Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Effect of Injection Pattern On Neat Jatropha Oil Combustion in DI Diesel Engine

Caricato da

Bao-Phuc NguyenTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Effect of Injection Pattern On Neat Jatropha Oil Combustion in DI Diesel Engine

Caricato da

Bao-Phuc NguyenCopyright:

Formati disponibili

日本マリンエンジニアリング学会執筆要項

Effect

EffectofofInjection Pattern

Injection on Neat

Pattern onJatropha Oil Combustion

Neat Jatropha in

Oil Combustion in

Direct Injection

Direct DieselDiesel

Injection Engine*Engine*

Kim-Bao NGUYEN** Tomohisa DAN** Ichiro ASANO**

Kim-Bao NGUYEN, Tomohisa DAN, Ichiro ASANO**

The use of bio-fuels has attracted attention as a promising approach to reduce CO2. While many bio-fuels come from food

crops, Jatropha which is inedible has been the focus of interest recently. Jatropha oil has, however, high viscosity and low

volatility which would influence the emission characteristics and fuel consumption, especially in the low load engine

condition. Electrically controlled fuel injection seems to be effective to improve the combustion of such fuels. However, the

combustion characteristics of Jatropha fueled diesel engine with a fully electrically controlled fuel injection system which

can vary the injection pattern in a wide range have not been investigated. In this study, experimental research has been

conducted to investigate the effects of double injections with various injection timings, and amount of after-injection on the

combustion, engine performance, and emission characteristics in a high speed, 4-stroke diesel engine fueled with neat

Jatropha oil. Retarding main- and after-injection timings significantly reduced the peak combustion pressures and peak heat

release rate; slightly reduced ignition delay; and shifted the combustion to the later phase. Retarded double injection timings

reduced emissions of NOx, while increasing dust, smoke, CO, CO2, and HC. Large amounts of the fuel in after-injections

significantly reduced combustion pressures and rates of heat release at lower and medium loads. In addition, large amounts

of the fuel in after-injections reduced thermal efficiency and increased emissions of CO2, CO, smoke, and dust concentration,

while reducing HC and NOx emissions.

various non-edible vegetable oils [5]. Properties of Jatropha

1. Introduction oil compared with diesel are given in Table 1. Unlike other

common biofuel crops, it is easy to cultivate even on poor and

Recently, diesel engines have been faced with problems like arid soil conditions because it does not suffer excessively from

the fossil fuel crisis, and the more stringent criteria for NOx droughts or require concentrated irrigation. High viscosity,

and particulate regulated by governments the world over low volatility, and low cetane number of the Jatropha oil were

attempting to protect the air quality. Additionally, the reported in previous studies [6]. M. S. Kumar et al. [3]

production of global warming gas (CO2) is unavoidable observed higher smoke, HC, CO and NOx emissions of the

whatever the fuel when using diesel engines. To allay these engine operated with Jatropha oil. B. S. Chauhan et al. [7]

concerns, vegetable oils have gained attention as a promising reported that Jatropha oil lowered NOx and break thermal

alternative fuel for a greener future. Most vegetable oils are efficiency. While it produced higher smoke, CO, HC [7, 8]

capable of being used directly in existing diesel engines as when compared to diesel due to high viscosity and low

indicated in short-term tests. Unfortunately, long-term tests volatility. The drawbacks of Jatropha oil could be overcome

reported some issues such as piston ring sticking, injector by preheating [7] and/or blending with diesel [9, 10].

coking, engine deposits, gum formation and oil thickening as Bio-fuel was also investigated in marine diesel engine. When

a result of high viscosity and poor volatility of vegetable oils compared with those of marine fuels at high load conditions,

[1]. In the other hand, vegetable oils result in an increase in the emissions of CO, HC, PM, and smoke were reduced,

CO, HC and PM, but lower NOx emissions compared to

diesel oil [2-4]. Among vegetable oils, Jatropha has been of Table 1 Properties of test fuels [3]

interest because it is not a food source [3]. It was also Properties Diesel Jartropha

identified as a leading candidate for an alternative fuel among Density (kg/m )3

840 918.6

Viscosity (mm2/s) 4.59 49.93

*Received February 4, 2014 Cetane index 45-55 40-45

**Graduate school of Maritime Sciences, Kobe University Flash point (℃) 50 240

Journal of the JIME Vol.00,No.00(2005) -1-

Journal of the JIME Vol. 50, No. 3(2015) ― 93 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

369 JournalOil

Effect of Injection Pattern on Neat Jatropha of Combustion

the JIME in Direct Injection Diesel Engine

while it produced higher NOx, and vice versa at low load filters with the help of D-25 UP gas sampler and D-83AD gas

conditions [11, 12, 13]. The drawback of bio-fuel can be absorber (Oct Science).

overcome by blending with marine fuel or using assist The engine was fed with the neat Jatropha oil at room

injection system [13]. temperature and the data was recorded at each setting power

