Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

F Performance Qualification Protocol

Caricato da

Mug ZiumbwaDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

F Performance Qualification Protocol

Caricato da

Mug ZiumbwaCopyright:

Formati disponibili

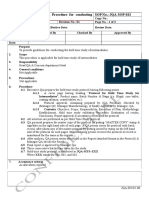

Document ID: F-0112

Title: PERFORMANCE QUALIFICATION PROTOCOL TEMPLATE Revision: A

This document is to be used as a template for generating Performance Qualification (PQ) protocols. As

such, use only the sections that are applicable to the equipment being qualified. Add sections which are

specific for the equipment being qualified, as needed. Use the attachments (report sheets) to report PQ

data and information. They can be amended to create forms that are directly relevant to the

documented activities. Remove all gray sections. “N/A” any section that is not applicable. Fill out the

header section. Remove these instructions.

1. PURPOSE

The purpose of this protocol is to establish a set of uniform steps to complete the performance

qualification (PQ) of the process validation for [Insert Product Name] for [Insert Company Name], in

accordance with the Validation Master Plan (XXXX).

2. PREREQUISITES

2.1. Component criticality assessment performed (prior to or as part of IQ)

2.2. Operational assessment performed (OQ)

2.3. Installation Qualification (IQ)

2.4. Roles and responsibilities should be defined

2.5. Training on PQ activities should be performed and documented

2.6. Validation Plan should be finalized

3. SCOPE

The objective of the Performance Qualification (PQ) is to establish, through documented testing,

that all critical components and equipment are capable of performing within established limits and

tolerances over an extended period of time. This protocol will define the PQ requirements,

specifications and acceptance criteria for the operation of the [Insert Equipment Name, Equip ID],

located at [Insert Company Name], [Insert Company Address].

4. EQUIPMENT DESCRIPTION

Include a detailed description of equipment (e.g., specific components, critical instrumentation,

control/alarm set point, required utilities, etc.) and a statement of the expected operation of the

identified unit. This protocol will cover multiple pieces of equipment that are of a general type (e.g.,

slitter, rewinder, etc.), provide a generic description. In this case, the specific details of the

equipment will be included in the PQ report’s equipment description. The description needs to be

detailed enough to judge the adequacy of the validation sections of the protocol.

Boyd Technologies, Proprietary

Printed copies are not controlled. Upon receipt of this document, verify it is the current version prior to use.

F-0112-A Page 1 of 3

Tester: ____________________________________ Date: ______________ Verifier:________________________________ Date:___________

Document ID: F-0112

Title: PERFORMANCE QUALIFICATION PROTOCOL TEMPLATE Revision: A

5. REFERENCES

Document /Form/ Record Document ID Revision

Document Name XXXX Insert Current Rev

6. RESPONSIBILITIES

Designate the equipment owner and those responsible for the protocol generation, protocol

execution, resolving protocol discrepancies, final report generation and approval of all documents.

Role Responsibility

7. TRAINING

Prior to the execution of the protocol, the individual(s) involved in the validation activities must be

trained on the documents listed below. Training is documented per [Insert Company Name]

Standard Operation Procedure, Control of Documents Procedure (XXXX), and Control of Records

Procedure (XXXX), which can be found in the [Document Control System]. Refer to the table below

for training requirements.

Document Document ID Revision

Control of Documents Procedure XXXX Insert Current Rev

Control of Records Procedure XXXX Insert Current Rev

8. MATERIALS

8.1. Material Selection

Provide the sample description, requirements, and limitations for this OQ. Include what

components, assemblies, or devices will be used.

8.2. Sample Size

State the sample size and provide justification. Use the Sample Plan Procedure to determine

the samples size and acceptance and rejection numbers.

9. MANUFACTURING PROCEDURE

9.1. [describe the process step by step]

9.1.1.[substep of the process]

9.1.1.1. [This is any Additional Details or lists associated with this step of the procedure]

9.2. [This is any Additional Details or lists associated with this step of the procedure

Boyd Technologies, Proprietary

Printed copies are not controlled. Upon receipt of this document, verify it is the current version prior to use.

F-0112-A Page 2 of 3

Tester: ____________________________________ Date: ______________ Verifier:________________________________ Date:___________

Document ID: F-0112

Title: PERFORMANCE QUALIFICATION PROTOCOL TEMPLATE Revision: A

10. TEST METHOD

Explain what data will be used in the OQ and how it will be evaluated.

