Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Autoclaving Practice Microbiology Of: in Laboratories

Caricato da

Suchetana Sen0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni5 pagineThesis

Titolo originale

418.full

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoThesis

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

17 visualizzazioni5 pagineAutoclaving Practice Microbiology Of: in Laboratories

Caricato da

Suchetana SenThesis

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 5

J Clin Pathol: first published as 10.1136/jcp.31.5.418 on 1 May 1978. Downloaded from http://jcp.bmj.com/ on 3 December 2018 by guest. Protected by copyright.

Journal of Clinical Pathology, 1978, 31, 418-422

Autoclaving practice in microbiology laboratories:

report of a survey

THE PUBLIC HEALTH LABORATORY SERVICE SUBCOMMITTEE'

ON LABORATORY AUTOCLAVES2

From the Public Health Laboratory Service, Head Office, 61 Colindale Avenue, London NW9 SEQ, UK

SUMMARY The performance of autoclaves in 27 laboratories, operated in accordance with the

normal routine of local practice, has been monitored using thermometric equipment. Sterilising

performance was unsatisfactory on 10 of 62 occasions, and cooling was inadequate on 52 of 60 oc-

casions.

As part of the general concern over safety standards, Method

laboratories in the Public Health Laboratory Service

(PHLS) were encouraged to obtain thermometric Tests were made when the autoclaves were loaded,

equipment to monitor the performance of their operated, and unloaded in their normal manner

autoclaves. This provided an opportunity to dis- according to local custom and practice. Most

cover whether, when the autoclaves were operated in temperature measurements were made with copper/

accordance with the normal practices in use in those constantan thermocouples (02 mm diameter)

laboratories at the time of acquisition of the equip- insulated with polytetrafluoroethylene (PTFE) but

ment, sterilising performance was satisfactory and unsheathed. Usually these could be led into the

cooling of the loads was adequate to allow the autoclave chamber between the door and the seal.

autoclaves to be opened safely. The results of a They were inserted at those points in the load where

survey of these aspects of autoclaving practice in 27 experience had shown that performance was likely

laboratories are reported here. to be unsatisfactory as regards either sterilising or

subsequent cooling. For example, when testing the

Survey material processing of discarded cultures, a thermocouple was

placed inside one of the cultures making up the load,

LABORATORIES AND AUTOCLAVES and this was placed at the centre and about one-third

In all, 46 downward-displacement autoclaves in 27 of the way up the discard container. Similarly, when

laboratories were tested. Twenty-four of the auto- observing cooling times, thermocouples were placed

claves were vertical and cylindrical, and 22 were in the largest units of volume making up the load

horizontal. Some were the responsibility of the since it was in these that cooling was likely to be most

PHLS Board, some of Area Health Authorities and, prolonged.

in one case, of a university department. Thermocouple signals were recorded on a suitable

Twenty-three of the laboratories were engaged, to instrument; these were checked at intervals against a

a varying extent, in clinical microbiology and four mercury-in-glass thermometer which had been

were reference laboratories in special microbiology. certified by the National Physical Laboratory.

Not surprisingly, the choice of sterilising tempera-

"J. E. M. Whitehead (Chairman), J. V. Dadswell, P. H. tures or times among the laboratories was not

Everall, R. J. Henderson, J. C. Kelsey, E. R. Mitchell, uniform, thus making comparison difficult. Further-

C. A. Morris, M. W. Scruton, and R. H. Westlake more, distinction has to be drawn between the

2Correspondence: Dr C. A. Morris, Public Health treatment given to discarded cultures and other

Laboratory, Mytton Oak Road, Shrewsbury SY3 8XH, materials that have to be sterilised to make them

UK safe, and that accorded to culture media which

require to be heated to the minimum temperature

Received for publication 7 November 1977 and for the time which experience will have shown

418

J Clin Pathol: first published as 10.1136/jcp.31.5.418 on 1 May 1978. Downloaded from http://jcp.bmj.com/ on 3 December 2018 by guest. Protected by copyright.

