 Page 2 of 5

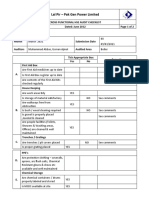

Environmental Audit – Worldwide Operations

Facility: ABAN II Inspection Date: 04/02/14

Location: KG BASIN Operating Condition: WELL TESTING

H Material Safety Data Sheets (MSDS), Control of Substances Hazardous to Health

Yes, No or N/A

(COSHH)

1 Does the facility maintain a MSDS/COSHH file for all industrial products arriving onboard?

YES

ENV 140.00 - 5.3

2 Is there a MSDS/COSHH on file onboard? ENV 140.00 - 5.3 YES

3 Are all employees made aware of the location of the MSDS/COSHH file within 24 hours

YES

after arriving at the facility? ENV 140.00 - 5.3

4 Do employees review the MSDS/COSHH before using a hazardous / special material? ENV

YES

140.00 5.3

5 Is each arriving MSDS/COSHH compared with existing copies for any changes since the

YES

product was last received? ENV 140.00 - 5.3

I Hazardous Waste Shipment and Disposal Yes, No or N/A

1 Are Hazardous Waste Manifests completed for all hazardous wastes leaving the generator's

YES

facility? ENV 180.00 - 4.17

2 Do all hazardous waste shipment containers have appropriate labels affixed? ENV 180.00 - NOT FOR ALL

4.18

3 Are Aban approved Transporters used for all hazardous waste shipments? ENV 180.00 - NO

4.18

4 Is a return copy of each Hazardous Waste Manifest with certificate of destruction/disposal NO

received from the TSDF within 25 days of shipment? ENV 180.00 - 4.18

5 Is the TSDF notified if the return copy of the manifest is not received within 25 days of NO

shipment? ENV 180.00 - 4.18

J Treated Effluent Yes, No or N/A

1 Is the marine sanitation device operating properly? ENV 230.00 - 4.2 YES

2 Is the treated sanitary effluent monitored monthly for residual chlorine and daily for

NO

floating solids? ENV 230.00 - 4.2

3 Are sanitary effluent residual chlorine and floating solids information documented on the

NO

Effluent Monitoring and Daily Visual Observation form? ENV 230.00 - 4.2

4 Are any residual chlorine concentrations greater than 1.5 parts per million (ppm) or less

NO

than 0.5 ppm reported to relevant Regional HSET Manager? ENV 230.00 - 4.2

5 Is oil/water separator operating and fully functional? ENV 230.00 - 4.5 NO

6 Is the treated effluent from the oil/water separator not exceeding 15 parts per million oil

NO

concentration? ENV 230.00 - 4.5

7 Are the preventative maintenance for marine sanitation device and oil/water separator

recorded monthly in the Effluent Monitoring and Daily Visual Observation form? NO

ENV230.00 - 4.4, 4.5

K Refrigerant Recovery Yes, No or N/A

1 Is there an operable recovery machine onboard? ENV 320.00 - 4.2 NA

2 Is all refrigerating equipment in good repair in accordance with 2.9 Engineering Standard

YES

723.1500? ENV 320.00 4.2

3 Are all containers properly labeled? ENV 320.00 - 4.9 YES

Form No. ENV-005, 1 September 2009, Reference ENV 110.00 Page 3 of 5

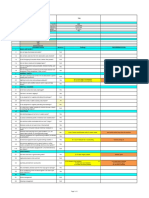

Environmental Audit – Worldwide Operations

Facility: ABAN II Inspection Date: 04/02/14

Location: KG BASIN Operating Condition: WELL TESTING

4 If any releases occurred, were they recorded? ENV 320.00 - 5.1

NO

5 Is refrigerant paperwork in order? ENV 320.00 - 5.1

YES

L Incineration Yes, No or N/A

1 Have all necessary permits been obtained prior to incineration? ENV 200.00 - 4.1 NA

2 Are only acceptable burnable wastes incinerated? ENV 200.00 - 4.2 NA

3 Are all wastes burned or incinerated logged into the Burnable Solid Waste Incineration NA

Log? ENV 200.00 - 4.4

M Refurbishment Operations Yes, No or N/A

1 Has the Project Manager had an environmental assessment conducted on the facilities NO

/companies involved in the operation? ENV 330.00 - 3.1, 4.1

2 Is a copy of an Environmental Management Plan onboard the drilling unit for the YES

operation/project? ENV 330.00 - 3.2

N Asbestos Containing Material Yes, No or N/A

1 Are the following documents onboard the rig: Asbestos Bulk Survey, Asbestos Operation N/A

&Maintenance Manual, and Asbestos Air Monitoring report? ENV 300.00 - 4.1

2 Is there at least one person onboard at all times who has completed the 16 hour asbestos N/A

Operation & Maintenance Training? Please provide name(s) of personnel/job title in

