Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Job Safety Analysis JSA Applied in Const

Caricato da

fadli.lpgDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Job Safety Analysis JSA Applied in Const

Caricato da

fadli.lpgCopyright:

Formati disponibili

IJSTE - International Journal of Science Technology & Engineering | Volume 4 | Issue 09 | March 2018

ISSN (online): 2349-784X

Job Safety Analysis (JSA) Applied In

Construction Industry

Shekhar Choudhary Pulkit Solanki

PG Scholar Assistant Professor

Shiv Kumar Singh Institute of Technology and Science, Shiv Kumar Singh Institute of Technology and Science,

Indore Indore

Dr. GD Gidwani

Executive Director

Shiv Kumar Singh Institute of Technology and Science, Indore

Abstract

Indian construction industry is passing through very unique phase. Massive infrastructure like, National Highway, Dam

construction for Irrigation, Airports up-gradation for Tourism of domestic & International tourists, Urban rapid transportation like

Metros, Bus Rapid Transport system Flyover poised to grow exponentially within last 10 years. This situation leads to excellent

opportunities for the construction industry in terms of business opportunity. This also leads to Indian economic growth even

through FDI. Many national constructions housed such as Hindustan Construction Company, DLF, Tata projects and Larson &

Turbo limited actively managing projects in India & Aboard. Job safety analysis (JSA) was one of the great methods used for the

purpose of safety analysis. Here we approach the method on construction area and also elaborate our results. We are here provide

a vast knowledge of various hazards developed in the construction department with their brief study and also give knowledge of

solving and overcoming these hazards.

Keywords: Construction sites, JSA (Job Safety Analysis), Materials, Manufacturing etc.

________________________________________________________________________________________________________

I. INTRODUCTION

The main reason of boost of the construction industry is due to increase of Purchas power of middle class and improved living

standard. Only Construction industry would provide the basic physical infrastructure for the nation as well as other industries.

Today, Housing & Real estate construction business is around 15.3% of total Construction, is the only one segment which

flourished not only in Metro cities but also at Taluka level places construction. With reference to recent survey, Construction

industries generate maximum jobs for skilled & unskilled labors in urban & ruler areas in India

Many Public Private Partnership projects construction activities undergoing in the following sectors:

1) Passenger Jetty, seaports, Roads and bridges, airports, inland waterways.

2) Thermal Hydro Power, Non-conventional power.

3) Bus Rapid Transport Systems in Metros, Elevated Urban transport, sewerage, water supply, solid waste management and other

physical infrastructure in industrial estates & urban areas.

4) Special Economic Zones; Agriculture Economic Zones Infrastructure projects

5) Tourism infrastructure projects International convention centers

These Infrastructure project expenses covered under scheme as:

1) Contractor provide a service against payment of a predetermined tariff or user charge like Toll

2) Condition that that the tariff/user charges cannot be increased to eliminate or reduce the viability gap of the Public private

Partnership.

3) Project Period/Term cannot be increased for reducing the viability gap by contractor.

4) Material standards and specifications applicable to such projects

Type of Construction

Residential Construction: It is apartment or a group of buildings whenever construction work is being performed for residential

purpose [1].

All rights reserved by www.ijste.org 177

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

Fig. 1.1: Residential Flats [1]

In urban Area in India Commercial cum Residential buildings also acceptable by society for daily requirements shops like

Grocery, Hotel and General stores etc. In Metros, apartment complex would more likely be considered a commercial residential

project instead of a residential project.

Commercial Construction:

Generally Commercial construction includes a large variety of projects including building, skyscrapers, restaurants, grocery stores,

shopping centers, sports facilities, hospitals, private schools, etc [2].

The definition of Commercial construction is the construction of any buildings or similar structures for business purposes.

Today, in any Indian Urban areas you may observe construction boom of IT Buildings, multiplex. Shopping Mall, Convention hall

and Recreation complexes construction.

Fig. 1.2: Infosys Technologies Limited’s building [2]

Industrial Construction:

Industrial projects include power plants, manufacturing plants, solar wind farms, refineries, etc this is a relatively small segment

of the construction industry. While termed “industrial construction,” it is also called with “commercial purpose construction.” [3]

All rights reserved by www.ijste.org 178

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

Fig. 1.3: POL Storage Tanks [3]

There are more several types of constructions like

Infrastructure construction

Tunnel

Ports

Modern Oil Terminal

Break water wall

Bridges

The main reason for working in this area is to study and overcome the accidents held in construction department. The deep

knowledge of my study was explained in this section given below.

Construction related Accidents in India

National safety council of India published that about 7.5% Labors involved in construction Industry .In world, 16.4% of fatal

accidents occurs during construction activities. ILO indicate that about 11% of occupational injuries and 20% of deaths resulting

from accidents in the construction industry [4]. The possibility of a fatality is five times more likely than in a manufacturing

industry, the risk of a major injury is two and a half times higher. Each year, up to hundreds of people is killed at work place in the

developed countries like UK/USA too. Not only construction workers but Visitors, pubic and children also suffer from unsafe

conditions of construction industry.

Fig. 1.4: Scaffolding collapse fetal accident [4]

Indian construction industry is more labor-intensive than that of the developed countries, involving 2.5-10 times more workers

per activity.

All rights reserved by www.ijste.org 179

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

II. LITERATURE REVIEW

As we know before doing any research or innovation we have to adopt knowledge of previous researchers who already do

something on the same or related topic for the betterment. So here in this section we are going to acknowledge the work of some

past researchers from whom we got help for our study.