Autoclaving practice in microbiology laboratories: report of a survey 419

to be just adequate to produce an acceptable yet quently to lie not in the autoclaves themselves but in

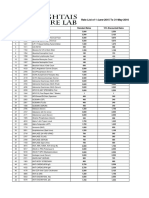

sterile medium. Because of these considerations other factors. These are listed in Table 3, in which

sterilising performance was expressed as the ratio of the temperature reached is shown as a percentage

the minimum load temperature at the end of the of the temperature intended for the sterilization of

sterilising period to the intended sterilising tempera- discarded materials.

ture or to that actually reached in the chamber Table 3 Probable causes offailure in eight cycles for

during the sterilising period. Both possibilities had sterilising discard loads

to be allowed for, because not infrequently either

the chamber pressure-gauge or the chamber-drain Probable cause offailure Temperature reached as a

percentage of that intended

temperature gauge, or both, were inaccurate. (On

one instrument when the chamber pressure gauge Container

read 18lb psig (0-22 MN/m2)* the chamber-drain 1 Overlarge containers 81

2 Plastic bags impervious to steam 85

temperature gauge read 116'C. The true figures 3 Lids on containers 73

were 15 lb psig (0-2 MN/M2) and 121'C.) 4 Occlusion of container opening by

other loads 85

Sterilising cycles were judged satisfactory if the

ratio, expressed as a percentage, was above 95 %, Load

doubtful if between 90 and 95 %, and unsatisfactory 5 Water added to container 89

6 Homogenous load of small tissue

if below 90%. culture tubes 61

Other factors

Results 7 Overfast chamber heat-up 88

8 Inadequate air removal from

autoclave chamber 78

STERILISING PERFORMANCE

Applying the above criteria, 40 operating cycles were

considered satisfactory, 12 were doubtful, and 10 Only in examples 7 and 8 in Table 3 could failure

were unsatisfactory. The distribution of these results be ascribed to the autoclaves, and in one of these it

between the two types of autoclaves is shown in was its installation rather than the instrument itself

Table 1. which was at fault. High pressure steam (11(0 lb psig;

0O8 MN/M2) was supplied to this autoclave, the

Table 1 Sterilising performance and autoclave type outlet of which had been fitted with a pipe bypassing

Result Vertical/Cylindrical Horizontal Total the trap in the chamber-drain. Consequently

temperatures rose rapidly in the chamber but not in

Satisfactory 19 21 40 the load (Rubbo and Gardner, 1965). At the end of

Doubtful 8 4 12

Unsatisfactory 4 6 10 the sterilising period, when the chamber temperature

had reached 1320C, the load temperature was only

The results were further analysed according to the 1170C.

age of the autoclaves and are shown in Table 2. The attainment of this temperature in a load

which then had to cool slowly might not be re-

Table 2 Sterilising performance and age of autoclave garded as evidence of unsatisfactory performance in

Result Age (years)

sterilising a load of discarded cultures, and con-

Up to 5 5-10 Over 10 sequently the method of judging sterilising perfor-

mance might be considered to be unrealistic.

Satisfactory 23 7 8 However, selecting load temperaures at the finish of

Doubtful 9 1 2 the sterilising period as the criterion for evaluating

Unsatisfactory 7 2 1

the process provided, on the whole, a generous

Two instruments, age unknown, have been omitted. assessment of it, and, furthermore, the operators and

their supervisors were unaware-and without the

PROBABLE CAUSES OF FAILURE essential thermometric equipment could not have

There was no apparent correlation between the type made themselves aware-of the actual temperatures

or age of autoclaves and their sterilising performance. attained. Thus when a difficult load (example 6 in

This is further borne out by analysis of the 10 Table 3) was autoclaved in the same instrument,

cycles (in 9 autoclaves) judged to be unsatisfactory. this, combined with the over-rapid heating of the

Two cycles were for the preparation of culture media chamber, resulted in a maximum load temperature

and eight were 'sterilising' cycles to render discarded of only 780C.

material safe. The causes of failure appear fre-

*10' N/Mi (or pascals) = 1 Bar = 14 7 lb per square COOLING

inch The results given in Table 4 indicate that cooling of

J Clin Pathol: first published as 10.1136/jcp.31.5.418 on 1 May 1978. Downloaded from http://jcp.bmj.com/ on 3 December 2018 by guest. Protected by copyright.