Corrective Action. ENV 300.00 - 3.2

3 Are records for percent complete of Asbestos Awareness 2 hour training for all personnel YES

onboard (Aban personnel, 3rd parties, visitors etc.). Please provide percent complete in

Corrective Action. ENV 300.00 - 3.3, 3.4, 4.2, 4.5

4 Is the required Asbestos 2 hour awareness training information onboard and used for YES

awareness training? Training material includes the PowerPoint presentation, and 2 videos:

"Asbestos Awareness - Controlling Exposure" (Part Number AV-ST-32, MCID 3507 02116)

and "Asbestos Awareness - Are You at Risk" (Part Number AV-ST-33, MCID 3507 02117).

ENV 300.00 - 4.2

5 Has any work taken place which disturbed ACM? ENV 300.00 - 4.3, 4.4 YES

6 Has air sampling been conducted by an independent third party within the last 12 months? NO

Provide date of last survey in Corrective Action. ENV 300.00 - 4.6

7 Is an Asbestos Operation and Maintenance Kit complete with all items listed in Safety NO

Catalog onboard and inspected? ENV 300.00 - 4.7

O Emergency Response Yes, No or N/A

1 Has an environmental spill response drill been conducted once every 3 months? Please

YES (27-01-14)

provide date of last environmental spill drill.

2 Were all spill kits inspected weekly to ensure that they contain all required items and the

YES

items are in good condition?

Form No. ENV-005, 1 September 2009, Reference ENV 110.00 Page 4 of 5

Environmental Audit – Worldwide Operations

Facility: ABAN II Inspection Date: 04/02/14

Location: KG BASIN Operating Condition: WELL TESTING

P Respiratory Yes, No or N/A

1 Have all personnel onboard received Respiratory Protection Training either before arriving

YES

or shortly after? TRA 200.40 - 5.1

2 Is Respiratory Refresher Training conducted annually? TRA 200.40 - 5.1 YES

3 Have personnel using a respirator fit tested prior to using a respirator? HLT 100.00 - 4.1 WAITING FOR

TEST KIT

4 Have personnel using a respirator been fit tested on an annual basis after initial fit test?

WAITING FOR

HLT100.00 - 4.1

TEST KIT

Q Noise Yes, No or N/A

1 Is single hearing protection available in all areas with 80-99 decibels (dBA)? HLT 400.00 -

YES

4.1

2 Is double hearing protection available in all areas with greater than 99 decibels (dBA)?

YES

HLT400.00 - 4.1

Signature:

Submitted By: Mr. Anil Kumar Sharma-Rig Manager

Form No. ENV-005, 1 September 2009, Reference ENV 110.00 Page 5 of 5

Potrebbero piacerti anche

- Lab 042Documento12 pagineLab 042Néstor VargasNessuna valutazione finora

- ISO 45001 H&S Gap AnalysisDocumento90 pagineISO 45001 H&S Gap Analysistracey.gartonNessuna valutazione finora

- NZDL - EMS - 033 - EMS Internal Audit - 22-02-2023Documento7 pagineNZDL - EMS - 033 - EMS Internal Audit - 22-02-2023Abdurrahim KhalifaNessuna valutazione finora

- 4638 20210429 10 23 18 Sci-Ims-P-10.2 Form 2 Page 1 Rev. 02 Ehs Non-Conformity or Safety Observation Checklist FormDocumento10 pagine4638 20210429 10 23 18 Sci-Ims-P-10.2 Form 2 Page 1 Rev. 02 Ehs Non-Conformity or Safety Observation Checklist Formvelumurgan mNessuna valutazione finora

- Mine Safey Audit Checklist - SafetyCulture PDFDocumento26 pagineMine Safey Audit Checklist - SafetyCulture PDFhalvawinNessuna valutazione finora

- 1 June 2011 Environmental Check ListDocumento3 pagine1 June 2011 Environmental Check ListJoão de Deus MemoNessuna valutazione finora

- Method Statement & Risk AssDocumento8 pagineMethod Statement & Risk AssUsman QayyumNessuna valutazione finora

- Bi-Weekly MEWP Inspection Checklist-25.12.2023Documento1 paginaBi-Weekly MEWP Inspection Checklist-25.12.2023kamalprem70Nessuna valutazione finora

