Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Swegon Inductioin Units Vs Fan Coil Units

Caricato da

Moriyasu NguyenDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Swegon Inductioin Units Vs Fan Coil Units

Caricato da

Moriyasu NguyenCopyright:

Formati disponibili

HotelSolution

Induction units VS custom Fan-coil solution

Parasol & Paragon units

Induction units VS Fan-Coil

Induction units are devices that utilizes nozzles instead of a fan Fan-coil units usually work only with recycle air or with small

to move air. Three functions in one device - cooling, heating and fresh air quantity (additional air mixing box in front of unit has to

ventilation. Outdoor prepared air is supplied through noiseless Description be provided). Air direction is toward comfort area, without

nozzles forming "coanda" effect, with no draft, and with neutral "coanda" effect, and air temperature is to low or to high,

air temperature in comfort area. making unpleasant environment with draft.

4-Pipe configuration to provide both heating and cooling 2/4 pipe system 4-Pipe configuration to provide both heating and cooling

Fresh air quantity is usually doubled comparing requested

minimum defined by design. Environment is healthy and very Air quantity Fresh air quantity is minimally requested

pleasant

Smaller height and wider Equipment dimensions Bigger height with smaller width

Use nozzles to induce air and, therefore, do not have a fan. This Use fans for air supply. Usually fans have 3 speeds. Noise level is

Sound/Noise

results in an extremely low noise level, 20-30 dB from 30-40 dB depending of fan speed.

During summer period supplied water temperature for unit

Usually supplied water temperature, during summer period, for

heat exchanger is no less then 14 C. This water temperature

unit heat exchanger is 7 C. Unit is working in condensate regime.

doesn`t allow condensate generation on heat exchanger. No Condensate drain

Unit has condensate drain, network, usually pump (lot of weak

condensate drain, no condensate pump, no condensate

spots for possible condensate leaking)

network, no bad smell.

Do not require an Electrical Connection. Only a control wiring Units have a fan that requires an electrical connection. Control

Electrical connection

connection is required. wiring is also required.

Units have a fan and require filtration local to the terminal unit.

Units do not have a fan. Therefore, they do not have the need

Filters This filter will require scheduled maintenance to ensure the unit

for a filter to be installed local to the terminal unit.

does not become clogged.

Maintenance team must change filters on regular bases (6 times

per year), service fans upon failure, clean condensate trey in

Little or no maintenance requirements Maintenance

order to avoid smells, service condensate pump upon failure

(weak spot).

Longer life cycle - up to 30-40 years Life cycle Shorter life cycle - up to 10 years

Units do not have a fan, no energy consumption. Also can have Units have a fan that attributes towards energy usage. Fan Coil

a dedicated heat recovery chiller that can operate at very high Units have a lower, more traditional, operating chilled water

Energy performance

efficiencies due to a higher operating chilled water temperature. To generate this lower chilled water temperature,

temperature. the heat recovery chiller cannot operate at its highest efficiency.

Units allow the chiller plant to operate more efficiently, and

they use less energy themselves. This could result in an Fan Coil Units should be assumed to be the baseline system for a

LEED energy points

estimated 1 or 2 more points from LEED EAc1 in comparison to high-end hotel.

a Fan Coil Unit system.

Investment cost, depending of Investor comfort requests, is up

to 5-10% more expensive then fan-coil system. Exploitation Baseline system, little lower investment cost, bigger exploitation

Cost

costs is lower because better energy performance and no cost and maintenance costs.

for maintenance.

Potrebbero piacerti anche

- PM PeraturanDocumento2 paginePM Peraturanyan energiaNessuna valutazione finora

- Technology of Ducted SystemDocumento1 paginaTechnology of Ducted SystemIsmat AraNessuna valutazione finora

- The Little Book of Vacuum Tube Pre-Amplifier ProjectsDa EverandThe Little Book of Vacuum Tube Pre-Amplifier ProjectsNessuna valutazione finora

- Classifications of Air Conditioning System: Based On Major FunctionDocumento67 pagineClassifications of Air Conditioning System: Based On Major Functionjet latorreNessuna valutazione finora

- A Wind Turbine Recipe Book 2014 English Units EdtionDa EverandA Wind Turbine Recipe Book 2014 English Units EdtionValutazione: 5 su 5 stelle5/5 (2)

