Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Mechanical Legend: Circuit Setter Detail

Caricato da

KoJoeDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Mechanical Legend: Circuit Setter Detail

Caricato da

KoJoeCopyright:

Formati disponibili

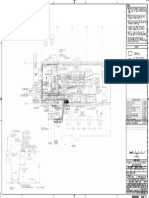

TEMPERATURE CONTROL FOR NEW EQUIPMENT: GENERAL NOTES:

EXISTING PIPING

SUPPORTS (TYP.)

1. ALL DUCTWORK AND PIPES SHALL BE COORDINATED WITH (OTHER NEW AND EXISTING PIPES AND DUCTWORK ) LIGHTS, STRUCTURAL

MECHANICAL LEGEND

THE CHILLER SHALL BE ENERGIZED AND DE-ENERGIZED BY THE OWNER'S EXISTING BUILDING AUTOMATION SYSTEM (BAS) BASED ON THE

OWNER'S CURRENT OCCUPANCY AND SCHEDULE CONTROL. PRIMARY CHILLED WATER PUMPS (CWP-1 & 2) AND CONDENSER WATER PUMPS SYSTEM, CEILING SUPPORTS AND FRAMING BEFORE INSTALLATION. MINOR DUCT AND PIPE OFFSETS AND MINOR TRANSITIONS SHALL BE AIR SEPARATOR AS

TO COOLING (CDP) SHALL BE CONFIGURED TO OPERATE THROUGH THE BAS IN CONJUNCTION WITH THE NEW CHILLER CONTROLLER. PROVIDED AS REQUIRED. MEASUREMENTS FOR VERTICAL CLEARANCES OF DUCTWORK AND PIPING SHALL BE TAKEN AT THE JOB SITE ANCHOR

TOWER BEFORE INSTALLATION. ANGLE VALVE

WATER COOLED CHILLER: BALANCING VALVE

CWR CDR 2. ALL EQUIPMENT SHALL BE INSTALLED IN ACCORDANCE WITH MANUFACTURER'S PUBLISHED INSTRUCTIONS. CAPACITY CAP

GENERAL: THE CHILLER SHALL BE CONTROLLED THROUGH THE UNIT-MOUNTED STAND-ALONE MICROPROCESSOR CONTROLLER AND CEILING CLG

FACTORY-INSTALLED BAS COMMUNICATION MODULES. THE BAS COMMUNICATION MODULES SHALL BE COORDINATED TO INTEROPERATE VIA 3. MATERIALS AND INSTALLATION SHALL COMPLY WITH LOCAL CODES, APPLICABLE PROVISIONS OF LATEST EDITION OF NATIONAL FIRE CHECK VALVE

CWS CDS

THE APPROPRIATE PROTOCOL WITH THE EXISTING NOVAR BAS. PROTECTION ASSOCIATION, LOCAL UTILITY REGULATIONS AND GOVERNMENTAL DEPARTMENTS HAVING JURISDICTION. CIRCUIT SETTER

CS(GPM)

TO SYSTEM 4. CONTRACTOR SHALL SEAL AND FLASH ALL PENETRATIONS IN EXISTING WALLS. CLEANOUT CO CO

THE CHILLER AND ITS PRIMARY CHILLED WATER PUMP (CWP-P1 AND CWP-P2) AND CONDENSER WATER PUMPS (CDP) SHALL BE SEQUENCED IN

EXISTING PIPING ACCORDANCE TO CONTROL SOFTWARE WITHIN THE CHILLER MICROPROCESSORS AND THE BAS. THE CHILLER MICROPROCESSORS SHALL BE COMMON C

ENABLED THROUGH THE BAS SCHEDULE AND AMBIENT TEMPERATURE. AN INPUT SHALL ALLOW FOR OPERATION OVERRIDE. 5. VERIFY WALL OPENINGS WITH STRUCTURE. CONTROL SWITCH S

PRESSURE DEGREES FAHRENHEIT °F

GAUGE (TYP.) CHILLER OPERATION: THE CONTROLS SHALL START AND STOP THE CHILLER BASED UPON THE SYSTEM CHILLED WATER SUPPLY 6. VERIFY THE LOCATION OF ALL THERMOSTATS, TEMPERATURE SENSORS, PANELS AND CONTROL INSTRUMENTS WITH THE OWNER PRIOR TO DIAMETER DIA

TEMPERATURE AND SYSTEM CHILLED WATER RETURN TEMPERATURE. THE CHILLED WATER SUPPLY TEMPERATURE SETPOINT SHALL BE 44°F ROUGH-IN. DIRECTION OF FLOW

(ADJUSTABLE THROUGH THE BAS). UPON A CALL FOR CHILLER STARTUP, THE FOLLOWING SHALL OCCUR:

NEW SCHEDULE 80 CPVC 7. VERIFY LOCATIONS OF NEW AND EXISTING EQUIPMENT AND ROUTE OF PIPING AND DUCTWORK WITH EXISTING CONDITIONS. DIRECTION OF SLOPE DOWN

PIPING (CONDENSER a. START THE CHILLED WATER PUMP. DOMESTIC COLD WATER PIPE CW

WATER PIPING ONLY) b. PROVE THAT CHILLED WATER IS FLOWING THROUGH THE EVAPORATOR. 8. ALL CUTTING AND PATCHING FOR THE INSTALLATION OF NEW WORK IN EXISTING BUILDING SHALL BE DONE BY THE CONTRACTOR. DOWN DN

c. IF CHILLER FLOW IS NOT PROVEN WITHIN A TIME DELAY, A SIGNAL SHALL ALARM THE BAS. THE BAS SHALL DISABLE THE DRY BULB DB

CHILLED WATER FLEXIBLE PIPE 9. COORDINATE THE EXACT LOCATIONS OF CHILLERS, PUMPS, PIPING, DUCTWORK AND OTHER MECHANICAL EQUIPMENT WITH LIGHTS, BEAMS EACH EA

CHILLER.

FLOW SWITCH CONNECTORS AND OTHER BUILDING COMPONENTS. ENTERING WATER TEMPERATURE EWT

d. START THE CONDENSER WATER PUMP.

(TYP.) EXISTING EX

e. PROVE THAT CONDENSER WATER IS FLOWING THROUGH THE CONDENSER.

f. IF CONDENSER FLOW IS NOT PROVEN WITHIN A TIME DELAY, A SIGNAL SHALL ALARM THE BAS. 10. CONTRACTOR SHALL PROVIDE ALL SUPPORTS REQUIRED TO MOUNT MECHANICAL EQUIPMENT, DUCTWORK, PIPING AND ACCESSORIES.

