Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Volume Flow Calculation

Caricato da

kalaiCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Volume Flow Calculation

Caricato da

kalaiCopyright:

Formati disponibili

Formulae

Volume

flow calculation

Calculation of Calculation of Calculation of

kv value volume flow pressure drop

Q (m3/h)

kv (m3/h) G (kg/h) ∆p (bar)

Liquids 2

ρ ∆p Q

kv = Q × Q = kv × ∆p = ρ ×

∆p ρ kv

Gases p1

p2 >

2 Qn ρn × T1 ∆p × p 2 ρn × T1 × Q2n

kv = × Qn = 514 × k v × ∆p =

∆p × p 2 ρn × T1 p2 × (k v × 514)

p1 514 2

∆p <

2

p1

p2 <

2 Qn 1

kv = × ρn × T1 Qn = 257 × k v × p1 ×

p1 257 × p1 ρn × T1

∆p >

2

Steam p1

p2 > 2

2 G v2 ∆p G v

kv = × G= 31,6 × k v × ∆p = × 2

p1 31,6 ∆p v2 k v 1000

∆p <

2

p1

p2 <

2 G 2 × v∗ p1

kv = × G= 31,6 × k v ×

p1 31,6 p1 2 × v∗

∆p >

2

Water 2

Q Q

kv = Q =k v × ∆p ∆p =

5 - 30°C ∆p kv

ρ ≈ 1 kg/dm3

Air p1

p2 > 2

2 kv =

Qn Q 1

Qn = 26,4 × k v × ∆p × p2 ∆p = n ×

p1 ∆p × p2 × 26,4 kv p2 × 699

20°C ∆p <

2

ρ ≈ 1.20 kg/m3

p1

p2 <

2 Qn

kv = Qn = k v × p1 × 13,2

p1 p1 × 13,2

∆p >

2

kv m3/h Valve capacity

Q m3/h Volume flow

Qn m3n/h Volume flow (0°C 760 mm Hg)

p1 bar (abs) Pressure ahead of valve

p2 bar (abs) Pressure after valve

∆p bar Pressure drop across valve

G kg/h Mass flow

ρ kg/m3 Density of medium ahead of valve

ρn kg/m3n Normal density (0°C 760 mm Hg)

t1 °C Temperature of medium ahead of valve

T1 K 273 + t1 = absolute temperature of medium ahead of valve

v2 m3/kg Specific volume (from steam table) for p2 and t1 condition

p

v* m3/kg Specific volume (from steam table) for 1 and t1 condition

2

Note on calculations: it is a necessary condition, that the valve is fully open.

114 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Air at low pressure

EVI valves

EVI 1.5-25, EVI-C 1.5-3 de-energized closed and EVI 1.5-3 N.O. (de-energized open)

Example 10 Nm3/h can be obtained with

EVI 25 at ∆p = approx. 2.2 mbar

EVI 20 at ∆p = approx. 7 mbar

EVI 15 at ∆p = approx. 17 mbar

EVI 10 at ∆p = approx. 64 mbar

EVI 6 at ∆p = approx. 300 mbar

IK.11.A4.02 Danfoss A/S 08-1998 115

Capacity diagrams

Air at higher pressure

EVI and EVSI valves

EVI 1.5 - 3, EVI-C 1.5-3, EVSI 6-22 de-energized closed and EVI 1.5-3 N.O. (de-energized open)

Inlet pressure

Outlet pressure

Example Assumptions: Result:

- Capacity required = 90m³/h The required capacity can be obtained with

- Inlet pressure = 5 bar an EVSI 10, of which the actual capacity is

- Outlet pressure = 3.25 bar 95 m³/h.

Procedure:

Take a vertical line from the outlet pressure

(3.25 bar) until it intersects the inlet pressure

(5 bar). From this point take a horizontal line

to intersect the capacity curves.

116 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Air at higher pressure

EVSI and EVSI-C 15 - 50 valves

De-energized closed EVSI 15-50 and EVSI-C 15-50 with valve body of Dezincification resistant brass

Inlet pressure

Outlet pressure

Example Problem: Results:

What capacity is obtainable from EVSI 15-50 EVSI 15 = approx. 240 m3/h

at an inlet pressure of 5 bar and an outlet EVSI 20 = approx. 485 m3/h

pressure of 3.5 bar? EVSI 25 = approx. 670 m3/h

EVSI 32 = approx. 1100 m3/h

Procedure: EVSI 40 = approx. 1400 m3/h

Take a vertical line from the outlet pressure EVSI 50 = approx. 2450 m3/h

(3.5 bar) until it intersects the inlet pressure

(5 bar). From this point take a horizontal line

to intersect the capacity scales.

