Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

SAIC-J-6501 Rev 8

Caricato da

Rashid ArshadCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

SAIC-J-6501 Rev 8

Caricato da

Rashid ArshadCopyright:

Formati disponibili

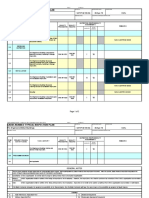

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Documentation Review

SAEP-16

The loop document/Package shall comprise of documents detailed Sec.4.1.12 &

A1

below: SAEP-1636

Appendix 1

SAEP-16

Sec.4.1.12 &

A2 Instrumentation Installation Record

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A3 Loop Check Punchlist Form

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A4 Loop Check Sheet

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A5 Instrumentation Calibration Records

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A6 Instrument Data Sheets

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A7 Control Valve Pneumatic Hook-up (for complex valves only)

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A8 Instrument Loop Diagrams

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A9 Instrumentation Points and Lines

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A10 Instrumentation Hook up Drawings

SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A11 Instrument Cables Test Reports

SAEP-1636

App.1 Sec.5&6

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

SAEP-16

Instrument Pressure Test Reports (Process Impulse / Air supply line / Sec.4.1.12 &

A12

Pneumatic signal tubing) SAEP-1636

App.1 Sec.5&6

SAEP-16

Sec.4.1.12 &

A13 Piping and Instrument Diagram

SAEP-1636

App.1 Sec.5&6

B Pre-Loop Check

SAEP-16

Ensure that actual field installation is completed in all aspects for the Sec.4.1.14 &

B1

concerned loops. SAEP-1636

App.1 Sec.5.5

SAEP-16

The installation record sheets to be verified and formed as part of loop Sec.4.1.14 &

B2

folder. SAEP-1636

App.1 Sec.6

SAEP-16

Sec.4.1.14 &

B3 Ensure that all individual loop components have been calibrated.

SAEP-1636

App.1 Sec.5.5&6

SAEP-16

Aramco Inspection/Proponent, Contractor QC signatures to be verified on Sec.4.1.14 &

B4

installation inspection as well as test/calibration sheets. SAEP-1636

App.1 Sec.6.4

SAEP-16

The completed instrument loop shall be tested as one system and where Sec.4.1.14 &

B5

necessary adjustments shall be made to the calibrations. SAEP-1636

App.1 Sec.5

SAEP-16

The loop testing shall be performed from the field instrument to the DCS

Sec.4.1.14 &

B6 maintenance consoles and associated systems located either at the CCR

SAEP-1636

or PIB control rooms.

App.1 Sec.5

SAEP-16

DCS loop checks may include verification of all PCS functions such as

Sec.4.1.14 &

B7 database parameters, alarm initiations, trending, report generation,

SAEP-1636

graphics etc.

App.1 Sec.5

After successful completion of each loop, check the individual loop SAEP-16

components and marked with a colored label bearing the date of loop Sec.4.1.14 &

B8

check and initials of witnessing party. SAEP-1636

The color code shall be: RED - Loop Check Complete. App.1 Sec.5

C Testing Method

Ensure that all loop diagrams, cause and effects, charts and logic SAEP-1636

C1

diagrams are available prior to testing. App.1 Sec.5&6

During loop check, the following items shall be confirmed or checked: C3 SAEP-1636

C2

to C16. App.1 Sec.5&6

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

In the control room:

1. Indication and output signal level on the PCS CRT console

2. Function of flow counter

SAEP-1636

C3 3. Action of Controller of PCS

App.1 Sec.5&6

4. Function of alarm display

5. Function of all other components such as computing devices, limiting

devices, low/high signal, selectors, etc.

In The Field:

1. Action control valves with positioners, stroke may be checked with

stroke indicator and output signal from positioner shall be checked.

SAEP-1636

C4 2. Control valve stroke time shall be less than maximum time or larger

App.1 Sec.5&6

than the minimum time specified in the specification sheet.