EXISTING, REMOVE FROM THIS POINT

g. OPERATE THE CONDENSER WATER BYPASS/MIXING VALVE TO MAINTAIN REFRIGERANT HEAD PRESSURE REQUIREMENTS

STRAINER (TYP) IN ACCORDANCE WITH THE CHILLER MANUFACTURER'S RECOMMENDATIONS. 11. WHERE PIPE CONNECTIONS ARE SHOWN CONNECTING TO EXISTING, CONTRACTOR SHALL DETERMINE EXACT LOCATIONS AND CONNECTION

EXPANSION JOINT EJ

h. SOFT START THE CHILLER AFTER BOTH CHILLED WATER AND CONDENSER WATER FLOW IS PROVEN. THE CHILLER SHALL SIZES PRIOR TO INSTALLATION.

CONDENSER WATER EXPANSION TANK ET

FLOW SWITCH START UNLOADED AND AFTER AN ADJUSTABLE TIME BECOMES LOADED THROUGH CURRENT LIMITING. CONTROLS

12. NEW PIPING AND PIPE INSULATION SHALL BE AS SPECIFIED. INSULATION THAT IS DAMAGED OR REMOVED FOR NEW WORK SHALL BE FEET FT

SHALL MONITOR THE SYSTEM TEMPERATURES AND ANTICIPATE CHANGES TO ACCOMPLISH SOFT START.

REPLACED, REPAIRED AND SEALED AS REQUIRED. FEET PER MINUTE FPM

R i. THE CHILLER SHALL LOAD AND UNLOAD TO MEET CHILLED WATER SUPPLY SETPOINT. THE CALCULATED SETPOINT FOR

FLEXIBLE PIPE CONNECTION

THE CHILLER SHALL DEPEND UPON:

TO FLOOR DRAIN 13. ALL CHILLED WATER PIPING SHALL BE INSULATED. FLOAT & THERMOSTATIC TRAP

CHILLER (1) SYSTEM SUPPLY WATER TEMPERATURE SETPOINT,

FLOOR FL E ALT H O F V

(2) SYSTEM FLOW SWITCH,

14. EXPOSED PIPING RUNOUTS SHALL BE INSTALLED IN PRACTICAL ALIGNMENT WITH THE BUILDING AND SHALL BE ADEQUATELY SECURED TO FLOW SWITCH FSW FSW NW

IR

O

(3) SYSTEM RETURN WATER TEMPERATURE,

FROM FRM 09 /12/ 17

M

THE BUILDING STRUCTURE.

GI

EXISTING CONCRETE (4) CAPACITY OF THE CHILLER PLANT,

CO M

FUEL OIL SUPPLY PIPE FOS FOS

NI A

HOUSEKEEPING PAD (5) OPERATOR DEFINED MINIMUM CHILLED WATER SETPOINT FOR THE CHILLER

15. PROVIDE ACCESS DOORS OF SUFFICIENT SIZE FOR ALL CONCEALED CONTROLS, DAMPERS OR ANY ITEMS REQUIRING ACCESS. GALLONS PER MINUTE GPM

j. THE CONTROLS SHALL ALLOW ADJUSTABLE TIME DELAYS FOR CHILLER START/STOP TO PREVENT EXCESSIVE CHILLER GAS COCK

CYCLING. GLOBE VALVE GBV

16. ALL REMOTE MOUNTED TEMPERATURE CONTROL DEVICES AND TEMPERATURE CONTROL WIRING SHALL BE FURNISHED AND INSTALLED BY

HEATING WATER PUMP HWP

R

THE CONTRACTOR.

PR

CHILLER MALFUNCTION SHALL BE COMMUNICATED TO THE BAS FOR ALARM.

EE

FLOOR HEATING WATER RETURN PIPE HWR HWR

O

FE

17. ALL EQUIPMENT SHALL BE SECURED TO CONCRETE HOUSEKEEPING PADS WITH HOLD-DOWN BOLTS TO PREVENT MOVEMENT. HEATING WATER SUPPLY PIPE HWS HWS SS IN

HOSE END DRAIN VALVES (TYP.) CHILLER CONTROL PANEL SHALL BACNET INTERFACE WITH THE BAS AND PROVIDE THE FOLLOWING FEATURES AT THE CENTRAL BUILDING HORSEPOWER HP IO NA L ENG

NEOPRENE VIBRATION CONTROL STATION.

18. CONDUIT, WIRING, PIPING AND SUPPORTS SHALL NOT IMPEDE MECHANICAL EQUIPMENT ACCESS. HOUR HR

ISOLATION PADS (TYP.)

INCH IN

THE FOLLOWING POINTS SHALL BE MONITORED BY THE CHILLER CONTROL SYSTEM AND SHALL BE REPORTED TO THE BUILDING AUTOMATION

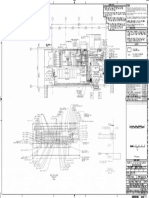

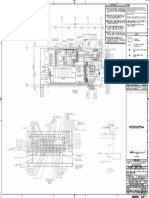

CHILLER CONNECTION DETAIL SYSTEM (BAS) TO AUTOMATICALLY MAKE A DAILY LOG: CHILLED WATER INLET TEMPERATURE, CHILLED WATER OUTLET TEMPERATURE,

EVAPORATOR REFRIGERANT PRESSURE, EVAPORATOR REFRIGERANT TEMPERATURE, CONDENSER WATER INLET TEMPERATURE,

19. PIPING AND DUCTWORK SHALL NOT BE INSTALLED ABOVE ELECTRICAL PANELS. COORDINATE INSTALLATION OF PIPING AND DUCTWORK

WITH ELECTRICAL PANELS WHEN SHOWN NEAR PANELS OR OVER ELECTRICAL ROOMS.

