Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Especificaciones Del Jumbo DD 311

Caricato da

RimbertTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Especificaciones Del Jumbo DD 311

Caricato da

RimbertCopyright:

Formati disponibili

Technical Specification

6-233 S-D

2007-06-01

Sandvik DD310-26C

APPLICATION MAIN SPECIFICATIONS

Sandvik DD310-26C is a single boom electro hydraulic Carrier 1 x TC 5

jumbo for mine development and tunneling in cross Safety cabin 1 x FOPS / ROPS

sections up to 38 m². Rock drill 1 x HLX5

Feed 1 x TF 500

The robust universal boom have a large optimum

Boom 1 x B 26 F

shaped coverage, 360° rotation and full automatic

Control system 1 x THC 560

parallelism for fast and easy face drilling. The boom can

Powerpack 1 x HP 560 (55 kW)

also be used for cross-cutting and bolt-hole drilling.

Shank lubrication device 1 x KVL 10-1

The jumbo layout is designed for good visibility and Air compressor 1 x CT 10

balance, this and the powerful four-wheel-drive Water pump 1 x WBP 1

articulated carrier ensure fast and safe manoeuvering in Main switch 1 x MSE 05

narrow drifts. Cable reel 1 x TCR 1

Length 10 855 mm

The high performance drilling system allows high drilling

Width 1 750 mm

performance with good drill steel economy and high

Height 2 920mm

machine reliability.

Weight (without options) 12 000 kg

The operator environment and added automatic Tramming speed

functions allow the operator to concentrate on safe, fast - Horizontal 12 km/h

and accurate drilling. - 14% = 1:7 = 8° 5 km/h

Gradeability, max 35 %

All the service points are well protected but easy to

Noise level < 85 dB(A)

access.

© 2007 Sandvik Mining and Construction 1/4

Technical Specification

6-233 S-D

2007-06-01

Sandvik DD310-26C

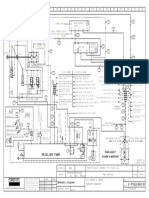

GENERAL DIMENSIONS

with Standard Cabin

2920

1980

1675 1600

160 Overall Length

1500 TF 500 x 10 10 855

2510 1500

TF 500 x 12 11 180

6350 TF 500 x 14 11 195

TF 500 x 16 12 250

All dimensions in mm

HLX5 ROCK DRILL (Technical specification 2-1852) B 26 F BOOM (Technical specification 4-200 S)

Weight 210 kg Type Parallel holding

Length 955 mm Weight (with hoses) 1 900 kg

Profile height 87 mm Feed roll-over 360°

Power class 20 kW Boom extension 1 200 mm

Max working pressure - Percussion 225 bar Feed extension 1 600 mm

- Rotation 175 bar

Max torque (80 ccm motor) 400 Nm THC 560 CONTROL SYSTEM

Hole size 43 - 64 mm Power control Adjustable full power

Recommended steel T38- H35-R32 Adjustable collaring power

T38-H35-alpha 330 Rotation control Adjustable rotation speed

T38-R39-R35 Reversible rotation

Shank adapter 7304-7585-01 (T38) Automatic functions Collaring

Flushing water pressure 10 - 20 bar Feed controlled percussion

Anti-jamming

TF 500 FEED (Technical specification 3-1400) Flushing

Stop-and-return

Feed type Cylinder - wire rope Boom controls Fully proportional

Feed force 25 kN

HP 560 POWER PACK

TF 500 500x10 500x12 500x14 500x16 Electrical motor 1 x 55 kW (75 hp)

