Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

ExpandebalCasting PDF

Caricato da

Sree Ramichetty0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni33 pagineHello I

Titolo originale

ExpandebalCasting Ppt PDF

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoHello I

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

18 visualizzazioni33 pagineExpandebalCasting PDF

Caricato da

Sree RamichettyHello I

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 33

CASTING

• Casting- It is a process in which molten liquid

metal will we allow to solidify in a pre define

mould cavity after solidification required

shape of object can be produced.

• Pattern : Replica of final object.(Wood, Metal

alloys, plastics- thermocole, pvc)

• Types of pattern:

• Single/solid piece pattern :-used for simple

shape of the pattern.

• Split/Two piece pattern:- if the object to be

produced in complex shape and size this

pattern can be used with number of split

pieces. Such that they can be removed from

cope & drag separately.

• Loose piece pattern:- if the pattern having

internal projection or undercuts loose piece

pattern can be used.

• Gated pattern:- it is use for simple shape of

object in mass production. Number of patterns

along with gating element will produce a single

pattern known as gated pattern

• Match plate pattern:- produce complex shape of

object in mass production. Number of pattern

can be split along pattern line and they will be

added on both side of match plate.

• Sweep pattern:- To produce complex shape of

3d objects, 2d plane pattern will be rotated on

the surface of the mould. It is used for the axis

symmetric object like cone, large size bell,

cylinder.

• Pattern allowance

1. Shrinkage/Contraction Allowance:-

• Liquid metal is allowed to solidify inside the

cavity, there is a chance of contraction or

shrinkage of the material. When the liquid

metal is cooled from pouring to freezing

temperature it is liquid shrinkage. During

phase transformation shrinkage of metal is

called solidification shrinkage. When solid

casting is cooled from freezing to room

temperature it is called solid shrinkage.

2. Draft allowance:- for easy removal of the

pattern and to minimize continuous contact

between pattern and mould surface this

allowance is provide.

3. Machining Allowance:- casting object are not

having smooth surface finish to get better

surface finish machining is required.

4. Shake/Rapid allowance:- moulding sand will stick

to the surface of the pattern during ramming, for

easy removal of pattern clearance is produced

between the pattern and mould surface by shaking

the pattern.

5. Distortion allowance:- depending on shape and

size of the casting due to difference in shrinkage

value there is a possibility of distortion of the

casting. To overcome this allowance is provided on

the pattern opposite to the direction of distortion.

Sand Casting

• Flask:- a moulding flask is one which hold the

sand mould intact. Depending upon the

position of the flask in the mould structure, it

is refered by various name such as cope, drag,

cheek. It is generally made up of wood for

temporary and metal for long term.

• Core:- it is used for making hollow cavity in

casting.

• Pouring basin:- a small funnel shaped cavity at

the top of the mould in to which the molten

metal is poured.

• Sprue:- the passage through which the molten

metal from the pouring basin reaches the

mould cavity.

• Runner:- the passage ways in the parting

plane through which molten metal flow is

regulated before they reach the mould cavity.

• Gate:- the actual entry point through which

molten metal enters the mould cavity.

• Chaplets:- it is used to support core inside the

mould cavity to take core of its own weight.

• Chills:- these are metallic objects which are

placed in the mould to increase the cooling

rate of casting to provide uniform or desired

cooling rate.

• Riser:- It is the reservoir of molten metal

provided in the casting so that hot metal can

flow back in to the mould cavity when there is

a reduction in volume of metal due to

solidification.

Properties of moulding sand

• Refractoriness:- it is the ability of the moulding

sand to withstand high temperature of molten

metal without fusion.

• Green strength:- The moulding sand that contains

moisture is termed as green sand.

• Dry strength:- when the molten metal is poured

into a mould the sand around the cavity is quickly

converted into dry sand as the moisture in the

sand immediately evaporates due to the heat in

the molten metal.

• Hot strength:- it is the strength of the sand that is

required to hold the shape of the mould cavity

after all the moisture is eliminted.

• Types of sand

• Green sand:- if the sand contains 2-6% of

moisture than the sand is called green sand.

• Dry sand:- it is the moisture available in the

moulding sand evaporates causes of high

temperature of molten metal than it is dry sand.

• Composition of moulding sand

Silica sand – 70-85%

Clay - 10-20%

Water - 3-6%

Additives - 1-6%

SHELL CASTING

• Shell casting:- Moulding material is in contact

with heated pattern activating the bonding

property of phenolic resin moulding sand will

stick to the surface of the pattern in form of

shell.

• Thickness of the shell depends on the contact

time between pattern and moulding material.