- Works ForemanDocumento3 pagineWorks ForemanMacNessuna valutazione finora

- Bangladesh Bank Defined Sector Specific Environmental & Social Due Diligence (ESDD) ChecklistDocumento23 pagineBangladesh Bank Defined Sector Specific Environmental & Social Due Diligence (ESDD) ChecklistMohammad Shafiqul Islam RoneeNessuna valutazione finora

- Environmental Inspection Model - Updated JanDocumento2 pagineEnvironmental Inspection Model - Updated JanShafie ZubierNessuna valutazione finora

- Environmental Inspection ChecklistDocumento3 pagineEnvironmental Inspection ChecklistFarhat Sethar100% (1)

- WASPL - Yearly Inspection Report - enDocumento2 pagineWASPL - Yearly Inspection Report - enMayara WolffNessuna valutazione finora

- 08 Pre-Startup Safety Review ChecklistDocumento21 pagine08 Pre-Startup Safety Review ChecklistLenaldy Nuari Garnoko67% (3)

- ISO 14001 Environmental Gap AnalysisDocumento44 pagineISO 14001 Environmental Gap Analysistracey.gartonNessuna valutazione finora

- July 2011 - Environmental Check ListDocumento3 pagineJuly 2011 - Environmental Check ListJoão de Deus MemoNessuna valutazione finora

- Ebrd Aesr Template (2010) SWDocumento9 pagineEbrd Aesr Template (2010) SWAleine Leilanie OroNessuna valutazione finora

- Information:: YellowDocumento6 pagineInformation:: YellowAllocation ResourceNessuna valutazione finora

- QREC 021 Supplier Q&ADocumento8 pagineQREC 021 Supplier Q&AdragasboyNessuna valutazione finora

- Ceylon Petroleum Corporation: Retail Outlet Inspection ReportDocumento7 pagineCeylon Petroleum Corporation: Retail Outlet Inspection Reportvidura99Nessuna valutazione finora

- Blank - Environmental Check ListDocumento3 pagineBlank - Environmental Check ListJoão de Deus MemoNessuna valutazione finora

- FM-SUS-0800-04 Site Environmental CheckDocumento3 pagineFM-SUS-0800-04 Site Environmental CheckdavidburkepsNessuna valutazione finora

- Ceylon Petroleum Corporation: Retail Outlet Inspection ReportDocumento6 pagineCeylon Petroleum Corporation: Retail Outlet Inspection Reportvidura99Nessuna valutazione finora

- Visible Safety and Induction: Hse Management Visit ChecklistDocumento6 pagineVisible Safety and Induction: Hse Management Visit ChecklistHARSHALNessuna valutazione finora

- Part C Gas TankerDocumento7 paginePart C Gas TankertuyenbsrNessuna valutazione finora

- MGAP Excel Checklist Version 1.3Documento37 pagineMGAP Excel Checklist Version 1.3Abdul HalimNessuna valutazione finora

- SK-078 OSP For ProcessingDocumento9 pagineSK-078 OSP For ProcessingNirmal SharmaNessuna valutazione finora

- Self CHK Ship e Audit Ism ChecklistDocumento10 pagineSelf CHK Ship e Audit Ism ChecklistIrdam Jono100% (2)

- Archirodon Group NV Integrated Management System Health, Safety & Environment (HSE)Documento5 pagineArchirodon Group NV Integrated Management System Health, Safety & Environment (HSE)Hamza ChouaiebNessuna valutazione finora

- NOP 007R207132010 Process HandlingChecklistDocumento16 pagineNOP 007R207132010 Process HandlingChecklistJoan FloresNessuna valutazione finora

- Chemical Management Functional Checklist Rev1Documento2 pagineChemical Management Functional Checklist Rev1Rashyd RidhaNessuna valutazione finora

- Waste QuestionnaireDocumento6 pagineWaste QuestionnaireAleine Leilanie OroNessuna valutazione finora

- Safety Representative Inspection ChecklistDocumento5 pagineSafety Representative Inspection ChecklistCandiceNessuna valutazione finora

- Safety STD Audit Check ListDocumento12 pagineSafety STD Audit Check Listfaraz ahmed0% (1)

- Boiler CFA March 2021Documento2 pagineBoiler CFA March 2021Muhammad AbbasNessuna valutazione finora

- Weekly Environmental Report: Riyadh City South Phase 5Documento4 pagineWeekly Environmental Report: Riyadh City South Phase 5Venkadesh Periathambi100% (1)