11. ACCEPTANCE CRITERIA

Define the acceptable results that must be met for the OQ to be considered successful.

12. DISCREPANCIES / JUSTIFICATION AND CORRECTIVE ACTIONS

List any data that did not meet the acceptance criteria. Include all amendments and deviations. Each

discrepancy must be resolved by justifying a change to the protocol specification or by changing the

item in question to conform to the original specification. All discrepancies must be reviewed and

approved by the appropriate parties.

13. CONCLUSION

This is the summary of the outcome of the protocol.

14. APPENDIX N/A [if this section does not apply]

Appendix 1 – [appendix 1 title]

[Enter description / title of Appendix]

[Include any referenced tables, forms, or figures.]

Boyd Technologies, Proprietary

Printed copies are not controlled. Upon receipt of this document, verify it is the current version prior to use.

F-0112-A Page 3 of 3

Tester: ____________________________________ Date: ______________ Verifier:________________________________ Date:___________

Potrebbero piacerti anche

- OQ FormatDocumento13 pagineOQ FormatAliqahwash100% (1)

- Risk Response PlanDocumento8 pagineRisk Response Planapi-639207174Nessuna valutazione finora

- PERFORMANCE QUALIFICATION FinalDocumento5 paginePERFORMANCE QUALIFICATION Finalkrishna murthyNessuna valutazione finora

- IQ, OQ & PQ. (Rev-1) - USP - RenataDocumento15 pagineIQ, OQ & PQ. (Rev-1) - USP - RenataJakaria Shawon100% (1)

- Installation Qualification Protocol For Walk - in Incubator System Name: Walk - in Incubator Document No.: NECPL/IQ/11220I/1 Page No.: 1 of 25Documento25 pagineInstallation Qualification Protocol For Walk - in Incubator System Name: Walk - in Incubator Document No.: NECPL/IQ/11220I/1 Page No.: 1 of 25vipin100% (1)

- Prosses Validation Protocol For Albendazole SuspensionDocumento25 pagineProsses Validation Protocol For Albendazole Suspensionمحمد عطاNessuna valutazione finora

- Performance Qualification Template: Insert Logo HereDocumento14 paginePerformance Qualification Template: Insert Logo Hereaborder-06-sonnetNessuna valutazione finora

- Process Validation Sample ProtocolDocumento5 pagineProcess Validation Sample ProtocolBilal Masood0% (1)

- Juvia Protocol 50-1000Documento16 pagineJuvia Protocol 50-1000ziauddin bukhariNessuna valutazione finora

- 7.4 Performance Qualification Protocol For Air Handling UnitDocumento27 pagine7.4 Performance Qualification Protocol For Air Handling UnitTanveer Ahmed QuadriNessuna valutazione finora

- Temperature Mapping For FG StoreDocumento19 pagineTemperature Mapping For FG Storemehrdarou.qaNessuna valutazione finora

- TEMPLATE FOR PROCESS VALIDATION PROTOCOL - Pharmaceutical GuidanceDocumento6 pagineTEMPLATE FOR PROCESS VALIDATION PROTOCOL - Pharmaceutical GuidancePackaging Development BernofarmNessuna valutazione finora

- Performance Qualification - AcmeDocumento17 paginePerformance Qualification - AcmeEr Sahil Kumar100% (2)

- Validation Master Plan As Per PICSDocumento26 pagineValidation Master Plan As Per PICSFari ShaikhNessuna valutazione finora

- F03qa038-00 VMPDocumento24 pagineF03qa038-00 VMPMeet Vermaa100% (1)

- Performance QUALIFICATION OF RLAFDocumento22 paginePerformance QUALIFICATION OF RLAFBRIJENDRA KUMAR SINGHNessuna valutazione finora

- Process Validation Protocol Packaging Validation (Performance Qualification) of Oii Axis Revision Knee SystemDocumento16 pagineProcess Validation Protocol Packaging Validation (Performance Qualification) of Oii Axis Revision Knee SystemMJ SapiterNessuna valutazione finora

- Area Qualification ProtocolDocumento19 pagineArea Qualification ProtocolBRIJENDRA KUMAR SINGH100% (1)

