Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Astm1884 Ressol Versa Ht3

Caricato da

Matteo DMCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Astm1884 Ressol Versa Ht3

Caricato da

Matteo DMCopyright:

Formati disponibili

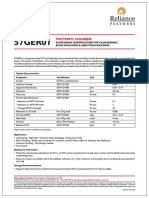

Residual Solvents Testing per

ASTM F1884-04 with the Versa and

HT3 Automated Headspace Sampler

Application Note

Abstract

Printing inks have been used extensively to enhance the visual appearance of packing materials of

consumer products. These inks are typically comprised of colorants and pigments, binder systems,

solvents, and additives. ASTM International is recognized for developing and delivering international

voluntary consensus standards. They provide packaging material suppliers with a standardized test

1

method, ASTM F 1884-04 to determine residual solvents remaining in their packaging materials from

printing processes utilizing solvent-based printing inks. Test method A, recommends an autosampler to

perform the headspace-gas chromatography examination of residual solvents in packaging materials.

This application note will demonstrate the capability of the Teledyne Tekmar Versa and HT3 automated

headspace sampler to meet the rigorous demands of ASTM F 1884-04. These scientific instruments can

provide packaging material suppliers with quality analysis following ASTM F1884-04 with minimal sample

preparation.

Introduction

This application note evaluates ASTM F 1884-04 using both the Versa and HT3 Automated Headspace

Analyzers. A 624-phase GC column was used for this study. The FDA recently standardized residual

solvent testing on this type of column. Calibrations were evaluated by the addition of a standard solution

by itself and with a blank film. A sample of printed film was used to determine the effects that water has

on residual solvent recoveries, by testing the dry sample film and the sample film with water added.

ASTM F 1884-04 does not prescribe a carrier gas to use for determining residual solvents in packaging

material. The calibration standards were evaluated on both headspace systems with helium and

nitrogen.

Experimental-Instrument Conditions

The Versa and the HT3 Automated Headspace Analyzers were connected to a Shimadzu 2010 Plus

GC/FID system for this study. Both analyzers were tested with helium and nitrogen, depending on the

carrier gas used for each evaluation. Table 1 displays the Versa and HT3 method parameters, while

Table 2 displays the Shimadzu GC/FID parameters.

Sales/Support: 800-874-2004 · Main: 513-229-7000

4736 Socialville Foster Rd., Mason, OH 45040

ASTM1884_ResSol_Versa_HT3.docx; 26-Nov-12 www.teledynetekmar.com

Teledyne Tekmar Automated Headspace Sampler Parameters

Variable Versa Value HT3 Value

Constant Heat Time N/A On

GC Cycle Time 27.00 min 27.00 min

Valve Oven Temp 105 °C 105 °C

Transfer Line Temp 110 °C 110 °C

Standby Flow Rate N/A 100 mL/min

Platen/Sample Temp 90 °C 90°C

Platen Temp Equil Time 0.10 min 0.50 min

Sample Equil Time 20.00 min 20.00 min

Pressurize 13.0 psig 13.0 psig

Pressurize Time 1.00 min 1.00 min

Pressurize Equil Time 0.25 min 0.20 min

Loop Fill Pressure 9.0 psig 9.0 psig

Loop Fill Time 1.00 min 1.00 min

Inject Time 0.50 min 0.50 min

Table 1: Versa and HT3 Headspace Conditions for ASTM F 1884-04

Shimadzu GC/FID Parameters

Column Restek Rxi-624Sil MS, 30 m, 0.32 mm ID, 1.8 µm df, Carrier gas – Helium or Nitrogen

40 °C for 2 min, 8 °C/min to 104 °C, 15 °C/min to 164 °C, 30 °C/min to 250 °C, hold for 4 min,

Oven Program

run time – 20.87 min

Inlet: Temperature - 250 °C, Split Ratio - 10:1 Constant Velocity – 40 cm/sec

Detector Temperature - 250 °C, Sampling rate 40msec

Flows Makeup (Same as Column) – 30.0 mL/min, Hydrogen – 40.0 mL/min, Air Flow – 400 mL/min

