Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Load Analysis Report

Caricato da

Kaustabha DasCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Load Analysis Report

Caricato da

Kaustabha DasCopyright:

Formati disponibili

6

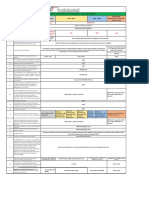

CONDITION OF SHIP ELEVATING HULL ELEVATED HULL EMERGENCY OPERATION

01

SL.NO REMARKS

RATING NO OF NO OF LOAD NO OF LOAD NO OF LOAD

LOAD DESCRIPTION KW L.F D.F L.F D.F L.F D.F

KW SETS SETS KW SETS KW SETS KW

1 MAIN & AUX MACHINERY

-2

1.1 JACKING HPU 42.00 4 168.00 4 0.9 1.0 151.20 0 0.8 1.0 0.00 0 0.8 0.2 0.00

Vendor:OTD

1.3 BILGE PUMP 11.00 1 11.00 1 0.8 0.5 4.40 1 0.8 0.2 1.76 0 0.8 0.1 0.00

60m3/h @3 bar (vendor: AZCUE)

1.4 BILGE BALLAST PUMP 11.00 1 11.00 1 0.8 0.5 4.40 1 0.8 0.2 1.76 0 0.8 0.1 0.00

60m3/h @3 bar (vendor: AZCUE)

EC

1.5 FIRE PUMP 30.00 2 60.00 1 0.8 0.1 2.40 1 0.8 0.2 4.80 1 1.0 1.0 30.00

65m3/h @7 bar(vendor: AZCUE)

1.6 RAW WATER & SUBMERGIBLE PUMP 45.00 2 90.00 1 0.8 1.0 36.00 1 0.8 1.0 36.00 1 1.0 1.0 45.00

400m3/h @ 4.5-5 bar(vendor : SIMEDARBY-caprari)

1.7 F.O. TRANSFER PUMP 1.10 2 2.20 1 0.8 0.3 0.26 1 0.8 0.3 0.26 1 0.8 0.1 0.09

5m3/h @2.5 bar

1.8 SPRINKLER PUMP 37.00 1 37.00 1 0.8 0.1 2.96 1 0.8 0.1 2.96 1 1.0 1.0 37.00

80m3/h @10 bar (vendor supply)

1.9 HELIDECK FOAM PUMP 75.00 1 75.00 1 0.8 0.1 6.00 1 0.8 0.2 12.00 0 1.0 1.0 0.00

125m3/h @10 bar (vendor: AZCUE)

-D

1.10 BALLAST PUMP 15.00 1 15.00 1 0.8 0.3 3.60 1 0.8 0.2 2.40 0 0.8 0.2 0.00

100m3/h @3 bar (vendor: AZCUE)

1.11 FRESH WATER TRANSFER PUMP 1.10 1 1.10 1 0.8 0.2 0.18 1 0.8 0.3 0.26 0 0.8 0.2 0.00

5m3/h @3 bar (vendor: AZCUE)

1.12 F.O.PURIFIER 2.57 2 5.14 1 0.8 1.0 2.06 1 0.8 1.0 2.06 0 0.8 0.2 0.00

1.13 FRESH WATER COOLING PUMP 22.00 2 44.00 1 0.8 1.0 17.60 1 0.8 1.0 17.60 0 0.8 0.2 0.00

130m3/h @4 bar (vendor: AZCUE)

22

1.14 SEA WATER COOLING PUMP 22.00 2 44.00 1 0.8 1.0 17.60 1 0.8 1.0 17.60 0 0.8 0.2 0.00

130m3/h @3-4 bar (No vendor data)

1.15 * TROLLEY BEAM MOTOR 8.00 1 8.00 0 0.8 0.0 0.00 1 0.8 0.1 0.64 0 0.8 0.2 0.00

1.16 CALORIFIER 15.00 1 15.00 1 0.7 0.2 2.10 1 0.8 0.5 6.00 0 0.8 1.0 0.00

500L(vendor: Hatenboer)

1.17 OILY WATER SEPERATOR 3.75 1 3.75 0 0.8 0.2 0.00 1 0.8 0.1 0.30 0 0.8 0.5 0.00

2.5m3/h (vendor: tech venture)

