Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pub056 013 00 - 0517 PDF

Caricato da

hieuTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pub056 013 00 - 0517 PDF

Caricato da

hieuCopyright:

Formati disponibili

Worldwide Projects and Services

Automation Projects

and Support Services

Keeping the World Flowing

RELIABILITY

IN FLOW CONTROL

CRITICAL

APPLICATIONS

RELIABLE OPERATION QUALITY-DRIVEN

WHEN IT MATTERS GLOBAL MANUFACTURING

Assured reliability for critical applications and environments. Products designed with 60 years of industry and

application knowledge.

Whether used 24/7 or infrequently, Rotork products will

operate reliably and efficiently when called upon. Research and development across all our facilities

ensures cutting edge products are available for

every application.

CUSTOMER-FOCUSED SERVICE LOW COST

WORLDWIDE SUPPORT OF OWNERSHIP

Solving customer challenges and developing new solutions. Long-term reliability prolongs service life.

From initial enquiry through to product installation, long- Rotork helps to reduce long term cost of ownership

term after-sales care and Client Support Programmes (CSP). and provides greater efficiency to process and plant.

2 Worldwide Projects and Services

Worldwide Projects and Services

Section Page Section Page

Rotork 2 Planned Shutdown Support 12

Worldwide Customer Support 4 Valve Automation Centres

Rotork Site Services Introduction 6 Actuator Replacement 15

Actuator Workshop Overhaul 8 New Valve Automation 16

Field Support 9 Control and Automation 17

Client Support Programme 10 System Integration 18

COMPREHENSIVE PRODUCT RANGE MARKET LEADER

SERVING MULTIPLE INDUSTRIES TECHNICAL INNOVATOR

Improved efficiency, assured safety and environmental The recognised market leader for 60 years.

protection.

Our customers have relied upon Rotork for innovative

Rotork products and services are used throughout industry solutions to safely manage the flow of liquids, gases

inclusive of Power, Oil & Gas, Water & Wastewater, and powders.

HVAC, Marine, Mining, Paper & Pulp, Food & Beverage,

Pharmaceutical and Chemical industries around the world.

GLOBAL PRESENCE CORPORATE SOCIAL

LOCAL SERVICE RESPONSIBILITY

Global company with local support. A responsible business leads to being the best business.

Manufacturing sites, service centres, sales offices and We are socially, ethically, environmentally responsible

Centres of Excellence throughout the world provide and committed to embedding CSR across all our

unrivalled customer services and fast delivery. processes and ways of working.

Keeping the World Flowing 3

ESTABLISHED

REPUTATION

GLOBAL

SUPPORT

CUSTOMER

Unrivalled global network of FOCUSED

manufacturing sites, service

Customers can source Rotork products locally in the

centres, sales offices and agents. knowledge that they will be supported by life-of-plant

maintenance, repairs and upgrade services wherever

Tailored support programmes they are in the world, with over 400 service engineers

available globally to provide support.

increase plant efficiency. We are committed to close customer ties, with our

global network supporting operations in some of the

most remote and challenging environments.

We understand the importance of being close to our

customers and understanding their needs – this is key

to driving innovation.

4 Worldwide Projects and Services

GLOBAL CLIENT

NETWORK SUPPORT

Rotork operates a truly global network of sales offices, As an international business, supporting clients

service centres and manufacturing plants sited in Europe, wherever their operations and project installations

Asia and North America. From heavy-duty gears to nuclear- are located is part of our culture.

certified actuators and pressure regulators, we are proud

Our worldwide international sales and service

to be delivering the best solutions everywhere we work.

network allows us to support our clients wherever

Rotork has more than 3,700 employees around the world they are based.

who are fundamental to maintaining our reputation for

In addition to manufacturing sites throughout the

excellence in innovation and the quality of our products

world, Rotork has regional Centres of Excellence

and services.

providing local service and support.

Keeping the World Flowing 5

Introduction

Actuator Workshop Overhaul

• Supporting Rotork and non-Rotork products

• Workshop facilities including torque testing and re-coating

• Large OEM stock in all workshops

• Fully trained and experienced service engineers

• Loan actuator facilities

Rotork has a history of innovation and

introducing technological advances to increase Field Support

product reliability and useability. We capitalise • Site repairs and commissioning

on our industry knowledge to develop and

• Upgrades

introduce solutions that support evolving

customer requirements. Rotork continues to • Fault finding and maintenance

invest in research and development, utilising • Call-out with fully equiped service vehicles

the latest technologies within our products to

increase performance and reliability. Client Support Programme (CSP)

• Select a level of service tailored for you – gold, silver

Rotork understands the value of its prompt and punctual

or bronze

customer site services and aims to supply its customers

with superior flow control solutions, by providing high • Improves production throughput

quality, innovative products and superior service – • Reduces the cost of maintenance year-on-year

on time, every time.