KILOWATT

LEAVING WATER TEMPERATURE

KW

LWT

SCHEMATIC CONDENSER WATER OUTLET TEMPERATURE, CONDENSER REFRIGERANT PRESSURE, CONDENSER REFRIGERANT TEMPERATURE, MAV

MANUAL AIR VENT REVISION DATE

20. INSTRUCT THE OWNER IN THE PROPER OPERATION AND MAINTENANCE OF THE MECHANICAL SYSTEMS UNTIL THE OWNER IS FULLY

CONDENSER APPROACH TEMPERATURE, COMPRESSOR REFRIGERANT DISCHARGE TEMPERATURE, COMPRESSOR REFRIGERANT SUCTION NATURAL GAS PIPE, NEW G G

PREPARED TO OPERATE AND MAINTAIN THE MECHANICAL SYSTEM. HOWEVER, LENGTH OF INSTRUCTION TIME SHALL BE LIMITED TO ONE

SUCTION DISCHARGE TEMPERATURE, PURGE EXHAUST TIME OR DISCHARGE RATE. EXISTING TO REMAIN G EX G

DAY.

WALL EXISTING TO BE REMOVED G G

GALVANIZED STEEL AT A MINIMUM THE FOLLOWING POINTS/INFORMATION SHALL BE COMMUNICATED FROM THE CHILLER CONTROL TO/FROM THE BAS: CHILLER

21. SYSTEMS SHALL OPERATE UNDER CONDITIONS OF LOAD WITHOUT UNUSUAL OR EXCESSIVE NOISE OR VIBRATION. UNUSUAL OR EXCESSIVE

PIPE SLEEVE CONTROL PANEL DIAGNOSTICS, COMPRESSOR MOTOR TEMPERATURE AND HIGH TEMPERATURE ALARM, CHILLER STARTER DIAGNOSTICS,

NOISE OR VIBRATION SHALL BE CORRECTED.

CHILLED WATER PUMP ENABLE, CHILLED WATER FLOW STATUS, CONDENSER WATER PUMP ENABLE, CONDENSER WATER FLOW STATUS, NEW CONNECTED TO EXISTING

LEAVING CHILLED WATER TEMPERATURE, ENTERING CHILLED WATER TEMPERATURE, LEAVING CONDENSER WATER TEMPERATURE,

22. EQUIPMENT, MATERIALS AND LABOR REQUIRED BY THESE CONTRACT DRAWINGS SHALL BE GUARANTEED TO BE FREE FROM DEFECTIVE

ENTERING CONDENSER WATER TEMPERATURE, SYSTEM CHILLED WATER SUPPLY TEMPERATURE, SYSTEM CHILLED WATER RETURN NORMALLY CLOSED NC

PIPE MATERIALS OR WORKMANSHIP FOR ONE YEAR AFTER FINAL ACCEPTANCE OF THE PROJECT UNLESS SPECIFIED OTHERWISE. DEFECTIVE

TEMPERATURE, EVAPORATOR REFRIGERANT TEMPERATURE AND PRESSURE, CONDENSER REFRIGERANT TEMPERATURE AND PRESSURE, NORMALLY OPEN NO

MATERIALS OR WORKMANSHIP OCCURRING DURING THIS PERIOD SHALL BE CORRECTED AT NO ADDITIONAL COST.

COOLING TOWER ENABLE. OUTDOOR AIR OA

1/4" COCK

CS 23. EQUIPMENT LISTED IN THE EQUIPMENT NOTES IS THE BASIS OF DESIGN. IF THE AWARDED BID RESULTS IN AN EQUIPMENT SUBSTITUTION, PIPING INDICATION WITH RESPECT

CHILLED WATER PUMPS (CWP-1 AND CWP-2): EACH PUMP SHALL OPERATE IN CONJUNCTION WITH THE OWNER'S EXISTING BAS SEQUENCE TO FLOW

ANY CHANGES REQUIRED TO ALL TRADES DUE TO EQUIPMENT SUBSTITUTION ARE THE RESPONSIBILITY OF THE INSTALLING CONTRACTOR

AND IN CONJUNCTION WITH THE CHILLER SYSTEM AS A PRIMARY CONSTANT VOLUME PUMP. THE CHILLER SHALL ENERGIZE CWP-1 OR CWP-2 BOTTOM TAKEOFF

AND SHALL BE PERFORMED WITHOUT ADDITIONAL COST TO THE OWNER.

HANG THIS PIPE (BASED ON RUN HOURS) AND PROVE FLOW PRIOR TO INITIATING THE CHILLER COMPRESSORS. ON THE FAILURE OF THE CHILLED WATER SIDE CONNECTION

FROM ABOVE SO

NO WEIGHT RESTS

1/4" COCK

1/4" SPACE BETWEEN

PUMP TO OPERATE, AN ALARM MESSAGE SHALL BE TRANSMITTED TO THE BAS. PUMP FLOW SHALL BE PROVEN PRIOR TO INITIATING CHILLER

OPERATION. UPON A PRIMARY PUMP FAILURE, THE BAS SHALL BE ALARMED AND THE STANDBY PUMP SHALL BE ENERGIZED.

SPECIAL PROJECT NOTES: TOP TAKEOFF

TURN DOWN OR FROM BELOW

FLEXIBLE PIPE

ON PUMP CASING SLEEVE & INSULATION TURN UP OR DOWN

(TYPICAL) PIPE INSULATION EXISTING CONDENSER WATER PUMP ( CDP REVISE EXISTING SEQUENCE): THE EXISTING CONDENSER WATER PUMP SHALL OPERATE IN IN ADDITION TO ALL OF THE REQUIREMENTS SHOWN ON THE DRAWINGS AND IN THE SPECIFICATIONS, THE CONTRACTOR SHALL BE RESPONSIBLE

TURN UP OR FROM ABOVE

PUMP (WHERE REQUIRED) CONJUNCTION WITH THE CHILLER SYSTEM AND CONTROLS TO PROVIDE COOLING TOWER WATER TO THE CHILLER CONDENSER. BEFORE THE FOR ALL OF THE FOLLOWING:

SUCTION DIFFUSER POUNDS LBS

CHILLER IS ENABLED, THE CHILLER SHALL ENERGIZE THE EXISTING CONDENSER WATER PUMP. PUMP FLOW SHALL BE PROVEN PRIOR TO POUNDS PER SQUARE INCH GAGE PSIG

WALL 1. THIS PROJECT CONSISTS OF REMOVING ONE (1) EXISTING WATER COOLED CHILLER AND REPLACING IT WITH ONE (1) NEW WATER COOLED

INITIATING CHILLER COMPRESSORS. UPON PUMP FAILURE, THE BAS SHALL BE ALARMED. PRESSURE DROP PD

MOTOR CHILLER AND ASSOCIATED ELECTRICAL AND CONTROLS WORK REQUIRED; ALSO INCLUDED ARE THE REMOVAL AND REPLACEMENT OF THE

3/4" HOSE-END LEVEL GROUT NOTE: COOLING TOWER (EXISTING SEQUENCE): WHENEVER THE EXISTING CONDENSER WATER PUMP CDP IS ENERGIZED, THE COOLING TOWER FAN CHILLED WATER PUMP WITH TWO NEW CHILLED WATER PUMPS AND THE ADDITION OF A NEW REFRIGERANT EVACUATION SYSTEM.