1.18 HOT WATER CIRCULTING PUMP 0.55 2 1.10 0 0.8 0.2 0.00 1 0.8 0.5 0.22 0 0.8 0.5 0.00

2m3/h @1.6 bar(vendor: Hatenboer)

ed

1.19 DIRTY OIL / SLUDGE PUMP 2.20 1 2.20 0 0.8 0.2 0.00 1 0.8 0.1 0.18 0 0.8 0.2 0.00

5m3/h @3 bar (vendor: AZCUE)

1.2 SEWAGE TREATMENT PLANT 5.89 1 5.89 1 0.8 0.5 2.36 1 0.8 0.6 2.83 0 0.8 0.2 0.00

for 13 person( vendor: teknik)

1.21 SEWAGE TRANSFER PUMP 0.75 1 0.75 1 0.8 0.2 0.12 1 0.8 0.2 0.12 0 1.0 1.0 0.00

3m3/h @2 bar ( vendor: AZCUE)

1.22 SLUDGE TRANSFER PUMP 1.10 1 1.10 1 0.8 0.2 0.18 1 0.8 0.2 0.18 0 1.0 1.0 0.00

at

1.23 FRESH WATER MAKER R.O PLANT 3.00 1 3.00 1 0.8 0.5 1.20 1 0.8 0.9 2.16 0 0.8 0.8 0.00

2.5 m3/ day(vendor: simedarby-mecomb)

1.24 WORKING AIR COMPRESSOR 3.50 1 3.50 1 0.8 0.1 0.28 1 0.8 0.1 0.28 0 0.8 1.0 0.00

Vendor :Aries

Vendor :Aries

D

1.25 WORKING AIR DRYER 0.40 1 0.40 1 0.8 0.1 0.03 1 0.8 0.1 0.03 0 0.8 1.0 0.00

1.26 ELEVATOR 15.00 1 15.00 1 0.9 0.1 1.35 1 0.9 0.2 2.70 0 0.8 1.0 0.00

Vendor :Hankook

1.27 EMG. GENERATOR BATTERY CHARGER - 1 0.50 1 0.50 1 0.9 0.1 0.05 1 0.9 0.2 0.09 1 0.8 1.0 0.40

1.28 EMG. GENERATOR BATTERY CHARGER - 2 0.50 1 0.50 1 0.9 0.1 0.05 1 0.9 0.2 0.09 1 0.8 1.0 0.40

48

1.29 F.W.HYDROPHORE PUMP 5.50 1 5.50 1 0.8 0.5 2.20 1 0.8 1.0 4.40 0 0.8 0.2 0.00

3m3/h @2.5 bar ( vendor: Hatenboer )

1.3 RADIATOR FAN MOTOR 30.00 2 60.00 2 0.9 1.0 54.00 1 0.9 1.0 27.00 0 0.0 0.0 0.00

Vendor: Mingyang

1.31 MGPS SYSTEM 0.06 1 0.06 1 0.9 1.0 0.05 1 0.9 1.0 0.05 0 0.0 0.0 0.00

1.32 RO MODULE 4.53 1 4.53 1 0.8 1.0 3.62 1 0.8 1.0 3.62 0 0.0 0.0 0.00

27

1.33 PRE-TREATMENT MODULE 3.15 1 3.15 1 0.8 1.0 2.52 1 0.8 1.0 2.52 0 0.0 0.0 0.00

1.34 UV STERILIZER 0.09 1 0.09 1 0.8 0.1 0.01 1 0.8 0.1 0.01 0 0.8 1.0 0.00

2 AIR COND., VENT.& REFRIGERATION

2.1 AIR CONDITION POWER CONSUMPTION 253.00 1 253.00 1 0.8 0.8 161.92 1 0.8 0.8 161.92 0 0.8 0.2 0.00

Vendor: As per the latest data from Rapid marine

58

MECHANICAL VENTILATION FOR

2.2 29.00 1 29.00 1 0.8 0.8 18.56 1 0.8 1.0 15.00 0 0.8 1.0 0.00

MACHINERY/ACCOMMODATION

BELOW MAIN DECK MACH. RM. VENT. FAN PANEL,

2.3 15.00 1 15.00 1 0.8 0.8 9.60 1 0.8 1.0 15.00 1 0.8 1.0 12.00

ENGINE RM. EX. FAN

T1

2.4 EMERGENCY POWER FOR COMM. ROOM 40.30 1 40.30 1 0.8 1.0 32.24 1 0.8 1.0 32.24 1 0.8 1.0 32.24

2.5 CHILLER AND FREEZER POWER CONSUMPTION 14.50 1 14.50 1 0.8 0.9 10.44 1 0.8 0.9 10.44 0 0.8 0.2 0.00

3 DECK MACHINERY

Power requirement

3.1 DECK CRANE 45.00 1 45.00 0 0.8 0.5 0.00 1 0.8 0.3 10.80 0 0.8 0.2 0.00

of 8MT crane has already been accounted.

