Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CEPA Surface Loading Stress Excel 2007 2010.Xlsmלחץ על צנרת מתחת לכביש

Caricato da

lameeyCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CEPA Surface Loading Stress Excel 2007 2010.Xlsmלחץ על צנרת מתחת לכביש

Caricato da

lameeyCopyright:

Formati disponibili

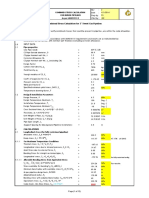

General Input for Surface Loading Calculations

PIPELINE INFORMATION: Enter Line Info HERE

PIPELINE LOCATION: Enter Line Location HERE

DATE: 12/31/18 1:54 PM

SELECT UNITS:

PIPE INPUT DATA Variable Description Notes

D= 0 mm <----- Outside Diameter

t= 0 mm <----- Wall Thickness

Pinternal = 0 kPa <----- Maximum Operating Pressure

SMYS = 0 MPa <----- Specified Minimum Yield Strength

ΔT = 20 °C <----- Temperature Differential (Tinstalled - Toperating) ---------> See NOTE #1

SOIL INPUT DATA Variable Description Notes

3

ρ= 0 kg/m <----- Soil Density

H= 0 m <----- Depth of Cover

Bedding Angle (θ):

θ= <----- Bedding Angle (degrees)

θ

Soil (Pipe Bedding)

Modulus of Soil Reaction (E'):

<----- Modulus of Soil Reaction (Defined by User)

E' = N/A kPa

<----- Modulus of Soil Reaction (Calculated from tables)

Soil Type:

Soil Compaction:

Select Soil Load Equation:

φ = N/A degrees <----- Angle of Shearing Resistance (Friction Angle) ------> See NOTE #2

MISCELLANEOUS INPUT Variable Description Notes

Impact Factor (IF):

Vehicle Type: <----- Vehicle Type: Used to determine Impact Factor

<----- Vehicles with high-pressure tires ---------------------> See NOTE #3

<----- Vehicles with low-pressure tires ----------------------> See NOTE #4

<----- Track Vehicles with steel or rubber tracks

Pavement Type: <----- Pavement Type: Used to determine Impact Factor

Select Equivalent Stress Equation:

<----- MORE conservative Equivalent stress equation

<----- LESS conservative Equivalent stress equation

Select Pipeline Regulatory Code:

<----- ASME Code for Liquid Pressure Piping (2012) -------> See NOTE #5

<----- ASME Code for Gas Pressure Piping (2010) -----------> See NOTE #5

<----- CSA Code for Oil and Gas Pipeline Systems (2011) ---> See NOTE #6

<----- Pipeline stress limits manually input by user --------> See NOTE #7

σHoop_%SMYS = N/A

σLongitudinal_%SMYS = N/A

σEquivalent_%SMYS = N/A

NOTE #1: 20°F or 11.1°C are DEFAULT values and should only be used if the actual temperature differential is unknown.

NOTE #2: To remain conservative when utilizing the Trap Door Equation, the program assumes soil cohesion is equal to zero.

NOTE #3: Tire pressures GREATER THAN OR EQUAL TO 30 psi should be considered high-pressure tires when using this calculator.

NOTE #4: Tire pressures LESS THAN 30 psi should be considered low-pressure tires when using this calculator.

NOTE #5: Pipeline stress limits programmed into this calculator are based on the current versions of the ASME codes. Future revisions to

these codes will require the programming for this calculator to be modified in order to maintain proper functionality in

accoordance with the latest versions of the ASME pipeline codes.

NOTE #6: The Canadian Standards Association (CSA) recommends in CSA-Z662 that the pipeline owner/operator develop stress limits

for their specific pipeline based on the design requirements set forth in the CSA-Z662 code. However, if these limits are

unknown, the user may select the "CSA-Z662" pipeline regulatory code, which has the following default stress limits:

σHoop = 0.9 SMYS, σLongitudinal = 0.9 SMYS, and σEquivalent = 0.9 SMYS.

NOTE #7: Stress Limits defined by user must be entered in terms of percent SMYS (i.e. a stress limit of 90% should be entered as 0.9).

