Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Construction Details For Nordic Lam™: Product Warranty

Caricato da

hahaerTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Construction Details For Nordic Lam™: Product Warranty

Caricato da

hahaerCopyright:

Formati disponibili

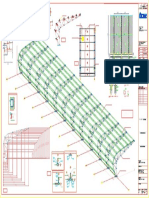

TYPICAL TALL WALL FRAMING ALLOWABLE HOLES AND NOTCHES

CONSTRUCTION DETAILS FOR NORDIC LAM™ N-C323 / December 2013

3c

Roof framing One hole may be cut anywhere along the

(by others) length of the stud or column but must be no

closer than 5/8" from the edge.

5/8" minimum edge distance

L/3

Maximum diameter:

Nordic Lam

- 1-1/8" for 3-1/2" thick walls

column

PRODUCT WARRANTY - 1-3/4" for 5-1/2" to 7-1/4" thick walls

C

hantiers Chibougamau guarantees that, in accordance with

our specifications, Nordic products are free from manufacturing One notch may be cut anywhere except

Nordic Lam stud L/3

Refer to the Construction Guide for Nordic Lam™ for additional information. defects in material and workmanship. the middle 1/3 of the length of the stud

CCMC EVALUATION REPORT 13216-R, APA PRODUCT REPORT PR-L294C or column.

F

urthermore, Chantiers Chibougamau warrants that our products,

Nordic Lam All additional blocking,

when utilized in accordance with our handling and installation instructions, trimmer studs trimmers, plates, etc.

www.nordicewp.com will meet or exceed our specifications for the lifetime of the structure.

Blocking at 8' not specified should

Maximum notch:

be the same as the - 1-1/8" for 3-1/2" thick walls

on-centre maximum

typical stud material. - 1-3/4" for 5-1/2" to 7-1/4" thick walls L/3

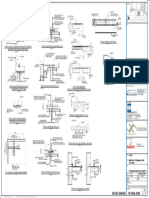

MULTIPLE MEMBER CONNECTIONS - BEAMS ALLOWABLE HOLES IN BEAMS 3a

Nordic Lam Nordic Lam

HORIZONTAL HOLES built-up column header

TOP-LOADED BEAMS

1-3/4" Width Pieces: Horizontal holes in glued laminated timbers are limited in size and location to maintain the

- Minimum of 2 rows 3-1/2" common wire nails (0.162 x 3-1/2 inches) at 12" o.c. for beam depths less than 14" structural integrity of the beam. The figure below shows the zones of a uniformly loaded, simply Bored holes shall not be located in the

- Minimum of 3 rows 3-1/2" common wire nails (0.162 x 3-1/2 inches) at 12" o.c. for 14" to 18" beam depths supported beam where the field drilling of holes may be considered. These non-critical zones are same section as a cut or notch in stud.

- Nailed connections require an additional row of nails when nail size is smaller than specified above located in portions of the beam stressed to less than 50 percent of design bending strength and

(minimum 0.128 x 3") less than 50 percent of design shear strength. For beams of more complex loading or other than

- 4-ply beams shall be attached with minimum of 2 rows 1/2-inch-diameter bolts or 1/4 x 6-inch wood simple spans, similar diagrams may be developed. 3b

screws at 24" o.c.

Field-drilled horizontal holes should be used for access only and should not be used as

3-1/2" Width Pieces: attachment points for brackets or other load bearing hardware unless specifically designed as

- Minimum of 2 rows 1/2-inch-diameter bolts or 1/4 x 6-inch wood screws at 24" o.c. staggered such by the engineer or designer. These field drilled horizontal holes should meet the following FRAMING CONNECTORS

guidelines:

SIDE-LOADED BEAMS 1. Hole size: The hole diameter should not exceed 1-1/2 inches or 1/10 the beam depth, LATERAL CONNECTIONS — ANGLE CLIPS

whichever is smaller. LATERAL CONNECTIONS — NAILS

Maximum factored uniform

Connector Dimensions Factored Resistance (lbs)

load (plf) applied to either 2-PLY 1-3/4" 3-PLY 1-3/4" 4-PLY 1-3/4" 1-3/4" + 3-1/2" 1-3/4" + 3-1/2" 2-PLY 2. Hole location: The hole should have a minimum clear distance, as measured from the Type Nails Lateral Perpendicular

+ 1-3/4" 3-1/2" Factored Resistance (lbs) W1 W2 L

outside member edge of the hole to the nearest edge of the beam, of 4 hole diameters to the top or bottom Type Diameter in-plane out-of-plane

face of the beam and 8 hole diameters from the end of the beam. Note that the horizontal End Grain Toe Nail

Nails or screws Nails or screws Screws One or Nails or screws Nails or screws Screws One or SIMPSON STRONG-TIE™ CONNECTORS

Connectors Spacing Rows One Side or Both Sides or Both Sides or One Side or Both Sides or Both Sides or hole should not be drilled in the moment-critical zone, as defined in the figure below, unless Common spiral spike 2-1/2" 0.109" 73 90

