Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Laticrete 252 Ag Silver1

Caricato da

Aarish KhanDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Laticrete 252 Ag Silver1

Caricato da

Aarish KhanCopyright:

Formati disponibili

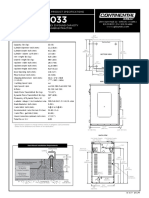

LATICRETE® 252 Ag SILVER

Thin-set Adhesive

• Exceeds ANSI A118.4 shear bond strength

requirements

• Complies to EN with a C2 E T classification

• Water and shock resistant.

Suitable Substrates

• Concrete • Concrete Masonry

• Cement Mortar Beds • Cement Plaster

• Tile and Stone • Brick Masonry

• Cement Backer Board** • Cement Terrazzo

• Exterior Grade Plywood*** • Gypsum Wallboard***

PRODUCT DESCRIPTION **Consult the backer board manufacturer’s data sheet for the

LATICRETE® 252 Ag Silver thinset adhesive is a multi-

specific recommendations.

purpose, polymer modified thinset powder offering vast

utility including applications on interior floor & wall as well ***Interior use only and when mixed with LATICRETE® 333

as limited exterior* floor & wall installations. It is a Super Flexible Latex admix.

cementitious thinset powder to be mixed only with water

to install various types of tiles & stone on variety of

substrates using thinset method of installation. Packaging – 5 kg & 20 kg bags

Application Colour: Grey and white

Designed especially for interior floor and wall as well as

limited exterior * floor and wall installations of all types of Coverage

ceramic tile, vitreous, semi-vitreous tile, porcelain, glass Approx 55-60 sft per 20kg bag with 1/4” x 1/4”

mosaic tiles, precast terrazzo, engineered stone and natural (6mm x 6mm) square notched trowel for a bed of 3mm.

stones over concrete and a variety of substrates. Good Coverage will vary depending on trowel notch size, type and size of tile and substrate

underwater shear bond allows this product to be used for

wet areas like swimming pools, sauna and wash rooms

Shelf Life

*Contact MYK LATICRETE technical services for exterior area applications Factory sealed bags of this product are guaranteed to be of first

quality for one (1) year* if stored off the ground in a dry area.

Advantages *High humidity will reduce the shelf life of bagged product.

• Single component, just add water

• High strength, polymer modified Limitations

•Not for use directly over particle board, luan, Masonite or

• Economical & Easy to use

hardwood floors.

• Bonds to various substrates •Not for use over VAT, VCT cutback, vinyl and plastic laminates.

•Use white mortar for white or light colored marble/stone.

•Adhesives/mastics, mortars and grouts for ceramic tile, pavers,

brick and stone are not designed as replacements for

waterproof membranes. When a waterproofing barrier is

required, use LATICRETE® Waterproofing Membrane. • Contains Portland cement and silica sand. May irritate eyes

• NOTE: Surfaces must be structurally sound, stable and and skin. Avoid contact with eyes or prolonged contact with

rigid enough to support tile/stone, thin brick and similar skin. In case of contact, flush thoroughly with water.

finishes. Substrate deflection under all live, dead and • Do not take internally. Silica sand may cause cancer or serious

impact loads, including concentrated loads, must not lung problems. Avoid breathing dust. Wear a respirator in dusty

exceed L/360 for thin bed ceramic tile/brick installations or areas.

L/480 for thin bed stone installations where L=span length. • Keep out of reach of children.

NOTE TO THE SPECIFIER AND INSTALLER: TECHNICAL DATA

Applicable Standard

• While installing tile/stone on the external walls ANSI A118.4-1999; EN 12004 & ISO 13007

and floors, we need to provide the movement

joints by creating spaces between the tiles/stones Performance Properties

and filling them up with LATICRETE® cement based LATICRETE® 252 Ag Silver Adhesive mixed with Water

grout mixed with L1776 grout admix plus or Test Test Method Results

silicone sealants.