PRESSURE GAUGE

DRAIN VALVE WHERE PIPES PENETRATE FIRE-RATED WALLS, FILL SHALL BE ALLOWED TO OPERATE. WITH WATER FLOW TO THE COOLING TOWER, THE BAS CONTROLLER SHALL CONTROL THE COOLING ADDITIONAL WORK INCLUDES CONTROL SYSTEM UPGRADES/MODIFICATIONS FOR THE ADDITION OF THE CONDENSER WATER BYPASS/MIXING

SPACE BETWEEN PIPE AND SLEEVE WITH A TOWER FAN THROUGH ITS EXISTING VFD TO MAINTAIN A MAXIMUM 85 DEG. F. SUPPLY CONDENSER WATER. IF THE CONDENSER SUPPLY VALVE AND THE REFRIGERANT EVACUATION SYSTEM. THE REPLACEMENT CHILLER SHALL BE MAGNETIC BEARING, OIL-FREE, SEMI-HERMETIC PRESSURE REDUCING VALVE (FILL VALVE) PRV

FLOOR LINE EXISTING CONCRETE BASE FIRE-RESISTANT MATERIAL WITH SUFFICIENT RATING TO WATER APPROACHES 85 DEG. F., THEN THE COOLING TOWER AIR FLOW SHALL BE AUTOMATICALLY INCREASED. ON A FALL IN THE CENTRIFUGAL TYPE, MODEL AS INDICATED ON SHEET M-1, AS SPECIFIED SHEET M-4.

MAINTAIN THE FIRE RATING OF THE WALL. WHERE PIPE TEMPERATURE OF THE CONDENSER SUPPLY WATER, THE REVERSE SHALL OCCUR. THE COOLING TOWER FAN IS VARIABLE SPEED TYPE WITH PRESSURE RELIEF VALVE

PIPE SUPPORT WITH PENETRATE EXTERIOR WALLS, FILL SPACE BETWEEN 2. FOR THE CHILLER AND THE CWP THE CONTRACTOR SHALL REMOVE EXISTING CONTROLS, CHILLED WATER PIPING, AND CONDENSER WATER

VARIABLE FREQUENCY DRIVE (VFD) CONTROLLER. REVOLUTIONS PER MINUTE RPM

VIBRATION ELIMINATOR PIPE AND SLEEVE WITH FIBERGLASS INSULATION. PIPING AND INSTALL ALL NEW ITEMS TO REPLACE THE EXISTING ITEMS. THE EXISTING SUPPORTS AND INDOOR PIPE HANGERS FOR THE SERVICE VALVE

PAD SAME AS BASE EXISTING CHILLED AND CONDENSER WATER PIPING SHALL BE REUSED FOR SUPPORT OF THE NEW PIPING. ADJUST THE LOCATIONS OF

COOLING TOWER BYPASS VALVE: COOLING TOWER BYPASS VALVE SHALL BE CONTROLLED BY THE STAND-ALONE CHILLER STATIC PRESSURE SP

MICROPROCESSOR CONTROLLER TO MODULATE AND MAINTAIN REFRIGERANT HEAD PRESSURE AT THE CHILLER. EXISTING PIPE SUPPORTS AND PROVIDE ADDITIONAL PIPE SUPPORTS AS REQUIRED FOR THE NEW CHILLED WATER AND CONDENSER PIPING. STRAINER

BASE MOUNTED PUMP DETAIL WALL PIPE SLEEVE DETAIL

HVAC LEGENDS, NOTES, EQUIPMENT NOTES

REFRIGERANT MONITOR ALARM: THE REFRIGERANT MONITOR ALARM SHALL BE MONITORED THROUGH THE BAS. THE REFRIGERANT 3. NEW CONTROLS FOR CHILLER, CWP-1, CWP-2, AND REF SHALL BE PROVIDED FOR CONNECTION TO THE OWNER'S EXISTING BUILDING THERMOMETER

NO SCALE NO SCALE MONITOR ALARM SYSTEM SHALL MONITOR MECHANICAL ROOM REFRIGERANT LEVEL IN PPM AND SHALL ALARM WHEN REFRIGERANT LEVELS AUTOMATION SYSTEM (BAS). ALERTON IS THE PREFERRED CONTROLS CONTRACTOR FOR THIS PROJECT. THE CONTRACTOR SHALL PROVIDE THERMOSTAT OR TEMPERATURE SENSOR T'STAT

HANGER ROD, SUPPORT EXCEED THE SET-POINT (ADJUSTABLE). UPON DETECTION OF A REFRIGERANT LEAK, THE BAS SHALL DE-ENERGIZE THE BOILERS, THE ALL HARDWARE AND SOFTWARE REQUIRED FOR CONTROL FROM AND FULL COMMUNICATIONS WITH THE OWNER'S EXISTING BAS SYSTEM. THOUSAND BTU PER HOUR MBH

FROM BUILDING STRUCTURE REFRIGERANT MONITOR ALARM SHALL OPEN THE ASSOCIATED MOTORIZED DAMPERS AND ENERGIZE THE EXHAUST FAN REF TO RUN AT ITS THE CONTRACTOR WILL DISCONNECT THE EXISTING BAS COMMUNICATION WIRING FROM EXISTING CHILLER AND CWP AND RECONNECT TO

MAXIMUM CFM SETTING. THE NEW TERMINALS. THE CONTRACTOR SHALL PROVIDE NEW CONTROL WIRING AND NEW CONDUIT FOR ALL NEW CONTROLS AS REQUIRED. THREE-WAY CONTROL VALVE

THE CONTRACTOR WILL MAKE FINAL BAS COMMUNICATION WIRING CONNECTIONS.