Advanced injection timing increases the peak pressure of 3.0 kW, 4.5 kW, and 6.0 kW with a speed of 2000 rpm. In

resulting in increase of NOx, and reduction of HC, CO, and this study, we tested double injections with various timings of

smoke as reported previously [14, 15]. This is consequence of main- and after-injection those given in Table 3, and various

more available time for oxidation process. Conversely, after-injection quantities those given in Table 4. It is

retarded injection timing shifts the combustion to the later emphasized that interval between injections was kept constant

phase, lowers peak of pressure, and shortens resident time of at lower loads (3.0 and 4.5 kW). Perhaps, at 6.0 kW, affected

high temperature, results in reduction of NOx emissions. by main-injection, thus after-injections occurred later. A

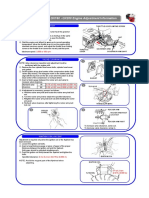

Multiple injections are reported to be successful in reducing schematic diagram of the experimental setup is illustrated in

NOx emissions due to the cooling effect of the second Fig. 1. Gas emissions were read from the analyzers. While,

injection [16], lower peak pressures, and lower peak of heat dust was captured on paper filters from 10 liters of exhaust gas,

release rate [17], or lower combustion temperatures and and was analyzed into soluble organic fraction (SOF) and in-

resident time of high temperatures [18]. L.D.K. Nguyen [16] soluble organic fraction (ISF).

reported that reduction of soot was due to reduced precursor

formation and increased soot oxidation in split injection. 3. Results and discussion

From this one might surmise that multiple injections may

reduce NOx and particulate of a diesel engine fueled with 3.1 Effect of injection timing

Jatropha oil. However, this test has not been tried to the best 3.1.1 Combustion and performance characteristics

of our knowledge. Our experimental research was conducted In-cylinder pressure is indicated in Fig. 2. The pressure data

to remedy this. The objective of this study is to reduce both was collected in 4 times at each step, and we checked their

NOx emissions and dust by changing injection pattern. We consistency during experiments. After finding their

studied experimentally the effect of double injection timings

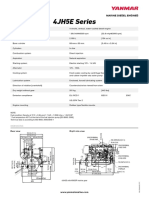

in term of main- and after-injection, and amount of after- Table 2 Specification of test engine

injection on the combustion, performance, and emissions of a Model YANMAR NFD 13-ME

Engine type Horizontal, single cylinder, four stroke

diesel engine fueled with neat Jatropha.

engine

Combustion type Direct injection

2. Experimental setup and procedures Bore × Stroke 92 × 96 mm

Displacement 0.638 liter

Experiments were conducted on a single cylinder, four-stroke, Compression ratio 17.7

high speed, direct injection diesel engine (Yanmar Co., Ltd., Rated output 8.1 kW @ 2400 rpm

Injection nozzle 4-hole nozzle

Japan). The specifications of the engine are given in Table 2.

Nozzle opening pressure 19MPa

An electronic injector of a modified common rail system is

connected to the engine’s mechanical injector used to inject Table 3 Set of injection timings

Power

the fuel into the combustion chamber. The in-cylinder Injection timings *

[kW]

pressure was measured using a piezoelectric pressure 3.0 m-15,a-2.5 m-13,a-0.5 m-11,a+1.5 m-9,a+3.5 m-7,a+5.5

transducer (Kistler) fitted into the engine cylinder. The signals 4.5 m-15,a-2.5 m-13,a-0.5 m-11,a+1.5 m-9,a+3.5 m-7,a+5.5

6.0 m-15,a+0.5 m-13,a+3.0 m-11,a+6.0 m-9,a+7.5 m-7,a+11

from the pressure transducer and the shaft encoder were

* m and a indicate for main- and after-injection, respectively

acquired and transmitted to a computer via a combustion

Table 4 Quantity of fuel in different injection patterns

analyzer (Yokogawa) for recording the in-cylinder pressure

Power Main injection After injection

Pattern

and crank angle. Load of the engine was set through an [kW] [mg/cycle] [mg/cycle]

electrical-dynamometer (Toyo Electric Co., Ltd.) coupled to 3.0

m-11,a+1.5-S 8.48 2.69

the shaft of the engine. A set of gas analyzers VIA-510, CLA- m-11,a+1.5-L 7.15 4.86

m-11,a+1.5-S 10.9 4.35

510SS (Horiba) was used to measure the emissions of CO2, 4.5

m-11,a+1.5-L 9.6 5.05

NOx, respectively, and along with MEXA-324J (Horiba) for m-11,a+6.0-S 17.8 3.15

measurement of CO, HC. Dust was collected on the paper 6.0

m-11,a+6.0-L 16.5 4.35

Journal of the JIME Vol.00,No.00(2005) -2-

Journal of the JIME Vol. 50, No. 3(2015) ― 94 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

Effect of Injection Pattern 日本マリンエンジニアリング学会執筆要項

on Neat Jatropha Oil Combustion in Direct Injection Diesel Engine 370

consistency, we selected one among the recorded data for 85

75 (a) m-15,a-2.5

Heat release rate [J/deg.]

analyzing. It can be seen that fast development of the pressures m-13,a-0.5

65

with advanced injection timings as a result of the accumulated m-11,a+1.5

55 m-9,a+3.5

fuel combusting near the top dead center (TDC). For late 45 m-7,a+5.5

injections, the peak pressures reduced substantially due to the 35

combustion occurred after the TDC. At 6.0 kW, the peak 25

15

pressures were lower than those of lower loads due to the fact

5

that second injection could be affected by first one. This -5 -15 0 15 30 45

increases residual gases as a role of internal exhaust gases Crank angle [deg.]

reducing the peak pressures. 85

75 (b) m-15,a-2.5

Heat release rate [J/deg.]

m-13,a-0.5

65 m-11,a+1.5

55 m-9,a+3.5

45 m-7,a+5.5

35

25

15

5

-5 -15 0 15 30 45

Crank angle [deg.]