• It is also important to note that the exterior tile /

stone installations are provided with joints Shear Bond, ANSI A118.4-1999; >300 psi

(spaces) on the periphery of the area without Porcelain Tile, F-5.2.4 (2.0 MPa)

allowing the tile / stone to be bound by the 28 day cure

peripheral masonry work or plaster. Shear Bond, ANSI A118.4-1999; >190 psi

• It is also important to note that the tiles/stones Porcelain Tile, F-5.2.3 (1.3 MPa)

are not installed directly on expansion joints. The Water

expansion joints need to be run through the tile / Immersion

Compressive ANSI A118.4-1999; >2750 psi

stone work till top surface and filled with materials

Strength F-6.1 (18.9 MPa)

which accommodate the movements.

• While installing tiles / stones on dry wall boards

Complies to EN & ISO standards: C2TE

like Gypsum wall boards, calcium silicate boards

and Cement backer boards, it is recommended to Working Properties at 70° F (21° C)

use LATICRETE® latex admix such as Laticrete 3642 LATICRETE 252 Ag Silver Adhesive mixed with Water

latex admix as a primer coat (should have been Open Time Approx 20 minutes

applied 8 to 10 hours before installation of tiles).

• No tile shall be installed on the joints of two

Pot Life Approx 4 hours

adjacent dry wall boards and the joint of two

boards shall be brought through to the top of the

tile / stone, which shall be filled with a silicone

Time to Heavy Traffic 16 - 24 hours

sealant / highly flexible joint filler to accommodate

the movements between the dry wall boards.

Specifications subject to change without notification. Results

Cautions

shown are typical but reflect test procedures used. Actual field

• During cold weather, protect finished work from traffic

performance will depend on installation methods and site

until fully cured.

• For installation of moisture sensitive stones and conditions.

engineered stones, please contact supplier / manufacturer

of stones for specific installation guidelines.

INSTALLATION all sheet ends must be supported by a framing member; glue

Surface Preparation sheets to joints with construction adhesive;

All surfaces should be between 40° F(4° C) and 90° F(32° C)

and structurally sound, clean and free of all dirt, oil, grease,

UNDERLAYMENT: 5/8” (15mm) thick exterior grade plywood

loose peeling paint, laitance, concrete sealers or curing

fastened 6” (150mm) o.c. along sheet ends and 8” (200mm) o.c.

compounds.

in the panel field (both directions) with 8d ring-shank, coated or

Rough or uneven concrete surfaces should be made smooth

hot dip galvanized nails (or screws); allow 1/8” (3mm) to ¼”

with LATICRETE® Latex Portland Cement underlayment to

(6mm) between sheets and ¼” (6mm) between sheet edges and

provide a wood float (or better) finish. Dry, dusty concrete

any abutting surfaces; offset underlayment joints from joints in

slabs or masonry should be dampened and excess water

subfloor and stagger joints between sheet ends; glue

swept off. Installation may be made on a damp surface.

underlayment to subfloor with construction adhesive.

New concrete slabs shall be damp cured and 28* days old

before application. *No minimum cure time for concrete Mixing

slabs when thin-set mortar is mixed with latex additive. All Place clean, potable water / LATICRETE® latex admix into a clean

slabs must be plumb and true to within ¼”(6mm) in 10 pail. Add LATICRETE® 252 powder into the pail. Use

ft(3m). Expansion joints shall be provided through the tile approximately 5 - 6L of water / LATICRETE® latex admix for 20 kg

work from all construction or expansion joints in the of powder.

substrate. Follow ANSI Specification AN-3.8 “Requirements Mix by hand or with a slow speed mixer to a smooth, trowelable

for Expansion Joints” or TCA Detail EJ171 “Expansion consistency. Allow adhesive to slake for 5-10 minutes. Adjust

Joints”. Do not cover expansion joints with mortar. Cement consistency if necessary. Remix and apply with the proper sized

Backer Board: follow TCA installation details W244. notched trowel.