Table 2: Shimadzu 2010Plus GC/FID Parameters

Standard Preparation

An internal standard solution was prepared by diluting 80 µL of 4-heptanone into 4 L of water. A five-

point calibration curve was prepared by diluting 1 µL of a commercially available packaging material

residual solvent standard mix into various volumes of the internal standard solution. Table 3 lists these

dilutions, the total residual solvent concentrations (volume/volume) and the concentration range of the

constituents (µg/mL).

Standard Volume (mL) Concentration (v/v) Concentration Range (µg/mL)

1000 0.00004 0.031 to 0.040

500 0.00008 0.062 to 0.081

250 0.00016 0.125 to 0.161

100 0.00040 0.312 to 0.404

50 0.00080 0.623 to 0.807

Table 3: Concentrations for the Five Standard Calibration Points

Sales/Support: 800-874-2004 · Main: 513-229-7000

4736 Socialville Foster Rd., Mason, OH 45040

ASTM1884_ResSol_Versa_HT3.docx; 26-Nov-12 www.teledynetekmar.com

Sample Preparation

A printable polypropylene film was obtained and prepared, following the ASTM F 1884-04 Section 9.1.1,

by heating the film in a vacuum oven at 90 °C for 24 hours. When cooled, the film was stored tightly

sealed in aluminum foil.

Two calibration curves were prepared; one using the calibration standards only and one matrix-matched

calibration using blank film. The first set consisted of 2.0 mL of each standard and the blank internal

standard solution added to separate 22 mL headspace vials. The second set contained strips of the

2

blank film totaling 25 in . 2.0 mL of each standard and the blank internal standard solution was added

separately to the film containing vials.

An actual printed film sample was obtained to evaluate the ASTM method. The sample was tested in

2

triplicate by placing 25 in into separate headspace vials. One of the vials was capped without the

addition of solvent. The second had 2 mL of water added, and the third had 2 mL of internal standard

solution added.

The calibration levels and samples were tested on both headspace systems using helium and nitrogen.

Most of the solvents in the standard were confirmed with known standard solvents. Peak numbers were

used to label the unconfirmed compounds.

Results

2

The correlation coefficients (r ) for the peaks were calculated by the external standard method using five-

point calibration curves on both automated headspace autosamplers. This data is presented in Table 4.

Since this assay was performed using an FID, with retention time as the only form of confirmation,

unknown compounds and coelutions are potentially problematic. 2-Methoxyethanol and isopropyl acetate

could not be resolved, but still maintained linearity. An unconfirmed solvent in the standard mix also

coeluted with the internal standard, biasing the internal standard calibration data.