Through Bolts Through Bolts Through Bolts Through Bolts Through Bolts Through Bolts

approved by an engineer or architect qualified in engineered timber design. A21 4-10dx1-1/2" 2" 1-1/2" 1-3/8" 335 185

2 rows 765 575 N/A 575 505 N/A Common spiral spike 3" 0.122" 90 112

3-1/2" 12" o.c. A23 8-10dx1-1/2" 2" 1-1/2" 2-3/4" 725 510

3 rows 1150 860 N/A 860 755 N/A 3. Hole spacing: The minimum clear spacing between adjacent holes, as measured between Common spiral spike 3-1/4" 0.122" 90 112

Common

Wire Nails 2 rows 1535 1150 N/A 1150 1010 N/A the nearest edge of the holes, should be 8 hole diameters based on the largest diameter of A34 8-8dx1-1/2" 1-7/16" 1-7/16" 2-1/2" 455 475

6" o.c. Common wire nail 2-1/2" 0.128" 98 122

3 rows 2305 1725 N/A 1725 1515 N/A any adjacent hole in the beam.

A35 12-8dx1-1/2" 1-7/16" 1-7/16" 4-1/2" 650 675

1/2" 24" o.c. 2 rows 655 490 435 490 435 1310 Common wire nail 3" 0.144" 123 152

A307 12" o.c. 2 rows 1310 980 870 980 870 2620

4. Number of holes: The maximum number of holes should not exceed 1 hole per 5 feet USP STRUCTURAL CONNECTORS™

Bolts 6" o.c. 2 rows 2620 1965 1745 1965 1745 5240 of beam length. In other words, the maximum number of holes should not exceed 4 for

NOTES: A3 8-10dx1-1/2" 1-7/16" 1-7/16" 2-3/4" 800 790

1/4" 24" o.c. 2 rows 650 645 570 645 570 1010 a 20-foot-long beam. The hole spacing limitation, as given above, should be satisfied

1. Tables are based on a load duration factor of 1.15.

Simpson 16" o.c. 2 rows 975 965 860 965 860 1515 separately. 2. Connection values based on a mean relative density of 0.42. AC5 6-10d 1-5/16" 2-3/8" 4-7/8" 755 815

SDW Screws 12" o.c. 2 rows 1300 1285 1145 1285 1145 2020

For glulam members that have been oversized, the guidelines given above may be relaxed based 3. For end grain connections, a 0.67 factor was used (CSA O86-09). AC7 8-10d 1-5/16" 2-3/8" 6-15/16" 1090 910

24" o.c. 2 rows 705 525 470 525 470 705 4. For toe-nail connections, a 0.83 factor was used (CSA O86-09).

1/4" USP on an engineering analysis. Regardless of the hole location, holes drilled horizontally through a

SDS Screws

18" o.c. 2 rows 935 705 620 705 620 935 AC9 10-10d 1-5/16" 2-3/8" 8-7/8" 1090 1515

12" o.c. 2 rows 1395 1050 935 1050 935 1395 member should be positioned and sized with the understanding that the beam will deflect over a

period of time under in-service loading conditions. This deflection could cause distress to NOTES:

NOTES: supported equipment or piping unless properly considered. 1. Factored resistances have been increased 15% for earthquake

1. Verify adequacy of beam in uniform load tables or design software prior to using values listed above. or wind loading with no further increase allowed; reduce where In-plane load

2. Glulam beams are assumed to be full length, have adequate lateral bracing to avoid buckling, have the same stiffness and other loads govern.

bending capacity, and have adequate bearing at supports to carry the applied load. Concentrated loads require special 2. Factored resistances have been adjusted for mean relative Out-of-plane load

consideration. VERTICAL HOLES density of ES11 Nordic Lam studs (G = 0.42).

3. Resistances given are for multiple-beam connections under standard term load duration. Increases for other load durations 3. All nails are common wire nails:10dx1-1/2" = 0.144" diameter x

Whenever possible, avoid drilling vertical holes through glulam beams. As a rule of thumb, 1-1/2" long, 10d = 0.144" diameter x 3" long.

are permitted. A23 or A3

vertical holes drilled through the depth of a glulam beam cause a reduction in the capacity at that AC5 AC7 AC9 A21 A34 A35

4. Nails shall conform to ASTM F1667 and have a minimum yield strength of 90,000 psi. Nails shall be located a minimum

location directly proportional to the ratio of 1-1/2 times the diameter of the hole to the width of

of 2 inches from the top and bottom of the member with a minimum spacing of 2 inches between rows. The end distance

shall not be less than 3 inches. Multiply tabulated connection capacities by 0.83 for 3-1/4" common wire nails (0.148 x the beam. For example, a 1-inch hole drilled in a 6-inch-wide beam would reduce the capacity of

3-1/4 inches). the beam at that section by approximately (1 x 1-1/2) / 6 = 25%.