* Contact MYK LATICRETE technical services for exterior

1. Installer must verify that deflection under all live, dead installations

and impact loads of interior plywood floors does not

exceed industry standards of L/360 for ceramic tile and Application

brick or L/480 for stone installations where L=span length;

a) Installation of Tile/Stone:

2. Minimum construction for interior plywood floors:

Apply adhesive to the substrate with the flat side of the trowel,

SUBFLOOR: 5/8” (15mm) thick exterior grade plywood, pressing firmly to work into surface. Comb on additional

either plain with all sheet edges blocked or tongue and adhesive with the notched side. Use the proper sized notched

groove, over bridged joints spaced 16” (400 mm) o.c. trowel to insure full bedding of the tile. Spread as much

maximum; fasten plywood 6” (150mm) o.c. along sheet adhesive as can be covered with tile in 10 minutes. Back butter

ends and 8” (200mm) large tiles (> 12”x12”) to provide full bedding and firm support.

o.c. along intermediate supports with 8d ring-shank, coated Place tiles into wet, sticky adhesive and beat in using a beating

or hot dip galvanized nails (or screws); allow 1/8” (3mm) block and rubber mallet to imbed tile and adjust level. Check

between sheet ends and ¼” (6mm) between sheets edges;

adhesive for complete coverage by periodically removing a Cold Weather Note: The setting of Portland cement adhesives

tile and inspecting bedding adhesive transfer onto back of and grouts are retarded by low temperatures. Protect finished

tile. work for an extended period when installing in cold weather.

If adhesive is skinned over (not sticky), remove and replace For faster setting adhesive use Xtrabond FSA 336, Fast Set

with fresh adhesive. adhesive OR LATICRETE® 73 (Rapid) Crete Admix with

LATICRETE® 111 Crete filler powder. Do not set tile when surface

b) Installation of Glass Mosaic tiles: temperature is below freezing or when substrate is frozen.

The LATICRETE®252 adhesive shall be applied to the surface Hot Weather Note: The evaporation of moisture in Portland

to be tiled with a notched trowel using a scraping motion to cement adhesives and grouts is accelerated by hot, dry

work the adhesive into good contact with the surface to be conditions. Apply to dampened surfaces and protect freshly

covered. Notch trowel with notches approximately 4mm is spread adhesive and finished work when installing in

recommended to get a bed thickness of 1.5-2mm. V-notch temperatures over 95°F (35°C).

of 3mm also can be used to get bed thickness of 1.5mm.

Apply only so much that can be covered with tile within 10- Cleaning

15 min or while the adhesive surface is still tacky. The Glass Clean tools and tile work with wet towel or wet sponge while

Mosaic tiles shall then be set in place and beaten gently adhesive is fresh.

with mallet or grouting float to insure 100% full bedding.

Tiles shall be aligned to achieve uniform joints and then AVAILABILITY AND COST

allowed to set until firm. Availability

The face of the sheets of front mounted glass mosaic tiles LATICRETE® and LATAPOXY® materials are available worldwide.

shall then be dampened and the face mount paper can be For distributor information:

removed. Telephone: +91-40-30413100

Excess adhesive must be cleaned from the surface of the FAX: +91-40-23378784

tile with a wet cloth or sponge while the adhesive is fresh E-mail: contact@myklaticrete.com

and has not hardened.

Grouting Cost

Grout installation shall be done after a minimum of 24 Contact a MYK LATICRETE® Distributor in your area.

hours curing time at 70°F (21° C). In case of LATICRETE®

latex admix mixed with adhesive, Grout installation shall be MAINTENANCE

done after a minimum of 48 hours of curing time at 70°F LATICRETE® and LATAPOXY® grouts require routine cleaning with

(21° C). Grout with LATICRETE® Sanded or Un-sanded Grout neutral pH soap and water or MYK LATICRETE Clenza series

suitable cleaners. All other LATICRETE® and LATAPOXY®

mixed with LATICRETE® 1776 Grout Admix Plus. For

materials require no maintenance but proper installation as per

maximum stain resistance of Internal applications, use instruction.

SpectraLOCK® Pro Premium Grout OR LATAPOXY SP-100 Performance and durability may depend on properly

Stainfree Grout. maintaining of Installed area.

WARRANTY

MYK LATICRETE India Pvt Ltd warrants that LATICRETE® 252

Ag Silver adhesive is free from manufacturing defects and

will not break down, deteriorate or disintegrate under

normal usage for a period of one (1) year from

manufacturing of the product subject to the terms and

conditions stated in MYK LATICRETE® Product Warranty.