Sales/Support: 800-874-2004 · Main: 513-229-7000

4736 Socialville Foster Rd., Mason, OH 45040

ASTM1884_ResSol_Versa_HT3.docx; 26-Nov-12 www.teledynetekmar.com

Autosampler Versa HT3

Carrier Gas Helium Nitrogen Helium Nitrogen

Solvent \ Standard Clean Film Clean Film Clean Film Clean Film

Methanol - 1 0.486 0.792 0.993 0.982 0.988 0.974 0.977 0.987

Ethanol - 2 0.993 0.982 0.998 0.992 0.997 0.997 0.995 0.997

Acetone - 3 0.996 0.991 0.999 0.997 0.996 0.996 0.995 0.996

Isopropanol - 4 0.993 0.989 0.999 0.997 0.992 0.995 0.992 0.992

Methyl Acetate - 5 0.998 0.997 1.000 0.997 0.996 0.996 0.996 0.999

n-Propanol - 6 0.993 0.999 0.998 0.996 0.996 0.996 0.994 0.997

Ethyl Acetate - 7 0.999 0.997 0.999 0.996 0.999 0.998 0.996 0.999

2-Butanone - 8 0.995 0.997 0.999 0.997 0.996 0.997 0.9995 0.993

Tetrahydrofuran - 9 0.998 0.999 0.999 0.998 0.998 0.998 0.994 0.999

Cyclohexane - 10 0.993 0.996 0.999 0.998 0.996 0.998 0.996 0.994

Isopropyl Acetate -11 0.999 0.998 0.997 0.996 1.000 0.999 0.998 0.999

Peak 12 0.991 0.998 0.999 0.995 0.996 0.997 0.996 0.996

Propyl Acetate - 13 0.999 0.998 0.999 0.998 0.9999 0.997 0.996 0.999

4-Methyl-2-pentanone - 14 0.999 0.999 0.999 0.997 0.999 0.998 0.996 0.999

Toluene - 15 1.000 0.998 0.997 0.997 1.000 0.997 0.998 0.999

Butyl Acetate - 16 0.999 0.997 0.998 0.998 0.999 0.997 0.997 0.999

Peak 17 0.997 0.995 0.995 0.996 0.996 0.996 0.894 0.996

Peak 18 0.995 0.998 0.999 0.998 0.996 0.998 0.995 0.998

Table 4: Correlation Coefficient for Residual Solvent Standards Analyzed Following ASTM F1884-04

The lowest detectable limit for all of the residual solvents was at or just below the 1 µL in 1000 mL of

water standard. This equates to 1 mg/ream of packaging material. Figure 1 is an overlay chromatogram

of the 1000 mL, 500 mL and 250 mL residual solvent standard levels.

Sales/Support: 800-874-2004 · Main: 513-229-7000

4736 Socialville Foster Rd., Mason, OH 45040

ASTM1884_ResSol_Versa_HT3.docx; 26-Nov-12 www.teledynetekmar.com

Figure 1: Comparison of the FID Chromatograms of the 1 L Mixed Standard diluted in 1000 mL (Bottom),

500 mL (Middle) and 250 mL (Top) of Internal Standard. The numbers correspond to the compounds in

Table 4. The S/F indicates that this peak was part of the system/film background.

The actual printed film sample contained 11 of the solvents identified by the standards and numerous

unknown peaks. The addition of water enhanced several of the early eluting residual solvent peaks, while

decreasing some of the later eluting residual solvent peaks. Figure 2 shows a comparison of

chromatograms of the film sample with and without water and a low-level standard.

Figure 2: Comparison of the FID Chromatograms of the 1 L Mixed Standard diluted in 1000 mL of Internal

Standard (Bottom), the Dry Sample Film (Middle) and Sample Film with Water (Top). The numbers

correspond to the compounds in Table 4.

Sales/Support: 800-874-2004 · Main: 513-229-7000

4736 Socialville Foster Rd., Mason, OH 45040

ASTM1884_ResSol_Versa_HT3.docx; 26-Nov-12 www.teledynetekmar.com

Conclusions

The Teledyne Tekmar Versa and HT3 Automated Headspace Analzyers provide excellent linearity for

residual solvent standards used in the analysis of residual solvents in packaging material as defined by

ASTM method F 1884-04, Standard Test Methods for Determining Residual Solvents in Packaging

Materials. This application note demonstrates detection of less than 1 mg/ream of residual solvents using

either helium or nitrogen as supply gases for the headspace GC/FID system. This allows packaging

material manufacturers to achieve lower detection levels to meet the ever-increasing regulatory demands,

which push for lower and lower levels of residual solvents in their products.

This study indicates an enhancement of some residual solvent peaks with the addition of water using the

sample temperature and heating times recommended by the ASTM method, but had a detrimental effect

on other residual solvent peaks. Further method optimization may prove useful depending on the

particular compounds of interest.

References

1. ASTM Method F1884-04, Standard Test Methods for Determining Residual Solvents in

Packaging Materials, ASTM International, West Conshohocken, PA, United States.