- Waste Shipment Record Keeping and Reporting Flowchart: StartDocumento1 paginaWaste Shipment Record Keeping and Reporting Flowchart: StartJailson SilvaNessuna valutazione finora

- CEFD6024Documento18 pagineCEFD6024Neha ChhabraNessuna valutazione finora

- HSE Objectives 2015Documento2 pagineHSE Objectives 2015Anonymous iI88Lt100% (2)

- Check SheetDocumento2 pagineCheck Sheetprashanth100% (2)

- MP18.1 New Equipment Audit v4Documento4 pagineMP18.1 New Equipment Audit v4Nata SoboNessuna valutazione finora

- Site Environmental ChecklistDocumento6 pagineSite Environmental ChecklistSherif MahmoudNessuna valutazione finora

- Pressure Vessel Compliance ChecklistDocumento3 paginePressure Vessel Compliance Checklistpineda44444100% (2)

- ChecklistsDocumento20 pagineChecklistsJune AlapaNessuna valutazione finora

- Ef Ei04 01Documento7 pagineEf Ei04 01TAHER AMMARNessuna valutazione finora

- Hse Audit Checklist Safety CompressDocumento7 pagineHse Audit Checklist Safety CompressnaeemNessuna valutazione finora

- Packaging Supplier QuestionnaireDocumento5 paginePackaging Supplier QuestionnaireRidho SaputraNessuna valutazione finora

- Sop-R-07 Safety Officers Monthly Inspection Report (VLCC, Product)Documento10 pagineSop-R-07 Safety Officers Monthly Inspection Report (VLCC, Product)김순혁Nessuna valutazione finora

- Checklist For 5-Star Safety Documentation-SOADocumento15 pagineChecklist For 5-Star Safety Documentation-SOAYASIRNessuna valutazione finora

- HSE Visit Walkabout ChecklistDocumento4 pagineHSE Visit Walkabout ChecklistEric T100% (1)

- EI InspectionDocumento1 paginaEI InspectionMohammed HamzaNessuna valutazione finora

- ChecklistDocumento10 pagineChecklistbharat ghantaNessuna valutazione finora

- Form # 2 Gap AnalysisDocumento7 pagineForm # 2 Gap AnalysisRyan ReasNessuna valutazione finora

- OHS WorkplaceAssessment InspectionChecklistDocumento9 pagineOHS WorkplaceAssessment InspectionChecklistAldrin ZlmdNessuna valutazione finora

- Part C Container ShipDocumento7 paginePart C Container ShipElijahNessuna valutazione finora

- Daimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta RisnerDocumento23 pagineDaimler-Chrysler Layered Process Audits (DCX Lpa) : Alberta Risneralberto100% (1)

- Ism ChecklistDocumento13 pagineIsm ChecklistMuthu KumarNessuna valutazione finora

- 7777Documento8 pagine7777BalakrishnanNessuna valutazione finora

- 47 National Safety Day / Week-Quiz ABAN-2: Name: DesignationDocumento1 pagina47 National Safety Day / Week-Quiz ABAN-2: Name: DesignationgkmlalNessuna valutazione finora

- 3m 6000 Series Half Mask Data SheetDocumento4 pagine3m 6000 Series Half Mask Data SheetgkmlalNessuna valutazione finora

- Learn From AccidentDocumento43 pagineLearn From AccidentgkmlalNessuna valutazione finora

- Safety Data Sheet Potassium Chloride: 1. Identification of The Substance/Preparation and Company/UndertakingDocumento4 pagineSafety Data Sheet Potassium Chloride: 1. Identification of The Substance/Preparation and Company/UndertakinggkmlalNessuna valutazione finora

- Confined Space Entrant Attendant Form PDFDocumento2 pagineConfined Space Entrant Attendant Form PDFgkmlalNessuna valutazione finora

- Heat Stress Essentials: Prevention in ActionDocumento38 pagineHeat Stress Essentials: Prevention in ActiongkmlalNessuna valutazione finora

- Floorman ResumeDocumento4 pagineFloorman ResumegkmlalNessuna valutazione finora

- JSA Welding Confined SpaceDocumento2 pagineJSA Welding Confined Spacegkmlal100% (4)

- Confined Space Entrant Attendant Form PDFDocumento2 pagineConfined Space Entrant Attendant Form PDFgkmlalNessuna valutazione finora

- Silica FumeDocumento6 pagineSilica FumegkmlalNessuna valutazione finora

- M&O Training Services Catalogue-Email 1.5Documento185 pagineM&O Training Services Catalogue-Email 1.5gkmlalNessuna valutazione finora