Ophir Rozenfeld et al [5] 2010 Job Safety Analysis (JSA), which is also known as Job Hazard Analysis, is an efficient proactive

measure for safety risk assessment used in industrial manufacturing settings. However, unlike the manufacturing set-tings for

which JSA was developed, at construction sites the physical environment is constantly changing, workers move through the site

in the course of their work, and they are often endangered by activities performed by other teams.

The method involves identification of potential loss-of-control events for detailed stages of the activities commonly performed in

construction, and assessment of the probability of occurrence for each event identified. It was applied to explore 14 primary

construction activities in an extensive trial implementation that included expert workshops and a series of 101 interviews with site

engineers and superintendents. Detailed quantitative results were obtained for a total of 699 possible loss-of-control events; the

most frequent events are those related to exterior work at height.

Henny Yustisia et al [6] 2014 this study focuses on constructability terms of construction safety. Safety here is not only an

occupational safety but within the scope of the safety dimension that worker, property, environmental and public. The purpose of

this study was to evaluate the project constructability issues associated with Kelok-9 bridge construction safety problems and

evaluate the implementation of the project if the contractor can do the appropriate design and implement construction safety. From

these results it can be concluded: Constructability evaluation of the safety construction on the Kelok-9 bridge project quite good

but design projects not yet incorporate the experience and knowledge of the construction in terms of construction safety.

Constructability evaluation of the safety of construction on Kelok 9 Bridge Project in terms of the analysis results obtained on

blasting work is good and the work Pillar is enough. Design projects not yet on the bridge Kelok 9 experience and knowledge of

the construction of safety in terms of construction, this can be proved with the requirements specified in the contract documents

are not everything can be applied in the field.

One of the principles of constructability in the operational phase applied to this project is the use of innovative construction

methods, for example using a launching girder Bridge installation.

Seok J. Yoon et al [7] 2013The study was conducted to investigate the current status of the occupational health and safety

management system (OHSMS) in the construction industry and the effect of OHSMS on accident rates. Differences of awareness

levels on safety issues among site general managers and occupational health and safety (OHS) managers are identified through

surveys. Methods: The accident rates for the OHSMS-certified construction companies from 2006 to 2011, when the construction

OHSMS became widely available, were analyzed to understand the effect of OHSMS on the work-related injury rates in the

construction industry. The Korea Occupational Safety and Health Agency 18001 is the certification to these companies performing

OHSMS in South Korea. The questionnaire was created to analyze the differences of OHSMS awareness between site general

managers and OHS managers of construction companies.

Abdulkadir Ganah et al [8] 2015 Health and safety (H&S) on a construction site can either make or break a contractor, if not

properly managed. The usage of Building Information Modeling (BIM) for H&S on construction execution has the potential to

augment practitioner understanding of their sites, and by so doing reduce the probability of accidents.

Conclusion: From the survey, toolbox talk will have to be integrated with the BIM environment, because it is the predominantly

used procedure for enhancing H&S issues within construction sites. The advantage is that personnel can visually understand H&S

issues as work progresses during the toolbox talk onsite. The Plan for Growth by the Government in the UK, published alongside

Budget 2011, emphasized the significance of an efficient construction industry in the country to the economy. Construction

accounts for about 7% of the gross domestic product or £110 bn of expenditure per year with approximately 40% of this being in

the public sector, with Central Government being the biggest customer of the construction industry In construction, it is apparent

that most practitioners within the industry still believe that the H&S file is the single most important repository within the UK

construction project, especially at the implementation phase for all H&S Further informal discussion with practitioners revealed

that BIM will be a duplicate information resource and that it is not necessary.

III. SYSTEM DOMAIN

Introduction

Madhya Pradesh Power Generation Company limited (MPPGCL) is a wholly owned company of government of engaged in

generation of electricity in state of Madhya Pradesh. The company while operating and maintain its existing units and also

construction new power plant for increasing capacity in the state of Madhya Pradesh. The company has been incorporated as a part

of the implementations of the power sector in government of Madhya Pradesh. The MPPGCL head Qatar in Jabalpur, India [9].

All rights reserved by www.ijste.org 180

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

`

Fig. 3.1: M.P.P.G.C.L (S.S.T.P.P) plant image and abut plant info chart [9]

The power generation capacity Madhya Pradesh Power Generation Company limited (GCL).

The installed capacity of as on 01.01.2015 is 5235 MW out of which Madhya Pradesh share is about 5237.5 MW.

The company has taken over the generation activities of MPSEB.

The company is a public company fully owned by Govt. of M.P.

The company obtained the certificate of commencement of business on 16-07-2002.

The corporate identity number of MPPGCL IS U40109MP2001SGC014882.

The opening balance sheet of Madhya Pradesh Power Generation Company limited (MPPGCL) as on 31-05-2005 has also

been notified.

L&T Power (Larsen & Toubro)

In M.P.P.G.C.L. the construction work of plant to L&T POWER (LARSEN & TOUBRO) in this the L&T got the tender for “

BOP-BALANCE OF PLANT AND BTG- BOILER TARBINE GENERATOR” this is the main construction process to be done

by the L&T POWER [10].

BOP:

In this balance of plant company construct building and chimney, cooling tower, main building , canteen, parking, boiler turbine

generator room, are buildup by company and transfer point of coal, coal storage, store room, reservoir, etc. in M.P.P.G.C.L. the

construction company L&T made 273 meter high chimney, and 253 meter high cool

BTG:

In this company will installed boiler, turbine, generator & big machine’s, for the plant and because of this heavy metal the

production of electricity will generated and main and big work is the installation of btg.