Potrebbero piacerti anche

- Static Calculation of Pipeline Free SpansDocumento1 paginaStatic Calculation of Pipeline Free SpansMannattil Krishna KumarNessuna valutazione finora

- RTR Pipe Check AWWA M45 (Effluent Water) - Modified ParametersDocumento37 pagineRTR Pipe Check AWWA M45 (Effluent Water) - Modified ParametersSana Ullah100% (1)

- Pipeline Buoyancy AnalysisDocumento12 paginePipeline Buoyancy AnalysisbonnicoNessuna valutazione finora

- K Peters-Tech Paper-Upheaval BucklingDocumento7 pagineK Peters-Tech Paper-Upheaval BucklingISRAEL PORTILLO100% (2)

- Hoop StressDocumento35 pagineHoop StressRezaSohrabiNessuna valutazione finora

- HdpeeDocumento38 pagineHdpeeSamet BelliNessuna valutazione finora

- External Load On PipelineDocumento21 pagineExternal Load On PipelineindeskeyNessuna valutazione finora

- Windows-1256 - Bending Stresses From External Loading On Buried PipeDocumento10 pagineWindows-1256 - Bending Stresses From External Loading On Buried PipeAnwar ALkurayshiNessuna valutazione finora

- Guidelines For Stress Analysis of Hdpe LinesDocumento5 pagineGuidelines For Stress Analysis of Hdpe Lineszahoor100% (1)

- ASME B16.49 Factory Made Wrought Steel Butt Welding Induction Bends For Transportation and Distribution Systems PDFDocumento19 pagineASME B16.49 Factory Made Wrought Steel Butt Welding Induction Bends For Transportation and Distribution Systems PDFMuhammadNessuna valutazione finora

- Structural Design Calculations FOR Retensioning of ClampDocumento13 pagineStructural Design Calculations FOR Retensioning of ClampFeroz Khan PatthanNessuna valutazione finora

- Buried Pipe Design M-1Documento12 pagineBuried Pipe Design M-1Michael J. BaneNessuna valutazione finora

- Determination of Pipe and Bedding Combinations For Drainage WorksDocumento26 pagineDetermination of Pipe and Bedding Combinations For Drainage WorksFitriansyah Adi PutraNessuna valutazione finora

- Combined Stress Calc Rev. 2Documento12 pagineCombined Stress Calc Rev. 2babu75% (4)

- Hydraulic Fracturing in Soil During HDDDocumento12 pagineHydraulic Fracturing in Soil During HDDamir_hayfaNessuna valutazione finora

- Virtual Anchor Length - KBRDocumento22 pagineVirtual Anchor Length - KBRSammar Adhikari100% (2)

- HDPE Liner WT For CS PipesDocumento2 pagineHDPE Liner WT For CS Pipesmasdarto7032100% (1)

- ICDA Line 26 Multiphase Flow Modeling Report Draft 1.1Documento66 pagineICDA Line 26 Multiphase Flow Modeling Report Draft 1.1Pedro MarquezNessuna valutazione finora

- SPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureDocumento1 paginaSPBG PLBG - Kalkulasi Tebal Pipa-ASME B31.3 - High PressureAris KancilNessuna valutazione finora

- Stability-Calculation For PipelineDocumento2 pagineStability-Calculation For PipelineGeorge100% (1)

- Hydrostatic TestingDocumento18 pagineHydrostatic TestingRicardoNessuna valutazione finora

- Critical Defect Length Calculation - MKRDocumento6 pagineCritical Defect Length Calculation - MKRanon_703996408Nessuna valutazione finora

- A Finite Element-Based InvestigationDocumento7 pagineA Finite Element-Based InvestigationSteve IpNessuna valutazione finora

- Stress Analysis of GRPDocumento4 pagineStress Analysis of GRPSuthan SelvarajNessuna valutazione finora

- Pipe Support IndexDocumento4 paginePipe Support IndexxkokarcaxNessuna valutazione finora

- Tugas 2 Rekayasa Pipa - Gita Surya Yahya - 04211640000045Documento10 pagineTugas 2 Rekayasa Pipa - Gita Surya Yahya - 04211640000045Gita SuryaNessuna valutazione finora

- D1599-14e1 Standard Test Method For Resistance To Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and FittingsDocumento4 pagineD1599-14e1 Standard Test Method For Resistance To Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittingsastewayb_964354182Nessuna valutazione finora

- PD 8010-2 Presentation April 2005 NewDocumento40 paginePD 8010-2 Presentation April 2005 NewayoungaNessuna valutazione finora

- MAOP UpratingDocumento32 pagineMAOP UpratingAbhinav GoyalNessuna valutazione finora

- Pressure Testing of Pipeline Systems (Version 1.1.0, MAY 2013)Documento46 paginePressure Testing of Pipeline Systems (Version 1.1.0, MAY 2013)Amit SharmaNessuna valutazione finora

- Gas Pipeline Hydraulic Analysis CalculationDocumento10 pagineGas Pipeline Hydraulic Analysis Calculationbalakrishna100% (3)