3.2 GANG WAY LADDER MOTOR 4.00 1 4.00 1 0.8 0.1 0.32 1 0.8 0.1 0.32 1 0.8 1.0 3.04

Arion

ef

3.3 LIFE BOAT DAVIT CRANE-1 15.00 1 15.00 1 0.8 0.1 1.20 1 0.8 0.2 2.40 0 0.8 1.0 0.00

Vangauard life boat

3.4 LIFE BOAT DAVIT CRANE-2 22.50 1 22.50 1 0.8 0.1 1.80 1 0.8 0.2 3.60 0 0.8 1.0 0.00

Vangauard life boat

4 DOMESTIC EQUIPMENTS

rR

4.1 PLANETARY MIXER,5 LITRES 0.45 1 0.45 0 0.8 0.3 0.00 1 0.8 0.3 0.11 0 0.8 0.2 0.00

4.2 FRY TOP WITH OPEN BASE 8.40 1 8.40 0 0.8 0.3 0.00 1 0.8 0.5 3.36 0 0.8 0.2 0.00

4.3 RANGES 16.40 1 16.40 0 0.8 0.3 0.00 1 0.8 0.5 6.56 0 0.8 0.2 0.00

4.4 ELECTRIC GYROS GRILL GR60E 5.80 1 5.80 0 0.8 0.3 0.00 1 0.8 0.3 1.39 0 0.8 0.2 0.00

4.5 MINI COMBI OVEN,PLUG & COOK 2.30 1 2.30 1 0.8 0.5 0.92 1 0.8 0.5 0.92 0 0.8 0.2 0.00

tte

4.6 DISH WASHER EUCIM (WT38M) 6.85 1 6.85 1 0.8 0.5 2.74 1 0.8 0.5 2.74 0 0.8 0.2 0.00

4.7 ICE CUBE MACHINE (ACM) 0.20 1 0.20 0 0.8 0.5 0.00 1 0.8 0.8 0.13 0 0.8 0.2 0.00

4.8 HOT CUPBOARD,FLAT TOP TYPE/BAIN MARIE 1.95 1 1.95 0 0.8 0.5 0.00 1 0.8 0.5 0.78 0 0.8 0.2 0.00

Le

4.9 REFRIGERATED COUNTERS 0.60 1 0.60 0 0.8 0.5 0.00 1 0.8 0.8 0.38 0 0.8 0.2 0.00

4.10 REFRIGERATOR 0.16 1 0.16 0 0.8 0.5 0.00 1 0.8 0.8 0.10 0 0.8 0.2 0.00

4.11 FREEZER,400 LITRES 0.53 1 0.53 0 0.8 0.5 0.00 1 0.8 0.8 0.34 0 0.8 0.2 0.00

4.12 FOOD WASTE DISPOSERS,500 SERIES 0.75 1 0.75 0 0.8 0.5 0.00 1 0.8 0.5 0.30 0 0.8 0.2 0.00

4.13 ELECTRIC TEA PORT 2.00 1 2.00 0 0.8 0.5 0.00 1 0.8 0.9 1.44 0 0.8 0.2 0.00

4.14 TOASTER 3.30 1 3.30 0 0.8 0.5 0.00 1 0.8 0.5 1.32 0 0.8 0.2 0.00

4.15 COFFEE MACHINE MTE/ATE,DATE 2.30 1 2.30 0 0.8 0.5 0.00 1 0.8 0.5 0.92 0 0.8 0.2 0.00

or

4.16 MICROWAVE OVEN (MWP1060-30M) 1.60 1 1.60 0 0.8 0.5 0.00 1 0.8 0.5 0.64 0 0.8 0.2 0.00

4.17 HAND STEAM IRON (GC2960) 2.20 1 2.20 0 0.8 0.5 0.00 1 0.8 0.9 1.58 0 0.8 0.2 0.00

4.18 WASHER EXTRACTOR,W555H 3.80 3 11.40 0 0.8 0.5 0.00 2 0.8 0.9 5.47 0 0.8 0.2 0.00

ap

4.19 TUMBLE DRYERS (T5130) 5.10 3 15.30 0 0.8 0.5 0.00 2 0.8 0.9 7.34 0 0.8 0.2 0.00

4.20 240V LIGHTING POWER CONSUMPTION 45.00 1 45.00 1 0.9 1.0 40.50 1 0.9 1.0 40.50 0 0.8 0.2 0.00

240V LIGHTING POWER CONSUMPTION Refer Dwg no. KU1201A-EL644DI02 &

4.21 9.26 1 9.26 1 1 1.0 9.26 1 1 1.0 9.26 1.0 1.0 1.0 8.80

[EMERGENCY]