EXHAUST FAN REF: UPON BOILER ROOM OCCUPANCY AS DETECTED BY THE OCCUPANCY SENSOR (REFER TO ELECTRICAL PLANS), THE THE TWO-WAY CONTROL VALVE

JACKSON VIA ELEMENTARY SCHOOL

BAS SHALL OPEN THE ASSOCIATED MOTORIZED DAMPER AND ENERGIZE THE EXHAUST FAN REF TO RUN AT ITS MINIMUM CFM SETTING. 4. THE CONTRACTOR SHALL COORDINATE WITH THE OWNER TO ENSURE A PROPER AND TIMELY INSTALLATION OF THE NEW EQUIPMENT. ALL UNION

HEAVY DUTY

PIPING, LOUVERS, DOORS AND WALL PANELS REQUIRED TO BE REMOVED FOR UNIT INSTALLATION SHALL BE STORED BY THE CONTRACTOR WET BULB WB

CLEVIS HANGER

FOR RE-INSTALLATION FOLLOWING INSTALLATION OF NEW CHILLER, CWP-1, CWP-2 & REF.

CHILLER (QTY 1): DAIKIN 5. EXISTING INSULATION DAMAGED AS A RESULT OF THE WORK SHALL BE REPAIRED OR REPLACED AS SPECIFIED FOR NEW INSULATION.

LID

MODEL WMC048DDSN15 MAGNETIC BEARING, CENTRIFUGAL WATER COOLED

6. DAMAGED INSULATION ON REMAINING PIPING SHALL BE REPAIRED OR REPLACED AS SPECIFIED FOR NEW PIPING.

CHILLER, R134a; TOTAL COOLING CAPACITY 175 TONS; MINIMUM TWO (2) VARIABLE

GLOBE VALVE SPEED COMPRESSORS; 610 GPM EVAPORATOR WATER FLOW, 55°F EWT, 44°F LWT,

PIPE 7. CONTRACTOR SHALL ENSURE THAT THE OWNER SHALL WITNESS ALL PIPING PRESSURE TESTS, WATER SYSTEM DRAIN DOWN AND REFILL.

19.0 FT H2O MAXIMUM PRESSURE DROP IN EVAPORATOR; 525 GPM CONDENSER

INSULATION WATER FLOW, 85°F EWT, 95°F LWT, 6.0 FT H2O MAXIMUM PRESSURE DROP IN 8. THE CONTRACTOR SHALL VISIT THE SITE AND CONSULT THE OWNER TO DETERMINE THE EXTENT OF THE WORK FOR THIS PROJECT BEFORE

VAPOR BARRIER CONDENSER. 460V/3PH; 171 MCA; 84 LRA (PER COMPRESSOR) - 99.5 kW (UNIT INPUT SUBMITTING BIDS. CONTRACTOR SHALL BE EXPERIENCED IN THIS TYPE OF CONSTRUCTION AND CAPABLE OF PROVIDING COMPLETE

CHILLER REPLACEMENT

WHERE REQUIRED POWER); .336 KW/TON NPLV; .5685 KW/TON EFFICIENCY. INCLUDES SINGLE POINT

FROM 3/4" PUMP FUNCTIONING SYSTEMS AT THE COMPLETION OF THIS PROJECT.

POWER CONNECTION, BACnet COMMUNICATIONS, ISOLATION PADS, INSULATION KIT,

DISCHARGE LOW AMBIENT KIT, REFRIGERANT SPECIALTY KIT,AND STRAINER KIT. MAX

16 GAGE ZINC COATED OPERATING WEIGHT 10,000 LBS.

SHEET STEEL SADDLE 12" LONG, HALF-SECTION

OF HYDROUS CALCIUM

GENERAL DEMOLITION NOTES:

CHARLOTTESVILLE, VIRGINIA

AT LEAST 12" LONG

SILICATE AT EACH HANGER FEEDER BODY

PUMPS: BELL & GOSSETT

SUPPORT

1. THE EXISTING CHILLER IN THE EXISTING MECHANICAL ROOM, INCLUDING THE CHILLED WATER PUMP, CHILLED WATER AND CONDENSER

REMOVABLE BASKET CAPACITY MAX / MIN VOLTAGE & WATER SUPPLY AND RETURN PIPING AS INDICATED ON THE DRAWINGS, RELIEF CONNECTIONS, DRAIN CONNECTIONS, AND CONTROLS

NOTE: MARK HEAD (FT. H ₂O) MOTOR (HP) RPM SERIES MODEL NO.

AND DETAILS

AND FILTER (GPM) PHASE SHALL BE REMOVED. INSULATION ON THE REMAINING EXISTING PIPING THAT IS DAMAGED OR REMOVED DUE TO THE DEMOLITION WORK

SADDLE AND HALF-SECTION OF HYDROUS CALCIUM

SHALL BE REPLACED AND SEALED AS REQUIRED.

SILICATE SHALL BE INSTALLED AT THE SAME TIME TO 3/4" PUMP CWP-1 610 90 20 1750 460V/3PH 1510 4EB

THAT THE PIPE AND PIPE HANGERS ARE INSTALLED. INTAKE 2. THE CONTRACTOR SHALL REMOVE OR ALTER AS NECESSARY ALL EXISTING PIPING, EQUIPMENT, EQUIPMENT FOUNDATIONS, CONTROLS,

CWP-2 610 90 20 1750 460V/3PH 1510 4EB

ELECTRICAL COMPONENTS, DUCTWORK, AND APPURTENANCES THAT ARE NOT REQUIRED FOR THE EXISTING SYSTEMS OR TO REMAIN.

SEE SPECIFICATIONS FOR LOCATIONS WHERE 3/4"

HOSE END CONTRACTOR SHALL VISIT THE SITE TO DETERMINE THE SCOPE OF THIS WORK AND VERIFY EXISTING CONDITIONS PRIOR TO PRICING.

HYDROUS CALCIUM SILICATE SHALL BE REQUIRED.

DRAIN VALVE

PIPE SUPPORT DETAIL NOTE:

3. THE CONTRACTOR SHALL REMOVE ALL HVAC CONTROLS, CONTROL PANELS, EXPOSED TUBING AND ACTUATORS NOT REQUIRED FOR THE

NEW SYSTEMS TO OPERATE. VERIFY WITH THE OWNER WHICH ITEMS MAY NEED TO BE RETAINED BY THE OWNER AND PROTECTED DURING

NO SCALE REMOVAL.

