Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aboveground Tank Installation Checklist

Caricato da

Hugo Mario Ariza PalacioCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aboveground Tank Installation Checklist

Caricato da

Hugo Mario Ariza PalacioCopyright:

Formati disponibili

Installation Checklist for Aboveground Storage Tanks

CELINA FIRE DEPARTMENT

972-382-2653

Business Name:

Address:

INSTALLING CONTRACTOR

Business:

Address:

Phone Number:

Job Forman:

Installing Contractor License Number:

Tanks:

1) Capacity: Product: UL#:

2) Capacity: Product: UL#:

3) Capacity: Product: UL#:

a) TCEQ provided with 30-day notice for tanks over 1,100 gallons

b) Installation plans and specifications are approved by CFD

c) Foam fire protection shall be provided for above-ground tanks over 500 gallons unless UL Listed 2080/2085 tanks.

d) Confirm foam system has approved plans

The Following Shall be Inspected Prior to Use:

1) Tanks located as indicated on approved plans from lot lines and buildings.

2) Tanks are marked with UL identification.

3) Tank serial number(s) and U.L. listing number(s) are recorded for each tank.

4) Tank diameter(s) checked and recorded.

5) Tank tightness Air test, 3-5 psi for minimum of 1-hr, witnessed prior to tank(s) being placed in service.

6) The interstitial space (annulus) of double-wall or secondary containment tanks shall be tested either:

a) Hydrostatically or with air pressure at a gauge pressure of 3 to 5 psi (20 to 35 kPa) or

b) By vacuum at 2.6 psi (18 kPa) or

c) In accordance with the tank’s listing or the manufacturer’s instructions.

d) The pressure or vacuum shall be held for not less than 1 hour or for the duration specified in the listing procedures

for the tank.

Form 1004 (Rev 12/2010)

The Following Shall be Inspected on Any Piping:

1) All piping and valves are U.L. listed or of approved type.

2) Underground piping shall be installed on at least 6 in. (150 mm) of well-compacted bedding material.

3) In areas subject to vehicle traffic, the pipe trench shall be deep enough to permit a cover of at least 18 in. (450 mm) of

well-compacted backfill material and pavement.

4) In paved areas where a minimum 2 in. (50 mm) of asphalt is used, backfill between the pipe and the asphalt shall be

permitted to be reduced to 8 in. (200 mm) minimum.

5) In paved areas where a minimum 4 in. (100 mm) of reinforced concrete is used, backfill between the pipe and the

asphalt shall be permitted to be reduced to 4 in. (100 mm) minimum.

6) In areas not subject to vehicle traffic, the pipe trench shall be deep enough to permit a cover of at least 6 in. (150 mm)

of well-compacted backfill material.

7) Piping within the same trench shall be separated horizontally by at least two pipe diameters. Separation need not

exceed 9 in. (230 mm).

8) Two or more levels of piping within the same trench shall be separated vertically by a minimum 6 in. (150 mm) of

well-compacted bedding material.

9) Piping is supported and separated to prevent damage and vibration.

10) Tank piping is supported and protected from mechanical damage or fire exposure.

11) Pipe joints are liquid tight, welded, threaded or flanged. Class 1 liquid joints are welded if the joints are located

inside the building.

12) Unless tested in accordance with the applicable section of ASME B31.9, all piping shall be tested before being

covered, enclosed or placed in use.

a) Testing shall be done hydrostatically to 150 percent of the maximum anticipated pressure of the system or

pneumatically to 110 percent of the maximum anticipated pressure of the system and the test pressure shall be

maintained while a complete visual inspection of all joints and connections is conducted.

b) In no case shall the test pressure be less than a gauge pressure of 5 psi (35 kPa) measured at the highest point of

the system

c) The test pressure is maintained for not less than 10 minutes.

d) Care shall be exercised to ensure that these pressures are not applied to vented storage tanks.

Such storage tanks shall be tested independently from the piping.

13) The interstitial (annular) space of secondary containment–type piping shall be tested:

a) Hydrostatically at a gauge pressure of 5 psi (35 kPa ) or

b) Air pressure at a gauge pressure of 5 psi (35 kPa) or

c) Shall be tested in accordance with its listing or with the manufacturer’s instructions.

d) The pressure source shall be disconnected from the interstitial space to ensure that the test is being conducted on a

closed system.

e) The pressure shall be maintained for a minimum of 1 hour.

14) All metal pipes is properly wrapped (with 50% overlap), properly coated, or catholically protected to prevent galvanic

action or corrosion.