Sales/Support: 800-874-2004 · Main: 513-229-7000

4736 Socialville Foster Rd., Mason, OH 45040

ASTM1884_ResSol_Versa_HT3.docx; 26-Nov-12 www.teledynetekmar.com

Potrebbero piacerti anche

- Types of TitrationDocumento16 pagineTypes of TitrationShaher Bano Mirza73% (11)

- 8HL.18.1 Lewis Acids and BasesDocumento19 pagine8HL.18.1 Lewis Acids and BasesJesus carbonoNessuna valutazione finora

- Handbook of Plastic FilmsDocumento422 pagineHandbook of Plastic FilmsStefan Boiadjiev100% (18)

- Handbook of Plastic FilmsDocumento422 pagineHandbook of Plastic FilmsStefan Boiadjiev100% (18)

- Polystyrene Processing GuideDocumento4 paginePolystyrene Processing GuidemadogodNessuna valutazione finora

- Flexible Intermediate Bulk Containers Specifications PDFDocumento13 pagineFlexible Intermediate Bulk Containers Specifications PDFZahir Khira100% (1)

- Hot Melt Adhesives - 2Documento8 pagineHot Melt Adhesives - 2QUALITY CONTROL100% (1)

- F 904 98 Bond PDFDocumento3 pagineF 904 98 Bond PDFWilmer GonzalezNessuna valutazione finora

- Equilibrium Practice Exam (Multiple Choice) With Answers PDFDocumento8 pagineEquilibrium Practice Exam (Multiple Choice) With Answers PDFJhon Carlo AgpalzaNessuna valutazione finora

- Astm D2414-21Documento9 pagineAstm D2414-21Rajdeep MalNessuna valutazione finora

- 12-Piller-Energy Savings Via Steam RegenerationDocumento16 pagine12-Piller-Energy Savings Via Steam RegenerationAndrew Xuguoming100% (1)

- BYK L-AG1.2.2 Solvent-Borne Solvent-Free IndustrialCoatings enDocumento3 pagineBYK L-AG1.2.2 Solvent-Borne Solvent-Free IndustrialCoatings enKinhNguyenNessuna valutazione finora

- Molecular Weight Cellulose EvansDocumento8 pagineMolecular Weight Cellulose Evansjulio070983Nessuna valutazione finora

- ASTM E17Documento3 pagineASTM E17wendeltrentoNessuna valutazione finora

- Accelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Documento3 pagineAccelerated Weathering Test Conditions and Procedures For Bituminous Materials (Fluorescent UV, Water Spray, and Condensation Method)Satya kaliprasad vangaraNessuna valutazione finora

- Static and Kinetic Coefficients of Friction of Plastic Film and SheetingDocumento6 pagineStatic and Kinetic Coefficients of Friction of Plastic Film and SheetingMartin AndradeNessuna valutazione finora

- Creative Design of A Flip Top Cap MoldDocumento10 pagineCreative Design of A Flip Top Cap MoldEtHical EmoTionNessuna valutazione finora

- Intrinsic Viscosity As Quality Control Parameter of PET: Relevant For: Polymers, Plastics, ISO 1628, PETDocumento3 pagineIntrinsic Viscosity As Quality Control Parameter of PET: Relevant For: Polymers, Plastics, ISO 1628, PETParesh Hadkar100% (1)

- Carboxyl End Group Content of Polyethylene Terephthalate (PET) YarnsDocumento3 pagineCarboxyl End Group Content of Polyethylene Terephthalate (PET) YarnsLupita RamirezNessuna valutazione finora

- PET Oxygen BarriersDocumento40 paginePET Oxygen Barriersvalgus432Nessuna valutazione finora

- Troubleshooting Cast FilmDocumento6 pagineTroubleshooting Cast FilmgredmirNessuna valutazione finora

- PVC 57ger01Documento1 paginaPVC 57ger01rajesh patelNessuna valutazione finora

- Film PropertiesDocumento22 pagineFilm PropertiescattausNessuna valutazione finora