3. Range of transmitters and local controllers.

4. Indication of remote mounted output indicators.

Transmitters Loops (Flow/Level/pressure):

a) Check and verify the DCS Configuration for applicable points.

b) Verify the transmitter set (Calibration) range as per latest ISS, by using

Foxcom (HHT) communicator for Foxboro Transmitters and HART for

Rosemount Transmitters or in DCS as applicable

c) Apply pressure for digital smart transmitters by using test equipment

(Hand Pump) for 50% simulation to check transmitter response at DCS.

This method shall be used for digital smart transmitters only.

d) Confirm/verify the corresponding reading in the DCS / Integral

indicator and at remote indicator, if applicable. SAEP-1636

C5

e) For analog Foxboro smart transmitters, Foxcom (HHT) communicator App.1 Sec.5&6

shall be used for simulation instead of hand pump.

f) For Rosemount smart transmitters, HART communicator shall be used

for simulation instead of hand pump.

g) For Non-smart transmitters, 4~20 mA source to be used for simulation

instead of hand pump.

h) Alarms function (in DCS) shall be checked by simulating/verifying the

required signal.

i) Transmitter loop test should be performed after completion of the

impulse line works including pressure test.

Control Valves Loops:

a) Check and verify the DCS Configuration for applicable points.

b) If any ESD logic or inter-locking are involved in applicable loop to

energize a solenoid valve, in normal condition, force the applicable ESD

points on ladder logic. The same procedure to be carried out for DCS

logic.

c) If instrument air supply is not available, use a nitrogen.

d) Apply a command from DCS for 0%, 50% and 100%. SAEP-1636

C6

e) Verify the corresponding valve position. App.1 Sec.5&6

f) Verify the controller action.

g) Verify the control valve action on increasing signal.

h) Verify the control valve action on air supply failure.

i) Verify the control valve Max/Min travel stopper setting, if applicable.

j) Check hand wheel manual operation/function, if applicable.

k) Control valve loop test should be performed after completion of the air

piping works.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

ON/OFF Valves Loops:

a) Check and verify the DCS Configuration for applicable points.

b) If any ESD logic or Inter locking are involved in applicable loop to

energize a solenoid valve, in normal condition, force the applicable ESD

points on ladder logic. The same procedure to be carried out for DCS

logic.

c) If instrument air supply is not available, use a nitrogen. Larger sizes of

valves require a larger volume of nitrogen.

d) Apply a command from DCS and Field for opening and closing the

SAEP-1636

C7 valve.

App.1 Sec.5&6

e) Verify the corresponding valve position in DCS and Field, as

applicable.

f) Verify the partial stroke function test of “ZV”.

g) Verify the valve action on air supply failure.

h) Verify the valve action on control signal failure.

i) Check hand wheel and hand jack manual operation/function, as

applicable.

j) On/Off valve loop test should be performed after completion of the air

piping works.

MOV’s Loops:

a) Check and verify the DCS configuration for applicable points.

b) If any ESD logic or Inter locking are involved in applicable loop, in

normal condition, force the applicable ESD points on ladder logic. The

SAEP-1636

C8 same procedure to be carried out for DCS logic.

App.1 Sec.5&6

c) Check and verify local/remote switch function.

d) Stroke the MOV from DCS and Field - Open, Close and Stop.

e) Verify the status of the MOV at DCS and Field.

f) Check hand wheel manual operation/function if applicable.

Switches Loops:

a) Check and verify the DCS configuration for applicable points.

b) Simulate the contact operation (Make/Break) at the switch terminal

SAEP-1636

C9 block and verify the status in the DCS/ESD. For ESD switch,actual

App.1 Sec.5&6

pressure simulation to be provided.

c) For ESD hand switches, Start/Stop and Open/Close switches shall be

checked by operating the switch mechanism.

Gas Detectors/Beacons/Horns:

a) Check and verify the DCS configuration for applicable points.

b) Proceed the calibration of gas detector by introducing the applicable

gas for H2S and LEL.

c) Apply the magnet for 0% and verify the status at gas detector display

and in DCS. SAEP-1636

C10

d) Apply 50% and 100% for the H2S gas detector and verify the status at App.1 Sec.5&6

gas detector display and in DCS.

e) Apply 50% gas for LEL gas detector and verify the status at gas

detector display and in DCS.

f) Check Beacon status at High Alarm condition.

g) Check Horn status at High-High Alarm condition.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

RTD Temperature Transmitter Loops:

a) Check and verify the DCS configuration for applicable points.

b) Verify temperature transmitter set (calibration) range per ISS.

c) Simulate resistance equivalent to 50% of the transmitter range, by

using decade resistance box or any other resistance simulator at the

RTD terminal head.