5. Bolts shall conform to ASTM A307 and have a minimum yield strength of 45,000 psi. Bolt holes are recommended to be For this reason, when it is necessary to drill vertical holes through a glulam member, the holes

MULTIPLE MEMBER

not more than 1/32 inch greater than the diameter of the bolts and shall be located a minimum of 2 inches away from the

should be positioned in areas of the member that are stressed to less than 50 percent of design in CONNECTIONS - COLUMNS BUILT-UP COLUMNS FASTENER PATTERN

glulam end and edges. Standard cut washers shall be used between head and nut of the bolt and the glulam.

bending. In a simply supported, uniformly loaded beam, this area would be located from the end Nails and Bolts Nails Bolts

6. Simpson SDW Screws: All screw pattern to be installed from one side only. Screws shall be installed with the screw head in

the loaded ply. If beam loaded on screw tip side, lower tabulated values by 15%. Required screw lengths: 1-3/4" 2-ply of the beam inward approximately 1/8 of the beam span. In all cases, the minimum clear edge

Column Maximum Number Minimum Minimum Minimum Minimum

distance, as measured from either side of the member to the nearest edge of the vertical hole, Fastener

beam = 3-3/8", 1-3/4" 3-ply beam = 5", 4-ply 1-3/4" and 2-ply 3-1/2" beams = 6-3/4". Minimum required fastener 2x4 Fastener Edge Edge

distances: to beam end: 6"; vertically to top/bottom edges: 1-7/16"; vertically between screws: 2-1/2" (staggered). should be 2-1/2 times the hole diameter. Use a drill guide to minimize “wandering” of the bit as it

2x6 / 2x8 Size Spacing of Rows Distance End Distance Distance End Distance

passes through knots or material of varying density, and to ensure a true alignment of the hole

(nominal) (nominal)

7. USP SDS Screws: Screws to be installed from both sides always, except in case of 1-3/4" 2-ply and 1-3/4"+3.5" beams. If 2-ply, 2x4 1 1-1/4"

3" (0.144") nails

installed on one side only, screws shall be installed with the screw head in the loaded ply. Required screw lengths: 3.5" for through the depth of the beam. 2-ply, 2x6 9" 2 1-3/8" 1-7/8" 3/4" 2-1/2"

all combinations, except for 1-3/4" 4-ply beams and 3-1/2" 2-ply beams, where the screw length shall be 6". Minimum 2-ply, 2x8 or 1/2" bolts 2 2-1/8"

required fastener distances: to beam end: 4"; vertically from top/bottom edges: 1-1/2"; vertically inbetween screws: 2-1/2" 3-ply, 2x4 1 1-1/4"

(staggered). 4-1/2" (0.212")

3-ply, 2x6 9" 2 1-3/8" 2-1/2" 3/4" 2-1/2"

8. 4-ply beams are recommended to be used only when loads are applied to both sides, or if the beam is not fully loaded. 3-ply, 2x8 nails or 1/2" bolts 2 2-1/8"

ZONES WHERE SMALL HORIZONTAL HOLES ARE PERMITTED IN A UNIFORMLY

The lesser load should be at least 25% of the higher load on the opposite side.

LOADED, SIMPLY SUPPORTED BEAM 4-ply, 2x4 6" (0.276") nails 1 1-1/4"

9. Offset connector spacing so that protruding fasteners do not interfere with intersecting side members. Stagger all fasteners 4-ply, 2x6 9" 2 1-3/8" 3-3/4" 3/4" 2-1/2"

installed from opposite side. 4-ply, 2x8 or 1/2" bolts 2 2-1/8"

Fastener

CONNECTION PATTERN WITH NAILS AND BOLTS spacing

(For screw connections, see the notes above.) d/4 Moment critical zone NOTES:

d/2 Shear critical zone Shear critical zone 1. Connection patterns shown are those required per CSA O86-09. Resistances shall be be calculated per CSA O86-09.

2-PLY 1-3/4" 3-PLY 1-3/4" 4-PLY 1-3/4" 1-3/4" + 3-1/2" 1-3/4" + 3-1/2" + 1-3/4" 2-PLY 3-1/2" 2. Individual studs assumed to be continuous over the full height of the built-up column and of the same grade.

d/4 Moment critical zone End

distance 3. Verify bearing resistance of the supporting member.

2" 2" 4. Nails are common wire nails, shall conform to ASTM F1667 and have a minimum yield strength of 90,000 psi.

Bearing critical zone Bearing critical zone 5. Bolts shall conform to ASTM A307 and have a minimum yield strength of 45,000 psi. Bolt holes are recommended to be not more than 1/32 inch

Nails from greater than the diameter of the bolts. Standard cut washers shall be used between head and nut of the bolt and the glulam.

Edge distance alternating sides 6. Install one row staggered, or two rows parallel in vertical direction.

Zones where horizontal holes are permitted for passage of wires, conduit, etc. 7. Nails shall be driven alternately from either face along the member's length.