420 The Public Health Laboratory Service Subcommittee on laboratory autoclaves

Table 4 Cooling of autoclave loads in 60 operating Conclusions

cycles

Cooling load temperature Vertical/Cylindrical Horizontal Working standards for holding times and tempera-

on opening (°C) tures should be ascertained by means of thermo-

4* 4*

couples distributed throughout a typical load. Only

Satisfactory (80 or less) in this way is it possible to determine the length of

81-90 3 0

91-100 17 21 time taken to reach sterilising temperatures and on

>100 5 6 cooling to have reached a temperature of less than

Total 29 31

80 C before opening the chamber.

*Includes one cycle in which the load temperature did not exceed

Until laboratory autoclaves are equipped with a

80'C during the sterilising period means for accelerating the cooling of loads it is

difficult to offer any advice on the unloading hazard

other than that already given in some interim

advisory notes by this Subcommittee on the safe and

most of the loads was inadequate-a not unexpected efficient use of laboratory autoclaves, in which the

finding in view of previous observations (Everall factors influencing the performance of autoclaves in

and Morris, 1975). In only eight of 60 cycles were sterilising discarded materials are also considered.

loads at the recommended temperatures of 800C or These notes are summarised in the Appendix.

below when the autoclaves were opened (Department

of Health and Social Security and Welsh Office, The Subcommittee thanks those laboratory directors

1972). In two of the eight the load temperature had who kindly supplied details of the observations made

not risen to 80'C during the whole 'sterilising' on autoclaves in their laboratories and is particularly

period. indebted to two of its members, Mr P. H. Everall,

As will be seen from Table 4, there was little Public Health Laboratory, Shrewsbury, and Mr M.

difference in the adequacy of cooling between hori- W. Scruton, Public Health Laboratory, Coventry,

zontal and vertical models. for many of the temperature measurements made

during the survey and for the preparation of the orig-

Discussion inal interim advisory notes (summarised in the

Appendix).

Most of the causes of failure in sterilising per-

formance should be well known as they are reason- APPENDIX

ably well documented. However, the concept of the

'difficult' load is one which may not be widely Safe and efficient use of laboratory autoclaves:

appreciated. As the volume of laboratory work has summary of advisory notes

increased and become more specialised, discarded

materials requiring sterilisation have tended to These notes are intended to supplement the advice

become more homogenous. The loads for sterilisa- given elsewhere (Department of Health and Social

tion from a virus laboratory may contain little but Security and Welsh Office, 1972; Collins et al.,

tissue-culture tubes and rubber bungs or loads may 1974) and do not describe the detailed operation of an

consist of large numbers of bijou (7-ml) bottles and autoclave. The three main hazards considered here

little else. It is easy to show that air removal is more are: (a) failure to sterilise; (b) the pressure vessel

difficult from homogenous loads of small individual hazard; and (c) the unloading hazard.

articles than from mixed loads containing larger

items. Although this is not surprising, it is not well FAILURE TO STERILISE (the making safe of

recognised and should be made known more widely. infected materials)

In 11 of 62 cycles autoclaves were opened with load The commonly used holding times and tempera-

temperatures above 100'C (Table 4). Should some of tures are: 1260C for not less than 10 min; and

the bottles making up the loads have had tight caps 121'C for not less than 15 min. Other times and

or have been tightly sealed in some other way, there temperatures sometimes used are 1340C for not less

would have been a real risk of explosion. One than 3 min and 115°C for not less than 25 min. The

laboratory recorded a temperature of 1 3 0C in times do not include the penetration or heating

2k-litre bottles of water on opening its autoclave. up time, which will vary with the physical character-

At such temperatures, and depending on the head istics of the load and which can be determined only

space above the fluid, the pressure inside a sealed by sensing the load temperatures.

bottle will certainly be in excess of two atmospheres Current practice is to measure the holding period

(0-2 MN/M2). from the moment the chamber drain thermometer

J Clin Pathol: first published as 10.1136/jcp.31.5.418 on 1 May 1978. Downloaded from http://jcp.bmj.com/ on 3 December 2018 by guest. Protected by copyright.

