Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tdi Air Starter Assembly Procedure

Caricato da

lusthawkCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tdi Air Starter Assembly Procedure

Caricato da

lusthawkCopyright:

Formati disponibili

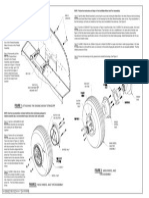

TDI AIR STARTER ASSEMBLY PROCEDURE

T312 – 600150 – 02R written 02SEP2018

- Press new bearings into the three (3) planetary gears and press the needle bearing into the nose cone.

- Take the three planetary gears and six (6) plastic spacers and press into the planetary carrier (each gear has a plastic spacer

above and below each gear)

- Pack the center section of the planetary carrier with grease – use a suitable clean tool to force the grease into the center.

- Insure all parts are present and are clean and free from dirt/debris

- Polish all shaft bearing surfaces

- Install the two larger sized and one medium sized o-rings on the bendix piston

- Install long spacer and press on the lip seal to stretch it

- Take the turbine shaft and start the 6202-13 v v bearing

- Take the first stage nozzle and tap in the seal flush with the surface

- Install the bearing/shaft assembly with the long spacer into the 1 st. stage nozzle. Insure the shoulder of the spacer is to the seal

and insure the seal lip is flush with the spacer.

- Install the four (4) hole plate and associated bolts using a 3/16” Allen key – insure the spacer does not fall out

- Install the saved woodruff key in the shaft and install the 1st. stage rotor – insure the “bucket points” orient with the vanes.

Consult with shop lead if not sure.

- Insure the rotor fit is not too sloppy – consult if not sure.

- Install outer o-ring on the nozzle assembly

- Swap pipe plug from old containment ring into new containment ring (if need be). Discard containment ring if it is an old style –

consult if not sure.

- Install lip seal flush into containment ring with lip facing up towrad the inlet side

- Install the two (2) jacking thread plugs into housing

- Moly 55 lube the outer nozzle ring and inlet opening

- With the bolt holes aligned only one way, install the nozzle assembly into the containment ring and install the five(5) bolts

- Flip assembly over – install the spacer and using two standard screwdrivers, push over the lip seal

- Install the two saved wave washers

- Install the 6201 – 13 v v bearing using an M12 washer to drive on bearing

- Install the next saved woodruff key

- Install the 2nd. Stage rotor – insure correct vane alignment – consult if not sure

- Install the fine thread rotor clamp nut using red Loctite

- Insure everything spins freely with no grinding sounds – consult if not sure.

- Install gear box o-ring and install ring gear – pack with grease to 1/3rd. full

- Install the lip seal (from the kit) into the inner piston – lip faces the o-ring end of piston.

- Install o-ring into the bottom of the gear box cover – insure the o-ring seats into the grooved land

- Moly 55 lube the big outer o-ring on the inner piston

- Install the inner piston into the gear cover housing

- While keeping a slight pressure on the piston to insure the o-ring does not fall out, align the bolt holes and install the four (4)

bolts.

- Moly 55 lube the outer piston o-rings and housing bore

- Installing only the one way, install the piston and push all the way to the bottom

- Place a slight amount of grease around bottom of planetary shaft

- Install housing onto planetary shaft with the gears at the flanged end

- Install the two saved thrust washers and saved snap ring – insure proper seating of snap ring

- Install the two (2) plastic rings on bendix assembly

- Install the o-ring onto the nose cone and Moly 55 lube it

- Install planetary set o-ring (outer)

- Install planetary set into gear box – insure proper alignment

- Install the four (4) bolts

- Slightly grease the splines on the shaft and install the bendix assembly into the housing

- Install large spiral spring and insuring proper housing alignment, install the nose cone.

- Test piston operation by using shop air on inlet port

- Test unit using only slight shop air pressure.

- Mask and cap appropriate areas and paint unit blue.