• Allows customers to manage the challenge of

Whether you have an actuator requiring on-site servicing, ‘Risk vs Budget’ in maintenance operations

a custom design service requirement or a new actuator

• Lifecycle management includes planned and predictive

installation, we can deliver the fastest turnaround with the

maintenance with a focus on equipment reliability and

least plant disruption. availability as well as asset management

• Generated reports detail cost savings and performance

improvements

Planned Shutdown Support

• Preventative maintenance

• On-site overhaul and testing

• OEM spares and support

• Support for Rotork and non-Rotork products

• Achieve tight shutdown return to service targets

• Project management and supervision

Valve Automation Centres

• Actuator replacement

• New valve automation

• Control and automation

• System integration

6 Worldwide Projects and Services

60 years of experience and

knowledge in all aspects of

flow control.

Predictive maintenance

programmes and comprehensive

customer services.

Health checks and performance

analysis for optimum plant

performance.

Keeping the World Flowing 7

Actuator Workshop Overhaul

Actuator Workshop Overhaul Services The overhaul, repair and upgrade activities

carried out in our workshops are an integral

• Supporting all Rotork and non-Rotork products part of the life-of-plant asset management

• Workshop facilities including torque testing support offered by Rotork Site Services.

and re-coating On completion of work, every overhauled actuator

• Large OEM stock in all workshops is torque rig tested, and a test certificate is provided

confirming that its performance is identical to the day

• Fully trained and experienced service engineers that it was built.

• Loan actuator facilities We service and repair all major brands of actuators.

Our service teams have many years of experience in the

overhaul and repair of non-Rotork actuators.

Benefits of having a certified workshop overhaul in

comparison to a complete actuator replacement:

• Less downtime compared to waiting for a replacement

• No valve modifications or machining of adaptions /

drive nuts

• Certification and calibrated torque / thrust testing

• Overhauled actuators are provided with a Rotork

warranty

• Workshop diagnostic rigs allow detailed fault analysis

• OEM parts are used, ensuring performance

and reliability

8 Worldwide Projects and Services

Field Support

Field Support Services Rotork provides prompt customer field service

response for all types and makes of actuator

• Site repairs and commissioning including those in hazardous environments

• Upgrades such as nuclear and offshore installations.

Our support can be planned or in response to

• Fault finding and maintenance emergency situations.

• Call-out with fully equipped service vehicles

Rotork Site Services are specialists in actuation services:

• All types and brands of actuators serviced and repaired

• Installation and commissioning services

• Upgrade, troubleshoot and repair / replacement of

damaged or deteriorating assets

• Fully trained and qualified service engineers

• Fully equipped fleet of service vans

• Majority of repairs carried out on-site, not taken away

• Often a loan actuator can be provided to minimise

plant downtime

• Guaranteed emergency response times

Rotork Site Services is recognised

and certified by major safety

authorities around the world.

Strict adherence to safety

regulations and procedures.

Warranty provided on all

work we undertake.

Keeping the World Flowing 9

Client Support Programme

Client Support Programme – Features Rotork offers a tailor-made programme

designed to increase reliability and availability

• Fixed term prices for Rotork products and services of valve actuator and control products via

• Tailored programme based on equipment planned maintenance, predictive maintenance

criticality to production and asset management.

• Equipment performance related targets for The primary goal of our Client Support Programme (CSP)

reliability and availability is to prevent the failure of equipment before it occurs.

This includes equipment checks, replacement of worn

• Priority support with customisable response times components and partial or complete overhauls at

specified periods.

• Fully parts and labour inclusive, no additional

costs or discounted labour and parts Planned preventative maintenance is a better alternative to

risking a potentially damaging breakdown of equipment,

• Fix or replace options and enables our clients to realise the full potential of

their business by ensuring the maximum reliability and

• Periodic equipment performance and availability of the assets.

status reports

Wherever our clients are in the world, Rotork is able to

• Built-in regular health checks on all equipment support them. We have workshops strategically located

around the world, with trained staff and full test and

maintenance facilities.