IK.11.A4.02 Danfoss A/S 08-1998 117

Capacity diagrams

Water at low pressure

EVI and EVSIT valves

De-energized closed EVI 1.5-25 and EVSIT 12-22

Example Problem: Results:

What capacity is obtainable from EVI and EVI 1.5 gives approx. 0.08 l/min.

EVSIT at a differential pressure of 10 mbar EVI 2 gives approx. 0.25 l/min.

(10 cmWG)? EVI 3 gives approx. 0.5 l/min.

EVI 6 gives approx. 1.2 l/min.

EVI 10 gives approx. 2.5 l/min.

EVI 15 gives approx. 4.5 l/min.

EVI 20 gives approx. 7.5 l/min.

EVI 25 gives approx. 13 l/min.

EVSIT 12 gives approx. 0.75 l/min.

EVSIT 18-22 gives approx. 5.9 l/min.

118 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Water at higher pressure

EVI valves

De-energized closed EVI 1.5-20

Example Problem: Result:

What capacity is obtainable from EVI valves EVI 1.5 gives approx. 0.035 m3/h

at a differential pressure of 0.5 bar? EVI 2 gives approx. 0.11 m3/h

EVI 3 gives approx. 0.21 m3/h

EVI 6 gives approx. 0.49 m3/h

EVI 10 gives approx. 1.1 m3/h

EVI 15 and EVI 20 cannot be applied at a

differential pressure of 0.5 bar.

IK.11.A4.02 Danfoss A/S 08-1998 119

Capacity diagrams

Water at higher pressure

SVI valves

De-energized closed SVI and SVI-C

Example Problem: Results:

What capacity is obtainable from SVI and SVI 1.2 gives approx. 0.028 m3/h

SVI-C valves at a differential pressure of SVI 1.5 gives approx. 0.057 m3/h

0.5 bar? SVI 2.0 gives approx. 0.078 m3/h

SVI 2.5 gives approx. 0.12 m3/h

SVI 3.0 gives aprox. 0.16 m3/h

SVI 3.5 gives approx. 0.18 m3/h

120 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Water at higher pressure

SVI N.O. valves

De-energized open SVI

Example Results:

Problem: SVI 1.5 N.O. gives approx. 0.042 m3/h

What capacity is obtainable from SVI N.O. at SVI 2.0 N.O. gives approx. 0.85 m3/h

a differential pressure of 0.5 bar? SVI 2.5 N.O. gives approx. 0.11 m3/h

SVI 3.0 N.O. gives approx. 0.13 m3/h

SVI 3.5 N.O. gives approx. 0.14 m3/h

IK.11.A4.02 Danfoss A/S 08-1998 121

Capacity diagrams

Water at higher pressure

SVI FL valves

De-energized closed

SVI 1.2-2.0 FL 22 × 22 mm

Problem:

What capacity is obtainable at a

differential pressure of 0.5 bar?

Results:

SVI 1.2 gives approx.

0.028 m 3/h

SVI 1.5 gives approx.

0.05 m 3/h

SVI 2.0 gives approx.

0.063 m 3/h

De-energized closed

SVI 1.2-2.5 FL 32 × 32 mm

Problem:

What capacity is obtainable at a

differential pressure of 0.5 bar?

Results:

SVI 1.2 gives approx.

0.035 m 3/h

SVI 1.5 gives approx.

0.049 m 3/h

SVI 2.0 gives approx.

0.078 m 3/h

SVI 2.5 gives approx.

0.11 m3/h

122 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Water at higher pressure

EVSI 6 - 100 and EVSIT 12 - 22

De-energized closed (N.C.) EVSI 6-100 and EVSIT 12-22 and de-energized open (N.O.) EVSI 15 - 50

Example Problem: Results:

What water volume is obtainable from EVSI 25 gives approx. 19 m3/h

EVSI 25 and EVSI 80 at a differential EVSI 80 gives approx. 130 m3/h

pressure across the valve of 3 bar?