Potrebbero piacerti anche

- How to Build a Global Model Earthship Operation I: Tire WorkDa EverandHow to Build a Global Model Earthship Operation I: Tire WorkNessuna valutazione finora

- RP2Documento24 pagineRP2Vennia PapadipoulouNessuna valutazione finora

- EP Big Bore Installation Instruction Rev4Documento8 pagineEP Big Bore Installation Instruction Rev4mahmoud yarahmadiNessuna valutazione finora

- AshydmotorDocumento28 pagineAshydmotordavidNessuna valutazione finora

- SKF Wheel Bearing Installation Guide With Free End PlayDocumento20 pagineSKF Wheel Bearing Installation Guide With Free End Play2bjornNessuna valutazione finora

- International 4400Documento4 pagineInternational 4400marioNessuna valutazione finora

- Change Procedure of Hub BearingsDocumento4 pagineChange Procedure of Hub BearingsRadu DumbravaNessuna valutazione finora

- ImsretrofitDocumento1 paginaImsretrofitHoward VanceNessuna valutazione finora

- A 713 Angle Valve Repair KitDocumento2 pagineA 713 Angle Valve Repair KitARMANDONessuna valutazione finora

- Fitting Instructions For RTC3176 Adjuster Shoes Drum Brake LAnd Rover SeriesDocumento2 pagineFitting Instructions For RTC3176 Adjuster Shoes Drum Brake LAnd Rover SeriesALP1981100% (1)

- Plug Setting Tool and Junk Basket: Purpose of The ServiceDocumento15 paginePlug Setting Tool and Junk Basket: Purpose of The Servicerobin2806Nessuna valutazione finora

- Blue Diamond Assembly Procedure 1593Documento2 pagineBlue Diamond Assembly Procedure 1593Stephen GerhauserNessuna valutazione finora

- Circulation Pump A27-A30angDocumento11 pagineCirculation Pump A27-A30angpavan3229100% (1)

- Heidts Superide IRSDocumento8 pagineHeidts Superide IRSNovita EmRoseNessuna valutazione finora

- 57714342149b4e81c4231d PDFDocumento1 pagina57714342149b4e81c4231d PDFtornomanNessuna valutazione finora

- P15025-Lower Well Control Valve ManualDocumento5 pagineP15025-Lower Well Control Valve ManualAlex RamirezNessuna valutazione finora

- Air CylinderDocumento4 pagineAir Cylindersimbua720% (1)

- 4x4 Wheel Hub (2wheel Drive Below) Removal All Vehicles: 1. Remove The Front Brake DiscDocumento17 pagine4x4 Wheel Hub (2wheel Drive Below) Removal All Vehicles: 1. Remove The Front Brake DiscTimboWestNessuna valutazione finora

- How To Rebuild The Double Cardan JointDocumento8 pagineHow To Rebuild The Double Cardan JointAnonymous jm3ZYI6pNessuna valutazione finora

- Piaggio Mp3 400 I.E Service Station Manual-6Documento20 paginePiaggio Mp3 400 I.E Service Station Manual-6H. KeithNessuna valutazione finora

- 2.2 Replacing Casing Oil Seal AssemblyDocumento3 pagine2.2 Replacing Casing Oil Seal AssemblynabiNessuna valutazione finora

- Lada Niva GEARBOX AssemblyDocumento17 pagineLada Niva GEARBOX Assemblyektoras49Nessuna valutazione finora

- Betico SB1 Assembly ManualDocumento16 pagineBetico SB1 Assembly ManualJORGENessuna valutazione finora

- Fristam Mainten Type FPH - 3542Documento12 pagineFristam Mainten Type FPH - 3542Hafid NaufalNessuna valutazione finora

- Assembly and Disaassembly of PumpsDocumento5 pagineAssembly and Disaassembly of Pumpsshin deiru100% (1)

- Installation Notes: 86000-R Race Series +3.5" L/T KitDocumento21 pagineInstallation Notes: 86000-R Race Series +3.5" L/T KitdocNessuna valutazione finora

- BMW 6 Cylinder Dual Vanos Piston Seal Repair Fix PDocumento13 pagineBMW 6 Cylinder Dual Vanos Piston Seal Repair Fix PRaul DoctoNessuna valutazione finora

- 80-96 F150 2 1/2" Lift Kit InstructionsDocumento4 pagine80-96 F150 2 1/2" Lift Kit Instructionsisaacllugo1Nessuna valutazione finora

- Renewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredDocumento5 pagineRenewing Valve Stem Oil Seals With Cylinder Head Installed: Special Tools and Workshop Equipment RequiredArkidNessuna valutazione finora