TECHNICAL SERVICES

Technical assistance

Information is available by calling the MYK LATICRETE®

Technical Service at:

Telephone: +91-40-30413100

FAX: +91-40-23378784

E-mail: technicalservices@myklaticrete.com

MYK Laticrete India Pvt Ltd.

8-2-703/A, Fourth Floor, Leela Gopal Towers

Road No-12, Banjara Hills,

Hyderabad – 500034 (A.P)

Tel: +91-40--30413100

Fax: +91-40-23378784

E-mail: contact@myklaticrete.com

Website: www.myklaticrete.com

Potrebbero piacerti anche

- Laticrete 252 TDSDocumento5 pagineLaticrete 252 TDSDilon FernandoNessuna valutazione finora

- Laticrete 252 TDS 2 PDFDocumento5 pagineLaticrete 252 TDS 2 PDFvikash singh tomarNessuna valutazione finora

- LATICRETE® Xtrabond FSA 336: Thin-Set AdhesiveDocumento4 pagineLATICRETE® Xtrabond FSA 336: Thin-Set AdhesiveChaitanya IdateNessuna valutazione finora

- t05 t06 Extrofix Adhesive Efa Tds DownloadDocumento5 paginet05 t06 Extrofix Adhesive Efa Tds DownloadprakashnethaNessuna valutazione finora

- Anupam - Roff Tile Fixing Solutions 2018Documento62 pagineAnupam - Roff Tile Fixing Solutions 2018seemeshwariNessuna valutazione finora

- Weber Set Nova Stone Tile AdhesiveDocumento6 pagineWeber Set Nova Stone Tile AdhesiveArunKumar ChandrasekarNessuna valutazione finora

- Latafix 305: Floor and Wall Thin Set AdhesiveDocumento4 pagineLatafix 305: Floor and Wall Thin Set Adhesivesunitkghosh1Nessuna valutazione finora

- Weberset Plus White DatasheetDocumento6 pagineWeberset Plus White DatasheetAbxNessuna valutazione finora

- Datasheet weberset plus whiteDocumento6 pagineDatasheet weberset plus whitezuber shaikhNessuna valutazione finora

- T03 T04 VITROFIX ADHESIVE VFA TDS DownloadDocumento5 pagineT03 T04 VITROFIX ADHESIVE VFA TDS DownloadprakashnethaNessuna valutazione finora

- L 9237 WaterproofDocumento4 pagineL 9237 WaterproofAbdul Raheem SyedNessuna valutazione finora

- 317 TDSDocumento3 pagine317 TDSTomtom YabayabNessuna valutazione finora

- Ceramic Tile Mortar enDocumento4 pagineCeramic Tile Mortar enKeith GarridoNessuna valutazione finora

- Roff NEW CONSTRUCTION TILE ADHESIVE NCA TDS DownloadDocumento5 pagineRoff NEW CONSTRUCTION TILE ADHESIVE NCA TDS DownloadprakashnethaNessuna valutazione finora

- High polymer modified cementitious tile adhesiveDocumento3 pagineHigh polymer modified cementitious tile adhesiveAarish KhanNessuna valutazione finora

- Weberfix PU - DatasheetDocumento7 pagineWeberfix PU - DatasheetAnonymous PkvM83sNessuna valutazione finora

- L 310TDS 1Documento4 pagineL 310TDS 1Chetan MahajanNessuna valutazione finora

- Terrazzo and Chequered TileDocumento33 pagineTerrazzo and Chequered Tileshiza shekhNessuna valutazione finora

- Roff Non Skid Adhesive Nsa Tds DownloadDocumento5 pagineRoff Non Skid Adhesive Nsa Tds DownloadChetan MahajanNessuna valutazione finora

- 1 - 3000139 Mapelastic 315 enDocumento6 pagine1 - 3000139 Mapelastic 315 enSiti KhotimahNessuna valutazione finora

- Glass Tile Premium Thin-Set MortarDocumento5 pagineGlass Tile Premium Thin-Set Mortarmuti_khan20006003Nessuna valutazione finora