L&T Main Office:

In the company main officer and meeting rooms and all facilities and official works done in this office and because of this the

every official work done.

RAW Material Storage Area:

This is the raw material storage area this is the area closer from construction side and all types of construction material will stored

like, send, cement, bricks, ballast, and iron rod. Etc.

Batching Plant:

The batching plant is that area at which we can produced concert from batching cell and in this a big tube well and well for water

mixing in raw material and its very closer from raw material storage and this concrete is supply by the concrete mixer from batching

plant to construction side.

Canteen:

This is canteen for workers and their officer in lunch time the canteen will provide lunch to workers, and company employee. It

gives refreshment and mil to workers and employee

Worker Rest Room:

This is the rest room which is very closer from work place and this facilities will provide by L&T POWER in the summer session

the hotness of that area is very high there is big open land at the under construction side and there is a glucoses and energy drink

facilities for worker and special facilities in raining & winter session.

All rights reserved by www.ijste.org 181

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

Hospital:

hospital facilities foe workers of M.P.P.G.C.L AND L&T POWER if there is an incident our injury or a big accident at plant they

can refer in internal hospital of plant, if there is an serious injury the refer to khandwa hospital the distance is 40km.

Store & Machine Parking:

This certified area for the big machines parking-crane, JCB, dumper, miller, concrete mixer, miller, boom placer, and this machines

are used which can work very quickly. This must the system

Rules & Regulations related to Construction

Now a Days need for safety awareness among construction companies has greatly increased because of high cost associated with

work-related injuries, workers’ compensation, insurance premium, indirect costs of injuries, and litigation. Basic safety rules and

regulations are observed by corporate construction companies but even today many accidents are not reported due to lack of

awareness .Hence government has enacted specific legislation like: -

1) The Minimum Wages Act

2) The Workmen’s Compensation Act of 1923 (modified in 1962)

3) The Contract Labor (Regulation and abolition) Act of 1970

4) National Building Code of India 2005 provides guidelines for regulating construction activities across the country.

5) The Building & Other Construction Workers’ (Regulation of Employment and Conditions of Service) Rules, 2007 protect

workman from their right of safe work conditions.

6) The Child Labor (Prohibition & Regulation) Act, 1986 protect child labor

IV. PROBLEM FORMULATION

Introduction

Construction work site is a dangers’ place with a large number of works taking place. It started with the basic of human need

shelter, home or dwelling house and the growing of population and their growing needs of residential and commercial buildings,

shops, offices, factories, roads, bridges, dams, railways, power transmission lines. The various types of accident occur in

construction industry. The many people are injured on construction work site. Many people are not completely trained but works

are occurring they are creating on dangerous situation on works site.

There is improving their working condition is the safety philosophy. It should be realized that construction is inherently

hazardous industry, contract based industry, demands heavy work load, contributes high frequency and severity of accidents, less

protected by law, movable and needs continuous efforts to maintain safety at all levels. It may not be possible to completely

eliminate the hazards, but it is certainly possible to minimize them by enforcing certain safety precautions. The working and service

conditions of the workers need to be improved. Peculiarity of accidents is well known. Falling from height, struck by falling body

including landslide, material and equipment, striking against object, falling on the flat or into pit, sump, and gutter etc. These types

of problem are generally occurred in construction site, for avoiding the chance of fatalities in construction site Job Hazard Analysis

is compulsory. In construction site, there are several types of hazard occurred due to unawareness and unsafe act.

Hazard Identification & Prevention Matrix

Here we make Hazard identification & prevention Matrix for Crane use in two types.

Table - 4.1

Two blocking

Provide a Safety Provide Provide

Eliminate the Hazard Guard the Hazard

Factor Redundancy Reliability

Hazard Safety Hazard safety hazard safety hazard safety

Natural Gravity/

instability

Anti- Two Block

Structural/ Cable

Stops Sources 100%

Mechanical Tensions

Tensions

Anti- Two

Electrical 100%

Block Alarm

Chemical

Radiant Energy

Biological

Automated

system

V. ANALYSIS AND METHODOLOGY

Job Safety Analysis (JSA), which is also known as Job Hazard Analysis, is an efficient proactive measure of safety risk assessment

used in industrial manufacturing settings. However, unlike the manufacturing settings for which JSA was developed, at

All rights reserved by www.ijste.org 182

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

construction sites the physical environment is constantly changing, workers move through the site in the course of their work, and

they are often endangered by activities performed by other teams.

To address this difficulty, a structured method for hazard analysis and assessment for construction activities, called

‘‘Construction Job Safety Analysis” (CJSA), was developed. The method was developed within the framework of research toward

a lean approach to safety management in construction, which required the ability to predict fluctuating safety risk levels in order

to support safety conscious planning and pulling of safety management efforts to the places and times where they are most effective.

The method involves identification of potential loss-of-control events for detailed stages of the activities commonly performed in

construction, and assessment of the probability of occurrence for each event identified.

Job Safety Analysis method

Identification: - choosing a specific job or activity and breaking it down into a sequence of stages, and then, identifying all

possible loss-of-control incident that may occur during the work.

Assessment: - evaluating the relative level of risk for all the identified incidents.

Action: - controlling the risk by taking sufficient measures to reduce or eliminate it.

CJSA Process

The Construction Job Safety Analysis (CJSA) method generates a large knowledge-base describing all possible loss-of-control

events in construction.