Autoclaving practice in microbiology laboratories: report of a survey 421

indicates phase boundary steam, that is, removal of recommended solely as a check on whether the

air as shown by correspondence between tempera- container has been subjected to the autoclaving

ture and pressure, but there is frequently no direct process. A colour change in the tape does not in-

correlation between chamber drain thermometer dicate that the contents of the container have been

readings and load temperature in the early stages of satisfactorily disinfected.

the cycle. Spore papers are not recommended for routine

The rate at which air is displaced by steam is testing of laboratory autoclaves.

affected (among other things) by (a) the method

by which steam is supplied to the chamber, and THE PRESSURE VESSEL HAZARD

(b) the size, shape, and material of the containers. 'When the door is opened at the end of the cycle there

may be residual pressure in the autoclave which is not

STEAM SUPPLY detectable by the pressure gauge' (Department of

1 Autoclaves (vertical and horizontal) with Employment, 1974). Most modern autoclaves have

independent steam supply interlocking safety devices on their doors (or lids).

Maximum turbulence should be produced during Even if such devices are fitted, it is important before

the air removal stage, the duration of which should using the autoclave to:

be determined by temperature measurements in 1 Inspect for any visible damage to the door seal.

typical loads. 2 Check the load to ensure that all caps are loose on

screw-capped bottles and that there is a generous

2 Autoclaves with steam generated by heating headspace (not less than 1/3) above the liquid in

water within the chamber (the pressure cooker each bottle. Remove any cracked or otherwise

principle) defective bottles.

Sufficient time must be allowed for the temperature 3 If the inclusion of sealed containers is un-

of the load to reach the temperature indicated by the avoidable or if the load is unusually large or

autoclave thermometer during the free-steaming consists of large unit volumes, display a notice

process before the outlet is closed and the chamber that special care is necessary on this account.

is brought up to the desired pressure. 4 Close the door in the approved manner (if

necessary referring to the written operating

THE CONTAINER procedure, which should be displayed in the same

The deeper the container, the longer will be the time room) and do not misuse the closing gear.

needed for removal of air from it. Perforated and 5 Check that the door is properly closed.

wire mesh containers are not suitable for discarded 6 Make no attempt to override any safety

cultures since their potentially infectious contents mechanism.

may leak before reaching the autoclave. Molten At the end of the run and before attempting to open

agar may also escape within the autoclave and, on the autoclave door:

cooling, block the pipework. 1 Ensure that the main steam inlet valve is closed

Experimental results suggest that, rather than (or its equivalent if steam has to be generated on

hastening air removal, the addition of water to a the site).

container prolongs the heat penetration time 2 Open the air break valve and the exhaust valve.

(Gillespie and Gibbons, 1975).

Working standards for holding times and tempera- THE UNLOADING HAZARD

tures should be ascertained by means of thermo- 'An autoclave must never be opened until the atmos-

couples distributed throughout a typical load. Only pheric pressure is reached in the chamber, the vent

in this way is it possible to determine the time taken is open and sufficient time has elapsed for the contents

to reach sterilising temperatures. to be at a safe temperature' (Department of Health

and Social Security and Welsh Office, 1972).

STERILISATION INDICATORS Most laboratory autoclaves, however, are not

Chemical indicators should be used only with full equipped with means of measuring the load tempera-

knowledge of their limitations. Only when they ture. On no account should the reading of a chamber

indicate failure can the results be relied upon; drain thermometer during the cooling period be

a 'pass' does not necessarily indicate that sterilising taken to indicate load temperature. Past experience

conditions were maintained. If used, they should be will have taught the user the necessary cooling times

placed about one-third of the way up a discard for various loads and, until load temperatures can

container. be measured, such experience must remain the best

Autoclave tape conspicuously positioned, for guide.

example, across the top of a discard bucket, is To minimise the risk from bottle explosion, apart

J Clin Pathol: first published as 10.1136/jcp.31.5.418 on 1 May 1978. Downloaded from http://jcp.bmj.com/ on 3 December 2018 by guest. Protected by copyright.