- AcetyleneDocumento9 pagineAcetylenegkmlalNessuna valutazione finora

- Section 2Documento25 pagineSection 2LTE002Nessuna valutazione finora

- Eia STSDocumento8 pagineEia STSKATE WEINSLETH NIELESNessuna valutazione finora

- Morfologi SungaiDocumento2 pagineMorfologi Sungaifeirani vironitaNessuna valutazione finora

- MuckrakerDocumento8 pagineMuckrakeresanderson101Nessuna valutazione finora

- Water Treatment Methods Water Treatment Methods: G L GeneralDocumento28 pagineWater Treatment Methods Water Treatment Methods: G L Generalalmeid13Nessuna valutazione finora

- Essay On GrasslandsDocumento2 pagineEssay On GrasslandsjNessuna valutazione finora

- HANNA General Catalog v28 Chapter12 TurbidityDocumento20 pagineHANNA General Catalog v28 Chapter12 TurbidityOrtomet_SANessuna valutazione finora

- Water Resources Day 10 2024Documento2 pagineWater Resources Day 10 2024fivestar12042015Nessuna valutazione finora

- Nanofiltration and Reverse Osmosis (NF/RO) : America's Authority in Membrane TreatmentDocumento2 pagineNanofiltration and Reverse Osmosis (NF/RO) : America's Authority in Membrane Treatmentbasu_soumen2011Nessuna valutazione finora

- Diamond Cooling and Closed Loop Filtration BrochureDocumento10 pagineDiamond Cooling and Closed Loop Filtration BrochureYosif ودقلباNessuna valutazione finora

- Underground Storage TanksDocumento8 pagineUnderground Storage TanksCypress Rovee FloresNessuna valutazione finora

- Pulsator TechnologyDocumento2 paginePulsator TechnologyDaniel Sanabria BarretoNessuna valutazione finora

- Treatment of Dairy Waste Water Using Low Cost AdsorbentsDocumento2 pagineTreatment of Dairy Waste Water Using Low Cost AdsorbentsijsretNessuna valutazione finora

- Chemical DegradationDocumento479 pagineChemical DegradationYanjia Liu100% (1)

- Chapter 3 Technical FeasibilityDocumento88 pagineChapter 3 Technical FeasibilityAnissa Munira100% (2)

- 268 658 1 PBDocumento14 pagine268 658 1 PBRaghav DhootNessuna valutazione finora

- O N MDocumento7 pagineO N Msrinivas69Nessuna valutazione finora

- Drinking Water Report 2021Documento6 pagineDrinking Water Report 2021api-277511356Nessuna valutazione finora

- Lagoon MathDocumento13 pagineLagoon MathmaqboolsaNessuna valutazione finora

- Doing More With Less: November 2017Documento52 pagineDoing More With Less: November 2017Municipal Sewer & Water MagazineNessuna valutazione finora

- Pureit Advanced Ro MF Manual PDFDocumento18 paginePureit Advanced Ro MF Manual PDFSaurabh MishraNessuna valutazione finora

- How To Manage Concrete Waste Water On Construction SitesDocumento6 pagineHow To Manage Concrete Waste Water On Construction SitesensafepsNessuna valutazione finora

- Chemical Product Line Up For AutomotiveDocumento4 pagineChemical Product Line Up For AutomotiveLuan NguyenNessuna valutazione finora

- Phed ReportDocumento286 paginePhed ReportALOK PRATAPNessuna valutazione finora

- Moringa Oleifera Seed As Antibacterial Agent in Water TreatmentDocumento6 pagineMoringa Oleifera Seed As Antibacterial Agent in Water TreatmentStephen MooreNessuna valutazione finora

- Bio-Degradation of The Pollutant Components. It Is An Integral Part of Most Biological WastewaterDocumento2 pagineBio-Degradation of The Pollutant Components. It Is An Integral Part of Most Biological Wastewaterglo lipaodNessuna valutazione finora

- Water Pollutant #1: PcbsDocumento4 pagineWater Pollutant #1: PcbsBindu M PillaiNessuna valutazione finora

- Municipal Solid Waste ManagementDocumento50 pagineMunicipal Solid Waste Managementeli_b15Nessuna valutazione finora

- EVS 18CIV59 (Assignment Questions)Documento8 pagineEVS 18CIV59 (Assignment Questions)1AP18CS037 Shirish KulkarniNessuna valutazione finora

- Cooling Tower Institute Win 10 JournalDocumento92 pagineCooling Tower Institute Win 10 JournalprakashNessuna valutazione finora