The CJSA Process Comprises Three Major Steps:

Identify Hazards: - identify the set of direct and supporting construction activities needed for a domain, define their procedures,

and analyze all possible loss-of-control events that may occur during their execution.

Assess Probability: - evaluate the likelihood of occurrence of each loss-of-control event, the levels of possible intensifying

factors, and the likelihood of use of personal safety gear.

Assess Severity: - associate the possible loss-of-control events with possible accident scenarios, and assess the expected degree

of severity for each type of accident scenario

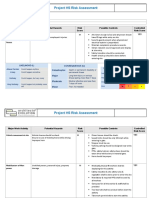

Table - 5.1

Job Safety Analysis

Diagrams which co-relate POTENTIAL SAFETY & PERSON

CONTROL MEASURES

with points ENVIRONMENTAL RESPONSIBLE

Working area to be delineated with clear signage

Dropped Loads (personnel / clearly stating that access is restricted. All control is

static object / equipment / necessary on construction fields. Around the crane Operator

machinery) area. Authorizes person of company are observed in

all process.

Use Taglines Wear correct PPE. the glove are good

Crush injuries (personnel /

quality of rubber materials .Observe the Load and Operator

static object

the load placement area and keep well clear

Oil leaks / fluid spills

Spill Kits are kept on all cranes Operator

(environmental)

Electrical power line which If required to work close to power line use a spotter

Operator

place overhead or where possible have the power lines turned off

All rights reserved by www.ijste.org 183

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

Pre-start Checks Plant to stick to designated

Faults with Crane Plant,

roadways and turning areas Personnel on hand to

becoming bogged in sand & Operator

warn others of crane Alternate pathway defined by

mud Onsite traffic / plan

bollards and reflective tape

Tagline used to guide into position PPE – Riggers

Falling from sling and injuring

Gloves ,Watch for crush & pinch points between

Lifting gear failure Crush Operator

chain and where it is inserted into the Tank

Injuries & Pinch Point

components lift points

Slings to be appropriately positioned to prevent

Load falling from lift Slippage. All slings and lifting equipment to be free Operator

from damage

The experts begin by dividing each activity into sub-activities. They determine the start and finish times of each sub-activity in

relation to the overall activity duration as it would be defined in a construction hazards. The planned duration (activity start = 0%,

activity end = 100%).

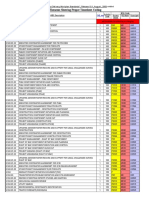

Fig. 5.1: work sheet of JSA

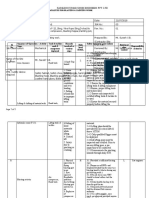

Table - 5.2

Job safety analysis

Sr. Work or Basic Job

Potential Hazard Control or Recommended Action

No. Steps

1. Work at height Fall, slip Safety belt, harness provide

Outriggers failure, crane touch to any electric wire,

2. Work at crane Maintain distance from electric sources

Struck by object falling from a crane

Work on

3. Earth slide Helmet, PPE

excavation

4. Foundation Fall of material Safety helmet, proper protection

5. Trenching Respiration problem Respiratory system

6. Steel erection Fall of object & workers Safety helmet, safety harness and belt provide

All rights reserved by www.ijste.org 184

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

7. Scaffold work Fall, slip of workers, object fall Safety harness at height,

8. Work at column Workers slip Safety harness, hook

9. Work at slabs Fall from height or slip Use net form, use proper safety belt and PPE

Should be used safety helmet, give proper

10. Lifting crane Fall any object,

instructions to the crane operator

Job Breakdown Sheet

Operation Step Description Hazards Precautions / controls

Check and adjust the Guard

Breakage of wheel

Adjust tool rest

1. Start the job. Contact with wheel

Get wheel dressed if necessary

Flying particles

Use goggles/ shield

Use hand gloves

Sharp edges Use Safety shoes

2. Pick up the job.

Unsafe gripping or lifting Proper method of storing

Proper training in lifting.

Use goggles shield

Flying particles

Do not jam

3. Grind Wheel breakage due to jamming etc.

Local exhaust for machine and respirator.

Dust-Silicosis, nuisance

Aprons Gloves

Use hand gloves

Sharp edges

Use safety shoes

4. Replace tjob. Fall of casting

Proper method of storing

Strain and sprain

Proper training in lifting

Table - 5.3

Severity rate

Severity Expected occurrence (%)

Severity weight Weighted average

Level With safety gear (33%) Without safety gear (67%)

Minor injury 1 79 1 0.3

Medium injury 5 17 5 0.5

Severe injury 25 4 23 4.2

Death 100 0 71 47.6

Severity level 52.6

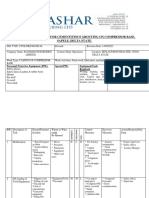

Table - 5.4

Activity analysis

Activity analysis summary

Activity Interviewee specialization

Number of stages Number of loss-of-control events

2

Piling Superintendent 3

57

2

Structural activities

Concrete slabs Superintendent 2 85

Cast-in-place concrete Superintendent 2

Foundations

8

columns and walls safety inspector 74

2

3

Erecting precast slabs Superintendent 59

2

3

Erecting precast walls Superintendent 57

2

4

Forming walls with stone cladding Superintendent 67

1

2

Superintendent

Brick masonry 33

Superintendent stone

1

4

Stone cladding contractor 32

Finishing activities

2

Exterior plastering Superintendent 7 62

1

Gypsum boards Finishing foreman 4 25

1

2

Floor tiling Finishing foreman 19

1

Roof insulation Insulation contractor 1 29

6

Roof sealing Sealing contractor 18

1

All rights reserved by www.ijste.org 185

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

Glazing Glazing contractor 1 46

2

Electrical installation Electrical engineer 3

Other activities 75

2

9

Plumbing Plumbing engineer 57

4

6

HVAC installation A.C. Engineer 80

3

4 87

8 5

TOTAL

R = P×S Where:

P = Likelihood of occurrence

S = Potential severity of harm

Now for work at height R= P×S=3×4=12

Now for work at cranes R= P×S=3×3=9

Table - 5.5

Risk Categories

Category of Risk Evaluation of Tolerability

Very low (Level 1, 2,3, 4) Acceptable (or Negligible)

Low (Level 5, 6) Risks that should be reduced so that they are tolerable or acceptable(Unwanted)

Medium (Level 8, 9) Risks that should be reduced so that they are tolerable or acceptable(Unwanted)

High (Level 10, 12) Risks that should be reduced so that they are tolerable or acceptable(Unwanted)

Very high (Level 15,16,) Unacceptable

VI. APPLICATION OF OUR PROJECT

The factory should prepare Safety Manual containing information on policies ( on safety, health and environment), safe methods,

practices and procedures on various operations and processes, first-aid treatment, fire protection & control, handling and storage

of materials, safe use of hand tools, testing and examination of equipment, electrical safety etc. Such manual will act as guided to

help achieving better safety and accident free performance in the factory.

VII. EXCEPTED OUTCOME & CONCLUSION

A constant throughout this discussion is recognition that workers in the construction industry are involved in a dangerous trade.

Construction work-related risks are well understood, but it remains a leader for raised injury, illness and fatality rates; and

associated costs to business, society and families. It is unconscionable that construction remains hazardous, while resources over

decades - statistics, causal factors, and control measures to reduce risk.

The CHASTE approach represents a progressive way to evaluate risks in construction. It confronts the difficulties and unique

hazards of the construction industry by considering likelihood of loss-of-control events and exposure of potential victims to their

consequences separately. The CJSA method provides a mechanism for collecting the extensive knowledge of the likelihood of

loss-of-control events in construction that is needed for implementation of the CHASTE approach. The CJSA method is loosely

based on the standard JSA approach to safety planning in manufacturing.

The CJSA method described was implemented for the construction activities and methods typical of the Israeli building

construction industry, and a comprehensive analysis was con-ducted of its results.

REFERENCES

[1] https://www.google.co.in/search?q=Residential+Flats&source=lnms&tbm=isch&sa=X&ved=0ahUKEwi4l7j-

lN3UAhVBo48KHT00BKsQ_AUICigB&biw=1024&bih=677

[2] https://www.google.co.in/search?q=Residential+Flats&source=lnms&tbm=isch&sa=X&ved=0ahUKEwi4l7j-

lN3UAhVBo48KHT00BKsQ_AUICigB&biw=1024&bih=677#tbm=isch&q=Infosys+Technologies+Limited%E2%80%99s

+building

[3] https://www.google.co.in/search?q=Residential+Flats&source=lnms&tbm=isch&sa=X&ved=0ahUKEwi4l7j-

lN3UAhVBo48KHT00BKsQ_AUICigB&biw=1024&bih=677#tbm=isch&q=POL+Storage+Tanks

[4] https://www.google.co.in/search?q=Residential+Flats&source=lnms&tbm=isch&sa=X&ved=0ahUKEwi4l7j-

lN3UAhVBo48KHT00BKsQ_AUICigB&biw=1024&bih=677#tbm=isch&q=Scaffolding+collapse+fetal+accident

[5] OphirRozenfeld , Rafael Sacks , Yehiel Rosenfeld , Hadassa Baum,” Construction Job Safety Analysis” Safety Science 48 (2010) 491–498, 21 December

2009.

[6] VitorSousa ,Nuno M. Almeida, Luís A. Dias , “Risk-based management of occupational safety and health in the construction industry – Part 1: Background

knowledge” Safety Science 66 (2014) 75–86, 3 March 2014.

[7] Amotz Perlman, Rafael Sacks,Ronen Barak, “Hazard recognition and risk perception in construction” Safety Science 64 (2014) 22–31, 12 December 2013.

All rights reserved by www.ijste.org 186

Job Safety Analysis (JSA) Applied In Construction Industry

(IJSTE/ Volume 4 / Issue 09 / 034)

[8] Ahmed, S.M., Kwan, J.C., Ming, F.Y.W., Ho, D.C.P., 2000. Site safety management in Hong Kong. Journal of Management in Engineering, November 2000,

34–42.

[9] www.mppgcl.mp.gov.in

[10] Power L&T India.