85

75 (c) m-15,a-2.5

Heat release rate [J/deg.]

m-13,a-0.5

65 m-11,a+1.5

Fig. 1 Schematic diagram of experimental setup

55 m-9,a+3.5

45 m-7,a+5.5

(a) m-7,a+5.5 35

7

In-cy linder pressure [MPa]

m-9,a+3.5

m-11,a+1.5 25

6 m-13,a-0.5

m-15,a-2.5

15

5 5

4 -5 -15 0 15 30 45

3 Crank angle [deg.]

2

Fig. 3 Heat release rate with different double injection

-40 -20 0 20 40

Crank angle [deg.] timings at (a) 3.0 kW, (b) 4.5 kW, (c) 6.0 kW

(b) m-7,a+5.5

7 m-9,a+3.5

In-cy linder pressure [MPa]

6

m-11,a+1.5

m-13,a-0.5

Heat release rate (HRR) is shown in Fig. 3. At 3.0, 4.5, and 6.0

m-15,a-2.5

kW, the peaks of HRR reduced significantly when double

5

timings were retarded. It reduced from 60.2, 77 and 59.4 J/deg.

4

of m-15,a-2.5 to 44.2, 41.2, and 30.3 J/deg. of m-7,a+5.5 with

3

a relative reduction of 26.6, 46, and 48.9%, respectively. This

2

-40 -20 0 20

Crank angle [deg.]

40 can be attributed to less accumulated fuel during the ignition

(c) m-7,a+5.5

delay period as a result of the better combustion conditions

7

m-9,a+3.5

with later injection timings. Moreover, the cooling effect of

In-cy linder pressure [MPa]

m-11,a+1.5

6 m-13,a-0.5

m-15,a-2.5 second injection could also reduce the peak of HRR. In the

5

other hand, later double injection timings increased HRR at the

4 later combustion stages. When compared with lower loads, the

3 peaks of HRR at 6.0 kW were lower as a result of much more

2-40 internal exhaust gases with double injections.

-20 0 20 40

Crank angle [deg.]

Ignition delay (ID) is indicated in Fig. 4a. ID increased slightly

Fig. 2 In-cylinder pressure with different double injection when double timings were advanced as a result of worse

timings at (a) 3.0 kW, (b) 4.5 kW, (c) 6.0 kW combustion conditions with early injection timing when

compared with timing near the TDC. Slight reduction can be

Journal of the JIME Vo00, No. 00 -3- 日本マリンエンジニアリング学会誌 第 00 巻 第 00 号 (0000-00)

Journal of the JIME Vol. 50, No. 3(2015) ― 95 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

371 JournalOil

Effect of Injection Pattern on Neat Jatropha of Combustion

the JIME in Direct Injection Diesel Engine

observed at 4.5 kW when compared with those at 3.0 kW. This with m-7,a+5.5 at 3.0, 4.5, and 6.0 kW, respectively. Other

may resulted from the better conditions for combustion at double timings had a comparative or slight difference in

higher engine load. ID slightly increased again at 6.0 kW. This emissions of HC.

can be attributed to the rich fuel sprays at high load, and the NOx emissions are depicted in Fig. 5d. The emissions of NOx

imperfect gas exchange process. decreased with an increase in the engine power and with

Break thermal efficiency (BTE) is depicted in Fig. 4b. It was retarded double timings. Timings of m-7,a+5.5 considerably

higher for higher engine loads since the better combustion reduced NOx of 37.5, 35, and 35.3% when compared with m-

conditions. At 3.0 and 4.5 kW, for timings between m-9,a+3.5 11,a+1.5, while the reduction was 48, 50.7, and 46.7% when

and m-13,a-0.5, BTE were comparable at around of 21.3 and compared with m-13,a-0.5. The reduction of the NOx

26.4%, , respectively, while they were 20.2, and 24.3% for m- emissions with retarded double injections can be attributed to

7,a+5.5. At 6.0 kW, BTE reached to 26.5% for m-11,a+1.5, the reduction of peaks pressure and peaks HRR as result of less

while for m-7,a+5.5 and m-15, a-2.5, they were 23.5 and 25%, accumulated fuel in delay period, and the cooling effect of

respectively. Late injection increases heat lost due to the late second injection.

combustion phase, while early injection develops negative Smoke is shown in Fig. 5e. Smoke increased substantially with

work before the TDC. Overall, the optimum timings were an increase in the engine power as result of rich combustion

between m-11,a+1.5 and m-13,a-0.5. conditions at higher loads. At higher loads, m-11,a+1.5 had a

slight reduction of 4.6, and 5% when compared with early or

3.1.2 Emission characteristics late injections. This is due to early and late injections needed

The emissions of the engine including CO2, CO, HC, NOx, much more fuel to offset the negative work, and heat loss,

smoke, dust, SOF, and ISF concentration are indicated in Fig. respectively.