Total length (mm) 4660 5270 5880 6490 3-phase motor

Pump types

Drill steel length (mm) 3090 3700 4305 4915

- Percussion, feed & boom Axial piston,

Hole depth (mm) 2830 3440 4050 4660 1 x 130 l/min variable displacement

Net weight (kg) 470 500 530 560 - Rotation 1 x 60 l/min gear pump

Filtration - Pressure 1 x 20 micron

- Return 1 x 10 micron

Hydraulic tank volume 180 liters

© 2007 Sandvik Mining and Construction 2/4

Technical Specification

6-233 S-D

2007-06-01

Sandvik DD310-26C

TRAMMING DIMENSIONS

with optional Cabin

for seated operator

2630

Overall Length

TF 500 x 10 10 855

320 15°

TF 500 x 12 11 180

TF 500 x 14 11 195 3000 2510

TF 500 x 16 12 250 6350

CS

TURNING RADIUS

R2

R1

R1 R2 CS

40° TF 500 x 10 3260 5655 3290

TF 500 x 12 3260 5800 3435

5550 TF 500 x 14 3260 5945 3580

TF 500 x 16 3260 6070 3705

All dimensions in mm

TC 5 CARRIER WATER CIRCUIT

Diesel engine Deutz BF4L 2011, 55 kW (74hp) Water pump type 1 x WBP 1

- Exhaust Catalyser - Capacity 30 l/min at 11 bar

Transmission Hydrostatic, automotive - Electric motor 4 kW (5.5 hp)

Transfer case Drop gear Clark-Hurth Oil cooler OW 30, water-actuated counterflow

Axles, Front & Rear Case New Holland D45 - Cooling capacity 30 kW

- Oscillation Rear axle, 2 x 10°

- Tyres 12.00 x 20 ELECTRICAL SYSTEM

Steering Frame steering, 2 x 40°

Brakes Total installed power 70 kW

- Service Hydrostatic transmission+positive braking Main switch 1 x MSE 05

- Emergency & parking Hydraulic oil immersed Standard voltages 380...690 V / 50 or 60 Hz

multiple disc brakes on both axles Voltage fluctuation Max ±10 %

Stabilizers 2 hydraulic jacks, front Starting method Direct start

2 hydraulic jacks, rear Cable reel 1 x TCR 1

Safety cabin FOPS-ROPS - Capacity (rubber cable) 130 m - 33 mm O.D

- Type Noise and vibration insulated Lighting (24 V)

Fuel tank 80 liters - Working lights 2 x 35 W HID, front

Hydraulic tank 55 liters 2 x 70 W, rear

- Driving lights 2 x 70 W, front

2 x 70 W, rear

AIR CIRCUIT

Compressor C.T. 10, screw type FULL DIESEL VERSION OPTIONAL

- Capacity 1000 l/min at 7 bar

Electric motor 7.5 kW (10 hp) Water-cooled engine Deutz BF4M 2012C

Shank lubrication device 1 x KVL 10-1 - Max. rating at 2200 rpm 93 kW (125 hp)

- Air consumption 250-350 l/min Fuel tank capacity 240 liters

- Oil consumption 180-250 g/h Compressor & water pump driven by hydraulic motors

Total machine weight 10 500 kg

© 2007 Sandvik Mining and Construction 3/4

Technical Specification

6-233 S-D

2007-06-01

Sandvik DD310-26C

COVERAGE AREA

Extra coverage with manual override

Auto-parallel coverage

5890

5190

DD310-26C on jacks.

All dimensions in mm.

1750

5510

6490

OPTIONAL EQUIPMENT

DRILLING SYSTEM CARRIER

*) HL 510S rock drill. Complete spare wheel.

*) Telescopic feed TFX 500 series. Hand pump for manual brake release.

TRS two rod system with controls (incl. TRR 1). *) Stainless steel 350 l water tank.

*) Rod retainer TRR 1. *) Exhaust scrubber.

*) B 26 NV boom. Air conditioning for cabin.

Drill angle measuring instrument TMS D1. Cabin heating.

Auto air flushing on rock drill return. *) Cabin for seated operator (2630 mm overall height).

*) SLU 1 shank lubricating device.

*) Double flushing (air/water) with CT 10 compressor (incl. OTHER OPTIONAL EQUIPMENT

2 x 60 l air receiving). Fire extinguisher (bottle only).

*) Double flushing (air/water) with 11 kW CT 16 compressor Manual fire suppression system ANSUL, 6 nozzles.

(incl. 2 x 60 l air receiving). Pressure cleaning system (10 bar) with reel.

Air cleaner IP5 plus auxiliary connection for mine air network. Automatic water hose reel (60 m capacity).

*) Air mist flushing kit for auxiliary water/air connection. Water hose 1”½.

*) Drilling on both electric and Diesel. *) Electric filling pump for oil.

Greasing reel with pump and nozzle.

ELECTRICAL SYSTEM Centralized greasing.

*) 1 000 V electric power supply. Automatic lubrication system (Lincoln).

Biodegradable oils.

Ground fault and overcurrent unit VYK

Fast filling and evacuation system (Wiggins) for fuel.

Electric cable rubber ou PUR.