All rights reserved by www.ijste.org 187

Potrebbero piacerti anche

- Profit and Loss Statement Template (Excel)Documento1 paginaProfit and Loss Statement Template (Excel)MicrosoftTemplates100% (7)

- AREMA Shoring GuidelinesDocumento25 pagineAREMA Shoring GuidelinesKCHESTER367% (3)

- JSA For Erection Modification QSTECDocumento7 pagineJSA For Erection Modification QSTECMohamed NouzerNessuna valutazione finora

- Akk Jha Installation of Diesel TankDocumento3 pagineAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- SRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578Documento9 pagineSRB-JSA-41-Thrust Boring - 01 Febr 2010 - 56PL - KM 1+578kkalvi100% (1)

- JSA Formet New Structural Steel FabricationDocumento7 pagineJSA Formet New Structural Steel Fabricationsakthi venkatNessuna valutazione finora

- JSA-02-trench Excavation by EquipmentDocumento1 paginaJSA-02-trench Excavation by Equipmentabou bakarNessuna valutazione finora

- 1st Aid Training Siemens ContractorDocumento11 pagine1st Aid Training Siemens ContractorTigor GurningNessuna valutazione finora

- Coshh Risk Assessemnt PDFDocumento29 pagineCoshh Risk Assessemnt PDFerwinNessuna valutazione finora

- 6.risk Assessment of Epoxy Coating System (Rev-2) NEW OKDocumento7 pagine6.risk Assessment of Epoxy Coating System (Rev-2) NEW OKRisal SinuNessuna valutazione finora

- Risk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Documento16 pagineRisk Assessment Installation of Aluminium Cladding Work For Ducting & Piping.Mohsin MohdNessuna valutazione finora

- Malampaya Case StudyDocumento15 pagineMalampaya Case StudyMark Kenneth ValerioNessuna valutazione finora

- Mobilization of CabinDocumento1 paginaMobilization of CabinRashidi RahmanNessuna valutazione finora

- TBT-Driving in FogDocumento2 pagineTBT-Driving in FogImran KhanNessuna valutazione finora

- Mie Hse Jha 004 Installation of TransformerDocumento5 pagineMie Hse Jha 004 Installation of TransformerMd Gulam SafiNessuna valutazione finora

- Job Hazard AnalysisDocumento3 pagineJob Hazard AnalysisChristine YasaNessuna valutazione finora

- JSA Confined Sapce EntryDocumento1 paginaJSA Confined Sapce EntryprasongNessuna valutazione finora

- Job Safety Analysis - Clinker StorageDocumento4 pagineJob Safety Analysis - Clinker StorageMohammed MinhajNessuna valutazione finora

- Arc Welding - JSADocumento6 pagineArc Welding - JSAdroffilcz27Nessuna valutazione finora

- Elementary Electronics 1968-09-10Documento108 pagineElementary Electronics 1968-09-10Jim ToewsNessuna valutazione finora

- RA - For Precast ChambersDocumento5 pagineRA - For Precast ChambersKallem RajashekarNessuna valutazione finora

- Project: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSDocumento2 pagineProject: Field Erection of 15000 Bbls Tank (Ik-2545) : Job Safety Analysis / Safe Work Method Statement-SWMSJohn100% (1)

- Safety at Construction Project A ReviewDocumento5 pagineSafety at Construction Project A ReviewIJRASETPublicationsNessuna valutazione finora

- JSA-Hydraulic Press Testing For PilesDocumento6 pagineJSA-Hydraulic Press Testing For PilesUMUTNessuna valutazione finora

- Suroj Buildcon Pvt. LTD.: Job Safety AnalysisDocumento6 pagineSuroj Buildcon Pvt. LTD.: Job Safety AnalysisKiran ChenchalaNessuna valutazione finora

- CSR Report On Tata SteelDocumento72 pagineCSR Report On Tata SteelJagadish Sahu100% (1)

- Pha ExcavationDocumento13 paginePha ExcavationirshadNessuna valutazione finora

- JSA Pipe Installation 2012Documento2 pagineJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Project HS Risk AssessmentDocumento8 pagineProject HS Risk AssessmentParasNessuna valutazione finora

- 07 - JSA Compaction and BackfillingDocumento4 pagine07 - JSA Compaction and Backfillingsatti100% (2)

- JSA For Scissor Lift, Rev-6Documento2 pagineJSA For Scissor Lift, Rev-6Mahamudul HasanNessuna valutazione finora

- Risk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Documento2 pagineRisk Assessment DAWRA001R4 Loading Unloading Vehicles 090621Danny100% (1)

- 12month P&L ProjectionDocumento1 pagina12month P&L Projectionapi-3809857Nessuna valutazione finora

- JSA Formet New Blasting & PaintingDocumento5 pagineJSA Formet New Blasting & Paintingsakthi venkatNessuna valutazione finora

- JSA - 015 - Concrete Breaking With Hydraulic BreakerDocumento2 pagineJSA - 015 - Concrete Breaking With Hydraulic BreakerAhmed AlderbiNessuna valutazione finora

- One Direct Method Statement: Preventative MeasuresDocumento4 pagineOne Direct Method Statement: Preventative MeasuresAyu Wanda SaraswatiNessuna valutazione finora

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocumento11 pagineThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh kumar yadav100% (1)

- Demolition JhaDocumento2 pagineDemolition JhaElvyn Fabellore HerreraNessuna valutazione finora

- Responsibilities Summary: Department of LaborDocumento2 pagineResponsibilities Summary: Department of LaborBonaventure NzeyimanaNessuna valutazione finora

- Job Hazard Analysis For Cementitious GroutingDocumento8 pagineJob Hazard Analysis For Cementitious Groutingaloysius akpanNessuna valutazione finora

- Construction Job Safety Analysis - Safety Science Y2010Documento10 pagineConstruction Job Safety Analysis - Safety Science Y2010Yongsak Yungyuen100% (2)

- Tylenol CrisisDocumento2 pagineTylenol CrisisNida SweetNessuna valutazione finora

- A Sample Script For Public SpeakingDocumento2 pagineA Sample Script For Public Speakingalmasodi100% (2)

- Balance-Sheet US GAAPDocumento1 paginaBalance-Sheet US GAAPvishnuNessuna valutazione finora