5. Fig. 5a shows the reduction of CO2 with an increase in the Dust concentration is indicated in Fig. 5f. Dust concentration

power as a result of better combustion conditions at higher increased with an increase of the engine load. The main

loads. In comparison with m-7,a+5.5, it was observed a component of dust is ISF especially for higher loads. These

reduction of CO2 of 6.0 and 11.5% for m-11,a-1.5, while it was resulted from richer injection and higher combustion

6.9, 11.6% for m-13,a-0.5 at 4.5 kW and 6.0 kW, respectively. temperatures which enhanced ISF growth. The optimum

At 3.0 kW, m-13,a-0.5 had a reduction of 4.8%. This may timing for dust concentration was at m-11,a+1.5 or m-13,a-0.5

result from the better thermal efficiency at these timings. Early with a reduction of 30, and 18%.

or late injection lowers BTE resulting in an increase in fuel

1.4

injection, and increase in emission of CO2. m-7,a+5.5 m-9,a+3.5

1.2 (a)

m-11,a+1.5 m-13,a-0.5

CO emissions are shown in Fig. 5b. At 3.0 kW, there are small

Ignition delay [ms]

1.0 m-15,a-2.5

differences between emissions of CO with different timings 0.8

due to less injected fuel at low load. At 4.5 and 6.0 kW, 0.6

respectively, there is a sudden reduction of 66.4, 24.8% for m- 0.4

11,a+1.5, and 72.1, 18.4% for m-13,a-0.5 when compared 0.2

with m-7,a+5.5. At 6.0 kW, early or late injection induced high 0.0

3 4.5 6

emissions of CO due to the inferior combustion conditions, Engine power [kW]

and the shorten time for oxidation, respectively. In comparison 35

m-7,a+5.5 m-9,a+3.5

with 3.0 kW, except two early injection patterns, CO emissions 30 m-11,a+1.5 m-13,a-0.5 (b)

Thermal efficiency [%]

reduced at 4.5 kW due to not only better combustion m-15,a-2.5

25

conditions but also not rich enough fuel injection. 6.0 kW 20

produced the local rich fuel zone leading to high increment of 15

CO emissions. 10

Fig. 5c indicates HC emissions. When compared with 3.0 kW, 5

HC decreased at the engine power of 4.5 kW and increased 0

3.0 4.5 6.0

significantly at 6.0 kW. The former is due to the better Engine power [kW]

combustion conditions, the latter is consequence of local rich Fig. 4 (a) Ignition delay, and (b) break thermal efficiency with

fuel injections. The optimum timings were at m-13,a-0.5 at different double injection timings

which it had a reduction of 16.8, 8.6, and 14.3% in comparison

Journal of the JIME Vol.00,No.00(2005) -4-

Journal of the JIME Vol. 50, No. 3(2015) ― 96 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

Effect of Injection Pattern日本マリンエンジニアリング学会執筆要項

on Neat Jatropha Oil Combustion in Direct Injection Diesel Engine 372

1000 18

m-7,a+5.5 m-9,a+3.5 m-7,a+5.5 m-9,a+3.5

(a) m-11,a+1.5 m-13,a-0.5 16 (d) m-11,a+1.5 m-13,a-0.5

CO2 emissions [g/kWh]

800

NOx emissions [g/kWh]

m-15,a-2.5 14 m-15,a-2.5

12

600

10

8

400

6

200 4

2

0 0

3.0 4.5 6.0 3.0 4.5 6.0

Engine power [kW] Engine power [kW]

30 18

m-7,a+5.5 m-9,a+3.5 m-7,a+5.5 m-9,a+3.5

(b) 16 (e)

CO emissions [g/kWh]

25 m-11,a+1.5 m-13,a-0.5 m-11,a+1.5 m-13,a-0.5

14 m-15,a-2.5

m-15,a-2.5

20 12

Smoke [%]

10

15

8

10 6

4

5

2

0 0

3.0 4.5 6.0 3.0 4.5 6.0

Engine power [kW] Engine power [kW]

0.5 500

m-7,a+5.5 m-9,a+3.5

(c) 3.0 kW 4.5 kW 6.0 kW

0.4 m-11,a+1.5 m-13,a-0.5 400

HC emissions [g/kWh]

ISF

SOF, ISF [mg/m3]

m-15,a-2.5 (f)

300 SOF

0.3

200

0.2

100

0.1

0

0

3.0 4.5 6.0

Engine power [kW]

Injection pattern

Fig. 5 Exhaust emissions with different timings of main-injection and after-injection

3.2 Effect of amount of after-injection J/deg of m-11,a+1.5-L to 30.3, 34.2, and 49.4 J/deg. of m-

Timings of m-11,a+1.5 were tested with small and large 11,a+1.5-S at 3.0, 4.5, and 6.0 kW, respectively. These

amount of after-injection so-called m-11,a+1.5-S and m- reductions resulted from the reduction of peak pressures as