- Qualification of Compressed Air ProtocolDocumento18 pagineQualification of Compressed Air ProtocolBRIJENDRA KUMAR SINGH100% (2)

- CommMill IQOQPQDocumento16 pagineCommMill IQOQPQAtul Sharma100% (2)

- Empower 3 Enterprise or Workgroup Software For ServersDocumento52 pagineEmpower 3 Enterprise or Workgroup Software For ServersMohamed Sallam100% (2)

- 9.1 Design Qualification Protocol For Dynamic Pass BoxDocumento10 pagine9.1 Design Qualification Protocol For Dynamic Pass BoxKeval Patel100% (1)

- Title: Cleaning Validation Report For - ToDocumento41 pagineTitle: Cleaning Validation Report For - TocpkakopeNessuna valutazione finora

- Process Performance Qualification ProtocolDocumento7 pagineProcess Performance Qualification Protocolsandeep sharmaNessuna valutazione finora

- PR 1400 Iq, Oq, PQDocumento28 paginePR 1400 Iq, Oq, PQvizay237_430788222Nessuna valutazione finora

- Capsule Filling Machine: 16 March, 2010Documento37 pagineCapsule Filling Machine: 16 March, 2010prakash67% (3)

- Validation Document For FLP-1.5Documento19 pagineValidation Document For FLP-1.5Reza Jafari100% (1)

- Installation QualificationDocumento14 pagineInstallation QualificationTuan Nguyen100% (1)

- VAL - 170401 - BMAA VAL Activity 4 IQ - Template PDFDocumento25 pagineVAL - 170401 - BMAA VAL Activity 4 IQ - Template PDFSheila Bersamin TabuconNessuna valutazione finora

- Scenario Planning and Strategic ThinkingDocumento2 pagineScenario Planning and Strategic ThinkingMug ZiumbwaNessuna valutazione finora

- VDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentDocumento36 pagineVDA Volume Assessment of Quality Management Methods Guideline 1st Edition November 2017 Online-DocumentR JNessuna valutazione finora

- Temperature Measurement: Temperature Assemblies and Transmitters For The Process IndustryDocumento32 pagineTemperature Measurement: Temperature Assemblies and Transmitters For The Process IndustryfotopredicNessuna valutazione finora

- VMP For EVFDocumento56 pagineVMP For EVFPrashansa ShresthaNessuna valutazione finora

- OPERATIONAL QUALIFICATION OF AIR COMPRESSOR - Pharmaceutical GuidanceDocumento8 pagineOPERATIONAL QUALIFICATION OF AIR COMPRESSOR - Pharmaceutical GuidanceWilliams Lucky Elvis100% (1)

- TEM 115 ProtocolRework Manufactured Finished Goods SampleDocumento1 paginaTEM 115 ProtocolRework Manufactured Finished Goods SampleOmnia ElshafieNessuna valutazione finora

- Process Validation Sample Protocol - PharmaguidelineDocumento3 pagineProcess Validation Sample Protocol - PharmaguidelineD Tech Dental Technologies100% (1)

- Operational Qualification TemplateDocumento9 pagineOperational Qualification TemplateBhuvana RamananNessuna valutazione finora

- Performance Qualification PQ GuidlineDocumento8 paginePerformance Qualification PQ Guidlinejanu1211Nessuna valutazione finora

- Validation Master Plan A Complete Guide - 2020 EditionDa EverandValidation Master Plan A Complete Guide - 2020 EditionNessuna valutazione finora

- Family Planning MethodsDocumento20 pagineFamily Planning MethodsRoel Marcial100% (2)

- Hold Time Study 1Documento3 pagineHold Time Study 1aboemadaldeenNessuna valutazione finora

- Installation Qualification (Iq) Protocol FOR Mechanical SifterDocumento22 pagineInstallation Qualification (Iq) Protocol FOR Mechanical SiftercorneliusNessuna valutazione finora

- CIQA Validation Master Plan Sample TemplateDocumento4 pagineCIQA Validation Master Plan Sample TemplateSatyam Gupta100% (1)

- Prosses Validation Protocol For Ivermectin InjectionDocumento25 pagineProsses Validation Protocol For Ivermectin Injectionمحمد عطاNessuna valutazione finora

- IQ Protocol Air ShowerDocumento9 pagineIQ Protocol Air Showerziauddin bukhariNessuna valutazione finora