422 The Public Health Laboratory Service Subcommittee on laboratory autoclaves

from the precautions described under pressure References

vessel hazard (b) above, the following should be Collins, C. H., Hartley, E. G., and Pilsworth, R. (1974).

observed: The Prevention of Laboratory Acquired Infection

1 Wear a safety visor when opening the door (if (Public Health Laboratory Service Monograph Series,

possible, the door should be only 'cracked' open No. 6), p. 35. HMSO, London.

Department of Employment (1974). Safety at Quick-

(1 to 1j in.; 12 to 36 mm) and the autoclave left Opening and Other Doors of Autoclaves (Technical

for 15 min to accelerate the further cooling of the Data Note, 46), p. 2. HMSO, London.

load before the actual unloading). During these Department of Health and Social Security and Welsh

operations the door should, as far as possible, be Office (1972). SafJty in Pathology Laboratories, p. 11.

kept between the person of the operator and the Department of Health and Social Security, London

chamber contents. and Welsh Office, Cardiff.

2 Wear insulated gauntlet gloves and a visor when Everall, P. H., and Morris, C. A. (1975). Some observa-

unloading. tions on cooling in laboratory autoclaves. Journal

3 Avoid mechanical and thermal shocks (from of Clinical Pathology, 28, 664-669.

cold, draught, etc) to the load. Gillespie, E. H. and Gibbons, S. A. (1975). Autoclaves

4 When possible leave large loads, or loads made and their dangers and safety in laboratories. Journal of

Hygiene, 75, 475487.

up of large unit volumes, overnight in a locked Rubbo, S. D., and Gardner, J. F. (1965). A Review of

autoclave to cool. Sterilization and Disinfection as applied to Medical,

5 Use containers for culture media as small as Industrial and Laboratory Practice, p.221. Lloyd Luke,

compatible with efficiency and convenience in use. London.

Potrebbero piacerti anche

- Freeze Drying-Principles and Practice For Successful Scale-Up To ManufacturingDocumento16 pagineFreeze Drying-Principles and Practice For Successful Scale-Up To ManufacturingJuan DavidNessuna valutazione finora

- Therm0chimica Acta: KeywordsDocumento9 pagineTherm0chimica Acta: Keywordssameer sahaanNessuna valutazione finora

- 5 Distillation Final ReportDocumento7 pagine5 Distillation Final ReportElzubair EljaaliNessuna valutazione finora

- 6 Adiabaticcalorimetry PDFDocumento14 pagine6 Adiabaticcalorimetry PDFEvelyn TapiaNessuna valutazione finora

- 7.0 LOAD PATTER-WPS OfficeDocumento9 pagine7.0 LOAD PATTER-WPS OfficeMohanad AlashkarNessuna valutazione finora

- Autoclave ValidationDocumento7 pagineAutoclave ValidationMohanad Alashkar100% (1)

- Separation of Acetonitrile From Hazardous Waste: Honors Senior Thesis Pass With DistinctionDocumento42 pagineSeparation of Acetonitrile From Hazardous Waste: Honors Senior Thesis Pass With DistinctionJoshua JohnsonNessuna valutazione finora

- Vapor Pressures of Phlegmatic Liquids. I. Simple and Mixed TriglyceridesDocumento7 pagineVapor Pressures of Phlegmatic Liquids. I. Simple and Mixed TriglyceridesShayane MagalhãesNessuna valutazione finora

- Guidelines For Assessment of Temperature UniformitDocumento4 pagineGuidelines For Assessment of Temperature UniformitGiaraf100% (1)

- Autoclave (Steam Sterlizer) Validation - Pharmaceutical GuidelinesDocumento3 pagineAutoclave (Steam Sterlizer) Validation - Pharmaceutical GuidelinesASHOK KUMAR LENKANessuna valutazione finora

- Phase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringDa EverandPhase Equilibrium in Mixtures: International Series of Monographs in Chemical EngineeringNessuna valutazione finora

- Grupo 5 InglesDocumento15 pagineGrupo 5 InglesSC A AntonyNessuna valutazione finora

- Lab Report Dist 1 Batch DistillationDocumento20 pagineLab Report Dist 1 Batch Distillationcsgo accountNessuna valutazione finora