- Kvetoslav R Spurny Editor Analytical Chemistry of Aerosols ScienceDocumento499 pagineKvetoslav R Spurny Editor Analytical Chemistry of Aerosols ScienceShibu Arjunan100% (1)

- Advances in Aerogel Composites for Environmental RemediationDa EverandAdvances in Aerogel Composites for Environmental RemediationAftab Aslam Parwaz KhanNessuna valutazione finora

- Characterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsDocumento11 pagineCharacterization of METHOCEL Cellulose Ethers by Aqueous SEC With Multiple DetectorsCastoriadisNessuna valutazione finora

- Distillation Column DesignDocumento69 pagineDistillation Column DesignHarshit100% (1)

- Comparison Between Dry Lamination and Extrusion LaminationDocumento26 pagineComparison Between Dry Lamination and Extrusion LaminationRicardo PratiwiharjaNessuna valutazione finora

- ASTM D 882-02 - Thin-Plastic-Sheeting PDFDocumento10 pagineASTM D 882-02 - Thin-Plastic-Sheeting PDFzeqs9Nessuna valutazione finora

- AmcorDocumento13 pagineAmcorSamuel DavisNessuna valutazione finora

- Issue #9 Printing and Graphics Science Group NewsletterDa EverandIssue #9 Printing and Graphics Science Group NewsletterNessuna valutazione finora

- Astm D 4603 Viscosidad Intrinseca PetDocumento7 pagineAstm D 4603 Viscosidad Intrinseca Petdayanara886Nessuna valutazione finora

- Ys-W01 Pet Chips Bottle Grade Water HainanDocumento1 paginaYs-W01 Pet Chips Bottle Grade Water HainanPhirate Dorind100% (1)

- "Chemical Pulping" Edited by Johan Gullichsen and Carl-Johan FogelholmDocumento15 pagine"Chemical Pulping" Edited by Johan Gullichsen and Carl-Johan FogelholmrdLuis1Nessuna valutazione finora

- Selig Sealing ProductsDocumento60 pagineSelig Sealing Productslaurentiu29Nessuna valutazione finora

- Testing of Packaging Manual - Keerthana DsecDocumento31 pagineTesting of Packaging Manual - Keerthana DsecAbishek. KNessuna valutazione finora

- Adsyl and Clyrell Advantage: Boost Performance With Advanced Sealing Resins From Industry Leader LyondellbasellDocumento6 pagineAdsyl and Clyrell Advantage: Boost Performance With Advanced Sealing Resins From Industry Leader Lyondellbasellnouman ashrafNessuna valutazione finora

- Propylene Glycol Usp-EpDocumento4 paginePropylene Glycol Usp-Epvanhung68Nessuna valutazione finora

- TDS Siamvic 258RBDocumento1 paginaTDS Siamvic 258RBPinyaporn VeerapraditNessuna valutazione finora

- Astm D 333 - 96Documento3 pagineAstm D 333 - 96Cynthia GutierrezNessuna valutazione finora

- TG3Film PDFDocumento64 pagineTG3Film PDFLubomirBenicek0% (1)

- Dispercoll C84: CharacterizationDocumento3 pagineDispercoll C84: Characterizationmufid_ainunNessuna valutazione finora

- Quantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFDocumento11 pagineQuantification of The Maleic Anhydride Grafted Onto Polypropylene by Chemical and Viscosimetric Titrations, and FTIR Spectros PDFThinh DangNessuna valutazione finora

- Rupa FlexiPOLYDocumento1 paginaRupa FlexiPOLYSaravvanan RajendranNessuna valutazione finora

- Cold Seal Product Info (Release & Receptive) PDFDocumento12 pagineCold Seal Product Info (Release & Receptive) PDFSachin Kothari100% (1)

- Pluronic PeDocumento16 paginePluronic PeTrev GlasbeyNessuna valutazione finora

- Slip AdhesivosDocumento24 pagineSlip AdhesivosMiguelAngelPerezEsparza100% (1)