11,a+1.5-L those given in Table 4. illustrated in Fig. 7. Moreover, the peak HRR of m-11,a+1.5-

3.2.1 Combustion and performance characteristics S was near the TDC, while it was far from the TDC for m-

In-cylinder pressure is illustrated in Fig. 6. The peak pressures 11,a+1.5-L at lower loads. At 4.5 kW large enough amounts

were 6.1 and 6.3 MPa for m-11,a+1.5-S at 3.0 and 4.5 kW, of after-injections created second peak. At 6.0 kW,

while it dropped to 5.6 and 5.5 MPa for m-11,a+1.5-L with a comparable pressures resulted in comparable HRR.

relative reduction of 8.2 and 12.7%. At 6.0 kW they were Break thermal efficiency is indicated in Fig. 8. It is evident

comparable at around 6.3 MPa. At lower loads, the peak that m-11,a+1.5-L reduced BTE. This resulted from the lower

pressures significantly reduced for m-11,a+1.5L since they HRR and late combustion, thus much more heat lost when

were determined mainly by main-injections. Perhaps, at the piston moved toward the BDC. Conversely, less heat loss

lower loads, the differences in main-injections amounts could for m-11,a+1.5-S increased the BTE.

lead to this difference, but at 6.0 kW it could not make

difference due to the upper threshold of pressures at these 3.2.2 Emission characteristics

timings. CO2 emissions reduced particularly at higher loads when

HRR is shown in Fig. 7. Peaks of HRR had a reduction of using m-11,a+1.5-S with a relative reduction of 2.6, 7.0, and

32.8, 36.3, and 5.2% when dropped from 45, 53.6, and 52.6 11.1% for 3.0, 4.5, and 6.0 kW as shown in Fig. 9a. Lower

Journal of the JIME Vol.00,No.00(2005) -5-

Journal of the JIME Vol. 50, No. 3(2015) ― 97 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

373 Journal Oil

Effect of Injection Pattern on Neat Jatropha of the JIME

Combustion in Direct Injection Diesel Engine

65

specific fuel consumption as consequence of better BTE of m-11,a+1.5-S

55 (a)

Heat release rate [J/deg.]

m-11,a+1.5-S resulted in lower CO2. Conversely, more heat m-11,a+1.5-L

45

lost for m-11,a+1.5-L increased specific fuel consumption,

35

consequently increased CO2.

25

Fig. 9b indicates emissions of CO. There was a significant

15

reduction of CO of 50, 78, and 49% for m-11,a+1.5-S at 3.0,

4.5, and 6.0 kW. Moreover, for m-11,a+1.5-S, emissions of 5

CO decreased slightly at 4.5 kW before increasing at 6.0 kW -5 -15 0 15 30 45

Crank angle [deg.]

as result of better combustion conditions and not so rich 65

enough of fuel injection. At 6.0 kW, late combustion phase as 55 (b) m-11,a+1.5-S

Heat release rate [J/deg.]

a result of delayed after-injection along with the local rich fuel m-11,a+1.5-L

45

injection resulted in higher CO emissions. The phenomenon

35

is more conspicuous for m-11,a+1.5-L.

25

Fig. 9c shows higher HC emissions for m-11,a+1.5-S when

15

compared with m-11,a+1.5-L. The relative increment was

5

77.8% at 4.5 kW, while it increased 7.5-fold at 6.0 kW.

-5 -15 0 15 30 45

Crank angle [deg.]

7 (a) m-11,a+1.5-S

m-11,a+1.5-L 65

In-cy linder pressure [MPa]

(c) m-11,a+1.5-S

55

Heat release rate [J/deg.]

6

m-11,a+1.5-L

45

5

35

4 25

3

15

5

2

-40 -20 0 20 40 -5 -15 0 15 30 45

Crank angle [deg.] Crank angle [deg.]

m-11,a+1.5-S

Fig. 7 Heat release rate with different amounts of after-

7 (b)

m-11,a+1.5-L injection at (a) 4.5 kW, (b) 4.5 kW, (c) 6.0 kW

In-cy linder pressure [MPa]

6 35

m-11,a+1.5-S

30

Thermal efficiency [%]

5 m-11,a+1.5-L

25

4 20

3 15

10

2

-40 -20 0 20 40 5

Crank angle [deg.]

0

m-11,a+1.5-S 3.0 4.5 6.0

7 (c)

In-cy linder pressure [MPa]

m-11,a+1.5-L Engine power [kW]

6 Fig. 8 Thermal efficiency with different amounts of after-injection

5

HC increased with an increase of the engine power for m-

4 11,a+1.5-S, while it reduced with m-11,a+1.5-L. Perhaps,

3

more fuel in main-injection for m-11,a+1.5-S along with

main-injection near the TDC, the injection jets could impinge

2

-40 -20 0 20 40 the piston head, consequently resulted in higher HC.

Crank angle [deg.]

Conversely, the m-11,a+1.5-L reduced fuel impingement

Fig. 6 In-cylinder pressure with different amounts of after- when after-injection combusted very fast after injection,

injection at (a) 4.5 kW, (b) 4.5 kW, (c) 6.0 kW consequently, reduced emissions of HC.