- ComfortStar CCH/CHH Series MiniSplit Air Conditioners BrochureDocumento16 pagineComfortStar CCH/CHH Series MiniSplit Air Conditioners Brochuree-ComfortUSA50% (2)

- Parapetni FC AparatiDocumento36 pagineParapetni FC AparatiEnis IvkovićNessuna valutazione finora

- What (Watt) We Need to Know to Reduce Electricity BillsDa EverandWhat (Watt) We Need to Know to Reduce Electricity BillsNessuna valutazione finora

- Carrier 42N TDB UnlockedDocumento32 pagineCarrier 42N TDB UnlockedSvetla NikolovaNessuna valutazione finora

- A Guide to Vintage Audio Equipment for the Hobbyist and AudiophileDa EverandA Guide to Vintage Audio Equipment for the Hobbyist and AudiophileNessuna valutazione finora

- Split Type Air Conditioners: DC Inverter Control 50 HZDocumento4 pagineSplit Type Air Conditioners: DC Inverter Control 50 HZlucio ruiz jrNessuna valutazione finora

- Fan Dry Coil UnitDocumento5 pagineFan Dry Coil UnitHiei ArshavinNessuna valutazione finora

- Rac Ha ReportDocumento8 pagineRac Ha ReportShreyas YadavNessuna valutazione finora

- AHUDocumento16 pagineAHUEddieNessuna valutazione finora

- Koolman Air-CooldedWater Chiller With Heat Pump OptionDocumento16 pagineKoolman Air-CooldedWater Chiller With Heat Pump OptionLuis PinoNessuna valutazione finora

- Window Ac: Working Principle, Its Parts and Its SignificanceDocumento11 pagineWindow Ac: Working Principle, Its Parts and Its SignificanceMuhammad Jamshaid Khan100% (1)

- Gree 2018 CAC PDFDocumento149 pagineGree 2018 CAC PDFTEMESGENNessuna valutazione finora

- Comparison Between Conventional Chilled Water System and VRF System PDFDocumento9 pagineComparison Between Conventional Chilled Water System and VRF System PDFAhmed100% (1)

- Comparison Between Conventional Chilled Water System and VRF SystemDocumento9 pagineComparison Between Conventional Chilled Water System and VRF Systemmahmoud mohamedNessuna valutazione finora

- PRINTOUT1Documento4 paginePRINTOUT1Nhyira Awuah-darkoNessuna valutazione finora

- Cooling Fan CalculationsDocumento13 pagineCooling Fan CalculationsF. A AhmedNessuna valutazione finora

- Principle and Working of FanDocumento11 paginePrinciple and Working of FanKanmani.P Assistant ProfessorNessuna valutazione finora

- NAMV PaperDocumento8 pagineNAMV PaperenginvservNessuna valutazione finora

- Brochure Delta Room Cool A Series-V2Documento18 pagineBrochure Delta Room Cool A Series-V2Phúc TrầnNessuna valutazione finora

- Ac Panasonic PDFDocumento16 pagineAc Panasonic PDFSudaryanto RachmatNessuna valutazione finora

- PLXDRMM1862 R410A Inv Wall Mounted 50Hz (Myanmar) CO - FTKQ V12 PDFDocumento4 paginePLXDRMM1862 R410A Inv Wall Mounted 50Hz (Myanmar) CO - FTKQ V12 PDFWai Lwin Ko100% (1)

- CARRIER Part-11 - All-Water-SystemDocumento35 pagineCARRIER Part-11 - All-Water-SystemNahiyan AbdullahNessuna valutazione finora

- Ducted Split Systems: Technical DataDocumento20 pagineDucted Split Systems: Technical DataFilipNessuna valutazione finora

- Daikin Parallel Fan Powered VAV Systems AppGuide AG 31-018 LRDocumento2 pagineDaikin Parallel Fan Powered VAV Systems AppGuide AG 31-018 LRSambhav TiwariNessuna valutazione finora

- Comparasion of Three SystemDocumento10 pagineComparasion of Three SystemManjeet CinghNessuna valutazione finora