SAEP-1636

C11 d) Verify the corresponding reading in the DCS, Integral indicator of the

App.1 Sec.5&6

transmitter and at remote indicator, if applicable.

e) Alarms functions in DCS to be checked by simulating and varying the

required signal.

f) Normalize all connections prior to closing the terminal head and

confirm ambient temperature at integral indicator of the temperature

transmitter and in DCS.

Thermocouple Temperature Transmitter Loops:

a) Check and verify the DCS configuration for applicable points.

b) Verify temperature transmitter set (calibration) range per ISS.

c) Simulate “MV” equivalent to 50% of the transmitter range by using MV

source (simulator) at the thermocouple terminal head.

d) Verify the corresponding reading in the DCS, Integral indicator of the

SAEP-1636

C12 transmitter and at remote indicator, if applicable.

App.1 Sec.5&6

e) Check the burn out features by disconnecting the wires, if applicable.

f) Alarms functions in DCS shall be checked by simulating and varying

the required signal.

g) Normalize all connection prior to closing the terminal head and confirm

ambient temperature at integral indicator of the transmitter, in DCS and

at remote indicator, if applicable.

Vibration Loops (with proximitors):

a) Check and verify VMS/DCS configuration for applicable points.

b) Connect a spare probe to extension cable of applicable proximitors.

c) Insert the probe into the TK-3 Wobulator (Bentley Nevada) and

connect the Multimeter leads at Proximitors terminals to check the gap

voltages.

SAEP-1636

C13 d) Adjust the probe at approximately (-10 VDC) gap voltage.

App.1 Sec.5&6

e) Simulate a signal using a Wobulator at 0%, 50% and 100% of the

range and verify the corresponding reading at VMS/DCS.

f) Verify the response of the High and High-High Alarm at VMS/DCS.

g) Normalized the connection of extension cables.

h) Actual probe gap voltage shall be adjusted at the final stage, prior to

commissioning/start up.

Velocity Seismo Probe Loops:

a) Check and verify VMS/DCS configuration for applicable points.

b) Create a vibration using a wooden hammer. Carefully and slowly hit

the probe housing by a wooden hammer. If the required values cannot be

SAEP-1636

C14 achieved, disconnect/remove the probe and shake well by hand. Create

Sec.5&6

a vibration to achieved a High and High-High Alarm points.

c) Verify the response reading at VMS/DCS.

d) Verify the response of the High and High-High Alarm at VMS/DCS.

e) Normalize all the connections.

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

FFVMS Loops (Trend Master 2000):

a) Check and verify the FFVMS/DCS configuration for applicable points.

b) Create a vibration using a steel hammer. Carefully hit near the probe SAEP-1636

C15

by a steel hammer. Sec.5&6

c) Verify the response reading at FFVMS/DCS.

d) Verify the response of the High and High-High Alarm at FFVMS/DCS.

MCC Loops:

a) MCC loops shall be executed after motor solo run test.

b) Check and verify the DCS configuration for applicable points.

c) If any ESD logic or Inter locking are involved in applicable loop, in

normal condition, force the applicable ESD points on ladder logic. The

same procedure to be carried out for DCS logic.

d) Remove the control transformer primary and secondary fuses for the

applicable cubicle.

e) Apply 120 VAC power (external power from building outlet) on the

secondary fuses load side to energize the control circuit.

f) Apply a Command from DCS/ESD/Field for Start, Stop or Trip, as SAEP-1636

C16

applicable. Sec.5&6

g) Verify the Running/Stop or Trip Status in DCS/Field/Sub Station, as

applicable.

h) Check and verify the Local/Remote Switch function, if applicable.

i) After completion of the applicable loop check, fuses should be returned

on the control transformer.

j) All the above mentioned steps can be carried out without removing the

pad lock on the MCC unit breakers.

k) Removal of the lock on the breakers requires permission from

Electrical section.