Fast filling and evacuation system (Wiggins) for fuel, transmis-

*) Star-Delta electric starting method (380...690 V only). sion, engine and hydraulic oil.

2 x 35 W High Intensity Discharge (HID) extra working lights. *) EU, UL, CSA, AUS norms package.

Manuals other than French/English language.

*) replaces standard component.

Sandvik Mining and Construction reserves the right to change this specification without further notice.

Sandvik Mining and Construction Lyon S.A.S.

B.P.46 - FR-69881 Meyzieu Cedex, France

Tel. +33 4 7245 2200, Telefax +33 4 7831 7980 4/4

www.sandvik.com

Potrebbero piacerti anche

- Frontonero SANDVIK DD311Documento4 pagineFrontonero SANDVIK DD311Arturo And100% (1)

- Jumbo Ficha TecnicaDocumento4 pagineJumbo Ficha TecnicaRodrigo FooNessuna valutazione finora

- Ds311-Ficha Tecnica PDFDocumento4 pagineDs311-Ficha Tecnica PDFAnonymous qnRoeLRiyNessuna valutazione finora

- DS410 83100fDocumento4 pagineDS410 83100fzliang100% (1)

- Jumbo Dd421Documento4 pagineJumbo Dd421Anonymous Iu8A4JC100% (2)

- 9852 1836 05f Operators Manual ST7 and ST7LPDocumento100 pagine9852 1836 05f Operators Manual ST7 and ST7LPNelio Lara Ricaldi100% (4)

- Technical Specification Boomer S1 D-DH 9851 2670 01 Tcm835-3516664Documento4 pagineTechnical Specification Boomer S1 D-DH 9851 2670 01 Tcm835-3516664Miguel Calderón0% (1)

- Especificaciones Tecnicas Dumper Mt2010Documento4 pagineEspecificaciones Tecnicas Dumper Mt2010CepiconSacNessuna valutazione finora

- Sandvik LH203-3 PDFDocumento3 pagineSandvik LH203-3 PDFjuan carlos0% (1)

- Ejc 130DDocumento4 pagineEjc 130DMiguel Ruiz Tataje100% (1)

- Track Drill Ecm 370 Ingersoll Rand PDFDocumento4 pagineTrack Drill Ecm 370 Ingersoll Rand PDFAlvaro OZ0% (1)

- Boltec DS411Documento4 pagineBoltec DS411fabian castroNessuna valutazione finora

- Acuñador Scaletec MC Atlas CopcoDocumento4 pagineAcuñador Scaletec MC Atlas CopcoMichael de la BarraNessuna valutazione finora

- Manual RN-S83FX-2Documento12 pagineManual RN-S83FX-2Ricardo Ramirez Estrello100% (1)

- Technical Specification Sandvik LH203-08 PDFDocumento3 pagineTechnical Specification Sandvik LH203-08 PDFacomisaminasNessuna valutazione finora

- Scoop EJC145Documento8 pagineScoop EJC145kelvisbaNessuna valutazione finora

- Martillo SB 202 PartsDocumento2 pagineMartillo SB 202 PartsRene Ramos MenesesNessuna valutazione finora

- TH663 Camion Bajo PerfilDocumento6 pagineTH663 Camion Bajo PerfilHernan Britowsky Krustofski von HohenheimNessuna valutazione finora

- Datos Tecnicos LH202Documento8 pagineDatos Tecnicos LH202Roel Aroni CuaresmaNessuna valutazione finora

- Axera D06Documento2 pagineAxera D06Cristián Fernando Cristóbal RoblesNessuna valutazione finora

- Atlas Copco: 9.5 Tonne Capacity Scooptram LHD Atlas Copco Wagner IncDocumento2 pagineAtlas Copco: 9.5 Tonne Capacity Scooptram LHD Atlas Copco Wagner IncNeil0% (1)

- IR ECM350 CrawlairDocumento4 pagineIR ECM350 CrawlairCarlos Jorge Sánchez Romero50% (2)

- ONRAM 1500: Diamond Core Drill Technical SpecificationDocumento7 pagineONRAM 1500: Diamond Core Drill Technical SpecificationFedericoButronNessuna valutazione finora

- 1253 s10 ScalerDocumento5 pagine1253 s10 ScalerpauloNessuna valutazione finora

- Manual de Parts Manual ST - LT - 270 PDFDocumento336 pagineManual de Parts Manual ST - LT - 270 PDFRicardo Ramirez Estrello100% (1)