- Small Bore Fitting (SBF) Vibration Fatigue CalculationDocumento26 pagineSmall Bore Fitting (SBF) Vibration Fatigue CalculationgopaltryNessuna valutazione finora

- Asme B31.4 VS Csa Z662Documento6 pagineAsme B31.4 VS Csa Z662Tiffany Davis100% (1)

- API RP 1102 SpreadsheetDocumento5 pagineAPI RP 1102 SpreadsheetMuhammad Farid TaufikNessuna valutazione finora

- Caesar DispalcmentDocumento8 pagineCaesar DispalcmentChirag BhagatNessuna valutazione finora

- Hdpe Pipe Design PDFDocumento27 pagineHdpe Pipe Design PDFAshley Dillon TothNessuna valutazione finora

- Book 2: Chapter 4 - Fluid Flow: Application LimitationsDocumento20 pagineBook 2: Chapter 4 - Fluid Flow: Application LimitationsVaniya GoelNessuna valutazione finora

- Pipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressDocumento75 paginePipes. Maximum Span Between Pipe Supports For A Given Maximum Bending StressMarius GhitaNessuna valutazione finora

- DNV RP F105Documento39 pagineDNV RP F105Jignesh PandyaNessuna valutazione finora

- ASME B16.47 Ser. A, Ser. B Industry Standard and AWWA Flanges Robert-James Sales, IncDocumento25 pagineASME B16.47 Ser. A, Ser. B Industry Standard and AWWA Flanges Robert-James Sales, IncChairul AnwarNessuna valutazione finora

- Surge CalculationsDocumento7 pagineSurge CalculationsSameer MinhajNessuna valutazione finora

- Pipeline Surface Loading Screening Process 2009Documento81 paginePipeline Surface Loading Screening Process 2009JHONDURANNessuna valutazione finora

- Client:: Calculation No: Stress Report No: Rev. Date: SHT: XX-PI-SLUG-000X XX-XXX-XX-XXXX A1 XX/XX/XXXX 1 of 3Documento3 pagineClient:: Calculation No: Stress Report No: Rev. Date: SHT: XX-PI-SLUG-000X XX-XXX-XX-XXXX A1 XX/XX/XXXX 1 of 3K. Paul100% (1)

- Enbridge Revised Pipeline Backfill Plan 20100817Documento14 pagineEnbridge Revised Pipeline Backfill Plan 20100817adeoye_okunoyeNessuna valutazione finora

- API RP 1102 SpreadsheetDocumento6 pagineAPI RP 1102 Spreadsheetm_michael_cNessuna valutazione finora

- Upheaval Buckling CalculationDocumento6 pagineUpheaval Buckling Calculationheldermanuel100100% (2)

- 1990 Palmer Upheaval BucklingDocumento10 pagine1990 Palmer Upheaval Bucklingppyim2012100% (1)

- Asme b31.4 InterpretationDocumento18 pagineAsme b31.4 InterpretationOrlando Rojas100% (1)

- Vortex Excitation of Metal BellowsDocumento8 pagineVortex Excitation of Metal BellowsMourad BenabderrahmaneNessuna valutazione finora

- Max Allowable Pressure of Pipes and PipellinesDocumento104 pagineMax Allowable Pressure of Pipes and Pipellinesprasoon_eilNessuna valutazione finora

- BuriedPipeDocumento9 pagineBuriedPipePaldexNessuna valutazione finora

- Heat Transfer. Heat Loss From A Pipe in An Oudoor Location (This File Is in Working)Documento65 pagineHeat Transfer. Heat Loss From A Pipe in An Oudoor Location (This File Is in Working)vyrgoNessuna valutazione finora

- API Casing DesignDocumento1 paginaAPI Casing Designhimansh1990Nessuna valutazione finora

- STD 226 PDFDocumento75 pagineSTD 226 PDFsamsurendran_mech4020Nessuna valutazione finora

- MPM 312 03 08Documento3 pagineMPM 312 03 08Mousa PetrolNessuna valutazione finora

- CalcvesselDocumento11 pagineCalcvesselHami Keserci100% (1)

- As 3600 2018 One Way Slab End SpanDocumento10 pagineAs 3600 2018 One Way Slab End SpanSteven SebastianNessuna valutazione finora

- Specifications: DaikinDocumento17 pagineSpecifications: DaikinyoyokNessuna valutazione finora

- Daikin JT160L P8Y1 Teknik DokumanDocumento18 pagineDaikin JT160L P8Y1 Teknik DokumanShuanglai LiuNessuna valutazione finora