REMARKS:

REFERENCE DOCUMENTS:

4. SAEP-16 - Project Execution Guide for Process Automation Systems, 24 October 2009

5. SAEP-1636 - Installation and Checkout Plan, 16 September 2009

ATTACHMENTS:

1. Attachment 1: Instrument Loop Check Sheet and Pre-Loop Check Sheet

NOTES:

1. Approved - Acceptable to the authority having jurisdiction (i.e., Saudi Aramco ID).

2. Identified - Recognizable as suitable for the specific application by a qualified testing laboratory (i.e., listing and/or labeling).

3. Listed - Equipment and materials included in a list published by an approved qualified organization concerned with evaluation of products or

services, that maintains periodic inspection of production of listed equipment or materials or periodic evaluation of services, and whose listing states

that the equipment, material or services either meets appropriate designated standards or has been tested and found suitable for a specified purpose.

4. Labeled - Equipment or materials to which has been attached a label, symbol or other identifying mark of an approved qualified organization

concerned with product evaluation, that maintains periodic inspection of production of labeled equipment or materials, and by whose labeling the

manufacturer indicates compliance with appropriate standards or performance in a specified manner.

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Work is Complete and Ready for Inspection: T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved: T&I Witnessed QC Record Reviewed Work Verified

Name, Organization,

Name, Sign and Date:

Initials and Date:

*Person Responsible for Completion of Quality Work / Test Y = YES N = NO F = FAILED

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

Attachment 1: Instrument Loop Check Sheet

Unit No.: System No.: Loop No. Loop Dwg. No.:

DCS INSPECTION PERFORMED

POINTING TAG YES NO N/A

POINT DESCRIPTION YES NO N/A

POINT CONFIGURATION YES NO N/A

POINT RANGE ( ) YES NO N/A

INPUT/OUTPUT FUNCTION YES NO N/A

CONTROLLER ACTION ( ) YES NO N/A

SCHEM. & ASSOC. GRAPHICS (NO.) YES NO N/A

ALARM (LL) YES NO N/A

ALARM (L) YES NO N/A

ALARM (HH) YES NO N/A

ALARM (H) YES NO N/A

DCS/FIELD INSPECTION PERFORMED

MOTOR CONTROLS/SWITCHES/MOV'S/AOV'S GAS DETECTOR

COMMANDS INDICATION GAS DETECTOR NO.:

YES NO N/A YES NO N/A

RESET ON INPUT

OUTPUT

BY PASS OFF (PPM/LEL)

ON/START RUNNING

OFF/STOP STOPPED

OPEN OPEN

CLOSE CLOSE

STOP CMDIS

SIMULATION RESULTS

TAG NO. : VALVE TAG NO.: SWITCH TAG NO. :

PROCESS INPUT RANGE : SWITCH SET POINT :

PROCESS OUTPUT VALVE SWITCH FUNCTION RESULT

INPUT % INPUT %

INPUT TO DCS TRAVEL SWITCH ACTIVATES AT

0 0 SWITCH ACTION AT SET POINT

25 25 SWITCH RESET AT

50 50

75 75

100 100

75 75

50 50

25 25

0 0

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID FORM REV 1 - 010109 Rev 8 COS 06/30/2014

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Instrumentation and Control Loop checking -

SAIC-J-6501 31.Dez.14 INST

Documentation Review (Procedures and Packages)

Attachment 1: Instrument Loop Check Sheet

LOOP CONTINUITY CHECK SHEET (PRE-LOOP CHECK)

SYSTEM NO LOOP NO EQPT CODE SYSTEM ID. PLANT NO.