IK.11.A4.02 Danfoss A/S 08-1998 123

Capacity diagrams

Water at higher pressure

SVSI valves

SVSI 13 - 24

Example Problem: Results:

What capacity is obtainable from SVSI valves SVSI 13 gives approx. 3.9 m3/h

at a differential pressure of 2 bar? SVSI 24 gives approx. 12 m3/h

124 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Water at higher pressure

EVSI-C 15-50 with valve body of stainless steel

De-energized closed EVSI-C 15-50 with valve body of stainless steel

Example Problem: Results:

What capacity is obtainable from EVSI-C at a EVSI-C 15 = approx. 5 m3/h

differential pressure of 3 bar? EVSI-C 20-25 = approx. 15 m3/h

EVSI-C 32-40 = approx. 38 m3/h

EVSI-C 50 = approx. 55 m3/h

IK.11.A4.02 Danfoss A/S 08-1998 125

Capacity diagrams

Water at fully open valve

EVSIM valves

De-energized closed EVSIM 6-20

Example Problem: Results:

What capacity is obtainable from EVSIM 6-20 EVSIM 6 gives approx. 1.4 m3/h

at a differential pressure of 3 bar? EVSIM 10 gives approx. 2.2 m3/h

EVSIM 15 gives approx. 3.6 m3/h

EVSIM 20 gives approx. 8.7 m3/h

126 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Steam

EVSI 15 - 50 valves

De-energized closed EVSI 15-50

A: Critical pressure drop

Example Assumptions: Results:

- Inlet pressure = 1.55 bar absolute a. EVSI 15 = approx. 75 kg/h

- Outlet pressure = 0.95 bar absolute b. EVSI 20 = approx. 130 kg/h

- Differential pressure (0.6 bar) exceeds the c. EVSI 25 = approx. 200 kg/h

valves’ minimum ∆p of 0.3 bar. d. EVSI 32 = approx. 300 kg/h

e. EVSI 40 = approx. 390 kg/h

Procedure: f. EVSI 50 = approx. 800 kg/h

Take a vertical line from the inlet pressure

(1.55 bar) until it intersects the differential

pressure curve (0.6 bar). From this point take

a horizontal line to intersect the capacity

curves. Now take a vertical line to intersect

the capacity scales.

IK.11.A4.02 Danfoss A/S 08-1998 127

Capacity diagrams

Steam

EVSIS and EVJHS valves

EVSIS 3 - 25

A: Critical pressure drop

Assumptions:

- Inlet pressure = 6 bar

absolute

- Differential pressure = 1 bar

Procedure:

Take a vertical line from the inlet

pressure (6 bar) until it

intersects the differential

pressure curve (1 bar). From

this point take a horizontal line

to intersect the capacity curves.

Now take a vertical line to read

the capacity on the capacity

scales.

Reading example:

The capacity of EVSIS 10 is P1 [bar] abs.

approx. 100 kg/h.

EVJHS 15 - 20

A: Critical pressure drop

Assumptions:

- Inlet pressure = 6 bar

absolute

- Differential pressure = 1 bar

Procedure:

Take a vertical line from the inlet

pressure (6 bar) until it

intersects the differential

pressure curve (1 bar). From

this point take a horizontal line

to intersect the capacity curves.

Now take a vertical line to read

the capacity on the capacity

scales.

Reading example:

The capacity of EVJHS 20 is

approx. 300 kg/h.

128 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Air

HP valves

HP 15 - 50

Example Assumptions:

- Inlet pressure (p1) = 9 bar

- Outlet pressure (p2) = 6 bar

- Air volume required: 1500 m³/h

Procedure:

Take a vertical line from the outlet pressure

(6 bar) until it intersects the inlet pressure

(9 bar). From this point take a horizontal line

to intersect the capacity scales.

Result:

The required capacity can be obtained with

an HP 25, of which the actual capacity is

approx. 1650 m³/h.

IK.11.A4.02 Danfoss A/S 08-1998 129

Capacity diagrams

Water and oil

HP valves

HP 15-50 at low pressure

and a viscosity of 2°E

(12 cSt) Differential pressure

Assumptions:

- Medium = water or oil

- Inlet pressure = 500 mm wg

(5 kPa)

- Outlet pressure = 0 bar

- Differential pressure

(∆p) = 500 mm wg (5 kPa)

- Capacity required = 10 m³/h

Procedure:

Take a horizontal line from the

differential pressure (5 kPa)

until it intersects the capacity

curves. The capacity at the

intersection point (the x value)

must be larger than or equal to

10 m³/h.

Result: Capacity

The required capacity can be

obtained with an HP 50, of

which the actual capacity is

approx. 12 m³/h.

HP 15-50 at high pressure

and a viscosity of 2°E

(12 cSt)

Problem:

What capacity is obtainable from

HP 15 in the following

conditions:

- Medium = water or oil

- Inlet pressure = 4 bar

- Outlet pressure = 0 bar

- Differential pressure

(∆p) = 4 bar

Procedure:

Take a horizontal line from the

differential pressure (4 bar) until

it intersects the capacity curve

for HP 15. From this point take a

vertical line to intersect the x

axis.