- 08 Fe 10035Documento1 pagina08 Fe 10035sooraj1234Nessuna valutazione finora

- PCBA-WP543HV HW Manual Rev1.05Documento21 paginePCBA-WP543HV HW Manual Rev1.05Surapong Pongchaiprateep100% (1)

- 8D ReportDocumento26 pagine8D ReportEbenezer FrancisNessuna valutazione finora

- 6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionDocumento2 pagine6.3. Example of Transmission Ratio Assessment 6.3.1. Power-Split Hydro-Mechanical TransmissionNita SebastianNessuna valutazione finora

- EE020-Electrical Installation 1-Th-Inst PDFDocumento69 pagineEE020-Electrical Installation 1-Th-Inst PDFSameera KodikaraNessuna valutazione finora

- What Is A Bioclimatic Chart - EHowDocumento2 pagineWhat Is A Bioclimatic Chart - EHowonkhgfg kjhh jghNessuna valutazione finora

- SYS600 System ConfigurationDocumento256 pagineSYS600 System ConfigurationDang JinlongNessuna valutazione finora

- En Mirage Classic Installation GuideDocumento4 pagineEn Mirage Classic Installation GuideMykel VelasquezNessuna valutazione finora

- 8060056-ELIVAC Smart Vacuum Systems ENDocumento8 pagine8060056-ELIVAC Smart Vacuum Systems ENseimarfelipeNessuna valutazione finora

- Industrial Visit Report OnDocumento41 pagineIndustrial Visit Report OnLalit SharmaNessuna valutazione finora

- Amerisolar Ficha TecnicaDocumento2 pagineAmerisolar Ficha Tecnicapepo222Nessuna valutazione finora

- PKG 101 Principles of Packaging Quiz 1ADocumento2 paginePKG 101 Principles of Packaging Quiz 1AuknowgaryNessuna valutazione finora

- TD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDocumento11 pagineTD62382APG, TD62382AFG: 8Ch Low Input Active Sink DriverDiego GrisalesNessuna valutazione finora

- HRTC RoutesDiverted Via KiratpurManali Four LaneDocumento9 pagineHRTC RoutesDiverted Via KiratpurManali Four Lanepibope6477Nessuna valutazione finora

- Dn7064519 - Installing Flexi Cabinet For IndoorDocumento63 pagineDn7064519 - Installing Flexi Cabinet For Indoorlettymc100% (1)

- FLIX Luggage Tags 8055071906Documento1 paginaFLIX Luggage Tags 8055071906Bhargav RamNessuna valutazione finora

- The Seven Deadly Sins of Strategy ImplementationDocumento4 pagineThe Seven Deadly Sins of Strategy ImplementationNavigators ReunionNessuna valutazione finora

- Getrag DTF BlessingDocumento26 pagineGetrag DTF BlessingRafael Nakazato RecioNessuna valutazione finora

- Dap 018 ADocumento28 pagineDap 018 AajoaomvNessuna valutazione finora

- Quick Operation Guide of DS-7200-ST DVR (V1.2.0)Documento40 pagineQuick Operation Guide of DS-7200-ST DVR (V1.2.0)Roman MayurNessuna valutazione finora

- Selfdrive Autopilot CarsDocumento20 pagineSelfdrive Autopilot CarsPavan L ShettyNessuna valutazione finora

- Capr-I En229Documento13 pagineCapr-I En229Anonymous WglGv0GNessuna valutazione finora

- NovaSeq X - Site PreparationDocumento3 pagineNovaSeq X - Site Preparationlifir67730Nessuna valutazione finora

- Deep Sea Research Submarine Report PDFDocumento128 pagineDeep Sea Research Submarine Report PDFy_596688032Nessuna valutazione finora

- Atul Gaonkar Resume 2017Documento6 pagineAtul Gaonkar Resume 2017Vinod KaleNessuna valutazione finora

- Himmlischer Adventjodler StringsDocumento2 pagineHimmlischer Adventjodler StringsSibille HuberNessuna valutazione finora

- Liquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Documento12 pagineLiquid Penetrant Test Procedure: Document No.: SP-1.5 Rev. 1.2Anas PratamaNessuna valutazione finora

- Fopid Controller and It's ApplicationDocumento6 pagineFopid Controller and It's Applicationshreeja dasguptaNessuna valutazione finora

- Media Gateway SoftswitchDocumento10 pagineMedia Gateway SoftswitchMahmoud Karimi0% (1)

- Ruth Clark ResumeDocumento2 pagineRuth Clark Resumeapi-288708541Nessuna valutazione finora

- HC110110007 Data Forwarding ScenarioDocumento17 pagineHC110110007 Data Forwarding ScenariojscansinoNessuna valutazione finora