- BoPET Applications 2016Documento32 pagineBoPET Applications 2016SHRIPAD AMATENessuna valutazione finora

- ESBO NanyaDocumento12 pagineESBO NanyaHuỳnh Thanh HảiNessuna valutazione finora

- Profile Requirements: 30 75 in Case of Full or Partial Blast CleaningDocumento3 pagineProfile Requirements: 30 75 in Case of Full or Partial Blast CleaningIsabelo AbaoNessuna valutazione finora

- Sheen CupDocumento4 pagineSheen CupquyhoathienbaoNessuna valutazione finora

- Epoxy - WikipediaDocumento11 pagineEpoxy - Wikipediaramthecharm_46098467Nessuna valutazione finora

- Joncry 678 TDSDocumento4 pagineJoncry 678 TDSkang8886021Nessuna valutazione finora

- RAHN Resinas FotocurablesDocumento25 pagineRAHN Resinas FotocurablesMargaret RogersNessuna valutazione finora

- Flow CupsDocumento4 pagineFlow CupsMuhamad Dwi RamdaniNessuna valutazione finora

- Buna CB 22Documento2 pagineBuna CB 22Tmac100% (1)

- Astm D1239 07Documento3 pagineAstm D1239 07Hernando Andrés Ramírez Gil100% (1)

- Final1 Additive StandardsDocumento16 pagineFinal1 Additive StandardsmohammedNessuna valutazione finora

- Exxelor PE1040 DatasheetDocumento2 pagineExxelor PE1040 DatasheetmaheshgupteNessuna valutazione finora

- Ambos Ol 2010Documento3 pagineAmbos Ol 2010jose.figueroa@foseco.comNessuna valutazione finora

- Cosmothene g812 LdpeDocumento1 paginaCosmothene g812 LdpedanuNessuna valutazione finora

- Witcobond W 234Documento1 paginaWitcobond W 234NashNessuna valutazione finora

- Hot Melt AdhesivesDocumento3 pagineHot Melt AdhesiveshosseinNessuna valutazione finora

- Introduction To DSCDocumento29 pagineIntroduction To DSCDr-Dinesh Tripathi0% (1)

- Skar BorealisDocumento22 pagineSkar BorealisAsier FloresNessuna valutazione finora

- Accelerated Ageing Tests of Vulcanized Rubber: Bpri Brussels, November 25 2009Documento34 pagineAccelerated Ageing Tests of Vulcanized Rubber: Bpri Brussels, November 25 2009Daria D'souzaNessuna valutazione finora

- TDS Siamvic 360NADocumento1 paginaTDS Siamvic 360NAPinyaporn VeerapraditNessuna valutazione finora

- Cleaning and disinfection of food factories: a practical guideDa EverandCleaning and disinfection of food factories: a practical guideNessuna valutazione finora

- Coefficient of Friction TableDocumento4 pagineCoefficient of Friction TableMatteo DMNessuna valutazione finora

- Bopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesDocumento2 pagineBopp Matt Film, Both Sides Heat Sealable, Treated: PropertiesMatteo DMNessuna valutazione finora

- Jindal Packaging Collecting Process 2015-1 PDFDocumento5 pagineJindal Packaging Collecting Process 2015-1 PDFMatteo DMNessuna valutazione finora

- Printing Flexographic Press: Fire Prevention AidDocumento4 paginePrinting Flexographic Press: Fire Prevention AidMatteo DMNessuna valutazione finora

- Metodo GCDocumento6 pagineMetodo GCMatteo DMNessuna valutazione finora

- D 646 - 96 R01 - Rdy0ng - PDFDocumento5 pagineD 646 - 96 R01 - Rdy0ng - PDFLukas JackesNessuna valutazione finora

- Unit 4 ExamDocumento20 pagineUnit 4 ExamRohini SelvarajahNessuna valutazione finora