Result:

Capacity = approx. 14 m³/h

130 IK.11.A4.02 Danfoss A/S 08-1998

Capacity diagrams

Water

HPV and HPV-C valves

HPV 15 - 50 and HPV-C 15 - 50

Example

Problem:

What water volume is obtainable from

HPV 25 and HPV 40 at a differential pressure

across the valve of 3 bar?

Procedure:

Take a horizontal line from the differential

pressure (3 bar) until it intersects the capacity

curves. From this point take a vertical line to

intersect the x axis.

Results:

HPV 25 gives approx. 33 m3/h

HPV 40 gives approx. 73 m3/h

IK.11.A4.02 Danfoss A/S 08-1998 131

Potrebbero piacerti anche

- Medium Size Section Mill Am Olaberria enDocumento6 pagineMedium Size Section Mill Am Olaberria enkalaiNessuna valutazione finora

- Danieli New Pot Grate Testing Facilities: A Case Study - Ahmsa Pellet PlantDocumento11 pagineDanieli New Pot Grate Testing Facilities: A Case Study - Ahmsa Pellet PlantkalaiNessuna valutazione finora

- Abs WBF 90tph Italy PDFDocumento2 pagineAbs WBF 90tph Italy PDFkalaiNessuna valutazione finora

- Sino Steel PDFDocumento32 pagineSino Steel PDFkalaiNessuna valutazione finora

- Belt Watch PDFDocumento5 pagineBelt Watch PDFkalaiNessuna valutazione finora

- Metals 164 Tata Steel Jamshedpur 0 PDFDocumento41 pagineMetals 164 Tata Steel Jamshedpur 0 PDFkalaiNessuna valutazione finora

- Midrex 2018 DFM4QTR Final2 PDFDocumento20 pagineMidrex 2018 DFM4QTR Final2 PDFkalaiNessuna valutazione finora

- Water Management Systems: Sustainable and Economic SolutionsDocumento36 pagineWater Management Systems: Sustainable and Economic SolutionskalaiNessuna valutazione finora

- ENGG.P&T.SC.001 - R04 Standard Technical Specification For Very Light Weight Insulating Castable (Low Iron)Documento3 pagineENGG.P&T.SC.001 - R04 Standard Technical Specification For Very Light Weight Insulating Castable (Low Iron)kalaiNessuna valutazione finora

- Treatment of Effluent From RefineriesDocumento26 pagineTreatment of Effluent From RefinerieskalaiNessuna valutazione finora

- GMR Kakinada Special Investment Region Overview PresentationDocumento11 pagineGMR Kakinada Special Investment Region Overview PresentationkalaiNessuna valutazione finora

- 2 - 1430 Peter SikstromDocumento17 pagine2 - 1430 Peter SikstromkalaiNessuna valutazione finora

- 2 - 1430 Peter Sikstrom PDFDocumento33 pagine2 - 1430 Peter Sikstrom PDFkalaiNessuna valutazione finora

- Lalit Gujral - Macawber Beekay PDFDocumento50 pagineLalit Gujral - Macawber Beekay PDFkalai100% (1)

- AA12 - Experience With Particle Breakdown in Gas Suspension CalcinersDocumento10 pagineAA12 - Experience With Particle Breakdown in Gas Suspension CalcinerskalaiNessuna valutazione finora

- Innovative Vacuum-Tank Degassing Technologies: Well-Established Metallurgical Performance Figures Achieved by Using Dry Mechanical PumpsDocumento12 pagineInnovative Vacuum-Tank Degassing Technologies: Well-Established Metallurgical Performance Figures Achieved by Using Dry Mechanical PumpskalaiNessuna valutazione finora

- 9606-Article Text PDF-22911-3-10-20170313Documento6 pagine9606-Article Text PDF-22911-3-10-20170313kalaiNessuna valutazione finora

- Bus A Bus B Board Loading Details Description Continous Load (KW)Documento1 paginaBus A Bus B Board Loading Details Description Continous Load (KW)kalaiNessuna valutazione finora

- Employment-Oriented Industry Studies: Resource-Based Technology Innovation in South AfricaDocumento26 pagineEmployment-Oriented Industry Studies: Resource-Based Technology Innovation in South AfricakalaiNessuna valutazione finora

- EER-1 Emergency ListDocumento2 pagineEER-1 Emergency ListkalaiNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- URS R404aDocumento1 paginaURS R404aironiteNessuna valutazione finora

- General Design ProcedureDocumento5 pagineGeneral Design ProcedureMutiaraNessuna valutazione finora