- Static Blower: FDN-H Series FGN-H SeriesDocumento7 pagineStatic Blower: FDN-H Series FGN-H SeriesAung Thiha SoeNessuna valutazione finora

- Hydronic Cassette Fan Coil Units: Product Selection DataDocumento20 pagineHydronic Cassette Fan Coil Units: Product Selection DataBulat IııNessuna valutazione finora

- Engy HE01Documento26 pagineEngy HE01kelvinalphonce97Nessuna valutazione finora

- Bladeless Ceiling FanDocumento2 pagineBladeless Ceiling FanAakash GhoderaoNessuna valutazione finora

- Fabrication of Water Cooler Cum Air ConditionerDocumento3 pagineFabrication of Water Cooler Cum Air Conditionersuchismita swainNessuna valutazione finora

- Ficha Tecnica Paquete Convertible Carrier 50VL-KDocumento30 pagineFicha Tecnica Paquete Convertible Carrier 50VL-Ke.garay.epseNessuna valutazione finora

- BlowerDocumento11 pagineBlowerGanesh ThoratNessuna valutazione finora

- Inverter Air ConditioningDocumento8 pagineInverter Air ConditioningKate Catherine RamosNessuna valutazione finora

- 4.0 Floor Standing Mount Hydronic TGF-W R32 18,000-36,000BTUH 5.3-10.6kW 1.5-3TRDocumento4 pagine4.0 Floor Standing Mount Hydronic TGF-W R32 18,000-36,000BTUH 5.3-10.6kW 1.5-3TRMoeenulHaqueNessuna valutazione finora

- Sub: Refrigeration and Air Conditioning (PE-ME601B) 6 Semester 2021-22Documento92 pagineSub: Refrigeration and Air Conditioning (PE-ME601B) 6 Semester 2021-22Amritendu AcharjeeNessuna valutazione finora

- S3378 1217Documento12 pagineS3378 1217eliot martinezNessuna valutazione finora

- Solar Air Conditioning System by Using Peltier ModuleDocumento5 pagineSolar Air Conditioning System by Using Peltier ModuleGodyNessuna valutazione finora

- Carrier - Room Fan Coils 42NDocumento38 pagineCarrier - Room Fan Coils 42NHamo HamoNessuna valutazione finora

- Trane Giải Nhiệt Gió CG-PRC048B-GB - 0121 - smDocumento52 pagineTrane Giải Nhiệt Gió CG-PRC048B-GB - 0121 - smPhạm ĐứcNessuna valutazione finora

- Presentation On Desert CoolerDocumento17 paginePresentation On Desert CoolerSooraj srjNessuna valutazione finora

- 48es 05pdDocumento56 pagine48es 05pdAjNessuna valutazione finora

- SA - Super Inverter - Original File PDFDocumento32 pagineSA - Super Inverter - Original File PDFJojit Cantillep MagbutayNessuna valutazione finora

- York VRV VRF CatalogDocumento30 pagineYork VRV VRF Catalogaqilabbasov87Nessuna valutazione finora

- VRF YorkDocumento40 pagineVRF Yorkbride junior tchuensuNessuna valutazione finora

- Unitrane™ D-Line: Ducted Fan CoilsDocumento56 pagineUnitrane™ D-Line: Ducted Fan CoilshanamanNessuna valutazione finora

- Chilled Water Fan Coil Unit (FWW-EC)Documento16 pagineChilled Water Fan Coil Unit (FWW-EC)Elliot MayerNessuna valutazione finora

- Selecting A Cooling Fan: Device CharacteristicsDocumento4 pagineSelecting A Cooling Fan: Device CharacteristicsGary KerrNessuna valutazione finora

- HVAC & Decentralized SystemDocumento33 pagineHVAC & Decentralized SystemAbhishek RajputNessuna valutazione finora

- Industrial FansDocumento15 pagineIndustrial FansMoch SolichinNessuna valutazione finora

- SAFETYDocumento4 pagineSAFETYthithikhine7.mmNessuna valutazione finora

- Packaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzDocumento8 paginePackaged Non Inverter - PLXPMT1725A R410A Static Blower H Series 50HzMavista TechnicNessuna valutazione finora

- Home Safety Checks: Report For Home CustomersDocumento4 pagineHome Safety Checks: Report For Home CustomersMeemoh ShuklaNessuna valutazione finora