- B40 Clutch ReplacementDocumento9 pagineB40 Clutch ReplacementTony CefaiNessuna valutazione finora

- 1991 Nissan-Datsun 240SX Cylinder Head RemovalDocumento11 pagine1991 Nissan-Datsun 240SX Cylinder Head Removalgigabyte3235840Nessuna valutazione finora

- Range Rover Manual Suspension PDFDocumento14 pagineRange Rover Manual Suspension PDFsleepyninjitsuNessuna valutazione finora

- Runner Dismantling InstallationDocumento7 pagineRunner Dismantling InstallationReynaldo PesqueraNessuna valutazione finora

- Chevy Manual Steering Gear Rebuild Instructions: Disassembly of Pitman Shaft From HousingDocumento3 pagineChevy Manual Steering Gear Rebuild Instructions: Disassembly of Pitman Shaft From Housingronald allan liviocoNessuna valutazione finora

- Demontare-Montare Arc VariatorDocumento5 pagineDemontare-Montare Arc VariatorcristianNessuna valutazione finora

- Transfer CaseDocumento6 pagineTransfer CaseTim SmithNessuna valutazione finora

- Manitou MT940-MT1740 HydraulicDocumento234 pagineManitou MT940-MT1740 HydraulicVeselina Gaidarska91% (22)

- Camshaft Install Qr25de InstructionsDocumento3 pagineCamshaft Install Qr25de InstructionsmehralsmenschNessuna valutazione finora

- SOP Reach Stacker01Documento7 pagineSOP Reach Stacker01vozefjadav100% (1)

- mK5 Jetta BrakesDocumento45 paginemK5 Jetta Brakesvixentd100% (2)

- 1CV Overhaul PDFDocumento15 pagine1CV Overhaul PDFsteve@air-innovations.co.zaNessuna valutazione finora

- Alfa 147 - Brake Pad and Disc Change Guide (Front)Documento15 pagineAlfa 147 - Brake Pad and Disc Change Guide (Front)arnold7894100% (3)

- Fork Strip ExtractDocumento24 pagineFork Strip Extract张连杉Nessuna valutazione finora

- Jet 700 4l60 e Billet Powr ServoDocumento4 pagineJet 700 4l60 e Billet Powr ServoJavier VelasquezNessuna valutazione finora

- Casing Packer Setting Tool (SLB)Documento12 pagineCasing Packer Setting Tool (SLB)Alexander KlmNessuna valutazione finora

- 8in Wafer Ball Vale IMODocumento2 pagine8in Wafer Ball Vale IMOw4uengineerNessuna valutazione finora

- Lathe - Spindle - Replacement - RemovalDocumento3 pagineLathe - Spindle - Replacement - RemovalAriel MercochaNessuna valutazione finora

- Volvo 240 Poly Bushing Install GuideDocumento7 pagineVolvo 240 Poly Bushing Install GuidemattNessuna valutazione finora

- Cam Install For Sr20Documento2 pagineCam Install For Sr20Carlos Miguel Montaño AlvarezNessuna valutazione finora

- Er 96 5 14Documento3 pagineEr 96 5 14DIEGO YECID MILLAN MENDOZANessuna valutazione finora

- Deus DiabolusHeadsetDocumento1 paginaDeus DiabolusHeadsetgillourunNessuna valutazione finora

- Van'S Aircraft, Inc.: Figure 1: Attaching The Engine Mount StandoffDocumento1 paginaVan'S Aircraft, Inc.: Figure 1: Attaching The Engine Mount StandoffMark Evan SalutinNessuna valutazione finora

- gb06 002 PDFDocumento1 paginagb06 002 PDFReza KühnNessuna valutazione finora

- Bulletin #D12EDocumento3 pagineBulletin #D12EPanos PanosNessuna valutazione finora

- Installation of Single Stage JacksDocumento3 pagineInstallation of Single Stage JacksReza KühnNessuna valutazione finora

- Eg Tuff Torq Axle ShaftDocumento10 pagineEg Tuff Torq Axle Shaftthomasax188Nessuna valutazione finora

- Honda Trx400ex NoPWDocumento7 pagineHonda Trx400ex NoPWJose Le MartinezNessuna valutazione finora