- Ezetimide AMTP G13 012Documento8 pagineEzetimide AMTP G13 012Dany RockNessuna valutazione finora

- DI IQ OQ ReportDocumento11 pagineDI IQ OQ ReportVemulapalli SaibabuNessuna valutazione finora

- Specific Instuctions To BiddersDocumento37 pagineSpecific Instuctions To BiddersShahed Hussain100% (1)

- Performance Qualification Protocol FOR Automatic Capsule Filling MachineDocumento13 paginePerformance Qualification Protocol FOR Automatic Capsule Filling Machinemehrdarou.qaNessuna valutazione finora

- Alarm Verification Protocol FOR Incubators (Microbiology, Q-Block)Documento10 pagineAlarm Verification Protocol FOR Incubators (Microbiology, Q-Block)cpkakope100% (1)

- 8.3 Operation Qualification Protocol For Dispensing BoothDocumento4 pagine8.3 Operation Qualification Protocol For Dispensing BoothTanveer Ahmed Quadri100% (1)

- Iq of LyophilizerDocumento36 pagineIq of Lyophilizermkm969Nessuna valutazione finora

- Process Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2Documento12 pagineProcess Performance Qualification Protocol For Autoclave - Pharmaceutical Guidelines 2MykolaNessuna valutazione finora

- Performance Qualification Protocol and Report For AutoclaveDocumento19 paginePerformance Qualification Protocol and Report For AutoclaveMubarak PatelNessuna valutazione finora

- Operational Qualification TemplateDocumento7 pagineOperational Qualification TemplateAnton MymrikovNessuna valutazione finora

- Compressed Air - 2 PDFDocumento18 pagineCompressed Air - 2 PDFnuwaNessuna valutazione finora

- Performance Qualification Protocol (PQP) For (Autoclave), Located inDocumento17 paginePerformance Qualification Protocol (PQP) For (Autoclave), Located inlouayNessuna valutazione finora

- URS-Glass WasherDocumento19 pagineURS-Glass Washerssureshkar7699100% (2)

- Vendor QualificationDocumento2 pagineVendor QualificationDharmesh PatelNessuna valutazione finora

- Helix Pharma (Private) Limited: Validation ProtocolDocumento4 pagineHelix Pharma (Private) Limited: Validation Protocolziauddin bukhari0% (2)

- CIQA PQ Template Protocol Lyophilization Process Sample VersionDocumento3 pagineCIQA PQ Template Protocol Lyophilization Process Sample VersionAbdul KalimNessuna valutazione finora

- VAL-085 Process Validation Guideline SampleDocumento2 pagineVAL-085 Process Validation Guideline SampleVizit31Nessuna valutazione finora

- IQ For Strip Packing Machine SE - 140Documento15 pagineIQ For Strip Packing Machine SE - 140Fernanda GarantiaNessuna valutazione finora

- Protocol of Calculator Qualification: Next Wave (India)Documento5 pagineProtocol of Calculator Qualification: Next Wave (India)sazid99924100% (1)

- PQ MULTI MILL LAB MODEL - SunriseDocumento11 paginePQ MULTI MILL LAB MODEL - SunriseRavii CurtisNessuna valutazione finora

- SOP For Handling of Market ComplaintDocumento32 pagineSOP For Handling of Market Complaintsubbu_281Nessuna valutazione finora

- PR 9 Rev 3Documento20 paginePR 9 Rev 3lavrikNessuna valutazione finora

- PR 9 Rev 3Documento20 paginePR 9 Rev 3lavrikNessuna valutazione finora

- Vapour Line ValvesDocumento3 pagineVapour Line ValvesMug ZiumbwaNessuna valutazione finora

- MIT2 092F09 Lec04Documento6 pagineMIT2 092F09 Lec04mokgokNessuna valutazione finora

- Api AdaptorsDocumento3 pagineApi AdaptorsMug ZiumbwaNessuna valutazione finora

- Lecture 3 - Analysis of Solids/Structures and FluidsDocumento4 pagineLecture 3 - Analysis of Solids/Structures and FluidsmokgokNessuna valutazione finora

- 2.092/2.093 F E A S F I: Inite Lement Nalysis of Olids and Luids F 2009Documento3 pagine2.092/2.093 F E A S F I: Inite Lement Nalysis of Olids and Luids F 2009Mug ZiumbwaNessuna valutazione finora