1.75" 1.75" 1.75" 1.75" 3.5" 1.75" 3.5" 3.5"

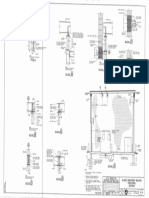

FLOOR FRAMING DETAILS HEADER FRAMING DETAILS

1a BEAM BEARING AT END WALL 1b BEAM BEARING AT END WALL 1c BEAM BEARING AT END WALL 1d BEAM BEARING AT MASONRY WALL 2a HEADER TO END WALL 2b HEADER TO END WALL 2c HEADER TO END WALL

Nordic Lam beam Nordic Lam beam 2x wall plates Nordic Lam header Nordic Lam header 2x wall plates

Nordic Lam beam 2x wall plates

Nordic Lam beam

3-1/2" Steel

nails Nordic Lam

angle 3-1/2" nails header

each

side

Steel tie plate

Wall plate

Steel post cap Double or triple

trimmer studs Anchor bolts

Nordic Lam column, Steel post cap

Nordic Lam column, solid-sawn post or King stud King stud nailed to header

multiple studs Concrete or Steel tie plate

solid-sawn post or

masonry wall

multiple studs Double or triple trimmer

Nordic Lam, wood post or Nordic Lam, wood post or multiple studs

studs

multiple studs

1e BEAM SUPPORT AT END WALL WITH FLOOR JOISTS OVER BEAM 1f BEAM SUPPORT AT END WALL WITH FLOOR JOISTS FLUSH WITH BEAM

2d HEADER OVER INTERMEDIATE SUPPORT 2e HEADER OVER INTERMEDIATE SUPPORT

Pre-engineered Floor sheathing NOTE:

2x floor joists or I-joists metal hangers PROVIDE ADEQUATE

Floor sheathing Nordic Lam header over

Nordic Lam header over two BEARING LENGTH AND

adjacent openings two adjacent openings BEARING ACROSS THE

Rim joist FULL WIDTH TO

Rim joist

SUPPORT GLULAM

HEADER.

Nordic Lam column,

King SEE 'BEARING LENGTH

solid-sawn post

stud REQUIREMENTS' IN THE

or multiple studs King stud

NORDIC LAM

2x floor joists Nordic Lam column, CONSTRUCTION

or I-joists solid-sawn post Steel tie plate

King stud 1/2" lag screws GUIDE AND CONSULT

Nordic Lam beam or multiple studs King stud Nordic Lam, wood post

nailed to beam Steel cap plate welded to LOCAL BUILDING

nailed to or multiple studs

beam steel column CODE FOR SPECIFIC

REQUIREMENTS.

Side View End View Side View End View Steel pipe or tube column

1g LUMBER JOISTS BEARING ON 1h I-JOISTS BEARING ON FLOOR BEAM 1j JOISTS MOUNTED FLUSH WITH 1k BEAM BUTTING OVER

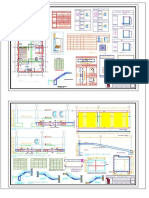

FLOOR BEAM FLOOR BEAM INTERMEDIATE WOOD SUPPORT WALL FRAMING DETAILS

Floor sheathing Face mount Top mount Beam butt joint

over joists Floor sheathing hanger* hanger* on column

Nordic Lam 3a HEADER TO COLUMN 3b COLUMN TO BOTTOM PLATE 3c COLUMN TO TOP PLATE

Nordic Lam beam over I-joists

beam

Face I-joists* Nordic Lam

Toe 2x floor nails Plate Trimmer Double top plate

nails joists* on flat stud(s) column

2x floor joists Nordic Lam Steel post cap Through-bolt

beam Sole plate

or I-joists Framing angles to

support lateral load Framing Framing

Nordic Lam column, angles angles

*Hangers installed per the manufacturer’s solid-sawn post or multiple studs Rim board

recommendations; the use of mixed hanger Nordic Lam

*Blocking between joists not shown for clarity *Blocking between joists not shown for clarity header

types is for illustration purpose only.

Sill plate

Nordic Lam

1m CONTINUOUS FLOOR BEAM OVER INTERMEDIATE WOOD SUPPORTS 1o BEAM SITTING IN CONCRETE OR MASONRY column

WALL POCKET Trimmer stud(s) to Solid blocking is

support vertical load Blocking

required if column and

panel as

trimmer stud(s) do not

required

Note: Plate width must equal wall thickness to provide lateral extend to sill plate

Nordic Lam beam Trimmer stud(s) Nordic Lam

bracing. (Plate not required if header width equals the column

wall thickness.)

Nordic Lam beam

Through-bolt

Steel tie plate Steel post cap

3j WIND BRACE 3k ROOF OUTLOOKER

Blocking between outlookers as required

Nordic Lam column, solid-sawn 1/2" minimum air space shall be provided (not shown for clarity)

post or multiple studs between wood and masonry surface

Wall bracing is Additional nailing may be required Connection to truss

necessary if double top between sheathing (by others)

Roof framing plate is not attached and outlooker

(by others) directly to the

1n CONTINUOUS BEAM OVER INTERMEDIATE STEEL COLUMN 1p FOUNDATION BEAM-POCKET DETAILS roof/floor diaphragm.