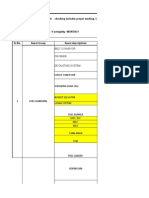

CS FLOW SIZE FILTER FEEDER AS RECOMMENDED BY UNIT MANUFACTURER. FANS: GREENHECK

BYPASS CHEMICAL FEEDER AREA MAXIMUM MINIMUM

2. EXISTING EQUIPMENT SHALL BE TURNED OVER TO THE OWNER, UNLESS DIRECTED OTHERWISE AND LOCATED ON SITE AS DIRECTED BY

THE OWNER. ALL OTHER ITEMS TO BE REMOVED SHALL BECOME THE PROPERTY OF THE CONTRACTOR AND REMOVED FROM THE

NO SCALE MARK ESP RPM MOTOR HP VOLTS/PH MODEL NOTES PREMISES.

SERVED CFM CFM

5 DIA'S 5 DIA'S 3. PROTECT ALL EXISTING ITEMS TO REMAIN FROM DAMAGE DURING DEMOLITION. EXISTING ITEMS THAT ARE DAMAGED OR MISTAKENLY

BOILER DESIGNED DRAWN

REF 2530 525 0.750 1605 1 115/60/1 SQ-140-VG 1 REMOVED DURING DEMOLITION SHALL BE REPAIRED OR REPLACED.

ROOM

NOTE: MEH MEH

1. THERE SHALL BE UNINTERRUPTED STRAIGHT PIPE 5 DIAMETERS 4. BUILDING SURFACES WHICH ARE AFFECTED BY HVAC DEMOLITION SHALL BE PATCHED AND REPAIRED TO MATCH THE EXISTING ADJACENT

NOTES: SURFACES.

OF PIPE DOWNSTREAM AND 5 DIAMETERS OF PIPE UPSTREAM CHECKED APPROVED

FROM EACH CIRCUIT SENSOR. BALANCE VALVE SHALL BE

1. PROVIDE MOTOR OPERATED DAMPERS (MOD) UNLESS OTHERWISE NOTED. 5. THE EXISTING SYSTEMS INDICATED ARE FROM CONSTRUCTION DOCUMENTS DATED JULY 12, 1968. ADDITIONAL INFORMATION IS FROM SITE JAP/MEH LPA

ADJUSTED TO PROVIDE GPM REQUIRED AT EACH C.S.

VISITS. THE CONTRACTOR IS CAUTIONED THAT THE EXISTING HVAC SYSTEM LAYOUTS ARE INDICATED AS ONLY AN APPROXIMATION OF

2. THE ENTIRE CIRCUIT SETTER SHALL BE INSULATED WITH EXISTING CONDITIONS. NOT ALL EXISTING SYSTEMS ARE SHOWN AND SELECTIVE DEMOLITION IS REQUIRED. THE CONTRACTOR SHALL COMM. NO. DATE

REMOVABLE SECTIONS OF PIPE INSULATION SIZED TO OVERLAP VERIFY ACTUAL SYSTEM CONFIGURATIONS, PIPING, DUCTWORK, AND EQUIPMENT LOCATIONS AND ELEVATIONS IN THE FIELD AND SHALL

17119.01 09-12-17

THE CONNECTED PIPE INSULATION. INSULATION SHALL COORDINATE ACCORDINGLY.

OVERLAP 3 INCHES.

6. WHERE EXISTING PIPING OR DUCTWORK IS SHOWN TERMINATED, PROVIDE CAPPED OUTLET. SHEET

CIRCUIT SETTER DETAIL

SCHEMATIC

7. DEMOLITION ACTIVITIES SHALL BE CLOSELY COORDINATED WITH THE OWNER TO MAINTAIN ACTIVE STATUS OF EXISTING SYSTEMS UNTIL

SUCH TIME THE PLANNED DEMOLITION CAN BE EXECUTED. M-1

Potrebbero piacerti anche

- Ashrae C26 (97) Climatic Design InformationDocumento53 pagineAshrae C26 (97) Climatic Design InformationDiegoNessuna valutazione finora

- Cooling Tower (2019) PDFDocumento5 pagineCooling Tower (2019) PDFYURI G. MELLIZANessuna valutazione finora

- AD 22 FuelOilSystemsDocumento4 pagineAD 22 FuelOilSystemsCire Lop CastroNessuna valutazione finora

- A Study On The Thermal Comfort in Sleeping Environments in The Subtropics-Developing A Thermal Comfort Model For Sleeping Environments PDFDocumento12 pagineA Study On The Thermal Comfort in Sleeping Environments in The Subtropics-Developing A Thermal Comfort Model For Sleeping Environments PDFWGT KENDARINessuna valutazione finora

- Hvac General Notes Hvac Legend Hvac Legend: (CPD) EDocumento4 pagineHvac General Notes Hvac Legend Hvac Legend: (CPD) EF. A AhmedNessuna valutazione finora

- Hvac Notes & AbbreviationsDocumento1 paginaHvac Notes & AbbreviationsShrikant SomvanshiNessuna valutazione finora

- Saudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-728550 005 P 0A3 K11 RestrictedWaqarNessuna valutazione finora

- 2018 1206 Fairfield County Auditor Drawings VOL 2 PDFDocumento40 pagine2018 1206 Fairfield County Auditor Drawings VOL 2 PDFAr Hanz Gerome SuarezNessuna valutazione finora

- MECHANICAL PLAN RAWIS 2 STOREY Model2Documento1 paginaMECHANICAL PLAN RAWIS 2 STOREY Model2Catherine ZamudioNessuna valutazione finora

- Saudi Arabian Oil Company: DA-727899 005 P 0A3 K07 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-727899 005 P 0A3 K07 RestrictedWaqarNessuna valutazione finora

- M-0.1 - Mechanical SpecificationsDocumento1 paginaM-0.1 - Mechanical SpecificationsAbdellatif AlhNessuna valutazione finora

- Mechanical Abbreviations and Symbols: Project Number: 629 - 247637Documento30 pagineMechanical Abbreviations and Symbols: Project Number: 629 - 247637phlxuNessuna valutazione finora

- Electrical General Notes: Abbreviations Electrical Symbol ListDocumento10 pagineElectrical General Notes: Abbreviations Electrical Symbol Listkennex rapanutNessuna valutazione finora

- PLATE 3-Layout1.pdfDFDFDFDocumento1 paginaPLATE 3-Layout1.pdfDFDFDFKhian PinedaNessuna valutazione finora

- Saudi Arabian Oil Company: DA-728390 005 P 0A3 K10 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-728390 005 P 0A3 K10 RestrictedWaqarNessuna valutazione finora

- El-15 Fire Alarm System DetailsDocumento1 paginaEl-15 Fire Alarm System DetailsEng Qais ShamikhNessuna valutazione finora