- SIMBA 1354 Pag 1-2 - 4Documento4 pagineSIMBA 1354 Pag 1-2 - 4lorenzo hener100% (1)

- Atlas Copco DiamecDocumento1 paginaAtlas Copco Diamecpradeep315100% (2)

- Dumper TH 540 PDFDocumento13 pagineDumper TH 540 PDFhernan avNessuna valutazione finora

- Spec Pantera Dp1500i t4 2 WebDocumento3 pagineSpec Pantera Dp1500i t4 2 WeblenardoangeloNessuna valutazione finora

- Manual NormetDocumento507 pagineManual Normetcarlos arturo coral peñaNessuna valutazione finora

- New Design DRWJ-1 (DRWJ-0.75) Underground LHD LoaDocumento5 pagineNew Design DRWJ-1 (DRWJ-0.75) Underground LHD LoaHola NumerosisNessuna valutazione finora

- Diagrama Eléctrico Jumbo Sandvik dd311Documento1 paginaDiagrama Eléctrico Jumbo Sandvik dd311Jairo Ulises Pizarro Urrutia100% (2)

- 3-Gama de Productos - Simbas (Documento31 pagine3-Gama de Productos - Simbas (dan roy wouters sarabiaNessuna valutazione finora

- LH 514 Technical Specification Sandvik LH514-10Documento3 pagineLH 514 Technical Specification Sandvik LH514-10Emanuel Nicolas Villarruel100% (1)

- ALPHA 20 Especificaciones TecnicasDocumento6 pagineALPHA 20 Especificaciones TecnicasRFIGUEROAC0% (1)

- Technical Specification Sandvik LH307Documento3 pagineTechnical Specification Sandvik LH307Franklin Labbe100% (1)

- Specification Jumbo Drill Sandvik DD311D-40EDocumento4 pagineSpecification Jumbo Drill Sandvik DD311D-40ENathania Boas E S50% (2)

- Presiones Transmision R1300GDocumento12 paginePresiones Transmision R1300GgeniusnetxxxxNessuna valutazione finora

- ST2G FolletoDocumento4 pagineST2G Folletomarcelonieto761Nessuna valutazione finora

- Ingersoll Rand Ecm 350 Ueq201008Documento3 pagineIngersoll Rand Ecm 350 Ueq201008John NottyNessuna valutazione finora

- Diagrama Hidráulico Scoop ST-1030 Atlas CopcoDocumento36 pagineDiagrama Hidráulico Scoop ST-1030 Atlas CopcoEric MiñoNessuna valutazione finora

- Atlas Copco Exploration Drilling Christensen CS14/CS14C Core DrillDocumento3 pagineAtlas Copco Exploration Drilling Christensen CS14/CS14C Core DrillControl de calidad Antamina100% (1)

- Getman Madero (8) 7026 Manual (3464)Documento939 pagineGetman Madero (8) 7026 Manual (3464)Pedro GarciaNessuna valutazione finora

- Jumbo Dd210-V 9604sbDocumento4 pagineJumbo Dd210-V 9604sbguidoaf19Nessuna valutazione finora

- DD310-26 6232sfDocumento4 pagineDD310-26 6232sfRoger TrujilloNessuna valutazione finora

- Ranger 700: SANDVIK TAMROCK Reserves The Right To Change This Specification Without Further NoticeDocumento5 pagineRanger 700: SANDVIK TAMROCK Reserves The Right To Change This Specification Without Further NoticeJesusFloresRodriguez100% (1)

- Manual Partes Del r1600hDocumento775 pagineManual Partes Del r1600htr eo100% (1)

- Brochure Tamrock Axera D05Documento4 pagineBrochure Tamrock Axera D05Esteban Fernando Meza IbacetaNessuna valutazione finora

- Manipulador Telescópico MANITOU MT-X 1033 MiningDocumento8 pagineManipulador Telescópico MANITOU MT-X 1033 MiningMario100% (2)

- R1600H - R1600G Comparison - 13 - Feb - 2013Documento42 pagineR1600H - R1600G Comparison - 13 - Feb - 2013Percy Chero100% (1)

- TDS Alpha 30 (EN) Rev6 PDFDocumento10 pagineTDS Alpha 30 (EN) Rev6 PDFFelipe Andrés Camarada SilvaNessuna valutazione finora