Manufacturer S.No LOOP DRAWING NO Data Sheet No

CONTINUITY CHECK SHEET

Calibration Inspection Remarks

FROM TO CHECKS PER SECTION

CABLE No. RE-INSP DATE

ITEM No. Area TAG/ITEM No. AREA Cont.Test Termination

Saudi Aramco: Company General Use

Potrebbero piacerti anche

- Saudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestDocumento4 pagineSaudi Aramco Test Report: 30.apr.13 Inst SATR-J-6501 Instrument Loop - Inputs - Transmitter Circuit TestRashid Arshad100% (1)

- Saudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalDocumento10 pagineSaudi Aramco Typical Inspection Plan: Pneumatic Pressure Testing SATIP-A-004-01 MechanicalTariqMalikNessuna valutazione finora

- Any Change Shall Be Submitted For Review.: Hindustan Urvarak and Rasayan Limited Barauni & SindriDocumento6 pagineAny Change Shall Be Submitted For Review.: Hindustan Urvarak and Rasayan Limited Barauni & Sindrigudapati9Nessuna valutazione finora

- PGHU-EH-LSPDS-000207 R1 Manual Sampling SystemsDocumento28 paginePGHU-EH-LSPDS-000207 R1 Manual Sampling SystemsRiyan EsapermanaNessuna valutazione finora

- Elster Instromet Q.sonicDocumento2 pagineElster Instromet Q.sonicsaid_rahmansyah4750Nessuna valutazione finora

- PP in Ii 001Documento15 paginePP in Ii 001Dav EipNessuna valutazione finora

- Installation StandardDocumento80 pagineInstallation StandardSukdeb Maity100% (1)

- Leak TestingDocumento5 pagineLeak Testingogie_0513Nessuna valutazione finora

- Amnit in 300 Wir 1003 Ded C Junction Box Schedule AppDocumento46 pagineAmnit in 300 Wir 1003 Ded C Junction Box Schedule Appzaraki kenpachiNessuna valutazione finora

- 3BCN8 15026 A01 G01 DCS Operation and Maintenance ManualDocumento58 pagine3BCN8 15026 A01 G01 DCS Operation and Maintenance Manualramses mantillaNessuna valutazione finora

- EG001 IC SPE 11 0029rB01v3 - 4Documento6 pagineEG001 IC SPE 11 0029rB01v3 - 4Cristinel NechiforNessuna valutazione finora

- Sow 1000483 TW 834 15 75 006Documento38 pagineSow 1000483 TW 834 15 75 006Sayed AhammadNessuna valutazione finora

- Sok0929245 PDFDocumento17 pagineSok0929245 PDFLeonardo Basante HerreraNessuna valutazione finora

- Fs 4041 TG Package, Rev-0Documento88 pagineFs 4041 TG Package, Rev-0Othman RejabNessuna valutazione finora

- AHS-KRS-30-BUB - DC-UPS2 - 00E652A3 - RedCorrex PDFDocumento24 pagineAHS-KRS-30-BUB - DC-UPS2 - 00E652A3 - RedCorrex PDFArchiford NdhlovuNessuna valutazione finora

- Hook Ups PDFDocumento8 pagineHook Ups PDFAnonymous d7Jde8Nessuna valutazione finora

- D62 - 740 - 3 - C4-Pressure Gauge General Arrangement Drawing PDFDocumento6 pagineD62 - 740 - 3 - C4-Pressure Gauge General Arrangement Drawing PDFSoumiyaNessuna valutazione finora

- National Oil Corporation: Rev Date Description Checked ApprovedDocumento37 pagineNational Oil Corporation: Rev Date Description Checked ApprovedRochdi SahliNessuna valutazione finora

- CIBI of GT # 5 Frame VI at IOCL VadodaraDocumento3 pagineCIBI of GT # 5 Frame VI at IOCL Vadodaramahesh_rathoreNessuna valutazione finora

- Cable Tray InstallationDocumento1 paginaCable Tray InstallationNaeemNessuna valutazione finora

- s10332300-3007 - 0 Process Flow MeteringDocumento11 pagines10332300-3007 - 0 Process Flow Meteringappril26Nessuna valutazione finora

- GTGT STGT Specification Vemagiri II R0Documento53 pagineGTGT STGT Specification Vemagiri II R0Jason Williams100% (1)

- PLC Tender - R2 - 17.11.22Documento34 paginePLC Tender - R2 - 17.11.22SUSOVAN BISWASNessuna valutazione finora

- GMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1Documento20 pagineGMS-SPT-013 Pneumatic On-Off Valve and Motor Operated Valve Specification - Rev 1prihartono_diasNessuna valutazione finora