- GCS Product Overview - Basyx VAVDocumento2 pagineGCS Product Overview - Basyx VAVGlobalContSolutionsNessuna valutazione finora

- Saudi Arabian Oil Company: DA-728849 005 P 0A3 K13 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-728849 005 P 0A3 K13 RestrictedWaqarNessuna valutazione finora

- Aq 211105 001Documento1 paginaAq 211105 001Qudsi NayazNessuna valutazione finora

- Description REV Date Construction Drawing 0 JUNE'22Documento1 paginaDescription REV Date Construction Drawing 0 JUNE'22rajavelNessuna valutazione finora

- 544173924Documento14 pagine544173924JOHN NUÑEZ MARALITNessuna valutazione finora

- Book 1Documento12 pagineBook 1Ravindra ChougaleNessuna valutazione finora

- Kfss 1: Deyu CaiDocumento1 paginaKfss 1: Deyu CaiSKYLERNessuna valutazione finora

- Davidson Fire Station 2 Plumbing Bound Int4Documento8 pagineDavidson Fire Station 2 Plumbing Bound Int4Renz Albert TejadillaNessuna valutazione finora

- ElectricalDocumento7 pagineElectricalKhalil AlluhaybiNessuna valutazione finora

- Plumbing Legend Plumbing Abbreviations Drawing Index: Dwg. No. DescriptionDocumento5 paginePlumbing Legend Plumbing Abbreviations Drawing Index: Dwg. No. DescriptionAnonymous ivgmL9tVZNessuna valutazione finora

- Saudi Arabian Oil Company: DA-728054 001 P 0A3 K08 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-728054 001 P 0A3 K08 RestrictedWaqarNessuna valutazione finora

- Saudi Arabian Oil Company: DA-728700 005 P 0A3 K12 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-728700 005 P 0A3 K12 RestrictedWaqarNessuna valutazione finora

- Saudi Arabian Oil Company: DA-727739 005 P 0A3 K06 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-727739 005 P 0A3 K06 RestrictedWaqarNessuna valutazione finora

- Drawing 5 of 6 - Fire Suppression and Fire Alarm v1Documento9 pagineDrawing 5 of 6 - Fire Suppression and Fire Alarm v1Renz Albert TejadillaNessuna valutazione finora

- Final Abiera Duplexplan MechanicalDocumento3 pagineFinal Abiera Duplexplan Mechanicalmarcelo serpa juanNessuna valutazione finora

- Bharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)Documento25 pagineBharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)MukeshKrNessuna valutazione finora

- Bharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)Documento25 pagineBharat Heavy Elelctricals Limited: Operation & Maintenance Manual of Bhelscan Flame Scanner System (Bn10)MukeshKrNessuna valutazione finora

- Aq 211103 001Documento1 paginaAq 211103 001Qudsi NayazNessuna valutazione finora

- Fire Protection Bid SetDocumento7 pagineFire Protection Bid SetMaxwellNessuna valutazione finora

- Saudi Arabian Oil Company: DA-728544 001 P 0A3 K11 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-728544 001 P 0A3 K11 RestrictedWaqarNessuna valutazione finora

- Auxiliary Drawing (CCTV AND DATA) For Sample ProjectDocumento3 pagineAuxiliary Drawing (CCTV AND DATA) For Sample ProjectengrpaulppangilinanNessuna valutazione finora

- EX00-CCTV-DT-XX0001-003003 REV-00-layoutDocumento1 paginaEX00-CCTV-DT-XX0001-003003 REV-00-layoutengrabbas75Nessuna valutazione finora

- Bhsarp 21 MTB ZZ Me DWG 320701 - D02Documento1 paginaBhsarp 21 MTB ZZ Me DWG 320701 - D02Jss Aircond & ElectricalNessuna valutazione finora

- Pages From All Drawings - Bid SetDocumento2 paginePages From All Drawings - Bid SetbilalNessuna valutazione finora

- Hudson RCIDocumento40 pagineHudson RCIpatolineitorNessuna valutazione finora

- ELECTRICAL MODEL SONCIO For A3 - E2-ModelDocumento1 paginaELECTRICAL MODEL SONCIO For A3 - E2-ModelChris ChanNessuna valutazione finora

- General Notes Symbol List Abbreviations: Reference Sheet - SprinklerDocumento64 pagineGeneral Notes Symbol List Abbreviations: Reference Sheet - SprinklerAnonymous qOBFvINessuna valutazione finora

- General Notes, Legends and Vicinity MapDocumento1 paginaGeneral Notes, Legends and Vicinity MapDenisse Dean OcampoNessuna valutazione finora

- WH10-FSYS-GN-XX0001-002002 REV-00-layoutDocumento1 paginaWH10-FSYS-GN-XX0001-002002 REV-00-layoutengrabbas75Nessuna valutazione finora

- Fcu Control Diagram: Sequence of OperationDocumento1 paginaFcu Control Diagram: Sequence of Operationkiran kumarNessuna valutazione finora

- YAY TAR SHAY - FIVE STORIES PROJECT - ACMV & FIRE FIGHTING DESIGN 12nd AUGUST UPDATE PDFDocumento21 pagineYAY TAR SHAY - FIVE STORIES PROJECT - ACMV & FIRE FIGHTING DESIGN 12nd AUGUST UPDATE PDFHnin PwintNessuna valutazione finora

- CK Lucena - CD Drawing Me 01 PDFDocumento1 paginaCK Lucena - CD Drawing Me 01 PDFVen Mar SalinasNessuna valutazione finora

- P1 Sheet WatersupplyDocumento1 paginaP1 Sheet WatersupplyorderNessuna valutazione finora

- Saudi Arabian Oil Company: DA-727893 001 P 0A3 K07 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-727893 001 P 0A3 K07 RestrictedWaqarNessuna valutazione finora

- Fire Protection General Notes Fire Protection Symbol and Abbreviation ScheduleDocumento9 pagineFire Protection General Notes Fire Protection Symbol and Abbreviation ScheduleMaxwellNessuna valutazione finora

- Themes For Research WorksDocumento15 pagineThemes For Research WorksMarinaldo RodriguesNessuna valutazione finora

- Mv-01 Project DetailsDocumento1 paginaMv-01 Project DetailsriyazNessuna valutazione finora

- Control Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810Documento1 paginaControl Application Diagram For Four Boilers Linear-Temp Installation HW-300 THRU HW-670 DURA-MAX 720 THRU 1810ErmiasNessuna valutazione finora