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceDa EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNessuna valutazione finora

- Elementary JournalDocumento23 pagineElementary JournallusthawkNessuna valutazione finora

- Type2 Diabetes Eating Plan 2010 PDFDocumento6 pagineType2 Diabetes Eating Plan 2010 PDFMinh AnhNessuna valutazione finora

- Guide For Alberta BusinessesDocumento24 pagineGuide For Alberta BusinesseslusthawkNessuna valutazione finora

- Westwood HistoryDocumento13 pagineWestwood HistorylusthawkNessuna valutazione finora

- Game Controller - Controls MapDocumento1 paginaGame Controller - Controls MaplusthawkNessuna valutazione finora

- Your Guide To Waste and Recycling: If You Live in A HouseDocumento6 pagineYour Guide To Waste and Recycling: If You Live in A HouselusthawkNessuna valutazione finora

- Start: Ault Finding Flow Chart For Motorcycle Charging SystemsDocumento4 pagineStart: Ault Finding Flow Chart For Motorcycle Charging SystemslusthawkNessuna valutazione finora

- 2011 Izod Indycar Series Rule Book Final Unformatted CleanDocumento229 pagine2011 Izod Indycar Series Rule Book Final Unformatted CleanlusthawkNessuna valutazione finora

- Using A Chain BreakerDocumento4 pagineUsing A Chain BreakerlusthawkNessuna valutazione finora

- Small Modular Biomass SystemsDocumento2 pagineSmall Modular Biomass SystemslusthawkNessuna valutazione finora

- Powder Coating in The Home ShopDocumento9 paginePowder Coating in The Home Shopsemperfidelis61Nessuna valutazione finora

- Gates Fluid Power EbookDocumento34 pagineGates Fluid Power EbooklusthawkNessuna valutazione finora

- Cylinder Head SheetDocumento1 paginaCylinder Head SheetlusthawkNessuna valutazione finora

- How To Identify Failure and Probable Cause: Spicer Driveshaft Components Failure Analysis GuideDocumento5 pagineHow To Identify Failure and Probable Cause: Spicer Driveshaft Components Failure Analysis GuidelusthawkNessuna valutazione finora

- Farm BlacksmithingDocumento99 pagineFarm BlacksmithingMichael WilsonNessuna valutazione finora

- Solar Water Heating PDFDocumento8 pagineSolar Water Heating PDFcarra80Nessuna valutazione finora

- Harley Vin CodesDocumento6 pagineHarley Vin CodeslusthawkNessuna valutazione finora

- Belt I.D. Chart 2012 SMDocumento1 paginaBelt I.D. Chart 2012 SMManuel Eduardo QuezadaNessuna valutazione finora

- Powder Coating in The Home ShopDocumento9 paginePowder Coating in The Home Shopsemperfidelis61Nessuna valutazione finora

- Basic HydraulicsDocumento916 pagineBasic Hydraulicsabraham_ginNessuna valutazione finora

- Abby S Vin DecoderDocumento9 pagineAbby S Vin DecoderlusthawkNessuna valutazione finora

- Triumph Rocket Service ManualDocumento425 pagineTriumph Rocket Service ManuallusthawkNessuna valutazione finora

- Landlord&TenantDocumento27 pagineLandlord&Tenantdrilling moneytreeNessuna valutazione finora

- How To Inspect DriveshaftsDocumento2 pagineHow To Inspect DriveshaftsJorge Gutiérrez LeyvaNessuna valutazione finora

- Welding HandbookDocumento48 pagineWelding HandbookMohan Prasad.M93% (27)

- Gearbox Failure AnalysisDocumento13 pagineGearbox Failure AnalysisVlad OprisNessuna valutazione finora

- Servo MechanismDocumento24 pagineServo Mechanismmushahid980Nessuna valutazione finora

- How To Build A Fuel CellDocumento7 pagineHow To Build A Fuel CellleechsterNessuna valutazione finora

- Automotive Power ElectronicsDocumento80 pagineAutomotive Power Electronicslusthawk100% (9)

- Circular No 02 2014 TA DA 010115 PDFDocumento10 pagineCircular No 02 2014 TA DA 010115 PDFsachin sonawane100% (1)