2x Connection

Minimum 1/2" air gap required at ends and sides to double

outlooker

top plate

Connect truss (not shown)

to double top plate

(by others)

Untreated Nordic Lam beam

Weld to Nordic Lam beam 1/2" Lag screws

steel column Moisture break required: treated plywood, Bottom chord Angled wind

metal bearing plate, flashing, plastic bearing truss bracing braces to connect Continuous tall-wall framing

Steel post cap Steel cap plate Engineered

Steel pipe or plates, etc., sized for bearing of glulam beam (by others) double top plate (from sill plate to top plate)

Steel tube welded to steel column tube column wall system

column to roof diaphragm

Foundation wall Note: Connection of double top plate to outlooker must be

(by others)

designed to transfer lateral load to roof

Potrebbero piacerti anche

- 98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverDocumento2 pagine98 140656 A01 Installation Guide Sailor 6588 Dgnss ReceiverAnonymous XnufDzrpoNessuna valutazione finora

- Self-Consolidating Concrete SheetDocumento2 pagineSelf-Consolidating Concrete SheethahaerNessuna valutazione finora

- Placing Reinforcing Bars - tcm45-344165Documento5 paginePlacing Reinforcing Bars - tcm45-344165x620Nessuna valutazione finora

- Marcos & Sumulong Highway, Rizal Applicant'S Information Sheet (Non-Academic)Documento2 pagineMarcos & Sumulong Highway, Rizal Applicant'S Information Sheet (Non-Academic)dummy testerNessuna valutazione finora

- FIN 1050 - Final ExamDocumento6 pagineFIN 1050 - Final ExamKathi100% (1)

- Fitting A Logistic Curve To DataDocumento12 pagineFitting A Logistic Curve To DataXiaoyan ZouNessuna valutazione finora

- Cancer of LarynxDocumento29 pagineCancer of LarynxQasim HaleimiNessuna valutazione finora

- OR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE CDocumento1 paginaOR4100-1-ATNM-AB4-SDW-00001-4A - Level-00-ZONE CAhmed SolankiNessuna valutazione finora

- Toll Plaza PCC Bar-1Documento1 paginaToll Plaza PCC Bar-1Praveen KumarNessuna valutazione finora

- R O A D SITE PLAN Scale 1: 500Documento1 paginaR O A D SITE PLAN Scale 1: 500Mercyline MaworereNessuna valutazione finora

- D2 - Tracker GA DrawingDocumento3 pagineD2 - Tracker GA DrawingManish Sonawane100% (1)

- Series C World Class Circuit Breakers L-Frame 300-630 AmperesDocumento4 pagineSeries C World Class Circuit Breakers L-Frame 300-630 Amperesbaskaranjay5502Nessuna valutazione finora

- benedetto17_3Documento1 paginabenedetto17_3Thierry QuesimuNessuna valutazione finora

- Estructura de Cubierta PDFDocumento1 paginaEstructura de Cubierta PDFAndres SuarezNessuna valutazione finora

- D01 D02 D03 W01 W02 Window and Door Schedule: Lobby DisabledDocumento1 paginaD01 D02 D03 W01 W02 Window and Door Schedule: Lobby DisabledIan ChumaNessuna valutazione finora

- 3bhk Plan Devichapada Sachin M-Model - Pdf... 9876Documento1 pagina3bhk Plan Devichapada Sachin M-Model - Pdf... 9876viveksawant242Nessuna valutazione finora

- Tiger Moth Sheet 2 of 2: DihedralDocumento1 paginaTiger Moth Sheet 2 of 2: DihedralFarooq AhmadNessuna valutazione finora

- Do Not Print From This File - For Reference Only: TürkçeDocumento2 pagineDo Not Print From This File - For Reference Only: TürkçeIlker AydınNessuna valutazione finora

- Crne 7.5tDocumento1 paginaCrne 7.5tAdam SniffNessuna valutazione finora

- Hoja 1Documento1 paginaHoja 1Juan Carlos SoriaNessuna valutazione finora

- Key Reinforcement PlanDocumento1 paginaKey Reinforcement PlanMazen IsmailNessuna valutazione finora

- ESKA 31in Oz6590 VectorDocumento1 paginaESKA 31in Oz6590 Vectorrider504Nessuna valutazione finora

- ESKA 31in Oz6590 PreviousDocumento1 paginaESKA 31in Oz6590 Previousrider504Nessuna valutazione finora

- 3d +2D eLEVATIONDocumento1 pagina3d +2D eLEVATIONfaisal saifNessuna valutazione finora

- Bowser: 3 3 3 Clap Hands On DrumDocumento3 pagineBowser: 3 3 3 Clap Hands On DrumPermaster Dci Vut YorworbandNessuna valutazione finora

- Riy0923 Ryqs0573Documento5 pagineRiy0923 Ryqs0573Rizwan HameedNessuna valutazione finora

- STP Exhaust Piping PlanDocumento1 paginaSTP Exhaust Piping Planbernard alcorizaNessuna valutazione finora