- SandvikDocumento4 pagineSandvikBenjamin Musa ダNessuna valutazione finora

- Axera 5 140 - 6240sd PDFDocumento4 pagineAxera 5 140 - 6240sd PDFDima SapronovNessuna valutazione finora

- Sandvik DD310-26XDocumento3 pagineSandvik DD310-26XMep RoleroNessuna valutazione finora

- DD210 6110 G PDFDocumento4 pagineDD210 6110 G PDFlorenzo henerNessuna valutazione finora

- Sandvik DT1130-C Data: Application Main SpecificationsDocumento4 pagineSandvik DT1130-C Data: Application Main SpecificationsLuis JaimesNessuna valutazione finora

- Sandvic DD420 60C SpecDocumento4 pagineSandvic DD420 60C SpecAlterSon Grafi KalayNessuna valutazione finora

- AXERA 6-226: Technical Specification 6-9650-B 2004-07-02Documento4 pagineAXERA 6-226: Technical Specification 6-9650-B 2004-07-02cristianNessuna valutazione finora

- Specifications JumboDocumento4 pagineSpecifications JumboChristianM.LeandroYauriNessuna valutazione finora

- Jumbo Dl420 7cDocumento4 pagineJumbo Dl420 7cRodrigo ContrerasNessuna valutazione finora

- Diagrama Hidraulico PDFDocumento12 pagineDiagrama Hidraulico PDFRimbert100% (1)

- Torque Pernos PDFDocumento5 pagineTorque Pernos PDFRimbertNessuna valutazione finora

- Welcome To My SadvikDocumento1 paginaWelcome To My SadvikRimbertNessuna valutazione finora

- EEC DetroitDocumento92 pagineEEC DetroitRimbert100% (4)

- Corona RT 46 160Documento120 pagineCorona RT 46 160Rimbert100% (2)

- Embrague EatonDocumento42 pagineEmbrague EatonRimbertNessuna valutazione finora

- Corona RT 46 164 SimpleDocumento94 pagineCorona RT 46 164 SimpleRimbert100% (1)

- Diagrama Hidraúlico RH90CDocumento264 pagineDiagrama Hidraúlico RH90CRimbertNessuna valutazione finora

- Compresor TuFlo 750-RepDocumento40 pagineCompresor TuFlo 750-RepRimbert100% (1)

- MANUAL Slurry MAX PUMP RM150 KM04579Documento61 pagineMANUAL Slurry MAX PUMP RM150 KM04579Rimbert100% (1)

- Part List AtlasDocumento46 paginePart List AtlasRimbertNessuna valutazione finora

- Diagrama Eléctrico Tractor D4GDocumento4 pagineDiagrama Eléctrico Tractor D4GRimbertNessuna valutazione finora

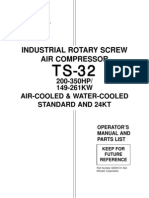

- TS-32 02250131-544Documento150 pagineTS-32 02250131-544Alejandro Dallos100% (2)

- Analisis de Motor de Traccion 730EDocumento29 pagineAnalisis de Motor de Traccion 730ERimbertNessuna valutazione finora

- Analisis de Motor de Traccion 730EDocumento29 pagineAnalisis de Motor de Traccion 730ERimbertNessuna valutazione finora

- Analisis Aceite 730EDocumento1 paginaAnalisis Aceite 730ERimbertNessuna valutazione finora

- FA D155AX-6 80001-Up GEN00049-03Documento118 pagineFA D155AX-6 80001-Up GEN00049-03RimbertNessuna valutazione finora

- Concrete Saw Core Drilling Swms 10067-8Documento12 pagineConcrete Saw Core Drilling Swms 10067-8JamesNessuna valutazione finora

- Order,+ERC+Case+No.+2014 174+RCDocumento9 pagineOrder,+ERC+Case+No.+2014 174+RCCoii Yee Jr.Nessuna valutazione finora

- Reason: God Had Made The Mistake of Sending Only 70 PesosDocumento2 pagineReason: God Had Made The Mistake of Sending Only 70 PesosS Vaibhav81% (21)

- Nestle Internship ResumeDocumento2 pagineNestle Internship ResumeHasnain AshrafNessuna valutazione finora

- Saberon StratMan2Documento3 pagineSaberon StratMan2paredesladyheart18Nessuna valutazione finora