- Vacuum Swing AdsorptionDocumento3 pagineVacuum Swing AdsorptionnagsraviNessuna valutazione finora

- References List - TPIA - INSPECTION - 31 Mar 22Documento9 pagineReferences List - TPIA - INSPECTION - 31 Mar 22isan.structural TjsvgalavanNessuna valutazione finora

- Cavitation in Centrifugal PumpDocumento22 pagineCavitation in Centrifugal Pumpnastyn-1Nessuna valutazione finora

- Ce140 PS 1 PDFDocumento1 paginaCe140 PS 1 PDFBianca MarianoNessuna valutazione finora

- Design and Performance Analysis of Centrifugal PumpDocumento8 pagineDesign and Performance Analysis of Centrifugal Pumpsudhirm16Nessuna valutazione finora

- Dräger EM200-E Diesel Exhaust MeasurementDocumento6 pagineDräger EM200-E Diesel Exhaust MeasurementOdilon AguilarNessuna valutazione finora

- VLE ReportDocumento4 pagineVLE ReportAmeerul AhwazNessuna valutazione finora

- Co 2 Flow Meters Vs RegulatorsDocumento2 pagineCo 2 Flow Meters Vs RegulatorswentropremNessuna valutazione finora

- Radial Turbine Performance Prediction and Design Optimization Whit Matlab ToolDocumento7 pagineRadial Turbine Performance Prediction and Design Optimization Whit Matlab Tooljr110livecomNessuna valutazione finora

- Principles of Flight - 081 POFDocumento476 paginePrinciples of Flight - 081 POFobrajiorNessuna valutazione finora

- Varodry: Dry Screw Vacuum PumpsDocumento8 pagineVarodry: Dry Screw Vacuum PumpsDilson Barbosa RamosNessuna valutazione finora

- BOSS Commissioning Valve BrochureDocumento14 pagineBOSS Commissioning Valve Brochuretrabant424Nessuna valutazione finora

- Testing and Adjusting 938F WHEEL LOADER IT38F INTEGRATED TOOLCARRIER HYDRAULIC SYSDocumento27 pagineTesting and Adjusting 938F WHEEL LOADER IT38F INTEGRATED TOOLCARRIER HYDRAULIC SYSDaniel AmanorNessuna valutazione finora

- FDV Iom Carrier 30xwDocumento34 pagineFDV Iom Carrier 30xwnaeem shakirNessuna valutazione finora

- Lift Cap Drill FluidDocumento48 pagineLift Cap Drill Fluiddn1366Nessuna valutazione finora

- Control Volume Part 1Documento42 pagineControl Volume Part 1Teja MaruvadaNessuna valutazione finora

- Capstone Project Stage-2Documento34 pagineCapstone Project Stage-2Dhruvil AkbariNessuna valutazione finora

- Charle's LawDocumento23 pagineCharle's Lawmark gonzalesNessuna valutazione finora

- Testcycle 1 For Nozzle 1 PDFDocumento28 pagineTestcycle 1 For Nozzle 1 PDFAnonymous bJZz94Nessuna valutazione finora

- RTOC 2010 Assessment ReportDocumento245 pagineRTOC 2010 Assessment ReportShivam tripathi100% (1)

- Limitations of ASME PTC 10 in Accurately Evaluating Centrifugal Compressor Thermodynamic PerformanceDocumento16 pagineLimitations of ASME PTC 10 in Accurately Evaluating Centrifugal Compressor Thermodynamic PerformancefjafarvandNessuna valutazione finora

- IAC PAC Power Plant BarhDocumento19 pagineIAC PAC Power Plant BarhMohammad AtaullahNessuna valutazione finora

- Spray Painting: Hazards and Control MeasuresDocumento1 paginaSpray Painting: Hazards and Control MeasuresRockroll AsimNessuna valutazione finora

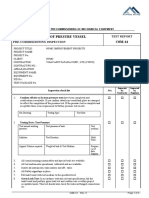

- C0M-14 Hydrostatic Test of Pressure VesselDocumento3 pagineC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongNessuna valutazione finora

- Gear Pump DiscussionDocumento2 pagineGear Pump DiscussionSlim ShaddysNessuna valutazione finora

- Odalog 7000 Mkii Multi Gas Monitor: Key FeaturesDocumento2 pagineOdalog 7000 Mkii Multi Gas Monitor: Key FeaturesLabLing DLH BontangNessuna valutazione finora

- Simbologia ValvulasDocumento43 pagineSimbologia Valvulasdanillomodesto100% (1)

- Cap. 05 PDFDocumento139 pagineCap. 05 PDFRamón Ramalho100% (1)