- Drawing 3.Documento1 paginaDrawing 3.tiyaniNessuna valutazione finora

- Plano Cimentaciones ConstruccionDocumento1 paginaPlano Cimentaciones Construccionkristhan borjaNessuna valutazione finora

- S1-521 Ticket Counter Details 02Documento1 paginaS1-521 Ticket Counter Details 02Milan PuzigaćaNessuna valutazione finora

- Li.05-DR-2500 Typical Landscape DetailsDocumento1 paginaLi.05-DR-2500 Typical Landscape Detailsstupido3337Nessuna valutazione finora

- ES102Documento1 paginaES102Juan Luis Nuñez HuayllapumaNessuna valutazione finora

- Ship specs: length, breadth, draft, speedDocumento2 pagineShip specs: length, breadth, draft, speedKyaw Win TunNessuna valutazione finora

- East Elevation South Elevation: Church HallDocumento1 paginaEast Elevation South Elevation: Church HallanzaniNessuna valutazione finora

- S004 76-10526-Detail Design: Typical Slab Thickening Under Block WallDocumento1 paginaS004 76-10526-Detail Design: Typical Slab Thickening Under Block WallMazen IsmailNessuna valutazione finora

- Thermadyne-Catalog CigweldDocumento292 pagineThermadyne-Catalog CigweldUmmi Rahmatul IstiqomahNessuna valutazione finora

- Final PlanDocumento1 paginaFinal PlanJJ TevesNessuna valutazione finora

- Ecl Travellers Inn 3Documento1 paginaEcl Travellers Inn 3Angelice Alliah De la CruzNessuna valutazione finora

- Amor Perdido - CelloDocumento2 pagineAmor Perdido - CelloJUAN PABLO ATEHORTÚA ZEANessuna valutazione finora

- Indigo - Admin - 31.03.20-First FLRDocumento1 paginaIndigo - Admin - 31.03.20-First FLRjaisonNessuna valutazione finora

- DWG-M02 - Rev 0Documento1 paginaDWG-M02 - Rev 0Erik Jhonattan Jara YpanaqueNessuna valutazione finora

- Door & Window ScheduleDocumento1 paginaDoor & Window ScheduleAchintya MohnishNessuna valutazione finora

- B2 Turret Cladding PlanDocumento1 paginaB2 Turret Cladding PlanCatalin HagiNessuna valutazione finora

- JB MC STR CA 202 r2Documento1 paginaJB MC STR CA 202 r2Fatih ArıkanNessuna valutazione finora

- Lot 125 To Lot 128Documento4 pagineLot 125 To Lot 128kewcottagesNessuna valutazione finora

- Block B: 164'-0" Wide Road 164'-0" Wide RoadDocumento1 paginaBlock B: 164'-0" Wide Road 164'-0" Wide RoadNikita DhingraNessuna valutazione finora

- 20% Tiger Moth Sheet1of2Documento1 pagina20% Tiger Moth Sheet1of2Farooq AhmadNessuna valutazione finora

- Ard D 01 en Ma Drw171437aa 20171220 He 20171227 PDFDocumento1 paginaArd D 01 en Ma Drw171437aa 20171220 He 20171227 PDFUus SuhadaNessuna valutazione finora

- Sheet 2 of 2: Turn TurnDocumento2 pagineSheet 2 of 2: Turn TurnJesùs AlfaroNessuna valutazione finora

- Cimentacion Formato A1Documento1 paginaCimentacion Formato A1Leonardo Quispe YncaNessuna valutazione finora

- 3.3. Design of Aluminium Framing Members: Reference Drawing: AJB ZEB BM Z Z Z SD FAC 42078 00Documento3 pagine3.3. Design of Aluminium Framing Members: Reference Drawing: AJB ZEB BM Z Z Z SD FAC 42078 00waweng22Nessuna valutazione finora

- Detalles Estructurales PDFDocumento1 paginaDetalles Estructurales PDFArthur Alba RosalesNessuna valutazione finora

- Sheet 3 Toilet Detail 03132019Documento1 paginaSheet 3 Toilet Detail 03132019Brylle De GuzmanNessuna valutazione finora

- Detalles Estructurales PDFDocumento1 paginaDetalles Estructurales PDFArthur Alba RosalesNessuna valutazione finora

- Union de Viga Y Columna en Cruz: Municipalidad Distrital de CascaparaDocumento1 paginaUnion de Viga Y Columna en Cruz: Municipalidad Distrital de CascaparaArthur Alba RosalesNessuna valutazione finora

- Detalles Estructurales PDFDocumento1 paginaDetalles Estructurales PDFArthur Alba RosalesNessuna valutazione finora

- MRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3Documento1 paginaMRS-DWG-DD-ST-01-SL-5004 - R0 - Detail - Steel Truss-3arman gauNessuna valutazione finora

- Gad RRS FPDocumento1 paginaGad RRS FPvishnu kumar VyasNessuna valutazione finora