- Alarm Tag ListDocumento15 pagineAlarm Tag Listআশিক পালোয়ানNessuna valutazione finora

- I-007 DP Transmitter Calibration CheckDocumento1 paginaI-007 DP Transmitter Calibration CheckAr RahmanNessuna valutazione finora

- Control Operation Philosophy of Ac PDFDocumento24 pagineControl Operation Philosophy of Ac PDFĐặng Trung AnhNessuna valutazione finora

- SP-2154 - 2015valves Technical SpecificationDocumento23 pagineSP-2154 - 2015valves Technical Specificationarjunprasannan7Nessuna valutazione finora

- Supplier'S Document Cover Page (For A4/A3 Documents Only)Documento2 pagineSupplier'S Document Cover Page (For A4/A3 Documents Only)Fomaa ElsayedNessuna valutazione finora

- Technical Doc 1 - Technical Scope of Work Drs Eac181Documento25 pagineTechnical Doc 1 - Technical Scope of Work Drs Eac181bhargavpansuria09Nessuna valutazione finora

- Transmittal Joseph Thomas: D F Power Systems Pvt. LTDDocumento58 pagineTransmittal Joseph Thomas: D F Power Systems Pvt. LTDVinod MahajanNessuna valutazione finora

- System Configuration and HMI ConfigurationDocumento6 pagineSystem Configuration and HMI ConfigurationKiên NguyễnNessuna valutazione finora

- Data Sheet Manual Alarm Call PointDocumento4 pagineData Sheet Manual Alarm Call Pointsugeng wahyudiNessuna valutazione finora

- 2-Test Pack Cover SheetDocumento1 pagina2-Test Pack Cover SheetPintu KumarNessuna valutazione finora

- Dfds CompressorDocumento54 pagineDfds CompressorRahul Dev GoswamiNessuna valutazione finora

- Logic DiagramDocumento1 paginaLogic DiagramkapsarcNessuna valutazione finora

- Attachment - #5 Valve Inspection ListDocumento4 pagineAttachment - #5 Valve Inspection ListzhangNessuna valutazione finora

- BD100IX0012 - B1 TR For Multiphase FlowMeterDocumento29 pagineBD100IX0012 - B1 TR For Multiphase FlowMetervamcodong100% (1)

- Annexure-A. Job Scope Remote CalibrationDocumento12 pagineAnnexure-A. Job Scope Remote CalibrationVision100% (1)

- Indra: Inspection and Test Plan For Lifting Device (Trolley Beams, A-Frame and Jib Crane /davit Type)Documento9 pagineIndra: Inspection and Test Plan For Lifting Device (Trolley Beams, A-Frame and Jib Crane /davit Type)med chabaneNessuna valutazione finora

- 3210-8550-FS-0008 Foundation Fieldbus Functional RequrementDocumento34 pagine3210-8550-FS-0008 Foundation Fieldbus Functional Requrementsuhailfarhaan100% (2)

- Attachment#6 Burner SystemDocumento3 pagineAttachment#6 Burner SystemzhangNessuna valutazione finora

- Control ValvesDocumento2 pagineControl ValvesJuan Pablo MarvalNessuna valutazione finora

- Instrument Stand Install Guide PDFDocumento4 pagineInstrument Stand Install Guide PDFChristianNessuna valutazione finora

- Leak Detection in Pipeline-JijoDocumento17 pagineLeak Detection in Pipeline-Jijoamulbaby31Nessuna valutazione finora

- Anubar SpecDocumento8 pagineAnubar SpecSHIVAJI CHOUDHURYNessuna valutazione finora

- SAIC & SATR - InstrumentationDocumento4 pagineSAIC & SATR - InstrumentationAdel KlkNessuna valutazione finora

- C22-Yb60-D-7770 - 1 Sa3-Ps2, Butterfly Valve, Pneumatic Wiring SchematicsDocumento4 pagineC22-Yb60-D-7770 - 1 Sa3-Ps2, Butterfly Valve, Pneumatic Wiring SchematicssartajNessuna valutazione finora

- s10332300-3008 - 0 Tank Gauging SystemsDocumento23 pagines10332300-3008 - 0 Tank Gauging Systemsappril26Nessuna valutazione finora