KU1201A-EL648DI02 (Emergecy Lightings)

ng

Refer Dwg no. KU1201A-EP618DI02 (1. Navigation Lights &

Signal 2. Marking of Offshore Structure 3. Internal

4.22 * MCO POWER DB PANEL 7.28 1 7.28 1 0.9 1.0 6.55 1 0.9 1.0 6.55 1.0 1.0 1.0 7.28

Communication Syste 4. Public Address System 5. Fire & Gas

Alarm System 6. Emergency Signals)

GFGI -GOVERNMENT FURNISHED GOVERNMENT

Si

4.23 80.00 80.00

As mentioned by the client TOA

INSTALLED

The Contingency has been considered in case there is any

4.24 CONTINGENCY 35.00 35.00

change of vendor equipment and subjected to approval of

packages submitted by AHI to TOA/USACE

TOTAL KW 1394.8 614.8 611.7

176.2

SUMMARY TABLE

PROPOSED THE MAIN GENERATOR #1 CAPACITY 825 KW

AB

PROPOSED THE MAIN GENERATOR #2 CAPACITY 825 KW

PROPOSED THE MAIN EMERGENCY GENERATOR 225 KW

ELEVATING HULL ELEVATED HULL

EMERGENCY OPERATION

TOTAL REQUIRED POWER 614.8 611.7

176.2

NUMBER OF GENERATOR IN OPERATION 2 1

1

AVAILABLE POWER 1650.0 825.0

225.0

% OF LOADING ON GENERATOR 37.3 74.2

78.3

NOTE : A. LOAD KW= NO.OF SETS X LOAD FACTOR X DIVERSITY FACTOR B. PERCENTAGE % OF LOADING GENERATOR=TOTAL REQUIRED POWER /AVAILABLE POWER REV E 12/11/2016

THIS IS A FINAL LOAD ANALYSIS AS OF 7th Sep. 2016. ALL THE MACHINERY AND EQUIPMENT HAVE BEEN SELECTED TO SUIT THE MTCC PROJECT AND ABS CLASS REQUIREMENTS

Se

* INDICATES - EQUIPMENT STILL UNDER FINALIZATION.

Potrebbero piacerti anche

- MCCB Selection: SL No. Load in KW Load in KW With 25% Standard MCCBDocumento2 pagineMCCB Selection: SL No. Load in KW Load in KW With 25% Standard MCCBshaikhsajid242Nessuna valutazione finora

- Work Load AnalysisDocumento5 pagineWork Load Analysisduong phanNessuna valutazione finora

- Shaft BBT Installation: Method Statement - 002Documento39 pagineShaft BBT Installation: Method Statement - 002Sufiyan KhedekarNessuna valutazione finora

- Load Distribution ScheduleDocumento6 pagineLoad Distribution Schedulejimmy_barredoNessuna valutazione finora

- Technical Stuff For Power Plant EngineerDocumento113 pagineTechnical Stuff For Power Plant EngineerPopescu Andrei-MihaiNessuna valutazione finora

- Satto Sinha Subject Matter ExpertDocumento3 pagineSatto Sinha Subject Matter ExpertSatto SinhaNessuna valutazione finora

- Cable sizing tables for PVC and XLPE insulated conductorsDocumento3 pagineCable sizing tables for PVC and XLPE insulated conductorsLucky MalihanNessuna valutazione finora

- ICC Yard - Rathmalana-Model PDFDocumento1 paginaICC Yard - Rathmalana-Model PDFsajeevi piumikaNessuna valutazione finora

- Project 22-EPM-QT-063 Electrical Panel DetailDocumento3 pagineProject 22-EPM-QT-063 Electrical Panel DetailRichardLemusNessuna valutazione finora

- Bar Chart S CurveDocumento2 pagineBar Chart S Curvejaphet ontongNessuna valutazione finora