Openings Other Than Vents

1) Filling, emptying, and vapor recovery openings are located outside the building, not less than 5 ft. from building

openings or lot lines.

2) For top load tanks, a metallic fill pipe is installed to minimize static electricity by terminating within 6 inches of the

tank bottom, 5704.2.7.5.5.

3) Tank openings are on the top only.

Spill/Overfill Prevention

1) An overfill prevention system is provided for each tank that operates as follows:

a) Automatically shut off the flow of fuel to the tank when the quantity reaches 95 percent of tank capacity and

b) Alert the transfer operator when the tank is no more than 90 percent full by restricting the flow of liquid into the tank

or triggering the high-level alarm

2) A spill container with a capacity of not less than 5 gallons is provided for each fill connection. Top fill containers are

noncombustible, fixed to the tank and equipped with a manual drain valve that drains into the main tank.

Vents

1) Vent pipes from underground tanks storing Class I liquids are located so that the discharge point is outside of buildings,

higher than the fill pipe opening, and not less than 12 ft. (3.6 m) above the adjacent ground level.

2) Vent pipe outlets are located and directed so that vapors will not accumulate or travel to an unsafe location, enter

building openings, or be trapped under eaves and shall be at least 5 ft. (1.5 m) from building openings and at least 15 ft.

(4.5 m) from powered ventilation air intake devices.

3) Vent pipes from tanks storing Class II or Class IIIA liquids terminate outside of the building and higher than the fill pipe

opening.

4) Vent outlets on atmospheric tanks storing Class IIIB liquids are allowed to discharge inside a building if the vent is a

normally closed vent.

5) Vent pipes are not be obstructed by devices provided for vapor recovery or other purposes unless the tank and

associated piping and equipment are otherwise protected to limit back-pressure development to less than the maximum

working pressure of the tank and equipment by the provision of pressure-vacuum vents, rupture discs, or other

tank-venting devices installed in the tank vent lines.

6) Vent outlets and devices are protected to minimize the possibility of blockage from weather, dirt, or insect nests.

7) Vent pipes are fitted with return bends, coarse screens, or other devices to minimize ingress of foreign material.

8) Vent pipes and vapor return piping are installed without sags or traps in which liquid can collect.

9) Where tank vent piping is manifold, pipe sizes are such as to discharge, within the pressure limitations of the system,

the vapors they could be required to handle when manifold tanks are filled simultaneously.

10) Piping systems are bonded and grounded.

11) Each loading and unloading riser is marked to identify the product for which it is to be used.

12) The use of a flame arrester or venting device in a vent line complies with their listing also compliant with API 2028 for a

flame arrestor.

13) Tank emergency vent does not vent inside a building.

Tank Support

1) Tank foundation, support, and anchorages are designed in accordance with NFPA 3 0 - 4.2.4 and the IBC, IFC

5704.2.9.3.

2) Tanks containing Class I, II, IIIA liquids that are elevated more than 12 inches above grade shall have a fire-

resistance rating of not less than 2-hours in accordance with ASTM E 1529 unless one of the three exceptions to

Section 5704.2.9.2.3 is applicable.

Miscellaneous

1) Location and verbiage for signs prohibiting open flames and no smoking are in accordance with approved plans.

a) Tanks exceeding 100 gallons have NFPA 704 placard.

b) Tank and piping subject to vehicular damage is protected by guard posts designed in accordance with IFC.

c) Drainage control and diking are provided in accordance with approved plans, or the tank is a listed tank with

secondary containment.

Potrebbero piacerti anche

- Split Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard seals-SNL 515-612 + 22215 K + H 315Documento2 pagineSplit Plummer Block Housings SNL and SE Series For Bearings On An Adapter Sleeve With Standard seals-SNL 515-612 + 22215 K + H 315Hugo Mario Ariza PalacioNessuna valutazione finora

- Tubo Sin Costura, Nps 6, SCH. 40, ASME B36.10MDocumento1 paginaTubo Sin Costura, Nps 6, SCH. 40, ASME B36.10MHugo Mario Ariza PalacioNessuna valutazione finora

- TRN NMD 0018 00 Rev - 01 - PDFDocumento19 pagineTRN NMD 0018 00 Rev - 01 - PDFHugo Mario Ariza PalacioNessuna valutazione finora

- Tia 86 19 1 PDFDocumento1 paginaTia 86 19 1 PDFHugo Mario Ariza PalacioNessuna valutazione finora