- Design Problem Concept Plans 04.09.17Documento3 pagineDesign Problem Concept Plans 04.09.17Devangie ShrivastavaNessuna valutazione finora

- MHP-23-DEC-CEB-0218 From DEICDocumento2 pagineMHP-23-DEC-CEB-0218 From DEICPasan RajasingheNessuna valutazione finora

- Robinson Pagadian - Bended Roof 9Documento1 paginaRobinson Pagadian - Bended Roof 9Cesar DuriasNessuna valutazione finora

- A Louver Detail B Accent Wall Groove Front Elevation: Drawn By: Project Title: Owner: LocationDocumento1 paginaA Louver Detail B Accent Wall Groove Front Elevation: Drawn By: Project Title: Owner: LocationBrylle De GuzmanNessuna valutazione finora

- Fables of Faubus - MSCZDocumento9 pagineFables of Faubus - MSCZMaurizio CongiuNessuna valutazione finora

- 21 Sa Home Ravi Hewawitarama 1Documento1 pagina21 Sa Home Ravi Hewawitarama 1Travel With RaviNessuna valutazione finora

- TSJ Transportation Frame Detail DrawingDocumento1 paginaTSJ Transportation Frame Detail DrawingBhuvan GanesanNessuna valutazione finora

- Aim High Classroom Labels and OrganizersDa EverandAim High Classroom Labels and OrganizersNessuna valutazione finora

- Atopex Metal ENG 3Documento6 pagineAtopex Metal ENG 3hahaerNessuna valutazione finora

- Li Jun 2013Documento233 pagineLi Jun 2013hahaerNessuna valutazione finora

- 06-TC-BM-00 CombinedDocumento10 pagine06-TC-BM-00 CombinedhahaerNessuna valutazione finora

- Reinforcement at Pipe Penetrations Through Steel Column TS-COL-01Documento4 pagineReinforcement at Pipe Penetrations Through Steel Column TS-COL-01hahaerNessuna valutazione finora

- Bridge Shop Drawing SignedDocumento1 paginaBridge Shop Drawing SignedhahaerNessuna valutazione finora

- 05-TC-SL-00 Combined PDFDocumento28 pagine05-TC-SL-00 Combined PDFhahaerNessuna valutazione finora

- Natural Pozzolan SCM Safety Data Sheet Provides Cancer, Skin and Eye Damage WarningsDocumento11 pagineNatural Pozzolan SCM Safety Data Sheet Provides Cancer, Skin and Eye Damage WarningshahaerNessuna valutazione finora

- AISI How To Build INTERIOR WALLS With SteelDocumento4 pagineAISI How To Build INTERIOR WALLS With SteeloscarNessuna valutazione finora

- Yard King Bridge Operation ManualDocumento7 pagineYard King Bridge Operation ManualhahaerNessuna valutazione finora

- Whale Seeing Nature TourDocumento3 pagineWhale Seeing Nature TourhahaerNessuna valutazione finora

- Tension Development Lengths and Lap Splices For Bars Grade 400 Mpa TC-REINF-01Documento5 pagineTension Development Lengths and Lap Splices For Bars Grade 400 Mpa TC-REINF-01hahaerNessuna valutazione finora

- Hollowcore Slab DetailsDocumento17 pagineHollowcore Slab DetailshahaerNessuna valutazione finora

- NRC Chemical AdmixtureDocumento7 pagineNRC Chemical AdmixturehahaerNessuna valutazione finora

- Housekeeping Pads / Built Up Slabs TC-MISC-01: NotesDocumento8 pagineHousekeeping Pads / Built Up Slabs TC-MISC-01: NoteshahaerNessuna valutazione finora

- Flagpole EmbedmentDocumento2 pagineFlagpole EmbedmenthahaerNessuna valutazione finora

- OPSS - PROV 1350 Ontario Specs 1305Documento28 pagineOPSS - PROV 1350 Ontario Specs 1305hahaerNessuna valutazione finora

- 19 1 PDFDocumento61 pagine19 1 PDFsunitkghosh1Nessuna valutazione finora

- Tremie ConcreteDocumento3 pagineTremie ConcreteChae Tyng FengNessuna valutazione finora

- Specs Concrete Post FoundationDocumento8 pagineSpecs Concrete Post FoundationhahaerNessuna valutazione finora

- OCCDC Reference Guide V31 PDFDocumento32 pagineOCCDC Reference Guide V31 PDFx620Nessuna valutazione finora

- Lesson 01 - BasicModeling1 - Steel - Precast PDFDocumento50 pagineLesson 01 - BasicModeling1 - Steel - Precast PDFmihai_purcaru1888Nessuna valutazione finora

- uNDERWATER gEOTECHNICAL fOUNDATION PDFDocumento224 pagineuNDERWATER gEOTECHNICAL fOUNDATION PDFhahaerNessuna valutazione finora

- Appendix A: Design Criteria: Davenport Diamond Grade Separation Feasibility Study Update (2015)Documento11 pagineAppendix A: Design Criteria: Davenport Diamond Grade Separation Feasibility Study Update (2015)hahaerNessuna valutazione finora