- PEPDocumento46 paginePEPKatherine AquinoNessuna valutazione finora

- Relevant Electrical Standards: Issue 2 October 2014Documento8 pagineRelevant Electrical Standards: Issue 2 October 2014zabiruddin786Nessuna valutazione finora

- EDL Monitoring Tanki HSD 6x5.000m3 FINAL (W4 Agustus) 30 AUGDocumento13 pagineEDL Monitoring Tanki HSD 6x5.000m3 FINAL (W4 Agustus) 30 AUGadiNessuna valutazione finora

- Load ScheduleDocumento18 pagineLoad SchedulevijayNessuna valutazione finora

- Daily Progress ReportDocumento1 paginaDaily Progress ReportPrabu BaskaranNessuna valutazione finora

- MS - Fire Alarm SytemDocumento11 pagineMS - Fire Alarm Sytemarun kurlanNessuna valutazione finora

- Capacitor Bank Calculation: All DubaiDocumento6 pagineCapacitor Bank Calculation: All Dubaishaikhsajid242Nessuna valutazione finora

- Entertainment Executive Assistant in NYC Resume Amanda GordonDocumento2 pagineEntertainment Executive Assistant in NYC Resume Amanda GordonAmandaGordon2100% (1)

- SAP FICO Consultant with 2+ Years ExperienceDocumento6 pagineSAP FICO Consultant with 2+ Years ExperienceriteshNessuna valutazione finora

- CS Employee Qualification Improvement ProgramDocumento3 pagineCS Employee Qualification Improvement ProgramAnonymous voA5Tb0Nessuna valutazione finora

- Sep Mgse DC Pro 0001 3Documento22 pagineSep Mgse DC Pro 0001 3guoNessuna valutazione finora

- Excel Gantt Chart Template TeamGanttDocumento19 pagineExcel Gantt Chart Template TeamGanttkurniawananNessuna valutazione finora

- List of BTS Site Punch PointsDocumento4 pagineList of BTS Site Punch PointsDiwakar MishraNessuna valutazione finora

- Approved Vendor ListDocumento1 paginaApproved Vendor ListSumit TyagiNessuna valutazione finora

- TasergantchartDocumento17 pagineTasergantchartapi-445387927Nessuna valutazione finora

- Gantt ChartDocumento6 pagineGantt ChartNathanLaertePiaiNessuna valutazione finora

- DC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525Documento1 paginaDC Motor With Permanent Magnet: PG 4520 PG 4520 PG 4525 PG 4525NewsUPdateNessuna valutazione finora

- UKPN G81 Design Planning Appendix v1.0 KK 040711Documento20 pagineUKPN G81 Design Planning Appendix v1.0 KK 040711Sandeep LallNessuna valutazione finora

- Yes Items Instrument Oil and GasDocumento3 pagineYes Items Instrument Oil and GasSheraz TariqNessuna valutazione finora

- 20150525-Camp ServicesDocumento16 pagine20150525-Camp ServicesSuresh KumarNessuna valutazione finora

- Emergency D.G. Sizing 16.11.07Documento3 pagineEmergency D.G. Sizing 16.11.07mahesh_sali2003Nessuna valutazione finora

- K321-05041 A2 - Electrical Load AnalysisDocumento4 pagineK321-05041 A2 - Electrical Load AnalysisJerome EugeneNessuna valutazione finora

- Alveolate Motor: SpecificationsDocumento1 paginaAlveolate Motor: Specificationssieged_rj3165Nessuna valutazione finora

- Bid Form - Trees - T3 - Electrical and Auxiliary WorksDocumento1 paginaBid Form - Trees - T3 - Electrical and Auxiliary WorksMike AdvinculaNessuna valutazione finora

- Electrical Load Requirements for 36M Catamaran FerryDocumento11 pagineElectrical Load Requirements for 36M Catamaran FerryVECTOR MARINE & OFFSHORE TECHNOLOGYNessuna valutazione finora

- CTG FCBN 51b 081810 Bom r0 1Documento3 pagineCTG FCBN 51b 081810 Bom r0 1Juca o PegadoNessuna valutazione finora

- CALCULATED EXTERNAL STATIC PRESSURE FOR FAN FAHU-1Documento1 paginaCALCULATED EXTERNAL STATIC PRESSURE FOR FAN FAHU-1melvinNessuna valutazione finora

- Booster Pump SizingDocumento1 paginaBooster Pump SizingjibinNessuna valutazione finora