Client Support Programme – Benefits

As part of the CSP, clients have 24/7 access to the Rotork

Support Centres, with priority technical assistance, backed

• Year-on-year reduced maintenance costs

by comprehensive resources and dedicated systems. With

• Easy budget management over 400 directly employed engineers and more service

technicians available via agents, we have the infrastructure

• Maximised production – reduced downtime required to effectively support all of our clients’ needs.

• Year-on-year improved reliability and availability In addition, Rotork will help with your site development

when you need to expand, diversify or introduce a new

• Optimised resource usage, accelerate in-house process to your plant. Our engineers and technicians will

projects bring 60 years of application experience to help you plan

the way ahead.

• Reduced lifecycle costs

Through consultation, the CSP is tuned to deliver the

optimum level of maintenance through predictive

maintenance algorithms.

The CSP covers service and on-site repairs of all brands of

Asset Management actuators used in process industries.

Rotork is a corporate member of For further information, or to arrange a consultation

the Institute of Asset Management, please contact one of our dedicated sales team or

the professional body for whole life service managers.

management of physical assets.

10 Worldwide Projects and Services

Above: Rotork’s intelligent asset management system showing

torque data from multiple actuator datalogs.

Right: Overview of asset status showing a combination of both

real-time live data and data uploaded via datalogs.

Detailed actuator performance reports, produced at agreed

frequencies, allows data analysis and predictive maintenance

planning. This enables plant operators to plan shutdown

maintenance and minimise the impact on production.

The detailed data obtained from Rotork actuators allows us

to optimise actuator performance and production efficiencies

during scheduled maintenance. We analyse the condition of

assets against universal data, and use root cause analysis to

define the right solution to any anomalies.

Client Support Programme (CSP)

provides a premium level of

product reliability and availability.

Predictive maintenance minimises

unplanned plant downtime.

Tiered maintenance planning

reduces plant downtime and costs.

Keeping the World Flowing 11

Planned Shutdown Support

Planned Shutdown Support Services Actuators are recognised as major contributors

to efficiency, economy and safety. They facilitate

• Preventative maintenance the quick start-ups demanded by today’s

• On-site overhaul and testing commercial pressures, and they play their part

in supporting the demands of modern business

• OEM spares and support environments.

• Support for Rotork and non-Rotork products

Rotork provides actuator removal, service, repair, test,

• Achieve tight shutdown return to service targets re-connection and re-commissioning on a wide range of

electric, pneumatic and hydraulic actuators, including

• Project management and supervision non-Rotork units.

Our customers frequently use Rotork Site Services to remove,

overhaul, reinstall and commission hundreds of actuators

concurrently in our workshops during shutdown periods.

We can carry out upgrade projects simultaneously to ensure

that customers make the most of their plant shutdown time,

and we excel at meeting tight shutdown schedules.

Rotork guarantees that your actuators are fully operational in

time for your return to service deadlines.

12 Worldwide Projects and Services

Actuators contribute to

efficiency, economy and safety.

They facilitate the quick

start-ups demanded by today’s

commercial pressures.

They help meet the emission

reductions demanded by

environmental legislation.

Keeping the World Flowing 13

Rotork provide a one-stop-shop

for all your actuator upgrade

and replacement requirements.

Design, manufacture, supply

and installation of all

mechanical and electrical

components to facilitate your

plant upgrade.

14 Worldwide Projects and Services

Valve Automation Centres – Actuator Replacement

Actuator Replacement Services Rotork has a wealth of experience in fitting

actuators to valves, penstocks or dampers

• Replacement of obsolete or ageing actuators in that are already installed on a plant. Whether

the field with the latest Rotork product range a customer is replacing obsolete actuators,

• Correct product selection for the right application changing power source or motorising manual

valves we are able to offer tailor made solutions

• Design and manufacture of adaption components designed to comply with our customers'

• Electrical interface design and installation requirements.

• Factory trained installation team Retrofitting actuators to valves installed in the pipeline

is a safe and cost effective solution that minimises plant

• Fully commissioned to the plant control room disruption. Working from basic valve data we are able to

• Extended warranty on all products installed by offer a full sizing service that matches actuator models to the

valves’ requirements.

Rotork technicians

We carry out full and detailed site surveys, collecting all the

dimensions needed to design the mechanical components

that will mount the new actuator to the existing valve.