- Moving Money Box: Pig (Assembly Instructions) : The Movements Work Better With Heavier CoinsDocumento6 pagineMoving Money Box: Pig (Assembly Instructions) : The Movements Work Better With Heavier CoinsjuanNessuna valutazione finora

- Sensors & Transducers: (Code: EI 401)Documento4 pagineSensors & Transducers: (Code: EI 401)Mayukh BiswasNessuna valutazione finora

- National Railway Museum Annual Review 04-05Documento40 pagineNational Railway Museum Annual Review 04-05sol.loredo1705530Nessuna valutazione finora

- SSMTT-27 E1 PDFDocumento8 pagineSSMTT-27 E1 PDFblackNessuna valutazione finora

- Vanilla Farming: The Way Forward: July 2019Documento6 pagineVanilla Farming: The Way Forward: July 2019mituNessuna valutazione finora

- tmpE0D4 TMPDocumento7 paginetmpE0D4 TMPFrontiersNessuna valutazione finora

- Explaining Zambian Poverty: A History of Economic Policy Since IndependenceDocumento37 pagineExplaining Zambian Poverty: A History of Economic Policy Since IndependenceChola Mukanga100% (3)

- Research Argumentative EssayDocumento6 pagineResearch Argumentative EssayHoney LabajoNessuna valutazione finora

- Vision For Mobile Robot Navigation - A Survey PDFDocumento31 pagineVision For Mobile Robot Navigation - A Survey PDFtes donlodNessuna valutazione finora

- A Slice of History - Pizza Turim 4-7-15Documento2 pagineA Slice of History - Pizza Turim 4-7-15Mae Princess BolivarNessuna valutazione finora

- IPC-S-816 SMT Process Guideline ChecklistDocumento4 pagineIPC-S-816 SMT Process Guideline Checklistmigant23uNessuna valutazione finora

- Attacks On Cryptosystems PDFDocumento18 pagineAttacks On Cryptosystems PDFUjjayanta BhaumikNessuna valutazione finora

- TL K1 2 1 04 VSD35 Varyset DE enDocumento25 pagineTL K1 2 1 04 VSD35 Varyset DE enAkilaJosephNessuna valutazione finora

- QuestionsDocumento6 pagineQuestionsRomeo martinezNessuna valutazione finora

- Management Science - Lecture 2Documento9 pagineManagement Science - Lecture 2Nicole SallanNessuna valutazione finora

- (Rect-15) Experimental Study On Partial Replacement of Cement With Coconut Shell Ash in ConcreteDocumento3 pagine(Rect-15) Experimental Study On Partial Replacement of Cement With Coconut Shell Ash in Concretefrancis dimakilingNessuna valutazione finora

- DuctBank For Electrical SystemDocumento4 pagineDuctBank For Electrical SystemAnonymous XYAPaxjbYNessuna valutazione finora

- 1 s2.0 S0956713515002546 Main PDFDocumento9 pagine1 s2.0 S0956713515002546 Main PDFIfwat ThaqifNessuna valutazione finora

- 31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngDocumento15 pagine31. (NÂNG CAO) Đề soạn theo cấu trúc minh họa 2021 - Tiếng Anh - Đề 31 - DươngNguyễn Quế Anh100% (1)

- Ohms LawDocumento16 pagineOhms Lawmpravin kumarNessuna valutazione finora

- Dead Zone I Air AgeDocumento7 pagineDead Zone I Air AgeJaponec PicturesNessuna valutazione finora

- EnglishDocumento18 pagineEnglishSarah SiddiquiNessuna valutazione finora

- Titanvene ll0209sr Product Data SheetpdfDocumento1 paginaTitanvene ll0209sr Product Data SheetpdfHanry WRNessuna valutazione finora

- 2019 BMS1021 Practice Questions Answers PDFDocumento12 pagine2019 BMS1021 Practice Questions Answers PDFaskldhfdasjkNessuna valutazione finora

- Nonmelanoma Skin Cancer: Prof - Dr.Dr. Teguh Aryandono, SPB (K) Onk Division of Surgical Oncology, GmuDocumento22 pagineNonmelanoma Skin Cancer: Prof - Dr.Dr. Teguh Aryandono, SPB (K) Onk Division of Surgical Oncology, GmuFazaKhilwanAmnaNessuna valutazione finora