- Roof DrainDocumento20 pagineRoof DrainMug ZiumbwaNessuna valutazione finora

- Dust Handling MethodologiesDocumento1 paginaDust Handling MethodologiesMug ZiumbwaNessuna valutazione finora

- The Uv Environment Production System Best Practice OperationDocumento2 pagineThe Uv Environment Production System Best Practice OperationFarzad ValizadehNessuna valutazione finora

- Capacitor Trip Device CTD-4Documento2 pagineCapacitor Trip Device CTD-4DAS1300Nessuna valutazione finora

- Curriculum Vitae: Educational Background Certification Major Name of Institute PeriodDocumento2 pagineCurriculum Vitae: Educational Background Certification Major Name of Institute PeriodTHEVINESHNessuna valutazione finora

- Decolonization DBQDocumento3 pagineDecolonization DBQapi-493862773Nessuna valutazione finora

- Exploring Nurses' Knowledge of The Glasgow Coma Scale in Intensive Care and Emergency Departments at A Tertiary Hospital in Riyadh City, Saudi ArabiaDocumento9 pagineExploring Nurses' Knowledge of The Glasgow Coma Scale in Intensive Care and Emergency Departments at A Tertiary Hospital in Riyadh City, Saudi Arabianishu thapaNessuna valutazione finora

- American University of Beirut PSPA 210: Intro. To Political ThoughtDocumento4 pagineAmerican University of Beirut PSPA 210: Intro. To Political Thoughtcharles murrNessuna valutazione finora

- Exchange 2010 UnderstandDocumento493 pagineExchange 2010 UnderstandSeKoFieNessuna valutazione finora

- Maintaining Godly Spirituality in The Face of ChallengesDocumento3 pagineMaintaining Godly Spirituality in The Face of ChallengesDavid OmoniyiNessuna valutazione finora

- Manual ML 1675 PDFDocumento70 pagineManual ML 1675 PDFSergio de BedoutNessuna valutazione finora

- TextdocumentDocumento254 pagineTextdocumentSaurabh SihagNessuna valutazione finora

- JurnalDocumento12 pagineJurnalSandy Ronny PurbaNessuna valutazione finora

- Emulsion LectureDocumento30 pagineEmulsion LectureRay YangNessuna valutazione finora

- Mge - Ex11rt - Installation and User Manual PDFDocumento38 pagineMge - Ex11rt - Installation and User Manual PDFRafa TejedaNessuna valutazione finora

- The Politics of GenreDocumento21 pagineThe Politics of GenreArunabha ChaudhuriNessuna valutazione finora

- Army Public School No.1 Jabalpur Practical List - Computer Science Class - XIIDocumento4 pagineArmy Public School No.1 Jabalpur Practical List - Computer Science Class - XIIAdityaNessuna valutazione finora

- Statistics and Probability Course Syllabus (2023) - SignedDocumento3 pagineStatistics and Probability Course Syllabus (2023) - SignedDarence Fujihoshi De AngelNessuna valutazione finora

- Dial 1298 For Ambulance - HSBCDocumento22 pagineDial 1298 For Ambulance - HSBCDial1298forAmbulanceNessuna valutazione finora

- Electron LayoutDocumento14 pagineElectron LayoutSaswat MohantyNessuna valutazione finora

- Coping Mechanism and Academic Performance Among FiDocumento14 pagineCoping Mechanism and Academic Performance Among FiMary Margaret MorillaNessuna valutazione finora

- Luxi User's GuideDocumento14 pagineLuxi User's GuidephilsouthNessuna valutazione finora

- Syllabus: Cambridge IGCSE (9-1) Art & Design 0989Documento27 pagineSyllabus: Cambridge IGCSE (9-1) Art & Design 0989Jashan LoombaNessuna valutazione finora

- Super Gene 1201-1300Documento426 pagineSuper Gene 1201-1300Henri AtanganaNessuna valutazione finora

- Aloe Vera An Ancient Herb For Modern Dentistry-A LDocumento7 pagineAloe Vera An Ancient Herb For Modern Dentistry-A LRuth Ransel Yadao ValentinNessuna valutazione finora

- MarimbaDocumento5 pagineMarimbaLeonardo D'AngeloNessuna valutazione finora