- Fisher Valve Flow Calculations for 4 Inch and 2 Inch ValvesDocumento3 pagineFisher Valve Flow Calculations for 4 Inch and 2 Inch ValvesBesan LaduNessuna valutazione finora

- Landscape Hydraulic Calculation (DN50 Pipe)Documento1 paginaLandscape Hydraulic Calculation (DN50 Pipe)halem hafidzNessuna valutazione finora

- Koolwal MATERIALDocumento2 pagineKoolwal MATERIALSunil KoolwalNessuna valutazione finora

- Ases NZ 007 001Documento1 paginaAses NZ 007 001SantoshKumarNessuna valutazione finora

- Perhitungan Skedul BebanDocumento41 paginePerhitungan Skedul BebanAlif LintangNessuna valutazione finora

- EBARA Dry Vacuum PumpsDocumento8 pagineEBARA Dry Vacuum PumpsAlexandroNessuna valutazione finora

- Weekly Progress 30Documento114 pagineWeekly Progress 30Taufik HeruNessuna valutazione finora

- Reverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018Documento3 pagineReverse Osmosis System Analysis For Filmtec™ Membranes Rosa 9.1 Configdb U399339 - 282 Project: Enerau - Hydro Case: 1 NP, MFT 10/25/2018unconformistNessuna valutazione finora

- Hanyoung Limit SwitchDocumento3 pagineHanyoung Limit Switchfrans yama putraNessuna valutazione finora

- Eccentric FootingDocumento1 paginaEccentric FootingGravity SuperNessuna valutazione finora

- KEI W F List Price 12th Dec 2020Documento2 pagineKEI W F List Price 12th Dec 2020Prateek Agarwal100% (1)

- KEI W&F List Price - 22nd Jun 2021Documento2 pagineKEI W&F List Price - 22nd Jun 2021SUSOVAN BISWASNessuna valutazione finora

- Solar Off-Grid Design ExcelDocumento3 pagineSolar Off-Grid Design Excelmurugaraj50% (2)

- Estimated Electrical Power Requirement for Office Project in Pasar Kemis, TangerangDocumento1 paginaEstimated Electrical Power Requirement for Office Project in Pasar Kemis, Tangerangyahya nurhidayatNessuna valutazione finora

- 1201-996 Ayer Tawar Packing ListDocumento1 pagina1201-996 Ayer Tawar Packing ListMuhammad FirdausNessuna valutazione finora

- San Fernando La Union City Document Lists Parts and PricesDocumento126 pagineSan Fernando La Union City Document Lists Parts and PricesLoremar Ellen Dacumos HalogNessuna valutazione finora

- Raw Sales Plan Dec'22 - R3Documento1 paginaRaw Sales Plan Dec'22 - R3Gokulnath Kongunadu SingamNessuna valutazione finora

- Analysis Report - Tower 62 Tbi 3Documento72 pagineAnalysis Report - Tower 62 Tbi 3Muhammad AmarNessuna valutazione finora

- Price List: 28 February 2022 LP NO. KEI/W&F/LP/21-22/07 DT.28.02.2022 Industrial Multi Strand Cables HSN CODE: 85.44.60.20Documento2 paginePrice List: 28 February 2022 LP NO. KEI/W&F/LP/21-22/07 DT.28.02.2022 Industrial Multi Strand Cables HSN CODE: 85.44.60.20anirban 007Nessuna valutazione finora

- PL Dab 2021Documento1 paginaPL Dab 2021Anggara PangestuNessuna valutazione finora

- Vmot-H53-300-02 - 230vac - Lighting Load ChartDocumento4 pagineVmot-H53-300-02 - 230vac - Lighting Load ChartVECTOR MARINE & OFFSHORE TECHNOLOGYNessuna valutazione finora

- P0420 Pulse Datasheet 8366683Documento2 pagineP0420 Pulse Datasheet 8366683Moazzam KhalilNessuna valutazione finora

- Build buyer-centric LinkedIn profile focused on prospects' achievementsDocumento1 paginaBuild buyer-centric LinkedIn profile focused on prospects' achievementsKaustabha DasNessuna valutazione finora

- Self Declaration Form Details For International Arriving PassengersDocumento2 pagineSelf Declaration Form Details For International Arriving PassengersCris BrownNessuna valutazione finora

- Paper Title: A. Unknown B. UnknownDocumento2 paginePaper Title: A. Unknown B. UnknownKaustabha DasNessuna valutazione finora

- Cover LetterDocumento1 paginaCover LetterKaustabha DasNessuna valutazione finora