- Din 2768 English VersionDocumento1 paginaDin 2768 English VersionCesar Augusto Castellar OrtegaNessuna valutazione finora

- Tia 86 19 1 PDFDocumento1 paginaTia 86 19 1 PDFHugo Mario Ariza PalacioNessuna valutazione finora

- 07 05 DATA-PumpDocumento7 pagine07 05 DATA-PumpHugo Mario Ariza PalacioNessuna valutazione finora

- Shaft Design and CalculationDocumento4 pagineShaft Design and CalculationHugo Mario Ariza PalacioNessuna valutazione finora

- Fibreglass Tank and Vessel SpecificationDocumento43 pagineFibreglass Tank and Vessel SpecificationJorge Andres Caro CortesNessuna valutazione finora

- Title: Benefit-Cost Analysis of Building Information Modeling (BIM) in A Railway Site Authors: Min Ho, Shin, PH.DDocumento11 pagineTitle: Benefit-Cost Analysis of Building Information Modeling (BIM) in A Railway Site Authors: Min Ho, Shin, PH.DHugo Mario Ariza PalacioNessuna valutazione finora

- SOLIDWORKS Complete Uninstall Guide: ImportantDocumento8 pagineSOLIDWORKS Complete Uninstall Guide: ImportantbilelNessuna valutazione finora

- Introduction To The Draft ISO 19650 andDocumento3 pagineIntroduction To The Draft ISO 19650 andHugo Mario Ariza PalacioNessuna valutazione finora

- Basic Concepts of Stairwell PressurizationDocumento4 pagineBasic Concepts of Stairwell PressurizationHugo Mario Ariza PalacioNessuna valutazione finora

- Basic Concepts of Stairwell PressurizationDocumento4 pagineBasic Concepts of Stairwell PressurizationHugo Mario Ariza PalacioNessuna valutazione finora

- Architecturally Exposed Structural Steel 05125Documento16 pagineArchitecturally Exposed Structural Steel 05125Hugo Mario Ariza PalacioNessuna valutazione finora

- Regconomica - Proyecto Norma Técnica Colombiana 430 04Documento1 paginaRegconomica - Proyecto Norma Técnica Colombiana 430 04Hugo Mario Ariza PalacioNessuna valutazione finora

- CertificateOfCompletion - Solidworks Simulation For Finite Element AnalysisDocumento1 paginaCertificateOfCompletion - Solidworks Simulation For Finite Element AnalysisHugo Mario Ariza PalacioNessuna valutazione finora

- CertificateOfCompletion - Fusion 360 Designing For MetalDocumento1 paginaCertificateOfCompletion - Fusion 360 Designing For MetalHugo Mario Ariza PalacioNessuna valutazione finora

- CertificateOfCompletion - Autodesk Inventor Professional Stress Analysis Tools PDFDocumento1 paginaCertificateOfCompletion - Autodesk Inventor Professional Stress Analysis Tools PDFHugo Mario Ariza PalacioNessuna valutazione finora

- Commissioning Procedure Vagen Screw Conveyor With Check ListDocumento3 pagineCommissioning Procedure Vagen Screw Conveyor With Check Listrahmankhan823100% (1)

- Program Management FoundationsDocumento1 paginaProgram Management FoundationsMaverickPNessuna valutazione finora

- CertificateOfCompletion - Autodesk Inventor Professional Stress Analysis ToolsDocumento1 paginaCertificateOfCompletion - Autodesk Inventor Professional Stress Analysis ToolsHugo Mario Ariza PalacioNessuna valutazione finora

- FRP Tank Selip Technical SpecificationDocumento29 pagineFRP Tank Selip Technical SpecificationAiman Hamam100% (3)

- Combustible Dust PosterDocumento1 paginaCombustible Dust PosterEvert W. VanderBergNessuna valutazione finora

- Active Listening - EbookDocumento1 paginaActive Listening - EbookHugo Mario Ariza PalacioNessuna valutazione finora

- PNSC0035 TracingDocumento57 paginePNSC0035 TracingGNessuna valutazione finora

- k-90-9044 900 LB FM-200 Cylinder 10-7-14Documento2 paginek-90-9044 900 LB FM-200 Cylinder 10-7-14Hugo Mario Ariza PalacioNessuna valutazione finora

- Seismic Design of Circular Liquid-ContainingDocumento19 pagineSeismic Design of Circular Liquid-ContainingBruna MacedoNessuna valutazione finora

- Combustible Dust PosterDocumento1 paginaCombustible Dust PosterEvert W. VanderBergNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 7 Step PfmeaDocumento132 pagine7 Step PfmeaRajdeep SikdarNessuna valutazione finora