- High-Quality Tile Adhesives and GroutsDocumento4 pagineHigh-Quality Tile Adhesives and Groutsasiiiif04Nessuna valutazione finora

- Sika Davco k10 Plus Data SheetDocumento4 pagineSika Davco k10 Plus Data SheetJiang TerenceNessuna valutazione finora

- Sikaceram - 288 MyDocumento4 pagineSikaceram - 288 MyKenji TanNessuna valutazione finora

- Ceramic Tile Adhesive Guide for Internal & External UseDocumento2 pagineCeramic Tile Adhesive Guide for Internal & External UseNurhayati Muhamad NorNessuna valutazione finora

- VersaBond DS 5 - 08Documento3 pagineVersaBond DS 5 - 08cdubos1Nessuna valutazione finora

- Weberset Plus: A Standard-Setting Non-Slip Tile Adhesive For Low-Porosity Tiles and SubstratesDocumento2 pagineWeberset Plus: A Standard-Setting Non-Slip Tile Adhesive For Low-Porosity Tiles and SubstratesKhoa ChuNessuna valutazione finora

- Sikaceram 255 LargetileDocumento4 pagineSikaceram 255 LargetileanamikakahlatihaiNessuna valutazione finora

- Ultra Lites 2Documento4 pagineUltra Lites 2sanjayNessuna valutazione finora

- 14a Tile Adhesive Ultralite S2 - MAPEIDocumento15 pagine14a Tile Adhesive Ultralite S2 - MAPEIbasu0chapagainNessuna valutazione finora

- LDS6330 - LATAPOXY 300 AdhesiveDocumento4 pagineLDS6330 - LATAPOXY 300 AdhesiveanamikakahlatihaiNessuna valutazione finora

- Tiling 2022Documento4 pagineTiling 2022VR RajNessuna valutazione finora

- Type N Mortar MixDocumento2 pagineType N Mortar MixAnatoliy StepchinNessuna valutazione finora

- Professional Tile Adhesive & Grout Specification GuideDocumento44 pagineProfessional Tile Adhesive & Grout Specification GuideAl-Khreisat HomamNessuna valutazione finora

- Morta R: CE 225: Construction Materials and TestingDocumento61 pagineMorta R: CE 225: Construction Materials and TestingEdison SantosNessuna valutazione finora

- Recomendaciones GEODocumento11 pagineRecomendaciones GEOSocrates GebremedhinNessuna valutazione finora

- Vitra FixDocumento2 pagineVitra FixgoldenmediaNessuna valutazione finora

- Davco Dampfast Data Sheet PDFDocumento4 pagineDavco Dampfast Data Sheet PDFShanaei MiskinNessuna valutazione finora

- Sika PDS E SikaCeram - 250Documento4 pagineSika PDS E SikaCeram - 250lwin_oo2435Nessuna valutazione finora

- Successful PlasteringDocumento13 pagineSuccessful PlasteringCoulis UtaumireNessuna valutazione finora

- Levelquik® Rs (Rapid Setting) Self Leveling Underlayment: Surface Prep / Tds-108Documento5 pagineLevelquik® Rs (Rapid Setting) Self Leveling Underlayment: Surface Prep / Tds-108Alex TronNessuna valutazione finora

- Weberwall Premium PlasterDocumento5 pagineWeberwall Premium PlasterRahulNessuna valutazione finora

- Mapei PlanobondDocumento4 pagineMapei PlanobondSherif ShahinNessuna valutazione finora

- Roff Master Fix Adhesive Mfa Tds DownloadDocumento5 pagineRoff Master Fix Adhesive Mfa Tds DownloadsanjayNessuna valutazione finora

- Topic: Cementitious Grouts Assignment: 2 Done By: 18BCL023 18BCL025 Guided By: Prof. Vineet KothariDocumento10 pagineTopic: Cementitious Grouts Assignment: 2 Done By: 18BCL023 18BCL025 Guided By: Prof. Vineet KothariKaran DalalNessuna valutazione finora

- 31 Ultralite Rapid Flex s1 Uk NoRestrictionDocumento4 pagine31 Ultralite Rapid Flex s1 Uk NoRestrictionFloorkitNessuna valutazione finora