- Capstone Reflection - 4Documento6 pagineCapstone Reflection - 4api-295870217Nessuna valutazione finora

- Hco2H + H20 Hco2 + H30 Initial 0.050 M 0 0 Change - X +X +X Equilibrium 0.050 M - X X X KaDocumento8 pagineHco2H + H20 Hco2 + H30 Initial 0.050 M 0 0 Change - X +X +X Equilibrium 0.050 M - X X X KaShaira CogollodoNessuna valutazione finora

- Development and Application of A Novel UV Methodfor The Analysis of Ascorbic AcidDocumento5 pagineDevelopment and Application of A Novel UV Methodfor The Analysis of Ascorbic Acidronahaniifah11Nessuna valutazione finora

- KEM MKV 710 Series Brochure PDFDocumento12 pagineKEM MKV 710 Series Brochure PDFdonlot pilemNessuna valutazione finora

- Buffer SolutionDocumento6 pagineBuffer SolutionAdrija MandalNessuna valutazione finora

- Sample: 368aDocumento4 pagineSample: 368aNazar JabbarNessuna valutazione finora

- Capillary Electrophoresis by Sunil BudkeDocumento34 pagineCapillary Electrophoresis by Sunil BudkesunilbudkeNessuna valutazione finora

- PJ - 2 - 5 - Bougainvillea Glabra.....Documento4 paginePJ - 2 - 5 - Bougainvillea Glabra.....irishjamile dulosNessuna valutazione finora

- Atomic Emission SpectrosDocumento3 pagineAtomic Emission SpectrosRaj MalhotraNessuna valutazione finora

- ErrorsDocumento6 pagineErrorsSubhash DhungelNessuna valutazione finora

- In Class Exercise For Chapter 13 KeyDocumento2 pagineIn Class Exercise For Chapter 13 KeyJennifer TabitaNessuna valutazione finora

- CHEM 31.1 - Liquid - Liquid Extraction of Benzoic Acid (UNEDITED)Documento39 pagineCHEM 31.1 - Liquid - Liquid Extraction of Benzoic Acid (UNEDITED)claudine_lukban0% (2)

- Msc-Chemistry (Under CBCS) FIRST YEAR 2017-18 Two Semesters: 15 Weeks EachDocumento37 pagineMsc-Chemistry (Under CBCS) FIRST YEAR 2017-18 Two Semesters: 15 Weeks EachHimanshiNessuna valutazione finora

- Metrohm - Application Work AW IC CH6-1136-112012Documento4 pagineMetrohm - Application Work AW IC CH6-1136-112012Alaa NoureldeenNessuna valutazione finora

- FR Act DistillDocumento13 pagineFR Act DistilljahmanNessuna valutazione finora

- Qualitative Analysis LabDocumento4 pagineQualitative Analysis LabScottyNessuna valutazione finora

- INSTRUCTIONS FabALACTICA Fab Kit Microspin Rev Nov 2017Documento3 pagineINSTRUCTIONS FabALACTICA Fab Kit Microspin Rev Nov 2017carlos bernalNessuna valutazione finora

- Analytical Biochemistry PDFDocumento40 pagineAnalytical Biochemistry PDFharpreet0% (1)

- Lab ReportDocumento4 pagineLab Reportdhash23Nessuna valutazione finora

- Sample DataDocumento4 pagineSample DataNazar JabbarNessuna valutazione finora

- Chemsheets A2 1079 KP Basics ANSDocumento2 pagineChemsheets A2 1079 KP Basics ANSAashis Singh KHATTARNessuna valutazione finora

- Converted Dhanush KDocumento15 pagineConverted Dhanush KPrathik SwamyNessuna valutazione finora

- Drying of Metal Bearing Ores, Concentrates, and Related Metallurgical Materials For The Determination of MercuryDocumento2 pagineDrying of Metal Bearing Ores, Concentrates, and Related Metallurgical Materials For The Determination of MercurypravkovoilaNessuna valutazione finora