Journal of the JIME Vol.00,No.00(2005) -6-

Journal of the JIME Vol. 50, No. 3(2015) ― 98 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

Effect of Injection Pattern日本マリンエンジニアリング学会執筆要項

on Neat Jatropha Oil Combustion in Direct Injection Diesel Engine 374

1000 18

m-11,a+1.5-S 16 (d)

(a) m-11,a+1.5-S

NOx emissions [g/kWh]

CO2 emissions [g/kWh]

800 m-11,a+1.5-L 14 m-11,a+1.5-L

12

600

10

8

400

6

200 4

2

0 0

3.0 4.5 6.0 3.0 4.5 6.0

Engine power [kW] Engine power [kW]

40 18

35 (b) m-11,a+1.5-S 16 (e)

CO emissions [g/kWh]

30 m-11,a+1.5-L 14 m-11,a+1.5-S

12 m-11,a+1.5-L

25

Smoke [%]

10

20

8

15 6

10 4

5 2

0 0

3.0 4.5 6.0 3.0 4.5 6.0

Engine power [kW] Engine power [kW]

0.4 600

(c) m-11,a+1.5-S 3.0 kW 4.5 kW 6.0 kW

500

HC emissions [g/kWh]

ISF

m-11,a+1.5-L

SOF, ISF [mg/m3]

0.3

400 (f) SOF

0.2 300

200

0.1 100

0

0

3.0 4.5 6.0

Engine power [kW]

Injection pattern

Fig. 9 Exhaust emissions with different amounts of after-injection

Emissions of NOx decreased with an increase of the engine due to the late combustion phase. When compared with m-

power as illustrated in Fig. 9d. For m-11,a+1.5-L, the 11,a+1.5-S, we observed a relative increment of 141, 104, and

reductions of NOx were observed of 40.2, 26.9, and 6.7% at 70% for m-11,a+1.5-L at 3.0, 4.5, 6.0 kW, respectively.

3.0, 4.5, and 6.0 kW. At lower loads, larger reduction in Concentration of SOF slightly decreased with load of the

emissions of NOx were observed for m-11,a+1.5-L as a result engine as consequence of better combustion condition.

of considerably suppressed of premixed combustion as

indicated obviously in the HRR graph. 4. Conclusions

Smoke is depicted in Fig. 9e. It increased with an increase in

the engine power and with m-11,a+1.5-L. For m-11,a+1.5-L, We studied the effects of double injection with various

smoke had a relative increment of 198.3, 54.3, and 34.3% timings of main-injection and after-injection, and amounts of

when compared to those of m-11,a+1.5-S at 3.0, 4.5, and 6.0 after-injection on the combustion, engine performance, and

kW. This resulted from the local rich injection at higher loads, emissions characteristics of a diesel engine fuelled with

and the late combustion phase of m-11,a+1.5-L as a result of Jatropha oil. In summary, the main features are as follows.

increased residual gas for m-11,a+1.5-L. 1. Effect of double injection timings

Fig. 9f shows dust concentration. It can be seen that dust and i. Retarded double timings significantly reduced the peaks

ISF concentration increased with an increase of the engine of combustion pressure, peaks of HRR, and shifted the

load, especially, for m-11,a+1.5-L. This resulted from the combustion to the later phase. Late double timings

higher fuel consumption, the shorten time for soot oxidation increased HRR at the later combustion stage.

Journal of the JIME Vo00, No. 00 -7- 日本マリンエンジニアリング学会誌 第 00 巻 第 00 号 (0000-00)

Journal of the JIME Vol. 50, No. 3(2015) ― 99 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

375 Journal Oil

Effect of Injection Pattern on Neat Jatropha of the JIME

Combustion in Direct Injection Diesel Engine

ii. There was slight reduction of ID for retarded double [8] J. N. Reddy and A. Ramesh, Renewable Energy, 31 (2006-10)

timings at low load; ID increased slightly at 6.0 kW due 1994-2016.

to imperfect gas exchange. Optimum double injection [9] B. S. Chauhan, N. Kumar, and H. M. Cho, Energy, 37 (2012-1),

timings for BTE were between m-11,a+1.5 and m-13,a- 616-622.

0.5. [10] M. Mofijur, H. H. Masjuki, M. A. Kalam, and A. E. Atabani,

iii. Emissions of CO2, CO, HC, Smoke and dust were lower Energy, 55 (2013-6), 879-887.

at timings between m-11,a+1.5 and m-13,a-0.5. Late [11] Z. Xu, S. Nishio, M. Ikame, E. Ishimura, and M. Kuwabara,

double timings significantly reduced emissions of NOx. Journal of the JIME, 46-1 (2011-1), 127-132.