- Kinetics of The Dehydrogenation of Ethanol ToDocumento6 pagineKinetics of The Dehydrogenation of Ethanol ToReyes Lopez EstebanNessuna valutazione finora

- Incubators: What Are Laboratory Incubators Used For?Documento7 pagineIncubators: What Are Laboratory Incubators Used For?Vyomi ThakkarNessuna valutazione finora

- 17chp06 Process Heat Transfer LabDocumento50 pagine17chp06 Process Heat Transfer LabpandianvijaybharathiNessuna valutazione finora

- Sterilization Performance of Autoclave Units On Cannular MaterialsDocumento10 pagineSterilization Performance of Autoclave Units On Cannular MaterialsFahim FahimNessuna valutazione finora

- Operation and Calibration of The AutoclaveDocumento6 pagineOperation and Calibration of The Autoclaveemje pebeNessuna valutazione finora

- Microbial Contamination of Food Refrigeration EquipmentDocumento8 pagineMicrobial Contamination of Food Refrigeration EquipmentNeida SanabriaNessuna valutazione finora

- Jacket-Side Nusselt Number: Isaac LehrerDocumento6 pagineJacket-Side Nusselt Number: Isaac LehrerJimmy Miranda100% (1)

- AutoclaveDocumento18 pagineAutoclaveGorwadiya_Hite_1818Nessuna valutazione finora

- Lab Policies Temperature Recording and Maintenance of Temperature Dependent Equipment Lab 0265Documento3 pagineLab Policies Temperature Recording and Maintenance of Temperature Dependent Equipment Lab 0265Helen grace NidoyNessuna valutazione finora

- In Situ Verification Techniques For Multipoint Thermocouples Rev ADocumento17 pagineIn Situ Verification Techniques For Multipoint Thermocouples Rev AXuanNessuna valutazione finora

- Thermo Prject 2-1Documento20 pagineThermo Prject 2-1Syed AhmerNessuna valutazione finora

- Incubators ValidationDocumento12 pagineIncubators ValidationDonig FermanianNessuna valutazione finora

- Autoclave MethodDocumento16 pagineAutoclave MethodGretta100% (1)

- Performance of Aluminium Trays For SteriDocumento18 paginePerformance of Aluminium Trays For Steridavid catur widodoNessuna valutazione finora

- Respiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManDa EverandRespiration Calorimeters for Studying the Respiratory Exchange and Energy Transformations of ManNessuna valutazione finora

- Calorimetry: Physikalisch-Chemisches Praktikum I Calorimetry - 2016Documento19 pagineCalorimetry: Physikalisch-Chemisches Praktikum I Calorimetry - 2016Agu15kelvinNessuna valutazione finora

- A Simple Technique For Refrigerant Mass MeasurementDocumento11 pagineA Simple Technique For Refrigerant Mass MeasurementDaniel WeeksNessuna valutazione finora

- Failure Scenarios For ReactorsDocumento17 pagineFailure Scenarios For ReactorsYorman Zambrano Silva100% (2)

- USP 1229.8 Dry Heat SterilizationDocumento3 pagineUSP 1229.8 Dry Heat SterilizationDoan Chi ThienNessuna valutazione finora

- 1 s2.0 0009250964850922 MainDocumento12 pagine1 s2.0 0009250964850922 MainPedro SiscatoNessuna valutazione finora

- Whitepaper 140°C 12-03 PDFDocumento7 pagineWhitepaper 140°C 12-03 PDFrajeeshNessuna valutazione finora

- Wang 1995Documento5 pagineWang 1995László SágiNessuna valutazione finora

- 2550 Temperatura PDFDocumento2 pagine2550 Temperatura PDFPenelope MeloNessuna valutazione finora

- Heat Transfer Lab ManualDocumento59 pagineHeat Transfer Lab ManualMarNessuna valutazione finora

- Heat of Adsorption: I TheoryDocumento10 pagineHeat of Adsorption: I TheorymahmoudsabryNessuna valutazione finora

- Expt Guide - F4 - Drying Under Constant Conditions Using Tray DryerDocumento9 pagineExpt Guide - F4 - Drying Under Constant Conditions Using Tray DryerBabyyFacedNessuna valutazione finora