- 2.63 Transmittal Log (PO-PGB-MBRD-0001) (VIT1)Documento8 pagine2.63 Transmittal Log (PO-PGB-MBRD-0001) (VIT1)zhangNessuna valutazione finora

- Data Sheet Daniel Model 788 Digital Control Valve en 43714Documento16 pagineData Sheet Daniel Model 788 Digital Control Valve en 43714dreyko77Nessuna valutazione finora

- (FGDS) 250-70P-0002Documento104 pagine(FGDS) 250-70P-0002Kamal PunnNessuna valutazione finora

- Signal Flow Diagram: Electronics Division, Bangalore - 26Documento65 pagineSignal Flow Diagram: Electronics Division, Bangalore - 26Deepak GuptaNessuna valutazione finora

- S10332300-3010 - 0 Control ValvesDocumento29 pagineS10332300-3010 - 0 Control Valvesappril26Nessuna valutazione finora

- Vol Ii CDocumento161 pagineVol Ii Ckumarcv89Nessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento15 pagineSaudi Aramco Inspection Checklistnisha_khanNessuna valutazione finora

- SAIC-J - 6501 - Rev 0Documento7 pagineSAIC-J - 6501 - Rev 0Adel KlkNessuna valutazione finora

- Saudi Aramco Inspection ChecklistDocumento10 pagineSaudi Aramco Inspection ChecklistAli AhmedNessuna valutazione finora

- SATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocumento13 pagineSATIP-L-450-03 Mechanical Ne: Saudi Aramco Typical Inspection Plan Cross Country Above Ground Pipelikarthi51289Nessuna valutazione finora

- SAIC-A-2003 Rev 7 Review of Test Package PreparationDocumento7 pagineSAIC-A-2003 Rev 7 Review of Test Package PreparationPrince JoseNessuna valutazione finora

- Saes B 067 PDFDocumento12 pagineSaes B 067 PDFRashid ArshadNessuna valutazione finora

- STD 002Documento1 paginaSTD 002Rashid ArshadNessuna valutazione finora

- Instrument QC EngineerDocumento3 pagineInstrument QC EngineerRashid ArshadNessuna valutazione finora

- Extended Explaination of Q&ADocumento1 paginaExtended Explaination of Q&ARashid ArshadNessuna valutazione finora

- Saes B 058Documento15 pagineSaes B 058Rashid ArshadNessuna valutazione finora

- Instrument Loop DiagramDocumento121 pagineInstrument Loop Diagramroutine1976Nessuna valutazione finora

- C.T. Jones - Step 7 in 7 StepsDocumento468 pagineC.T. Jones - Step 7 in 7 StepsRashid ArshadNessuna valutazione finora

- M13 ADocumento30 pagineM13 ADebanil MajumderNessuna valutazione finora

- BMS OverviewDocumento1 paginaBMS OverviewEngr Dil KhurshidNessuna valutazione finora

- Eating Entilation and Ir Onditioning: Air Handling SystemsDocumento20 pagineEating Entilation and Ir Onditioning: Air Handling SystemsMudassar Idris RautNessuna valutazione finora

- Ats PDFDocumento1 paginaAts PDFddsf2012Nessuna valutazione finora

- ValveDocumento126 pagineValveRashid ArshadNessuna valutazione finora

- Chapter 6 Refractory Lining Procedure PTT Global Chemical Company Limited (GC)Documento17 pagineChapter 6 Refractory Lining Procedure PTT Global Chemical Company Limited (GC)มิตร อันมาNessuna valutazione finora

- Drilled Pier Inspection Module PDFDocumento49 pagineDrilled Pier Inspection Module PDFanalyticalNessuna valutazione finora

- SOP - Ready Mix Annual Facility AuditDocumento2 pagineSOP - Ready Mix Annual Facility AuditTri widiyah VitantiNessuna valutazione finora

- ISO 30401 Lead Auditor Course......Documento435 pagineISO 30401 Lead Auditor Course......Somto NwachukwuNessuna valutazione finora