- QualityGuidelineFabrication2E WithCommentaryDocumento42 pagineQualityGuidelineFabrication2E WithCommentaryhahaerNessuna valutazione finora

- 19 1 PDFDocumento61 pagine19 1 PDFsunitkghosh1Nessuna valutazione finora

- 1180 002Documento5 pagine1180 002hahaerNessuna valutazione finora

- DSI Canada DYWIDAG PT Anchor Bolt CA 01Documento2 pagineDSI Canada DYWIDAG PT Anchor Bolt CA 01suvraNessuna valutazione finora

- CodeStandardPractice8E Jun 3 2016Documento62 pagineCodeStandardPractice8E Jun 3 2016shakirhamid6687Nessuna valutazione finora

- Cast Copper Alloy Solder Joint Pressure Fittings: ASME B16.18-2018Documento41 pagineCast Copper Alloy Solder Joint Pressure Fittings: ASME B16.18-2018crescon designNessuna valutazione finora

- Easy Gluten Free RecipesDocumento90 pagineEasy Gluten Free RecipesBrandon Schmid100% (1)

- Class 7 Summer Vacation PDFDocumento4 pagineClass 7 Summer Vacation PDFPrince RajNessuna valutazione finora

- Dti Fbgas Conso 2017Documento3 pagineDti Fbgas Conso 2017Hoven MacasinagNessuna valutazione finora

- Xtreme 5 (Answer-Key)Documento120 pagineXtreme 5 (Answer-Key)arielsergio403Nessuna valutazione finora

- RQQDocumento3 pagineRQQRazerrdooNessuna valutazione finora

- Das Aufkommen Eines Neuen Pseudoephedrinprodukts Zur Bekämpfung Des MethamphetaminmissbrauchsDocumento17 pagineDas Aufkommen Eines Neuen Pseudoephedrinprodukts Zur Bekämpfung Des Methamphetaminmissbrauchszossel ringoNessuna valutazione finora

- Keyboard notes to Fur Elise melodyDocumento2 pagineKeyboard notes to Fur Elise melodyReji SarsalejoNessuna valutazione finora

- Spain Usa ExtraditionDocumento2 pagineSpain Usa ExtraditionAdrian BirdeaNessuna valutazione finora

- Court of Appeals: DecisionDocumento11 pagineCourt of Appeals: DecisionBrian del MundoNessuna valutazione finora

- Ajaz CVDocumento1 paginaAjaz CVAjazNessuna valutazione finora

- Karnataka Email Id DataDocumento5.173 pagineKarnataka Email Id DataSumalatha Venkataswamy100% (6)

- RPP Microteaching TaruliDocumento9 pagineRPP Microteaching TaruliTaruli Sianipar 165Nessuna valutazione finora

- Euro Tuner 1 2008 PDFDocumento2 pagineEuro Tuner 1 2008 PDFDarwinNessuna valutazione finora

- HED - PterygiumDocumento2 pagineHED - Pterygiumterry johnsonNessuna valutazione finora

- BIS Standards in Food SectorDocumento65 pagineBIS Standards in Food SectorRino John Ebenazer100% (1)

- Mechanics of Solids Unit - I: Chadalawada Ramanamma Engineering CollegeDocumento1 paginaMechanics of Solids Unit - I: Chadalawada Ramanamma Engineering CollegeMITTA NARESH BABUNessuna valutazione finora

- Business Plan Presentation ON Air Conditioner: Presented By-V.Sowmith REG NO-2121BM010112Documento16 pagineBusiness Plan Presentation ON Air Conditioner: Presented By-V.Sowmith REG NO-2121BM010112Kavya Madanu100% (1)

- Building Materials Alia Bint Khalid 19091AA001: Q) What Are The Constituents of Paint? What AreDocumento22 pagineBuilding Materials Alia Bint Khalid 19091AA001: Q) What Are The Constituents of Paint? What Arealiyah khalidNessuna valutazione finora

- 1 Minute Witness PDFDocumento8 pagine1 Minute Witness PDFMark Aldwin LopezNessuna valutazione finora

- Midterm Exam ADM3350 Summer 2022 PDFDocumento7 pagineMidterm Exam ADM3350 Summer 2022 PDFHan ZhongNessuna valutazione finora

- BiblicalDocumento413 pagineBiblicalMichael DiazNessuna valutazione finora

- Chippernac: Vacuum Snout Attachment (Part Number 1901113)Documento2 pagineChippernac: Vacuum Snout Attachment (Part Number 1901113)GeorgeNessuna valutazione finora

- ABAP Program Types and System FieldsDocumento9 pagineABAP Program Types and System FieldsJo MallickNessuna valutazione finora

- English Literature RevisionDocumento61 pagineEnglish Literature RevisionAlex Cobain Glinwood100% (1)

- Sikkim Public Works Liability of Government and Contractor Act 1983Documento11 pagineSikkim Public Works Liability of Government and Contractor Act 1983Latest Laws TeamNessuna valutazione finora