- Performance Evaluation Report For Practicum TraineesDocumento2 paginePerformance Evaluation Report For Practicum TraineesJ.S100% (3)

- PMG 01Documento2 paginePMG 01fadli.lpgNessuna valutazione finora

- CSCU Module 08 Securing Online Transactions PDFDocumento29 pagineCSCU Module 08 Securing Online Transactions PDFdkdkaNessuna valutazione finora

- Job Hazard Analysis (Earth Mounted Tank)Documento8 pagineJob Hazard Analysis (Earth Mounted Tank)jay RNessuna valutazione finora

- JSA - Civil Compaction WorkDocumento4 pagineJSA - Civil Compaction WorkRajuNessuna valutazione finora

- 2020 06 17 JSA For AC Servicing-Server RoomDocumento12 pagine2020 06 17 JSA For AC Servicing-Server RoomDarren OscarNessuna valutazione finora

- Jsa PaintDocumento2 pagineJsa PaintKhalid NaseemNessuna valutazione finora

- JSA. Cleaning ToiletsDocumento1 paginaJSA. Cleaning ToiletsSajid HussainNessuna valutazione finora

- JSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Documento3 pagineJSA-For Hot Jobs NRL (Fin Fan Cooler Tie in Points)Perwez21Nessuna valutazione finora

- JSO Cable Drum (02 Sept.'07)Documento2 pagineJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNessuna valutazione finora

- Ladders: Generic Risk Assessment FormDocumento3 pagineLadders: Generic Risk Assessment Formvasanth pugazhendhiNessuna valutazione finora

- Doku - Pub Risk-AssessmentDocumento10 pagineDoku - Pub Risk-AssessmentUlviyye ElesgerovaNessuna valutazione finora

- Risk Assess T-23 - Hilti Cartridge Tool OperationDocumento2 pagineRisk Assess T-23 - Hilti Cartridge Tool OperationMAB Ali100% (1)

- Nitoproof 230Documento2 pagineNitoproof 230Balasubramanian Ananth50% (2)

- Jsa Ducting Rev 00Documento1 paginaJsa Ducting Rev 00SRR HSE Department, Sandvik Project,Nessuna valutazione finora

- Anchor Bolt Setting - Rev 01Documento26 pagineAnchor Bolt Setting - Rev 01Geherson AbustanNessuna valutazione finora

- Safety Moment There Is No Shortcut To Safety 448cuoDocumento6 pagineSafety Moment There Is No Shortcut To Safety 448cuoInnocent BhaikwaNessuna valutazione finora

- JSA ExcavationDocumento6 pagineJSA ExcavationidreisNessuna valutazione finora

- Trial Pit During ExcavationDocumento3 pagineTrial Pit During Excavationmujahid1137Nessuna valutazione finora

- Operating The Man LiftDocumento1 paginaOperating The Man LiftEllecer anthony Permejo67% (3)

- Question and Answer Ig1Documento8 pagineQuestion and Answer Ig1RahulNessuna valutazione finora

- Tool Box Talk - MK - Emergency Response ProceduresDocumento2 pagineTool Box Talk - MK - Emergency Response ProceduresPaul McGahanNessuna valutazione finora

- Job Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Documento3 pagineJob Safety Analysis: Hot Jobs (Welding Cutting & Grinding)Perwez21Nessuna valutazione finora

- 26 Barricades&TapeDocumento3 pagine26 Barricades&TapeMohammed MinhajNessuna valutazione finora

- Building De-Dusting JSADocumento3 pagineBuilding De-Dusting JSAJayesh J PillaiNessuna valutazione finora

- PVCMS-BMV-HSE-JSA-001 InsulationDocumento6 paginePVCMS-BMV-HSE-JSA-001 InsulationBkdn DungNessuna valutazione finora

- 325 UP-CSR-JRP IJRASETVolume9IssueIVApr2021Documento9 pagine325 UP-CSR-JRP IJRASETVolume9IssueIVApr2021Ly RatanakNessuna valutazione finora

- 22 2 Safety NEWDocumento8 pagine22 2 Safety NEWLost AloneNessuna valutazione finora

- 12 Month Cash Flow Statement1AZXDocumento3 pagine12 Month Cash Flow Statement1AZXfadli.lpgNessuna valutazione finora

- Idprd 000841Documento20 pagineIdprd 000841fadli.lpg100% (1)

- IMAT Tool EnglishDocumento12 pagineIMAT Tool EnglishEko PribadiNessuna valutazione finora

- Detailed Expense Estimates1Documento5 pagineDetailed Expense Estimates1mukhleshNessuna valutazione finora

- 12 Month Cash Flow Statement1AZXDocumento2 pagine12 Month Cash Flow Statement1AZXmukhleshNessuna valutazione finora

- Opening Day Balance SheetDocumento2 pagineOpening Day Balance Sheetapi-3809857Nessuna valutazione finora

- ReadmeDocumento3 pagineReadmeAlexa MariusNessuna valutazione finora

- PMG 01Documento2 paginePMG 01fadli.lpgNessuna valutazione finora

- 12 Month Cash Flow Statement1AZXDocumento6 pagine12 Month Cash Flow Statement1AZXMukhlish AkhatarNessuna valutazione finora

- 12 Month Cash Flow Statement1AZXDocumento17 pagine12 Month Cash Flow Statement1AZXfadli.lpgNessuna valutazione finora

- Project ManagementDocumento6 pagineProject ManagementferraryNessuna valutazione finora