- WD800-CZ250-00004 - Rev.0 FITP For Concrete Work (Onshore)Documento31 pagineWD800-CZ250-00004 - Rev.0 FITP For Concrete Work (Onshore)Ahmad AfeeqNessuna valutazione finora

- CH 6 Quality ManagementDocumento44 pagineCH 6 Quality ManagementYaredNessuna valutazione finora

- F2953-12 Standard Specification For Phenolic Raw Materials For The Use in Bearing CagesDocumento7 pagineF2953-12 Standard Specification For Phenolic Raw Materials For The Use in Bearing CageshugoNessuna valutazione finora

- DoD 4140.27-M Shelf Life ManagementDocumento79 pagineDoD 4140.27-M Shelf Life Managementorlomont100% (2)

- Technical Review For ISO 3834Documento1 paginaTechnical Review For ISO 3834Satish Keskar100% (3)

- Emdqp Ins 212Documento20 pagineEmdqp Ins 212EduardNessuna valutazione finora

- ASME Div 1 Vs Div 2Documento3 pagineASME Div 1 Vs Div 2shahmkamal100% (1)

- Ac7120 Rev e 2 - FinalDocumento32 pagineAc7120 Rev e 2 - FinalOswaldo Rivera100% (1)

- ITT - Sample of ITPDocumento3 pagineITT - Sample of ITPajiNessuna valutazione finora

- Irs S 99-2006, Data Logger SystemDocumento63 pagineIrs S 99-2006, Data Logger SystemGirdhar SrivastavaNessuna valutazione finora

- Electrical Engineering Experience Letter Format and CV ModelDocumento15 pagineElectrical Engineering Experience Letter Format and CV ModelprabhumanocNessuna valutazione finora

- E3. Sample Notification of Inspection (Noi) NOI No. VLV-NOI-381 Rev. 0Documento1 paginaE3. Sample Notification of Inspection (Noi) NOI No. VLV-NOI-381 Rev. 0Isaac EdusahNessuna valutazione finora

- Mil-Std-690 - Failure Rate Sampling Plans and ProceduresDocumento45 pagineMil-Std-690 - Failure Rate Sampling Plans and ProceduresjsadachiNessuna valutazione finora

- Technical Circular No 97Documento2 pagineTechnical Circular No 97Zipper NirvanaNessuna valutazione finora

- Saudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilDocumento2 pagineSaudi Aramco Typical Inspection Plan: Pre-Engineered Metal Buildings SATIP-M-100-04 30-Apr-13 CivilJeffrey Lipata Jr.Nessuna valutazione finora

- Euro Data Sheet AmsteelDocumento2 pagineEuro Data Sheet AmsteelRob WolfeNessuna valutazione finora

- Design For Quality - Achieving 0 PPM With SigmundWorks From EGS IndiaDocumento32 pagineDesign For Quality - Achieving 0 PPM With SigmundWorks From EGS IndiaNatarajan RamamoorthyNessuna valutazione finora

- Receiving & Inspection: Iwp Installation Work Package 010Documento7 pagineReceiving & Inspection: Iwp Installation Work Package 010HowardWrightNessuna valutazione finora

- Iso 4519 1999Documento9 pagineIso 4519 1999djmattmNessuna valutazione finora

- Flexible Learning CBC Car NC IiDocumento83 pagineFlexible Learning CBC Car NC IiGie KoNessuna valutazione finora

- FM Aprroval 7910-Non Sparking ToolsDocumento18 pagineFM Aprroval 7910-Non Sparking ToolsTaherNessuna valutazione finora

- FPANZ Code of Practice For Gaseous Fire Suppression Systems PDFDocumento19 pagineFPANZ Code of Practice For Gaseous Fire Suppression Systems PDFTịnh TrươngNessuna valutazione finora

- Home Inspection Business PlanDocumento48 pagineHome Inspection Business PlanJoseph QuillNessuna valutazione finora

- SPCC Blue BrochDocumento10 pagineSPCC Blue BrochDylan RamasamyNessuna valutazione finora

- M202A1Documento16 pagineM202A1thedlettermanNessuna valutazione finora

- Investment Group Assignment Zaki and LeeDocumento18 pagineInvestment Group Assignment Zaki and LeeLeeZhenXiangNessuna valutazione finora