- Vinyl Composition Tile Adhesive: SuperiorDocumento2 pagineVinyl Composition Tile Adhesive: SuperiorRenzel EstebanNessuna valutazione finora

- Cerabond 27: High Performance Polymer Based Tile AdhesiveDocumento2 pagineCerabond 27: High Performance Polymer Based Tile AdhesiveBharat KoraleNessuna valutazione finora

- M40Documento6 pagineM40dandragutescuNessuna valutazione finora

- RCT-ConTile Bond SDocumento2 pagineRCT-ConTile Bond SfahadNessuna valutazione finora

- Building Materials and Construction Ii: 3 SemesterDocumento64 pagineBuilding Materials and Construction Ii: 3 Semesterajith100% (1)

- Floors, Plastering, Pointing and PaintingDocumento91 pagineFloors, Plastering, Pointing and PaintingLoser GamingNessuna valutazione finora

- Sikaceram - 88Documento3 pagineSikaceram - 88sensor_versionNessuna valutazione finora

- White Star Tile AdhesiveDocumento3 pagineWhite Star Tile AdhesiveDilon FernandoNessuna valutazione finora

- Specification, Cost Estimation and Budgeting: Assignment 1Documento11 pagineSpecification, Cost Estimation and Budgeting: Assignment 1Sid SharmaNessuna valutazione finora

- RCT-ConTile BondDocumento2 pagineRCT-ConTile BondfahadNessuna valutazione finora

- BAYSET-Sec5-Concrete-Repair ProductsDocumento30 pagineBAYSET-Sec5-Concrete-Repair ProductsALONSO GOMEZNessuna valutazione finora

- Mortar Mix - Coloured DatasheetDocumento3 pagineMortar Mix - Coloured DatasheetHIMANSHU SRIVASTAVANessuna valutazione finora

- DPCDocumento7 pagineDPCVenkat LakshmiNessuna valutazione finora

- Fresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoDa EverandFresco Painting - Modern Methods and Techniques for Painting in Fresco and SeccoNessuna valutazione finora

- Nitocote EP405: Solvent Free Epoxy Resin Coating For Potable Water Retaining StructuresDocumento3 pagineNitocote EP405: Solvent Free Epoxy Resin Coating For Potable Water Retaining Structuresrajiv_quantumNessuna valutazione finora

- Conbextra GP3: High Performance Cementitious GroutDocumento4 pagineConbextra GP3: High Performance Cementitious GroutAarish KhanNessuna valutazione finora

- Dispersion in Long Term Stock PerformanceDocumento18 pagineDispersion in Long Term Stock PerformanceAarish KhanNessuna valutazione finora

- Masteremaco S 346 v1Documento2 pagineMasteremaco S 346 v1Aarish KhanNessuna valutazione finora

- High polymer modified cementitious tile adhesiveDocumento3 pagineHigh polymer modified cementitious tile adhesiveAarish KhanNessuna valutazione finora

- Hack Aid Plast PDFDocumento2 pagineHack Aid Plast PDFAarish KhanNessuna valutazione finora

- Hack Aid Plast PDFDocumento2 pagineHack Aid Plast PDFAarish KhanNessuna valutazione finora

- Assignment 1 Solution April 2018Documento3 pagineAssignment 1 Solution April 2018subhansamuelsNessuna valutazione finora

- Thin Is inDocumento4 pagineThin Is inKiran Sr Sr.Nessuna valutazione finora

- Bill of Quantity Name of Work-Septic Tank (29'-0"x8'-0"x7'-0")Documento36 pagineBill of Quantity Name of Work-Septic Tank (29'-0"x8'-0"x7'-0")Khin Thu Zar HtayNessuna valutazione finora

- USDCM Volume 2 2016 PDFDocumento350 pagineUSDCM Volume 2 2016 PDFLinn Kyaw ZawNessuna valutazione finora

- Precast Reinforced Concrete Box Sections For Culverts, Storm Drains, and Sewers With Less Than 2 FT of Cover Subjected To Highway LoadingsDocumento8 paginePrecast Reinforced Concrete Box Sections For Culverts, Storm Drains, and Sewers With Less Than 2 FT of Cover Subjected To Highway LoadingsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Targuard PDFDocumento4 pagineTarguard PDFsofian juniardiNessuna valutazione finora