- Air 2ADocumento4 pagineAir 2AMoriyasu NguyenNessuna valutazione finora

- Solar-1 0Documento4 pagineSolar-1 0Moriyasu NguyenNessuna valutazione finora

- SPS 2Documento9 pagineSPS 2Moriyasu NguyenNessuna valutazione finora

- Australian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesDocumento7 pagineAustralian/New Zealand Standard: Hot-Dip Galvanized (Zinc) Coatings On Fabricated Ferrous ArticlesMoriyasu NguyenNessuna valutazione finora

- Cấp ĐiệnDocumento8 pagineCấp ĐiệnMoriyasu NguyenNessuna valutazione finora

- Noiseandplanning Guidance Jun22Documento53 pagineNoiseandplanning Guidance Jun22Moriyasu NguyenNessuna valutazione finora

- NVL - TPC ID Concept - Public RestroomDocumento17 pagineNVL - TPC ID Concept - Public RestroomMoriyasu NguyenNessuna valutazione finora

- Hpac Pools Article2Documento6 pagineHpac Pools Article2Moriyasu NguyenNessuna valutazione finora

- 01-26-05 ENL - CoolingTowerDocumento106 pagine01-26-05 ENL - CoolingTowerMoriyasu NguyenNessuna valutazione finora

- Catalogo Incendio Rev500 ENGDocumento63 pagineCatalogo Incendio Rev500 ENGMoriyasu NguyenNessuna valutazione finora

- Twin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveDocumento7 pagineTwin City Fan & Blower Guide Specification Plenum Fans: Model MPQS, Direct DriveMoriyasu NguyenNessuna valutazione finora

- 2020.01.08 Winery - C&S Answers by Archea - GPADocumento3 pagine2020.01.08 Winery - C&S Answers by Archea - GPAMoriyasu NguyenNessuna valutazione finora

- 191210-01 CommentsDocumento7 pagine191210-01 CommentsMoriyasu NguyenNessuna valutazione finora

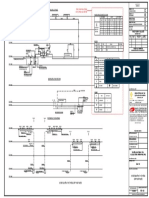

- Besa Guide To Good Practice For The Installation of Fire and Smoke Dampers (Sample)Documento7 pagineBesa Guide To Good Practice For The Installation of Fire and Smoke Dampers (Sample)Moriyasu Nguyen33% (3)

- Revise Code 10 7 2015Documento335 pagineRevise Code 10 7 2015Moriyasu NguyenNessuna valutazione finora

- Installation Operation MaintenanceDocumento64 pagineInstallation Operation MaintenanceMoriyasu NguyenNessuna valutazione finora

- 3246es en PDFDocumento2 pagine3246es en PDFMoriyasu NguyenNessuna valutazione finora

- Aritech Ceiling Mount Sensor Ds PDFDocumento2 pagineAritech Ceiling Mount Sensor Ds PDFMoriyasu NguyenNessuna valutazione finora

- Alastair Brockett PresentationDocumento65 pagineAlastair Brockett PresentationMoriyasu NguyenNessuna valutazione finora

- SG: trình bày: ở bản vẽ ký hiệu và viết tắtDocumento1 paginaSG: trình bày: ở bản vẽ ký hiệu và viết tắtMoriyasu NguyenNessuna valutazione finora

- 3 Sustainable Hvac Design Fro Green Building PDFDocumento26 pagine3 Sustainable Hvac Design Fro Green Building PDFMoriyasu NguyenNessuna valutazione finora

- Upvc Sewer Drainage Systems Product Brochure PDFDocumento32 pagineUpvc Sewer Drainage Systems Product Brochure PDFMoriyasu NguyenNessuna valutazione finora

- Poster SGT-2000E Series - Nov16 PDFDocumento1 paginaPoster SGT-2000E Series - Nov16 PDFDiego CarpioNessuna valutazione finora

- Mock Congress Research PaperDocumento5 pagineMock Congress Research Paperapi-303073122Nessuna valutazione finora

- Geothermal JapanDocumento16 pagineGeothermal JapanDoni Aditya SaputraNessuna valutazione finora