- Saudi Arabian Oil Company: DA-728999 005 P 0A3 K14 RestrictedDocumento1 paginaSaudi Arabian Oil Company: DA-728999 005 P 0A3 K14 RestrictedWaqarNessuna valutazione finora

- Description S.NO.: Produced by An Autodesk Educational ProductDocumento1 paginaDescription S.NO.: Produced by An Autodesk Educational ProductAshar HassanNessuna valutazione finora

- Fire Suppression System: Raaw Courtyard Riffa - BahrainDocumento1 paginaFire Suppression System: Raaw Courtyard Riffa - BahrainemaarbrothersNessuna valutazione finora

- 03 Taconic High School HVACDocumento12 pagine03 Taconic High School HVACkali highNessuna valutazione finora

- 254-SCCAD Base 5, 8430 Mexico RD., Ofallon, MO 63366 - MEP DwgsDocumento18 pagine254-SCCAD Base 5, 8430 Mexico RD., Ofallon, MO 63366 - MEP DwgsMirelNessuna valutazione finora

- Wh08-Cctv-Ups-Xx0001 - 001002 Rev-00Documento1 paginaWh08-Cctv-Ups-Xx0001 - 001002 Rev-00engrabbas75Nessuna valutazione finora

- Ae00000055 - Symbols, Abbreviations and General NotesDocumento1 paginaAe00000055 - Symbols, Abbreviations and General NotesKatherine GuivencanNessuna valutazione finora

- Saudi Arabian Oil Company: 14.0 Coating/PaintingDocumento1 paginaSaudi Arabian Oil Company: 14.0 Coating/PaintingParthiban RNessuna valutazione finora

- Chapter-1 Introduction to Chilled Water Systems: ၁.၁ What is heat?Documento18 pagineChapter-1 Introduction to Chilled Water Systems: ၁.၁ What is heat?KoJoeNessuna valutazione finora

- C C W S: Hillers and Hilled Ater YstemsDocumento16 pagineC C W S: Hillers and Hilled Ater YstemsKoJoeNessuna valutazione finora

- DigitalMultiMeter PDFDocumento4 pagineDigitalMultiMeter PDFKoJoeNessuna valutazione finora

- Windows Printer Test PageDocumento1 paginaWindows Printer Test PageKoJoeNessuna valutazione finora

- Tutorial 2 Spring 2018-19Documento3 pagineTutorial 2 Spring 2018-19ANMOLNessuna valutazione finora

- Mccormick - Tractor OEM Part #Documento8 pagineMccormick - Tractor OEM Part #Beniamin KowollNessuna valutazione finora

- E2 01.1 Temp MonitoringDocumento16 pagineE2 01.1 Temp MonitoringThien Doan ChiNessuna valutazione finora

- Effect of Impurities On Freezing and Boiling PointsDocumento6 pagineEffect of Impurities On Freezing and Boiling PointssakthivelNessuna valutazione finora

- Psy ChartDocumento1 paginaPsy Chartmustafa1011Nessuna valutazione finora

- Bitzer CompressorDocumento32 pagineBitzer Compressorka_te_19100% (2)

- Applied ThermodynamicsDocumento3 pagineApplied ThermodynamicsPRATAP SINGHNessuna valutazione finora

- UntitledDocumento7 pagineUntitledRahma sayedNessuna valutazione finora

- Lecture 6Documento18 pagineLecture 6Dianne GawdanNessuna valutazione finora

- Carnot CycleDocumento7 pagineCarnot CycleAmey DNessuna valutazione finora

- Water Cooled Type PL97 6ADocumento2 pagineWater Cooled Type PL97 6Aamit kumarNessuna valutazione finora

- NR71314 Air Conditioning (7.13.14) Ver1.2 PDFDocumento183 pagineNR71314 Air Conditioning (7.13.14) Ver1.2 PDFBabyface888Nessuna valutazione finora

- Design and Construction of An Evaporative Cooling System For The Storage of Fresh TomatoDocumento10 pagineDesign and Construction of An Evaporative Cooling System For The Storage of Fresh Tomatobedilu77Nessuna valutazione finora

- SCL K05-MS-MOR - Pressure-0Documento1 paginaSCL K05-MS-MOR - Pressure-0kushalkaushalNessuna valutazione finora

- C - E20-II - Projects - HUPA - L 1 - HAP49 - Systems Design ReportDocumento3 pagineC - E20-II - Projects - HUPA - L 1 - HAP49 - Systems Design ReportGonzalo Echeverria MartinezNessuna valutazione finora

- Article On Desuperheater 220709 PDFDocumento5 pagineArticle On Desuperheater 220709 PDFlkumar4454Nessuna valutazione finora

- Catalogo de Aire Acondicionado Compacto Carrier 50TC-17-30-V-02PD (17 A 30 T.R)Documento98 pagineCatalogo de Aire Acondicionado Compacto Carrier 50TC-17-30-V-02PD (17 A 30 T.R)Luis Eduardo Carmona VasquezNessuna valutazione finora

- Experiment No. 5 1Documento6 pagineExperiment No. 5 1JunNessuna valutazione finora

- Diagram PsychrometricDocumento4 pagineDiagram PsychrometricJanry EfriyantoNessuna valutazione finora

- Calibration of Special Relative Humidity and TempeDocumento8 pagineCalibration of Special Relative Humidity and TempeAGUS KURNIAWANNessuna valutazione finora

- HVACDocumento58 pagineHVACAnonymous 6V5QyM1M3LNessuna valutazione finora

- The Effects of Pressure On Boiling Point Temperatures: Example: Water at 5,280 Feet Will Boil at A Mere 203° FDocumento1 paginaThe Effects of Pressure On Boiling Point Temperatures: Example: Water at 5,280 Feet Will Boil at A Mere 203° FHisanNessuna valutazione finora

- IOM-107 YangjiangDocumento248 pagineIOM-107 YangjiangAlfarientino GeorgeNessuna valutazione finora

- Constant Pressure Analysis ChartsDocumento38 pagineConstant Pressure Analysis Charts林倉舒Nessuna valutazione finora

- MEC 4105 Test Marking GuideDocumento4 pagineMEC 4105 Test Marking GuideBirimumaso DavidNessuna valutazione finora

- EME Notes RefrigerationDocumento7 pagineEME Notes RefrigerationedhanaaNessuna valutazione finora

- 4-9a York NPLV ArticleDocumento4 pagine4-9a York NPLV Articlekah178Nessuna valutazione finora