- Boq PreambleDocumento16 pagineBoq PreambleIzo Serem100% (2)

- Bridge Design - Sample QuestionsDocumento23 pagineBridge Design - Sample QuestionsSena KenaNessuna valutazione finora

- Bulk BOQUpload TemplateDocumento12 pagineBulk BOQUpload TemplatemargamvivekkumarNessuna valutazione finora

- Concrete Production: Sika Viscocrete Technology For Precast ConcreteDocumento4 pagineConcrete Production: Sika Viscocrete Technology For Precast ConcretesullamsNessuna valutazione finora

- Concrete Test Slump and StrengthDocumento2 pagineConcrete Test Slump and Strengthosbo1611Nessuna valutazione finora

- Scope of Work Material Unit I. Facilities: Group MembersDocumento5 pagineScope of Work Material Unit I. Facilities: Group MembersAganon AristotleNessuna valutazione finora

- On-Job-Training Activities and Outputs: Week 1Documento42 pagineOn-Job-Training Activities and Outputs: Week 1Jem Fulgencio Dela CruzNessuna valutazione finora

- M.E. Construction Engineering and Management 30.10.08revisedDocumento36 pagineM.E. Construction Engineering and Management 30.10.08revisedAparna AkhileshNessuna valutazione finora

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersDocumento15 pagineMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhNessuna valutazione finora

- Jaycocrete p6JDocumento3 pagineJaycocrete p6JVirah Sammy ChandraNessuna valutazione finora

- Precast Reinforced Concrete Manhole Sections: Standard Specification ForDocumento9 paginePrecast Reinforced Concrete Manhole Sections: Standard Specification ForEligio Antonio CerdaNessuna valutazione finora

- The Future of 3D Printing Technology in The Construction Industry: A Systematic Literature ReviewDocumento16 pagineThe Future of 3D Printing Technology in The Construction Industry: A Systematic Literature ReviewSamuel Coquilla Solis Jr.Nessuna valutazione finora

- Architectural/Mechanical Product Specifications: GirbauDocumento4 pagineArchitectural/Mechanical Product Specifications: GirbauLovely BautistaNessuna valutazione finora

- Quotation False Ceiling Works To Asam Phase-1 Residential Development at Yas Island, Abu Dhabi - U.a.E.Documento36 pagineQuotation False Ceiling Works To Asam Phase-1 Residential Development at Yas Island, Abu Dhabi - U.a.E.Øwięs MØhãmmedNessuna valutazione finora

- Determination of Length Change of Concrete Due To Alkali-Silica ReactionDocumento6 pagineDetermination of Length Change of Concrete Due To Alkali-Silica ReactionEvert RiveraNessuna valutazione finora

- Cemento Hidratado PDFDocumento16 pagineCemento Hidratado PDFChristianNessuna valutazione finora

- Design of FalseworkDocumento15 pagineDesign of FalseworkSarada DalaiNessuna valutazione finora

- Lattice Girder Composite Floors-199Documento2 pagineLattice Girder Composite Floors-199rahuldevpatel5Nessuna valutazione finora

- Out of Plane Seismic Behavior of Cast in Situ Composite W - 2020 - Engineering SDocumento15 pagineOut of Plane Seismic Behavior of Cast in Situ Composite W - 2020 - Engineering SAliNessuna valutazione finora

- NTT Om PDFDocumento24 pagineNTT Om PDFrpichoNessuna valutazione finora

- Lightweight Insulating Concrete For Floors and Roof DecksDocumento6 pagineLightweight Insulating Concrete For Floors and Roof DecksPeter BussellNessuna valutazione finora

- SpecificationsDocumento20 pagineSpecificationsJohn Dominic Delos ReyesNessuna valutazione finora

- Presentations FinalDocumento4 paginePresentations FinalwedjefdbenmcveNessuna valutazione finora

- BS en 206Documento7 pagineBS en 206amit_halcrow100% (1)