• Moulding material: fine grain silica,

thermosetting plastics (Phenolic resin)

• To produce better surface of the object compare

to sand moulding this technique can be used.

• Pattern is used by producing metalic material it

will be heated up to 250 degree Celsius.

• Moulding material is in contact with heated

pattern by activating the bonding property of

phenolic resin.

• Moulding sand will be sticking to the surface of

the pattern in the form of shell

• Thickness of the shell will depend on contact time

between pattern and moulding material also

known as dwell time.

• After getting required thickness of the shell

pattern, it can be separated from the mould box

& producing number of the shell.

• It is difficult to produce very complex shape of

the object.

• Application:

• Cylinder block, I C Engine, Rocker arm, valve

plates of refrigerator.

SHELL CASTING

INVESTMENT CASTING

• Investment casting:- the investment casting

process also called the lost wax process. The

pattern made up of wax/plastics such as

polystyrene by moulding or rapid prototyping

technique. This sequence involve in

investment casting are shown in figure

INVESTMENT CASTING

• Application: Gas turbine blade, jet engine

parts, medical implants, surgical instrument,

gold ornaments.

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Complete Guide to Die Casting Processes and ApplicationsDocumento37 pagineComplete Guide to Die Casting Processes and ApplicationsSuhas KrishnaNessuna valutazione finora

- Metalwork Formulas and Tables MetalDocumento238 pagineMetalwork Formulas and Tables MetalAvil100% (1)

- Silo Cement CalculationDocumento11 pagineSilo Cement CalculationFikriaraz AfifNessuna valutazione finora

- The Order of Historical Time: The Longue Durée and Micro-HistoryDocumento17 pagineThe Order of Historical Time: The Longue Durée and Micro-HistoryGeorgia KoutaNessuna valutazione finora

- Training Matrix For TM IDocumento14 pagineTraining Matrix For TM IApril NavaretteNessuna valutazione finora

- Singer Basic Tote Bag: Shopping ListDocumento5 pagineSinger Basic Tote Bag: Shopping ListsacralNessuna valutazione finora

- Pomodoro Cheat SheetDocumento1 paginaPomodoro Cheat Sheetapi-187219090Nessuna valutazione finora

- 000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Documento22 pagine000 200 1210 Guidelines For Minimum Deliverables 3 November 2011Raul Bautista100% (1)

- Hilton Vacancies - Non/Skilled Workers & ProfessionalsDocumento3 pagineHilton Vacancies - Non/Skilled Workers & ProfessionalsSree RamichettyNessuna valutazione finora

- Pgdtd1024 Selfdefence Bottle Opner-ModelDocumento1 paginaPgdtd1024 Selfdefence Bottle Opner-ModelSree RamichettyNessuna valutazione finora

- Dennis P Thankachan: Career ObjectiveDocumento2 pagineDennis P Thankachan: Career ObjectiveSree RamichettyNessuna valutazione finora

- Presentation ON Press Tool: Name - Debasis Ojha ROLL NO. - 808 Batch - 15Documento15 paginePresentation ON Press Tool: Name - Debasis Ojha ROLL NO. - 808 Batch - 15Sree RamichettyNessuna valutazione finora

- 18th National CertifiateDocumento15 pagine18th National CertifiateSree RamichettyNessuna valutazione finora

- Pressure Die PPT InPDFDocumento84 paginePressure Die PPT InPDFSree RamichettyNessuna valutazione finora

- 02 Rural InfrDocumento19 pagine02 Rural InfrJyoti RockeyNessuna valutazione finora

- Cutting Tool Theory: Types, Angles & Reference SystemsDocumento47 pagineCutting Tool Theory: Types, Angles & Reference SystemsSree RamichettyNessuna valutazione finora

- Die Casting Process GuideDocumento41 pagineDie Casting Process GuideSree RamichettyNessuna valutazione finora

- Die Casting Process GuideDocumento41 pagineDie Casting Process GuideSree RamichettyNessuna valutazione finora

- Material ScienceDocumento41 pagineMaterial ScienceSree RamichettyNessuna valutazione finora

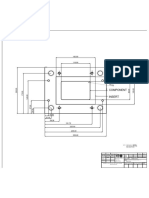

- Core Drawing ModelDocumento1 paginaCore Drawing ModelSree RamichettyNessuna valutazione finora

- Just in TimeDocumento34 pagineJust in TimeSree RamichettyNessuna valutazione finora

- Бхавишья Пурана (Краткое Изл Англ)Documento83 pagineБхавишья Пурана (Краткое Изл Англ)Andrei PascariNessuna valutazione finora