- MagmatismDocumento12 pagineMagmatismVea Patricia Angelo100% (1)

- Cover Letter For Lettings Negotiator JobDocumento9 pagineCover Letter For Lettings Negotiator Jobsun1g0gujyp2100% (1)

- Img - Oriental Magic by Idries Shah ImageDocumento119 pagineImg - Oriental Magic by Idries Shah ImageCarolos Strangeness Eaves100% (2)

- Spitzer 1981Documento13 pagineSpitzer 1981Chima2 SantosNessuna valutazione finora

- TrematodesDocumento95 pagineTrematodesFarlogy100% (3)

- LEWANDOWSKI-olso 8.11.2015 OfficialDocumento24 pagineLEWANDOWSKI-olso 8.11.2015 Officialmorpheus23Nessuna valutazione finora

- New Kanban System DesignDocumento4 pagineNew Kanban System DesignJebin GeorgeNessuna valutazione finora

- Introduction To Astronomical PhotometryDocumento452 pagineIntroduction To Astronomical PhotometrySergio Alejandro Fuentealba ZuñigaNessuna valutazione finora

- 5Documento3 pagine5Carlo ParasNessuna valutazione finora

- Answer Key For 1st QaurterDocumento5 pagineAnswer Key For 1st QaurterSteffi89% (9)

- Game Theory Presentation: Big BrotherDocumento11 pagineGame Theory Presentation: Big BrotherNitinNessuna valutazione finora

- ANI Network - Quick Bill Pay PDFDocumento2 pagineANI Network - Quick Bill Pay PDFSandeep DwivediNessuna valutazione finora

- Java Magazine JanuaryFebruary 2013Documento93 pagineJava Magazine JanuaryFebruary 2013rubensaNessuna valutazione finora

- AITAS 8th Doctor SourcebookDocumento192 pagineAITAS 8th Doctor SourcebookClaudio Caceres100% (13)

- (Adolescence and Education) Tim Urdan, Frank Pajares - Academic Motivation of Adolescents-IAP - Information Age Publishing (2004) PDFDocumento384 pagine(Adolescence and Education) Tim Urdan, Frank Pajares - Academic Motivation of Adolescents-IAP - Information Age Publishing (2004) PDFAllenNessuna valutazione finora

- Specification - Pump StationDocumento59 pagineSpecification - Pump StationchialunNessuna valutazione finora

- English 10-Dll-Week 3Documento5 pagineEnglish 10-Dll-Week 3Alyssa Grace Dela TorreNessuna valutazione finora

- Ev Wireless Charging 5 PDFDocumento27 pagineEv Wireless Charging 5 PDFJP GUPTANessuna valutazione finora

- Do You Agree or Disagree With The Following StatementDocumento2 pagineDo You Agree or Disagree With The Following StatementVũ Ngọc Minh ThuNessuna valutazione finora

- Placement TestDocumento6 paginePlacement TestNovia YunitazamiNessuna valutazione finora

- School Games Calendar Part-1Documento5 pagineSchool Games Calendar Part-1Ranadhir Singh100% (2)

- Human Development IndexDocumento17 pagineHuman Development IndexriyaNessuna valutazione finora

- Imc Case - Group 3Documento5 pagineImc Case - Group 3Shubham Jakhmola100% (3)

- Intro To Law CasesDocumento23 pagineIntro To Law Casesharuhime08Nessuna valutazione finora

- Repair and Field Service BrochureDocumento4 pagineRepair and Field Service Brochurecorsini999Nessuna valutazione finora

- Catalogue 2021Documento12 pagineCatalogue 2021vatsala36743Nessuna valutazione finora

- Name: Nur Hashikin Binti Ramly (2019170773) Course Code: Udm713 - Decision Making Methods and Analysis Assignment Title: Need Gap AnalysisDocumento2 pagineName: Nur Hashikin Binti Ramly (2019170773) Course Code: Udm713 - Decision Making Methods and Analysis Assignment Title: Need Gap AnalysisAhmad HafizNessuna valutazione finora

- OPSS 415 Feb90Documento7 pagineOPSS 415 Feb90Muhammad UmarNessuna valutazione finora

- PsychometricsDocumento4 paginePsychometricsCor Villanueva33% (3)