Ease of installation and maximum reliability of the whole

installation are guaranteed by a full Rotork warranty.

Keeping the World Flowing 15

Valve Automation Centres – New Valve Automation

New Valve Automation Services The careful assembly of the valve to the

actuator is critical to ensure that an automated

• Automation of new or refurbished valves in our valve performs correctly and reliably. There is

dedicated service centre a growing need for actuators to be installed

• Correct product selection to suit the process on valves after they have left the valve

demands manufacturers factory.

• Design and manufacture of all engineered With our complete range of electric and fluid power valve

components actuators, we can automate all valve types regardless of

the available power supplies. Working with the engineer

• Correct assembly of valve and actuator / gearbox responsible for the specification, we will select the correct

combinations actuator type and size based on the basic valve data and the

plant operational criteria.

• Selection and procurement of the preferred or

We engineer and manufacture all components necessary

specified valve for your application

to mount the actuator to the valve. Assembly takes place in

• Free issue valves accepted for automation in our controlled workshop environments by factory trained

technicians. An extended warranty is provided when the valve

our service centres

and actuator are commissioned on-site by Rotork technicians.

• Packed and shipped to the desired destination

16 Worldwide Projects and Services

Valve Automation Centres – Control and Automation

Control and Automation Services Every year Rotork carries out significant

control and automation projects throughout

• Flow control projects the world. This is a growing requirement from

• Flood prevention projects our customers who are often looking for a

“one-stop-shop” to automate part or all of

• Plant optimisation their processes.

• PID loop optimisation

Our capabilities cover all of the project phases:

• Uninterrupted power supplies (UPS) • Detailed survey

• Failsafe control systems SIL 3 • Detailed design

• Competitive procurement and timely expediting

• Control and monitoring

• Technical, manufacturing and quality monitoring

• Power and control systems

• Professional installation and commissioning

• Data logging • Detailed project management ensuring project delivery

on-time every-time

• Safety critical systems design and installation

projects Our projects team have specialist experience in:

• Civil works

• Pipe works and flow control systems

• Actuated valve and penstock installations

• Power distribution, control networks and cabling

Experts in the design and • Control system design and installation,

field communications and telemetry

implementation of actuation

and flow control solutions.

60 years' experience installing

equipment in all environments

and applications worldwide.

Keeping the World Flowing 17

Valve Automation Centres – System Integration

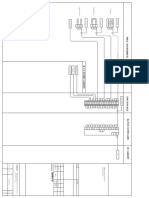

System Integration Services POWER SUPPLIES

• Design, manufacture, supply and installation services

to automate existing valves, penstock or dampers COMPLETE POWER

S O LU T I O N S

• Design, supply and installation of power distribution

systems, back-up power, uninterrupted power

supplies and associated equipment

• Control system integration and design including U N I N T E R R U P TA B L E

PLC, bus systems, logic, flow control systems, POWER SUPPLIES

PID control, failsafe critical plant

• Mechanical, instrumentation, electrical, controls C O N T R O L PA N E L

and automation (MIECA)

LO C A L C O N T R O L

A N D I N D I C AT I O N

Rotork has extensive expertise in the design,

manufacture and installation of custom control

systems for the specialist fields of pressure,

temperature, level and flow control applications

within the process control industry.

Rotork products integrate seemlessly with the majority

of industrial control systems as well as our own Pakscan CONTROL

network control system. SYSTEMS P LC

Power

• Power distribution systems upgrades and new installations R E M OT E C O N T R O L