Overall, the optimum injection timings for combustion, [12] S. Nishio, Z. Xu, M. Ikame, K. Harumi, K. Hirata, T. Kishi, T.

performance, and emissions were between m-11,a+1.5 Fukuda, T. Nagai, Journal of the JIME, 45-5 (2010-9), 120-127.

and m-13,a-0.5. [13] S. Nishio, Z. Xu, M. Ikame, A. Ohashi, M. Kuwabara, Journal

2. Timing of m-11,a+1.5 was tested with small and large of the JIME, 47-2 (2012-3), 110-117.

amounts of after-injection. We found a considerably influence [14] T. Ganapathy, R. P. Gakkhar, and K. Murugesan, Applied

to the combustion, performance and emissions. Energy, 88 (2011-12), 4376-4386.

i. Peaks of cylinder pressure and HRR were remarkably [15] C. Sayin and M. Gumus, Applied Thermal Engineering, 31

reduced with m-11,a+1.5-L at 3.0 and 4.5 kW. Otherwise, (2011-11), 3182-3188.

they were comparable at 6.0 kW with a minor reduction [16] L. D. K. Nguyen, N. W. Sung, S. S. Lee and H. S. Kim,

of peak HRR with m-11,a+1.5-L. International Journal of Automotive Technology, 12 (2011-5), 339-

ii. When compared with m-11,a+1.5-S, the injection pattern 350.

of m-11,a+1.5-L reduced BTE especially at higher engine [17] Y. Zhang and A. L. Boehman, Energy & Fuels, 21 (2007-5),

loads. 2003-2012.

iii. For m-11,a+1.5-S, reduction of emissions of CO2, CO, [18] D. Qi , M. Leick, Y. Liu, and C. F. Lee, Fuel, 90 (2011-5), 1884-

smoke and dust concentration was observed, while it 1891.

increased emissions of NOx, and HC.

Acknowledgement

We would like to acknowledge our Labo-members, Mr. Shota

Tanaka, Mr. Shingo Asa, Mr. Yasuhiro Nishimura, Mr. Naoto

Katayama, at the Internal Combustion Engineering

Laboratory, Faculty of Maritime Sciences, Kobe University

for their helps in conducting the experiments.

References

[1] R. Altn, S. Çetinkaya and H. S. Yücesu, Energy Conversion and

Management, 42 (2001-3), 529-538.

[2] N. Hemmerlein, V. Korte, H. Richter, and G. Schröder, SAE

Technical Paper 910848, (1991)

[3] M. S. Kumar, A. Ramesh, and B. Nagalingam, Biomass and

Bioenergy, 25 (2003-9), 309-318.

[4] A.S. Huzayyin, A.H. Bawady, M.A. Rady, and A. Dawood,

Energy Conversion and Management, 45 (2004-8), 2093-2112.

[5] S.-Y. No, Renewable and Sustainable Energy Reviews, 15 (2011-

1), 131-49.

[6] K. Pramanik, Renewable Energy, 28 (2003-2), 239-248.

[7] B. S. Chauhan, N. Kumar, Y. D. Jun, and K. B. Lee, Energy, 35

(2010-6), 2484~2492.

Journal of the JIME Vol.00,No.00(2005) -8-

Journal of the JIME Vol. 50, No. 3(2015) ― 100 ― 日本マリンエンジニアリング学会誌 第50巻 第 3 号(2015)

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Mitsubishi 6D31 6D31T 6D31C 6D31CT Engine Workshop Manual PDFDocumento230 pagineMitsubishi 6D31 6D31T 6D31C 6D31CT Engine Workshop Manual PDFRommy Spydergold100% (3)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Reciprocating Compressor Condition Monitoring - GEDocumento6 pagineReciprocating Compressor Condition Monitoring - GEBao-Phuc NguyenNessuna valutazione finora

- Reciprocating Compressor Condition Monitoring - GEDocumento6 pagineReciprocating Compressor Condition Monitoring - GEBao-Phuc NguyenNessuna valutazione finora

- Spark Plug Technical Training ManualDocumento40 pagineSpark Plug Technical Training ManualJustin LoweNessuna valutazione finora

- Ludeca-A Practical Guide To Shaft Alignment PDFDocumento0 pagineLudeca-A Practical Guide To Shaft Alignment PDFDelfinsh100% (1)

- Training CompresorDocumento18 pagineTraining Compresorpatrask0% (1)

- Marine Diesel Engines CatalogDocumento16 pagineMarine Diesel Engines CatalogDamian Cid MoralesNessuna valutazione finora

- Motocultivadores Diesel Kipor Kdt910ca Kdt910eDocumento25 pagineMotocultivadores Diesel Kipor Kdt910ca Kdt910eМарцис Гасунс100% (1)

- Fatigue Life Assessment of Boiler Components Under Cyclic Operating ConditionsDocumento11 pagineFatigue Life Assessment of Boiler Components Under Cyclic Operating ConditionsBao-Phuc NguyenNessuna valutazione finora

- Vibration Analysis Techniques For Gearbox Diagnostic: A ReviewDocumento10 pagineVibration Analysis Techniques For Gearbox Diagnostic: A ReviewBao-Phuc NguyenNessuna valutazione finora

- WAUKESHA Bearing - INTRODUCTION TO MaterialDocumento4 pagineWAUKESHA Bearing - INTRODUCTION TO MaterialBao-Phuc NguyenNessuna valutazione finora

- Condition Monitoring of Steam Turbines by Performance AnalysisDocumento12 pagineCondition Monitoring of Steam Turbines by Performance AnalysisBao-Phuc NguyenNessuna valutazione finora