- Fluid Mechanics Professor: Salvador Vargas Díaz Final Theoretical Quiz Student NameDocumento6 pagineFluid Mechanics Professor: Salvador Vargas Díaz Final Theoretical Quiz Student NameSALVADOR VARGAS DIAZNessuna valutazione finora

- Thermodynamics IDocumento7 pagineThermodynamics IJustinnNessuna valutazione finora

- Jojo 3 Canopy Design DoneDocumento27 pagineJojo 3 Canopy Design DoneLenard SantiagoNessuna valutazione finora

- TH5Documento18 pagineTH5Sia How TanNessuna valutazione finora

- Control System For Controllable Pitch Marine Propellers: Product Manual 36049 (Revision D)Documento34 pagineControl System For Controllable Pitch Marine Propellers: Product Manual 36049 (Revision D)Irancell TellNessuna valutazione finora

- Fluid MachineierDocumento11 pagineFluid MachineierAldwin AjocNessuna valutazione finora

- Cc2 ThermodynamicsDocumento22 pagineCc2 Thermodynamicsmark anthony tutorNessuna valutazione finora

- BOG CalDocumento6 pagineBOG CalSook Thiam LeeNessuna valutazione finora

- Gases and The Structure of MatterDocumento20 pagineGases and The Structure of MatterJaimeNessuna valutazione finora

- M24-Plate Heat ExcahngerDocumento16 pagineM24-Plate Heat ExcahngerAlexNessuna valutazione finora

- Exercise Permeability QDocumento7 pagineExercise Permeability QsidikNessuna valutazione finora

- CH - 5 Gas Well TestingDocumento51 pagineCH - 5 Gas Well TestingMohannad AbdulrahmanNessuna valutazione finora

- Chapter 6 - Gases (Part 1)Documento61 pagineChapter 6 - Gases (Part 1)Shivanni PonnusamyNessuna valutazione finora

- Process Instrumentation I: Vaal University of TechnologyDocumento61 pagineProcess Instrumentation I: Vaal University of TechnologyArpit SharmaNessuna valutazione finora

- Well DesignDocumento55 pagineWell DesignTheezz100% (2)

- BS en 00917-1997Documento12 pagineBS en 00917-1997mohamed guedichiNessuna valutazione finora

- Assignment 4Documento10 pagineAssignment 4mahmoud EissaNessuna valutazione finora

- PRO-II Thermodynamic Model SelectionDocumento79 paginePRO-II Thermodynamic Model Selectionchemsac2100% (1)

- 9b. RC WATER TANKSDocumento5 pagine9b. RC WATER TANKSYadhu .msa17Nessuna valutazione finora

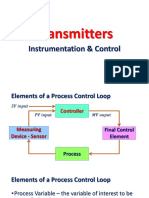

- TransmittersDocumento40 pagineTransmittersSka dooshNessuna valutazione finora

- Ust Mock Boards - PipeDocumento8 pagineUst Mock Boards - PipeVon Eric DamirezNessuna valutazione finora

- Water DistributionDocumento116 pagineWater DistributionJoshua GonzalesNessuna valutazione finora

- Chemical Thermodynamics: Module - 4Documento25 pagineChemical Thermodynamics: Module - 4TeachingTrainingCoaching KnowledgeSharingSessionNessuna valutazione finora

- 2009 Hydrothermal Model For Predicting Fire-Induced Spalling in ConcreteDocumento10 pagine2009 Hydrothermal Model For Predicting Fire-Induced Spalling in ConcreteMaha Ass'adNessuna valutazione finora

- Trampa Termo-Dinamica TD 52 PDFDocumento12 pagineTrampa Termo-Dinamica TD 52 PDFjose david CardozoNessuna valutazione finora

- Domed Roof Building 2020Documento8 pagineDomed Roof Building 2020Marco CamposNessuna valutazione finora

- Flow Through Fluidized Bed: Unit-Operation-Reaction-Engg.-Process-Control Lab (../index - HTML)Documento2 pagineFlow Through Fluidized Bed: Unit-Operation-Reaction-Engg.-Process-Control Lab (../index - HTML)Jishnu JohnNessuna valutazione finora

- The 523V Catalog PageDocumento1 paginaThe 523V Catalog PageAndres CortezNessuna valutazione finora

- 5th Form Assignment 2Documento2 pagine5th Form Assignment 2Philip MooreNessuna valutazione finora