- Geometry Formulas: Areas and Perimeters Sketch Area PerimeterDocumento2 pagineGeometry Formulas: Areas and Perimeters Sketch Area PerimeterKelvinSNessuna valutazione finora

- VedicReport11 28 20187 26 15AMDocumento54 pagineVedicReport11 28 20187 26 15AMSree RamichettyNessuna valutazione finora

- GAS-INSULATED SWITCHGEAR MODELS 72kV ADVANCED ENVIRONMENTALLY FRIENDLYDocumento6 pagineGAS-INSULATED SWITCHGEAR MODELS 72kV ADVANCED ENVIRONMENTALLY FRIENDLYBudi SantonyNessuna valutazione finora

- Leveling Limits For Stationary Reciprocating Compressors: Engineering ReferenceDocumento2 pagineLeveling Limits For Stationary Reciprocating Compressors: Engineering ReferencealtruismNessuna valutazione finora

- HFM Currency CubeDocumento2 pagineHFM Currency CubeSudhakar kNessuna valutazione finora

- QAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023Documento1 paginaQAF10A200S TheTimkenCompany 2DSalesDrawing 03 06 2023LeroyNessuna valutazione finora

- Introduction - Week 2Documento37 pagineIntroduction - Week 2Tayyab AhmedNessuna valutazione finora

- Instrumentation Design UTHMDocumento5 pagineInstrumentation Design UTHMAnis AzwaNessuna valutazione finora

- Scoop Atlas Wagner ST1810Documento4 pagineScoop Atlas Wagner ST1810Juan Manuel PerezNessuna valutazione finora

- Geophysical Report Megnatic SurveyDocumento29 pagineGeophysical Report Megnatic SurveyShahzad KhanNessuna valutazione finora

- The Professional DesktopDocumento318 pagineThe Professional Desktopalintuta2Nessuna valutazione finora

- Proper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFDocumento12 pagineProper Fluid Selection Maintenance For Heat Transfer TNTCFLUIDS PDFAnonymous bHh1L1Nessuna valutazione finora

- 4495 10088 1 PBDocumento7 pagine4495 10088 1 PBGeorgius Kent DiantoroNessuna valutazione finora

- User Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPDocumento6 pagineUser Mode I. System Support Processes: de Leon - Dolliente - Gayeta - Rondilla It201 - Platform Technology - TPCariza DollienteNessuna valutazione finora

- Example 3 - S-Beam CrashDocumento13 pagineExample 3 - S-Beam CrashSanthosh LingappaNessuna valutazione finora

- ENGG1330 2N Computer Programming I (20-21 Semester 2) Assignment 1Documento5 pagineENGG1330 2N Computer Programming I (20-21 Semester 2) Assignment 1Fizza JafferyNessuna valutazione finora

- Front Panel & Display Technical Data: User ManualDocumento2 pagineFront Panel & Display Technical Data: User ManualJulio PorleyNessuna valutazione finora

- UG WeibullDocumento776 pagineUG WeibullCharles GuzmanNessuna valutazione finora

- Technical Data: Pump NameDocumento6 pagineTechnical Data: Pump Nameسمير البسيونىNessuna valutazione finora

- Synology DS718 Plus Data Sheet EnuDocumento6 pagineSynology DS718 Plus Data Sheet EnuSteve AttwoodNessuna valutazione finora

- Smart Dustbin using ArduinoDocumento22 pagineSmart Dustbin using ArduinoEr Dinesh TambeNessuna valutazione finora

- Windows Mbox Viewer User Manual 1.0.3.4Documento33 pagineWindows Mbox Viewer User Manual 1.0.3.4Billy NoelNessuna valutazione finora

- CS 102 Programming Fundamentals Lecture NotesDocumento14 pagineCS 102 Programming Fundamentals Lecture NotesOkay OkayNessuna valutazione finora

- Winegard Sensar AntennasDocumento8 pagineWinegard Sensar AntennasMichael ColeNessuna valutazione finora

- Analisis Pengaruh Profitabilitas, Strategi Diversifikasi, Dan Good Corporate Governance Terhadap Nilai PerusahaanDocumento16 pagineAnalisis Pengaruh Profitabilitas, Strategi Diversifikasi, Dan Good Corporate Governance Terhadap Nilai PerusahaanEra ZsannabelaNessuna valutazione finora

- ID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuDocumento21 pagineID Pengaruh Persistensi Laba Alokasi Pajak Antar Periode Ukuran Perusahaan PertumbuGheaMarisyaPuteriNessuna valutazione finora

- Potenciometro 15KDocumento8 paginePotenciometro 15Kra101208Nessuna valutazione finora