- Tuolima Catalog (New)Documento95 pagineTuolima Catalog (New)Kaustabha DasNessuna valutazione finora

- Kolkata To Dubai TicketDocumento1 paginaKolkata To Dubai TicketKaustabha DasNessuna valutazione finora

- DEI ICT ODL - Alumni Meet 2022Documento1 paginaDEI ICT ODL - Alumni Meet 2022Kaustabha DasNessuna valutazione finora

- Defect Liability Period - Snag Observation FormDocumento1 paginaDefect Liability Period - Snag Observation FormKaustabha DasNessuna valutazione finora

- Vendor Prequalification FormDocumento3 pagineVendor Prequalification FormKaustabha DasNessuna valutazione finora

- DEWA BillDocumento3 pagineDEWA BillKaustabha Das100% (1)

- New Vacancies at Gulftek Arabia - Jan 2022: Apply To and Mention The PositionDocumento2 pagineNew Vacancies at Gulftek Arabia - Jan 2022: Apply To and Mention The PositionKaustabha DasNessuna valutazione finora

- Harris Pye Engineering: Packing ListDocumento2 pagineHarris Pye Engineering: Packing ListKaustabha DasNessuna valutazione finora

- Pay and Transfer - Hullor BBC PaymentDocumento2 paginePay and Transfer - Hullor BBC PaymentKaustabha DasNessuna valutazione finora

- Aakash PaymentDocumento1 paginaAakash PaymentKaustabha DasNessuna valutazione finora

- Letter To The Emirates Sky CargoDocumento1 paginaLetter To The Emirates Sky CargoKaustabha DasNessuna valutazione finora

- 1210 Lakeshore Tower JLT ReceiptDocumento1 pagina1210 Lakeshore Tower JLT ReceiptKaustabha DasNessuna valutazione finora

- Dn00046 GF Ex HP Stock Uk Hp-1001Documento2 pagineDn00046 GF Ex HP Stock Uk Hp-1001Kaustabha DasNessuna valutazione finora

- HP-ADM-00 Enquiry Request (Iss 06) Apr 2018 - DAR SALWADocumento1 paginaHP-ADM-00 Enquiry Request (Iss 06) Apr 2018 - DAR SALWAKaustabha DasNessuna valutazione finora

- Solar Panel Electric Energy Efficiency CalculationDocumento6 pagineSolar Panel Electric Energy Efficiency CalculationKaustabha DasNessuna valutazione finora

- Kaustabha Das: Kaustabha1985@gmail - Co M +971 - 527256298 Bloom Heights, Flat No - 703, Dubai, UAEDocumento1 paginaKaustabha Das: Kaustabha1985@gmail - Co M +971 - 527256298 Bloom Heights, Flat No - 703, Dubai, UAEKaustabha DasNessuna valutazione finora

- TOB - AUH - AlAin VisaDocumento1 paginaTOB - AUH - AlAin VisaKaustabha DasNessuna valutazione finora

- E&I Engineer (Schiedam) - NOV CareersDocumento5 pagineE&I Engineer (Schiedam) - NOV CareersKaustabha DasNessuna valutazione finora

- CV Johan KarlstrandDocumento6 pagineCV Johan KarlstrandKaustabha DasNessuna valutazione finora

- NIZWA LNG ENGINE SPECSDocumento3 pagineNIZWA LNG ENGINE SPECSKaustabha DasNessuna valutazione finora

- Electronic Reservation Slip IRCTC E Ticketing Service (Agent)Documento2 pagineElectronic Reservation Slip IRCTC E Ticketing Service (Agent)narayanaNessuna valutazione finora

- Dinesh. Kumanan: ObjectiveDocumento9 pagineDinesh. Kumanan: ObjectiveKaustabha DasNessuna valutazione finora

- Hawke Accessories NylonWasherDocumento1 paginaHawke Accessories NylonWasherKaustabha DasNessuna valutazione finora

- ComPact NSX - LV430391Documento3 pagineComPact NSX - LV430391Kaustabha DasNessuna valutazione finora

- Vehicle Registration No.: WB08G5438: Transport Department, Government of West Bengal, Saltlake ArtoDocumento3 pagineVehicle Registration No.: WB08G5438: Transport Department, Government of West Bengal, Saltlake ArtoKaustabha DasNessuna valutazione finora

- Penspen: Electrical Engineer / 11966Documento2 paginePenspen: Electrical Engineer / 11966Kaustabha DasNessuna valutazione finora