AND MONITORING

• Back-up power, uninterrupted power supplies

• Pneumatic and hydraulic power pack supplies and

back-up accumulators

• Failsafe systems

• Automatic shutoff

AND CONTROL

F E E D B AC K

Control

H Y D R AU L I C

• Electrical interface between existing and replacement SYSTEM

equipment

• Local and remote control panels supplied and installed

• Auto / manual stations

• PID control

• Safety critical system design and Installation

• Flow control systems

• Plant optimisation upgrades

• Continuous modulation of plant final control devices

Systems P N E U M AT I C

• Complete control system design, supply and installation SYSTEM

• PLC / HMI / SCADA / Telemetry

• Major manufacturers supported including Siemens, Rockwell,

Mitsubishi, Schneider, Wonderware and Iconics

• Functional safety systems

• Field networks: PakscanTM, Profibus®, Modbus®,

DeviceNet®, Foundation Fieldbus®, HART®

• Secure wireless networking

18 Worldwide Projects and Services

DISTRIBUTION P LU G & S O C K E T

B OA R D S

H A R D W I R E D C O N T R O L F R O M LO C A L C O N T R O L PA N E L

H A R D W I R E D C O N T R O L F R O M P LC

NET WORK CONTROL AND MONITORING

NET WORK CONTROL AND

MON ITORING SYSTEMS

R E M OT E O P E R AT I O N

W I R E L E S S VA LV E

MONITORING

VA LV E

POSITIONER

H Y D R AU L I C C O N T R O L PA N E L

P O S I T I O N I N D I C AT O R

P N E U M AT I C C O N T R O L PA N E L

Keeping the World Flowing 19

www.rotork.com

A full listing of our worldwide sales and

service network is available on our website.

Rotork plc Rotork is a corporate

Brassmill Lane, Bath, UK member of the Institute

tel +44 (0)1225 733200 of Asset Management

fax +44 (0)1225 333467

email mail@rotork.com

As part of a process of on-going product development, Rotork reserves the right to amend and change

specifications without prior notice. Published data may be subject to change. For the very latest version

release, visit our website at www.rotork.com

PUB056-013-00

The name Rotork is a registered trademark. Rotork recognises all registered trademarks. Published and

Issue 05/17 produced in the UK by Rotork Controls Limited. POWTG0517

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Load Computer Model 1010 CJDocumento8 pagineLoad Computer Model 1010 CJhieuNessuna valutazione finora

- UG Maintenance InstructionsDocumento1 paginaUG Maintenance InstructionshieuNessuna valutazione finora

- BCUDocumento1 paginaBCUhieuNessuna valutazione finora

- UG Maintenance InstructionsDocumento1 paginaUG Maintenance InstructionshieuNessuna valutazione finora

- Notifier AMPS 24 AMPS 24E Addressable Power SupplyDocumento44 pagineNotifier AMPS 24 AMPS 24E Addressable Power SupplyMiguel Angel Guzman ReyesNessuna valutazione finora

- BCUDocumento1 paginaBCUhieuNessuna valutazione finora

- Rotork: Product TrainingDocumento4 pagineRotork: Product TraininghieuNessuna valutazione finora

- ErreDocumento14 pagineErreMomoMaroufNessuna valutazione finora

- 1 CJ1010ARefDocumento48 pagine1 CJ1010ARefPRITHWISH CHAUDHURINessuna valutazione finora

- 40 40i Triple Ir Ir3 Flame Detector User Guide en Us 1459806 PDFDocumento88 pagine40 40i Triple Ir Ir3 Flame Detector User Guide en Us 1459806 PDFChristian RondonNessuna valutazione finora

- Sharpeye 40 40 Series Winhost Manual en Us 4845694Documento30 pagineSharpeye 40 40 Series Winhost Manual en Us 4845694Christian RondonNessuna valutazione finora

- Engineering Piping Design Guide Fiberglass Reinforced Piping SystemsDocumento36 pagineEngineering Piping Design Guide Fiberglass Reinforced Piping Systemsoscarhdef100% (1)

- Schneider Altistart ATS48 ManualDocumento84 pagineSchneider Altistart ATS48 ManualAjie SasmitaNessuna valutazione finora

- Emcp 4.1 & 4.2 1-16-14 PDFDocumento280 pagineEmcp 4.1 & 4.2 1-16-14 PDFAurelio Serrano93% (14)

- AMOS Business Suite Vrs. 10.1.00 Installation Guide PDFDocumento73 pagineAMOS Business Suite Vrs. 10.1.00 Installation Guide PDFhieu100% (1)

- s71500 Ai 8xu I Hs Manual en-US en-USDocumento53 pagines71500 Ai 8xu I Hs Manual en-US en-UShieuNessuna valutazione finora

- Espectro Scopia Infra RojaDocumento12 pagineEspectro Scopia Infra RojaWilliams MedinaNessuna valutazione finora

- Instruction Manual Series 880 CIU Prime: May 2009 Part No.: 4416525 Revision 4Documento36 pagineInstruction Manual Series 880 CIU Prime: May 2009 Part No.: 4416525 Revision 4hieuNessuna valutazione finora

- 118 - 4416381 - Rev0 - Low-Res Cau Hinh Entis ProDocumento60 pagine118 - 4416381 - Rev0 - Low-Res Cau Hinh Entis ProhieuNessuna valutazione finora