- Reid Vapor Pressure BCDocumento9 pagineReid Vapor Pressure BCMinh Trần LêNessuna valutazione finora

- Thermal Decomposition Final23 PDFDocumento13 pagineThermal Decomposition Final23 PDFMuhammad Danyal ShahidNessuna valutazione finora

- Nyberg AutoclaveDocumento3 pagineNyberg AutoclaveLászló SágiNessuna valutazione finora

- Laboratory Evaluation of Heat and MoistuDocumento6 pagineLaboratory Evaluation of Heat and MoistuCbdtxd PcbtrNessuna valutazione finora

- Adiabatic & Reaction Calorimetry PDFDocumento24 pagineAdiabatic & Reaction Calorimetry PDFpedroNessuna valutazione finora

- Use of Thermocouples in Measuring Temperature-Humidity Conditions in Commercial Dry KilnsDocumento3 pagineUse of Thermocouples in Measuring Temperature-Humidity Conditions in Commercial Dry Kilnsletter_ashish4444Nessuna valutazione finora

- Experiment 1 (Relative Density - A4)Documento17 pagineExperiment 1 (Relative Density - A4)Jamiel CatapangNessuna valutazione finora

- SCE Research Paper PDFDocumento12 pagineSCE Research Paper PDFmuoi2002Nessuna valutazione finora

- Amende 2007Documento6 pagineAmende 2007Warren PuthNessuna valutazione finora

- Benedict-Webb-Rubin Equation of State For An AlterDocumento8 pagineBenedict-Webb-Rubin Equation of State For An AlterSantiago AguirreNessuna valutazione finora

- 1 s2.0 S1385894713013302 MainDocumento7 pagine1 s2.0 S1385894713013302 MainAlex GutierrezNessuna valutazione finora

- Physical IndicatorsDocumento3 paginePhysical IndicatorsDipto Kumer Sarker50% (2)

- NAME 178 - ThermodynamicsLab SheetDocumento48 pagineNAME 178 - ThermodynamicsLab SheetMahadi HasanNessuna valutazione finora

- Experimental and Theoretical Study of Pool BoilingDocumento11 pagineExperimental and Theoretical Study of Pool Boilingvaibhav pawarNessuna valutazione finora

- Test Methods To Qualify Quarter-Turn Valves For Low Emissions ServiceDocumento3 pagineTest Methods To Qualify Quarter-Turn Valves For Low Emissions ServiceCricri CriNessuna valutazione finora

- 17chp06 Process Heat Transfer LabDocumento52 pagine17chp06 Process Heat Transfer LabpandianvijaybharathiNessuna valutazione finora

- Bath Ratio and Temperature Control Enhancement in The PotroomDocumento2 pagineBath Ratio and Temperature Control Enhancement in The PotroomMarc DupuisNessuna valutazione finora

- Cryo - Test - Jan 04 - 2010 - PATH - YellowDocumento23 pagineCryo - Test - Jan 04 - 2010 - PATH - Yellowdevon2610Nessuna valutazione finora

- BS 1881-PART-111 CONCRETE Method Forn Normal Curing of TestDocumento4 pagineBS 1881-PART-111 CONCRETE Method Forn Normal Curing of Testhajimak100% (1)

- Enzyme Kinetics Above Denaturation Temperature: A Temperature-Jump/Stopped-Flow ApparatusDocumento6 pagineEnzyme Kinetics Above Denaturation Temperature: A Temperature-Jump/Stopped-Flow ApparatusAshish TankNessuna valutazione finora

- r315 Quick Start PDFDocumento80 paginer315 Quick Start PDFfdsfasdsfadsNessuna valutazione finora

- Kyocera 1800Documento2 pagineKyocera 1800gendoetzNessuna valutazione finora

- CCNP 300 410 ENARSI NetworkTUT 26 5 2021Documento104 pagineCCNP 300 410 ENARSI NetworkTUT 26 5 2021Olga BradyNessuna valutazione finora

- Assignment Class X Similar Triangles: A D E B CDocumento2 pagineAssignment Class X Similar Triangles: A D E B CCRPF School100% (1)