- Aux. Boiler Mac Type: Level - Alarm and Fuel Oil CutDocumento5 pagineAux. Boiler Mac Type: Level - Alarm and Fuel Oil CutBao-Phuc NguyenNessuna valutazione finora

- ASTM Volume 05.04, March 2017 Petroleum Products, Liquid Fuels, and Lubricants (IV) : D6973-D7755Documento5 pagineASTM Volume 05.04, March 2017 Petroleum Products, Liquid Fuels, and Lubricants (IV) : D6973-D7755Cristian ValenzuelaNessuna valutazione finora

- ASTM Volume 05.04, March 2017 Petroleum Products, Liquid Fuels, and Lubricants (IV) : D6973-D7755Documento5 pagineASTM Volume 05.04, March 2017 Petroleum Products, Liquid Fuels, and Lubricants (IV) : D6973-D7755Cristian ValenzuelaNessuna valutazione finora

- 4-17.2 Variable Volume Clearance PocketsDocumento6 pagine4-17.2 Variable Volume Clearance PocketsBao-Phuc NguyenNessuna valutazione finora

- 1 Publication Bao@KMU2009Documento9 pagine1 Publication Bao@KMU2009Bao-Phuc NguyenNessuna valutazione finora

- AlhamdDocumento8 pagineAlhamdKhushnoodNessuna valutazione finora

- Air Standard Cycles-Otto, Diesel and Dual CycleDocumento42 pagineAir Standard Cycles-Otto, Diesel and Dual CycleVivek SharmaNessuna valutazione finora

- 0810 r16 Mech Viii Mec801 Dms Sample QBDocumento36 pagine0810 r16 Mech Viii Mec801 Dms Sample QBparvez khanNessuna valutazione finora

- Dpi Operating InstructionsDocumento46 pagineDpi Operating InstructionsNatane AlvesNessuna valutazione finora

- UNIT 1 Introduction To Tractors LFM AutosavedDocumento70 pagineUNIT 1 Introduction To Tractors LFM AutosavedPrisaca Rădășeni100% (1)

- HTTPS::WWW - Lsengineers.co - Uk:media:advice centre:GX160:GX160 Adjustment InformationDocumento1 paginaHTTPS::WWW - Lsengineers.co - Uk:media:advice centre:GX160:GX160 Adjustment InformationSady KanettiNessuna valutazione finora

- J Engine PDFDocumento128 pagineJ Engine PDFMohan CharanchathNessuna valutazione finora

- Generator 404D-22G ElectropaK PN1912Documento2 pagineGenerator 404D-22G ElectropaK PN1912Rizki Rangga DwipuraNessuna valutazione finora

- 002 - Brochure 2055g LightDocumento23 pagine002 - Brochure 2055g Lightmunawar786Nessuna valutazione finora

- Actual Fuel-Air Cycles PDFDocumento28 pagineActual Fuel-Air Cycles PDFanup chauhanNessuna valutazione finora

- Prime Movers in The Agricultural and Bio Production SystemsDocumento37 paginePrime Movers in The Agricultural and Bio Production SystemsMyla Jane CalabioNessuna valutazione finora

- History N Development ICEDocumento5 pagineHistory N Development ICEAneesh KumarNessuna valutazione finora

- AP Physics Heat and Thermodynamics Chapter 11 and 12Documento172 pagineAP Physics Heat and Thermodynamics Chapter 11 and 12Muhammad Sulthon SNessuna valutazione finora

- Yanmar-Datasheet 4JH5EDocumento2 pagineYanmar-Datasheet 4JH5EMuhammad rizkiNessuna valutazione finora

- Gen Set 30 KVA HA 494Documento20 pagineGen Set 30 KVA HA 494Pankaj TiwariNessuna valutazione finora

- Agricultural Mechanisatio1 (1) 1Documento122 pagineAgricultural Mechanisatio1 (1) 1joykulabaloNessuna valutazione finora

- Question Paper Code: X10699: (10×2 20 Marks)Documento3 pagineQuestion Paper Code: X10699: (10×2 20 Marks)Chatheriyan ThangarajuNessuna valutazione finora

- Diesel Engine Analysis Guide EPRIDocumento143 pagineDiesel Engine Analysis Guide EPRIAlfan RusdiansyahNessuna valutazione finora

- Me152l - Experiment 5 - AmahmudDocumento23 pagineMe152l - Experiment 5 - AmahmudAli Requiso MahmudNessuna valutazione finora

- Classification of Engines & Its ComponentsDocumento33 pagineClassification of Engines & Its ComponentsSunil DhankharNessuna valutazione finora

- The New Diesel Engine Book: Kees Kuiken Target Global Energy TrainingDocumento8 pagineThe New Diesel Engine Book: Kees Kuiken Target Global Energy Trainingwellington freitasNessuna valutazione finora

- EM II, 2 Engleza, PDFDocumento36 pagineEM II, 2 Engleza, PDFAndrei Minca100% (2)

- MCQ Practice Set 1Documento5 pagineMCQ Practice Set 1Amiteer KhelboNessuna valutazione finora

- Marine Diesel EngineDocumento5 pagineMarine Diesel Enginemy generalNessuna valutazione finora

- 2 StrokeDocumento8 pagine2 StrokeUsama AnsariNessuna valutazione finora