- Waste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationDocumento33 pagineWaste Heat Recovery at Compressor Stations: The Path Towards Novel and High-Impact Technologies and Their ImplementationraaaghaffarNessuna valutazione finora

- 3.1.2 Babcock and Wilcox BoilerDocumento8 pagine3.1.2 Babcock and Wilcox BoilerTitus RNessuna valutazione finora

- Stockage ENTECH-SE enDocumento4 pagineStockage ENTECH-SE enClementNessuna valutazione finora

- Boiler & Aux Operation PMIDocumento53 pagineBoiler & Aux Operation PMInikesh ranjanNessuna valutazione finora

- Windmill PlantDocumento10 pagineWindmill PlantPatoriku KunNessuna valutazione finora

- Project ProposalDocumento2 pagineProject ProposalHaries GarciaNessuna valutazione finora

- 2046 3943 2 PBDocumento8 pagine2046 3943 2 PBAlan NjsgNessuna valutazione finora

- Controlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerDocumento9 pagineControlling The Operation of Wind-Solar Hybrid Power System Using Arduino-Based Hybrid MPPT ControllerOdebunmi NathanielNessuna valutazione finora

- Unit 2.2.3.4.a.sr - LEED.v4HomesDesignConstructionChecklist StudentDocumento4 pagineUnit 2.2.3.4.a.sr - LEED.v4HomesDesignConstructionChecklist StudentKevin TorresNessuna valutazione finora

- LC1044 LRP14 3PH QRG 0823Documento2 pagineLC1044 LRP14 3PH QRG 0823FlakooNessuna valutazione finora

- Whirlpool WED5605MWDocumento1 paginaWhirlpool WED5605MWalNessuna valutazione finora

- Solar Combiner Box TrainingDocumento33 pagineSolar Combiner Box TrainingRavi Teja100% (1)

- Development of Mechanize Bamboo SplitterDocumento4 pagineDevelopment of Mechanize Bamboo SplitterKhaster NavarraNessuna valutazione finora

- Power System PresentationDocumento10 paginePower System PresentationBayeNessuna valutazione finora

- Electric Vehicles A SmartDocumento5 pagineElectric Vehicles A SmarthahaNessuna valutazione finora

- Controversy On Bataan Nuclear Power PlantDocumento5 pagineControversy On Bataan Nuclear Power PlantRuben ButalanNessuna valutazione finora

- Tech Vendor - Power PlantDocumento9 pagineTech Vendor - Power PlantSudi ArtoNessuna valutazione finora

- STF Gas&TurbineDocumento20 pagineSTF Gas&TurbinepedroanNessuna valutazione finora

- Nestle - PFADDocumento4 pagineNestle - PFADDarsh LathiaNessuna valutazione finora

- FSE Company Profile 15.07.2563Documento28 pagineFSE Company Profile 15.07.2563Puchong KongsriNessuna valutazione finora

- Solar Power Plant in MoroccoDocumento2 pagineSolar Power Plant in MoroccoUSMAN IBRAHIM0% (1)

- Excellent Thesis DesignDocumento117 pagineExcellent Thesis DesignHemanth Peddavenkatappa GariNessuna valutazione finora

- Converting My Volkswagen Jetta To A Vegetable Oil CarDocumento2 pagineConverting My Volkswagen Jetta To A Vegetable Oil CarGulf Restoration NetworkNessuna valutazione finora

- Photovoltaic System Design For A House in Karachi, PakistanDocumento7 paginePhotovoltaic System Design For A House in Karachi, PakistanTahir_Afzal_7610Nessuna valutazione finora

- Distributed Generation and Combined Heat & Power System Characteristics and Costs in The Buildings SectorDocumento146 pagineDistributed Generation and Combined Heat & Power System Characteristics and Costs in The Buildings SectorppourmoghaddamNessuna valutazione finora

- Green Rating System - Ritik JainDocumento6 pagineGreen Rating System - Ritik Jainmayuresh barbarwarNessuna valutazione finora

- Complex Engineering Problem: According To The Washington Accord Complex Engineering Problems Are Problems ThatDocumento1 paginaComplex Engineering Problem: According To The Washington Accord Complex Engineering Problems Are Problems ThatAhmad AnsariNessuna valutazione finora