- Starch Digestion by Amylase Lab ReportDocumento10 pagineStarch Digestion by Amylase Lab Report햇님Nessuna valutazione finora

- Innovations in Teaching-Learning ProcessDocumento21 pagineInnovations in Teaching-Learning ProcessNova Rhea GarciaNessuna valutazione finora

- MICROHARDNESS TESTER HMV-2 - SeriesDocumento9 pagineMICROHARDNESS TESTER HMV-2 - SeriesRicoNessuna valutazione finora

- Doubles and Doppelgangers: Religious Meaning For The Young and OldDocumento12 pagineDoubles and Doppelgangers: Religious Meaning For The Young and Old0 1Nessuna valutazione finora

- 1888 Speth Ars Quatuor Coronatorum v1Documento280 pagine1888 Speth Ars Quatuor Coronatorum v1Paulo Sequeira Rebelo100% (2)

- FCC TechDocumento13 pagineFCC TechNguyen Thanh XuanNessuna valutazione finora

- UCO Reporter 2021, December Edition, November 26, 2021Documento40 pagineUCO Reporter 2021, December Edition, November 26, 2021ucopresident100% (2)

- FA Program BrochureDocumento25 pagineFA Program BrochureThandolwenkosi NyoniNessuna valutazione finora

- Understanding PersonalityDocumento318 pagineUnderstanding PersonalityRoxanna12100% (1)

- Unit 20: Where Is Sapa: 2.look, Read and CompleteDocumento4 pagineUnit 20: Where Is Sapa: 2.look, Read and CompleteNguyenThuyDungNessuna valutazione finora

- Folk Tales of Nepal - Karunakar Vaidya - Compressed PDFDocumento97 pagineFolk Tales of Nepal - Karunakar Vaidya - Compressed PDFSanyukta ShresthaNessuna valutazione finora

- Ar 318Documento88 pagineAr 318Jerime vidadNessuna valutazione finora

- CES Wrong Answer SummaryDocumento4 pagineCES Wrong Answer SummaryZorg UANessuna valutazione finora

- 100 Inspirational Quotes On LearningDocumento9 pagine100 Inspirational Quotes On LearningGlenn VillegasNessuna valutazione finora

- Excel Working Cost ProjectDocumento3 pagineExcel Working Cost ProjectMuhammad MuzammalNessuna valutazione finora

- Pines City Colleges: College of NursingDocumento2 paginePines City Colleges: College of NursingmagisasamundoNessuna valutazione finora

- The Sociopath's MantraDocumento2 pagineThe Sociopath's MantraStrategic ThinkerNessuna valutazione finora

- Pinto Pm2 Ch01Documento21 paginePinto Pm2 Ch01Mia KulalNessuna valutazione finora

- Marketing Case Study - MM1 (EPGPX02, GROUP-06)Documento5 pagineMarketing Case Study - MM1 (EPGPX02, GROUP-06)kaushal dhapareNessuna valutazione finora

- Is the Prime Minister Too Powerful in CanadaDocumento9 pagineIs the Prime Minister Too Powerful in CanadaBen YuNessuna valutazione finora

- Air India CpioDocumento5 pagineAir India CpioVicky GautamNessuna valutazione finora

- SMS Romantis Bhs Inggris Buat Pacar TercintaDocumento5 pagineSMS Romantis Bhs Inggris Buat Pacar TercintaAdnan MaruliNessuna valutazione finora

- Amgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 423Documento19 pagineAmgen Inc. v. F. Hoffmann-LaRoche LTD Et Al - Document No. 423Justia.comNessuna valutazione finora

- PPT ch01Documento45 paginePPT ch01Junel VeriNessuna valutazione finora

- Registration Form: Advancement in I.C.Engine and Vehicle System"Documento2 pagineRegistration Form: Advancement in I.C.Engine and Vehicle System"Weld TechNessuna valutazione finora

- AMSY-6 OpManDocumento149 pagineAMSY-6 OpManFernando Piñal MoctezumaNessuna valutazione finora

- Eng CBLDocumento2 pagineEng CBLMengTangNessuna valutazione finora

- IFM Goodweek Tires, Inc.Documento2 pagineIFM Goodweek Tires, Inc.Desalegn Baramo GENessuna valutazione finora

- Sweet Emotion: Bass Line ForDocumento2 pagineSweet Emotion: Bass Line ForJames Gale100% (1)