- 422rfhcpu eDocumento150 pagine422rfhcpu eSkinny1001Nessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- PW3 PicDocumento23 paginePW3 PicNanaNessuna valutazione finora

- SAP ActivateDocumento7 pagineSAP ActivateImtiaz KhanNessuna valutazione finora

- Mayank PPT Gui Language Editor Using PythonDocumento20 pagineMayank PPT Gui Language Editor Using PythonMayank GuptaNessuna valutazione finora

- Cse111 PortfolioDocumento8 pagineCse111 PortfolioPraneeth RayaluNessuna valutazione finora

- Il NT Pramac Operator Guide 11 2008Documento10 pagineIl NT Pramac Operator Guide 11 2008yacinealg1Nessuna valutazione finora

- Service Bulletin: Technical Information To All Owners / Operators of Wärtsilä RT-flex50 and RT-flex50-B EnginesDocumento4 pagineService Bulletin: Technical Information To All Owners / Operators of Wärtsilä RT-flex50 and RT-flex50-B EnginesRaul Diaz100% (1)

- Proposal TemplateDocumento3 pagineProposal Templatenursyuhadah1609Nessuna valutazione finora

- Java ExpressionsDocumento1 paginaJava ExpressionsHanalyn SalikNessuna valutazione finora

- Daikin-Spot AC Equipment List (Rev.03) - Capacity AnalyzeDocumento11 pagineDaikin-Spot AC Equipment List (Rev.03) - Capacity AnalyzeVũ Mạnh ThắngNessuna valutazione finora

- ISA Fieldbus For Process Control, Eng, Ops, Maint, Jonas Berg, OCRDocumento240 pagineISA Fieldbus For Process Control, Eng, Ops, Maint, Jonas Berg, OCRAnonymous zdCUbW8HfNessuna valutazione finora

- IWICCAS24Documento2 pagineIWICCAS24SOUADNessuna valutazione finora

- SOP For Production DepartmentDocumento5 pagineSOP For Production DepartmentDaniel SusantoNessuna valutazione finora

- Parts Catalog: 0CD50-M05530ENDocumento28 pagineParts Catalog: 0CD50-M05530ENVladis0710100% (1)

- 1.4 Angular - Display A Selection ListDocumento10 pagine1.4 Angular - Display A Selection ListPedro Leite (Mindset Épico)Nessuna valutazione finora

- 123SOADocumento46 pagine123SOABala SubramanianNessuna valutazione finora

- jPOS EEDocumento111 paginejPOS EEAya SrhanNessuna valutazione finora

- Promo115 NEF Engine Programme-SmallDocumento20 paginePromo115 NEF Engine Programme-SmallAndreyIvanovNessuna valutazione finora

- Good Java Projects For ResumeDocumento5 pagineGood Java Projects For Resumeaflldvuhp100% (1)

- Trading Application SRS DocumentDocumento6 pagineTrading Application SRS Documentmanasdere2004Nessuna valutazione finora

- CCV ExamDocumento2 pagineCCV ExamAbhishek SinghNessuna valutazione finora

- Online Examination SystemDocumento81 pagineOnline Examination SystemPriyanka Gupta50% (2)

- Caterpillar C32Documento10 pagineCaterpillar C32Carlos BarbosaNessuna valutazione finora

- Chapter 4 Requirements EngineeringDocumento78 pagineChapter 4 Requirements EngineeringShabana TahirNessuna valutazione finora

- Devsecops Foundation (Dsof) : Dev OpsDocumento1 paginaDevsecops Foundation (Dsof) : Dev OpsDhivakar RadhakrishnanNessuna valutazione finora

- Systems Development Life CycleDocumento17 pagineSystems Development Life CycleanaeemkhanNessuna valutazione finora

- A Software Project Management FrameworkDocumento9 pagineA Software Project Management FrameworkLogika123Nessuna valutazione finora

- Web Dynpro SAPDocumento3 pagineWeb Dynpro SAPClasesXXXNessuna valutazione finora

- Ans: Following A Plan Over Responding To ChangeDocumento39 pagineAns: Following A Plan Over Responding To ChangeSangeetaNessuna valutazione finora

- Module 4 - EngineDocumento38 pagineModule 4 - EngineWilliam RuizNessuna valutazione finora

- Dotnet and C#Documento54 pagineDotnet and C#Som SanwalNessuna valutazione finora