- Software License AgreementDocumento1 paginaSoftware License AgreementHeroe TjahjonoNessuna valutazione finora

- GEN SVY 02 MatrixRotasiDocumento4 pagineGEN SVY 02 MatrixRotasifadli.lpgNessuna valutazione finora

- File 3Documento5 pagineFile 3fadli.lpgNessuna valutazione finora

- PMG 03Documento1 paginaPMG 03fadli.lpgNessuna valutazione finora

- Sta 0.000 - 200.000 MAXDocumento35 pagineSta 0.000 - 200.000 MAXNOVIKNessuna valutazione finora

- Annual Leave SampleDocumento12 pagineAnnual Leave Samplefadli.lpgNessuna valutazione finora

- PMG 01R1Documento5 paginePMG 01R1fadli.lpgNessuna valutazione finora

- Annual Leave SampleDocumento12 pagineAnnual Leave Samplefadli.lpgNessuna valutazione finora

- Discovery Eola MergedDocumento2 pagineDiscovery Eola Mergedfadli.lpgNessuna valutazione finora

- Kebayoran Village2 Kebayoran Villagebrosur1Documento1 paginaKebayoran Village2 Kebayoran Villagebrosur1fadli.lpgNessuna valutazione finora

- WSG r10-1 Outline App-D v1Documento18 pagineWSG r10-1 Outline App-D v1fadli.lpgNessuna valutazione finora

- File 3Documento5 pagineFile 3fadli.lpgNessuna valutazione finora

- Critical Path Method: Times (In Days)Documento4 pagineCritical Path Method: Times (In Days)fadli.lpgNessuna valutazione finora

- 149046671111Documento8 pagine149046671111fadli.lpgNessuna valutazione finora

- Kebayoran Harmony - Decco - Brosurrdecco - CompressedDocumento2 pagineKebayoran Harmony - Decco - Brosurrdecco - Compressedfadli.lpgNessuna valutazione finora

- Material Safety Data Sheet: - AdsealDocumento12 pagineMaterial Safety Data Sheet: - Adsealwuhan lalalaNessuna valutazione finora

- Pell (2017) - Trends in Real-Time Traffic SimulationDocumento8 paginePell (2017) - Trends in Real-Time Traffic SimulationJorge OchoaNessuna valutazione finora

- What Is Terrorism NotesDocumento3 pagineWhat Is Terrorism NotesSyed Ali HaiderNessuna valutazione finora

- Chapter 12Documento15 pagineChapter 12kk5522Nessuna valutazione finora

- Accounting System (Compatibility Mode) PDFDocumento10 pagineAccounting System (Compatibility Mode) PDFAftab AlamNessuna valutazione finora

- Acc 106 Account ReceivablesDocumento40 pagineAcc 106 Account ReceivablesAmirah NordinNessuna valutazione finora

- A Quantitative Method For Evaluation of CAT Tools Based On User Preferences. Anna ZaretskayaDocumento5 pagineA Quantitative Method For Evaluation of CAT Tools Based On User Preferences. Anna ZaretskayaplanetalinguaNessuna valutazione finora

- Amsterdam Pipe Museum - Snuff WorldwideDocumento1 paginaAmsterdam Pipe Museum - Snuff Worldwideevon1Nessuna valutazione finora

- Appendix 3 COT RPMS For T I III SY 2020 2021 in The Time of COVID 19Documento12 pagineAppendix 3 COT RPMS For T I III SY 2020 2021 in The Time of COVID 19Marjun PachecoNessuna valutazione finora

- RIBA PoWUpdate 131009 ProbynMiersDocumento28 pagineRIBA PoWUpdate 131009 ProbynMiersYellowLightNessuna valutazione finora

- PC's & Laptop Accessories PDFDocumento4 paginePC's & Laptop Accessories PDFsundar chapagainNessuna valutazione finora

- Lightolier Lytecaster Downlights Catalog 1984Documento68 pagineLightolier Lytecaster Downlights Catalog 1984Alan MastersNessuna valutazione finora

- The Function and Importance of TransitionsDocumento4 pagineThe Function and Importance of TransitionsMarc Jalen ReladorNessuna valutazione finora

- Unit 2 Operations of PolynomialsDocumento28 pagineUnit 2 Operations of Polynomialsapi-287816312Nessuna valutazione finora

- Silapathikaram 3Documento37 pagineSilapathikaram 3gavinilaaNessuna valutazione finora

- Elerick Ron Cynthia 1983 SouthAfricaDocumento4 pagineElerick Ron Cynthia 1983 SouthAfricathe missions networkNessuna valutazione finora

- Catalogue Laboratory Products - Heraeus KulzerDocumento288 pagineCatalogue Laboratory Products - Heraeus KulzerDentaDentNessuna valutazione finora

- License Fee PaidDocumento1 paginaLicense Fee Paidmy nNessuna valutazione finora

- Daily Plankton Agrabinta CianjurDocumento141 pagineDaily Plankton Agrabinta CianjurPutra Cahya GemilangNessuna valutazione finora

- Prediction of Mechanical Properties of Steel Using Artificial Neural NetworkDocumento7 paginePrediction of Mechanical Properties of Steel Using Artificial Neural NetworkInternational Association of Scientific Innovations and Research (IASIR)Nessuna valutazione finora

- A Summer Training ReportDocumento39 pagineA Summer Training ReportShubham SainyNessuna valutazione finora

- 120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnDocumento9 pagine120 Câu Tìm Từ Đồng Nghĩa-Trái Nghĩa-Dap AnAlex TranNessuna valutazione finora