- Zelio Control Relays - RM22TR33Documento7 pagineZelio Control Relays - RM22TR33SIVARAMANJAGANATHANNessuna valutazione finora

- 02 Unit I Environmental Studies-A Multidisciplinary Subject 14-01-2022Documento69 pagine02 Unit I Environmental Studies-A Multidisciplinary Subject 14-01-2022doramonbhaiyaNessuna valutazione finora

- Brochure - Citadines Flatiron Phnom Penh - EnglishDocumento4 pagineBrochure - Citadines Flatiron Phnom Penh - EnglishTix VirakNessuna valutazione finora

- YearbookDocumento55 pagineYearbookGODWIN IRIMORENNessuna valutazione finora

- NSO SPRDocumento9 pagineNSO SPRADITYA SINGHNessuna valutazione finora

- Rate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesDocumento25 pagineRate List of 1-June-2015 To 31-May-2016: S.No Code Test Name Standard Rates 15% Discounted RatesMirza BabarNessuna valutazione finora

- Mice and Men Naturalism Web SiteDocumento10 pagineMice and Men Naturalism Web SitedrooolNessuna valutazione finora

- A Bilateral Subdural Hematoma Case Report 2165 7548.1000112 PDFDocumento2 pagineA Bilateral Subdural Hematoma Case Report 2165 7548.1000112 PDFPutra GagahNessuna valutazione finora

- 1414-Electric Room 1 Calculation Report Rev.02Documento28 pagine1414-Electric Room 1 Calculation Report Rev.02zakariaelrayesusaNessuna valutazione finora

- Cleavage in MammalsDocumento51 pagineCleavage in MammalsIrfan Azram100% (4)

- Gurps Fallout HandgunsDocumento1 paginaGurps Fallout HandgunsAndrew Scott100% (1)

- Gayatri Mantras of Several GodDocumento10 pagineGayatri Mantras of Several GodAnup KashyapNessuna valutazione finora

- Growth Rate and Fattening Potetial of Meat AnimalsDocumento54 pagineGrowth Rate and Fattening Potetial of Meat AnimalsMuhammad Shahzad ChandiaNessuna valutazione finora

- Apti 2Documento17 pagineApti 2Arunkumar MurugappanNessuna valutazione finora

- Effect of Toe Treatments On The Fatigue Resistance of Structural Steel WeldsDocumento12 pagineEffect of Toe Treatments On The Fatigue Resistance of Structural Steel WeldsVicente Palazzo De MarinoNessuna valutazione finora

- Vol 2 No S12022 Actasdela XVIIConferencia Mundialsobre CineantropometraDocumento185 pagineVol 2 No S12022 Actasdela XVIIConferencia Mundialsobre CineantropometraAye JaimeNessuna valutazione finora

- NEET MADE EJEE Complete Handwritten Formulae Chemistry NEET andDocumento90 pagineNEET MADE EJEE Complete Handwritten Formulae Chemistry NEET andliyanderNessuna valutazione finora

- Standard MissileDocumento2 pagineStandard Missilemadox_3m100% (1)

- INFORMATION SHEET No. 1.1.1Documento7 pagineINFORMATION SHEET No. 1.1.1Sandre Walden-SCSCNessuna valutazione finora

- SpiralsDocumento12 pagineSpiralskkglobalNessuna valutazione finora

- Case Study Oil and Gas - PowerpointDocumento8 pagineCase Study Oil and Gas - PowerpointYaxssNessuna valutazione finora

- Water Treatment Lecture 4Documento34 pagineWater Treatment Lecture 4pramudita nadiahNessuna valutazione finora

- 1-Theory of Metal Cutting PDFDocumento144 pagine1-Theory of Metal Cutting PDFNithinArvindNessuna valutazione finora

- TM TC For NanosatelliteDocumento4 pagineTM TC For NanosatelliteSreeja SujithNessuna valutazione finora

- Revision For The First 1 English 8Documento6 pagineRevision For The First 1 English 8hiidaxneee urrrmNessuna valutazione finora

- Alien Magic - William Hamilton IIIDocumento179 pagineAlien Magic - William Hamilton IIICarlos Rodriguez100% (7)