Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Pipe and Tube Comparison and Application Areas

Caricato da

Karthikeyan ShanmugavelTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Pipe and Tube Comparison and Application Areas

Caricato da

Karthikeyan ShanmugavelCopyright:

Formati disponibili

ASTM A423 / A423M - 09(2014)

Standard Specification for Seamless and Electric-Welded Low-Alloy Steel Tubes

This specification covers standards for minimum-wall-thickness, seamless, and electric-resistance welded low-alloy steel tubes to be used for pressure containing parts, that is economizers, and for other

corrosion resistant applications. Steel tubes shall either be processed to hot or cold finish. All tubes shall be normalized or given such heat treatment as may be necessary to conform to the requirements of this

specification. Chemical composition shall adhere to specified carbon, manganese, phosphorus, sulfur, silicon, copper, chromium, nickel, and molybdenum contents. Tension, flattening, flaring, flange, hardness,

reverse flattening, and hydrostatic tests shall be performed. Tubes when inserted in the boiler shall stand expanding and bending without showing cracks or flaws. Tubes shall also conform to tensile strength,

yield strength, hardness, and elongation requirements.

1. Scope

1.1 This specification2 covers minimum-wall-thickness, seamless and electric-resistance welded, low-alloy steel tubes for pressure containing parts such as economizers or other applications where corrosion

resistance is important.

1.2 The tubing sizes and thicknesses usually furnished to this specification are 1/2 to 5 in. [12.7 to 127 mm] in outside diameter and 0.035 to 0.500 in. [0.9 to 12.7 mm] inclusive, in minimum wall thickness.

Tubing having other dimensions may be furnished, provided such tubes comply with all other requirements of this specification.

1.3 Mechanical property requirements do not apply to tubing smaller than 1/4 in. [3.2 mm] in inside diameter or 0.015 in. [0.4 mm] in thickness.

1.4 An optional supplementary requirement is provided and, when desired, shall be so stated in the order.

1.5 The values stated in either SI units or inch-pound units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system may not be exact

equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in non-conformance with the standard. The inch-pound units shall apply unless

the “M” designation of this specification is specified in the order.

ASTM Standards

A450/A450M Specification for General Requirements for Carbon and Low Alloy Steel Tubes

E213 Practice for Ultrasonic Testing of Metal Pipe and Tubing

E273 Practice for Ultrasonic Testing of the Weld Zone of Welded Pipe and Tubing

Keywords

Alloy Steel - Boilers And Pressure Vessels - Corrosive Service Applications - Electric Resistance-Welded Steel Tubes - Pressure-Containing Parts - Seamless Pipes And Tubes - Seamless Steel Tubes -

Welded Pipes And Tubes - Welded Steel Tubes

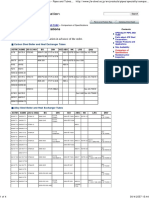

Carbon Steel Boiler and Heat Exchanger Tubes

ASTM ASME JIS G 3461 BS DIN ISO ABS NK LRS DNV

A178 SA178 A STB 340 3059-P1 320 17175 st 35.8 ABS D KSTB 33 Sec 6 320 Sec 4-E-TS360

3059-P2 360 17177 st 37.8

AA179 SA179 3606 320 ABS G KSTB 35 Sec 6 360

A192 SA192 ABS H

A214 SA214

A556 A2 SA556 A2

A178 C SA178 C STB 410 3059-P2 440 17175 st 45.8 ABS F KSTB 42 Sec 6 410 Sec 4-E-TS410-1

A210 A1 SA210 A1 3606 440 17177 st 42.8 ABS J

A556 B2 SA556 B2

STB 510 17175 19Mn 5 Sec 4-E-TS510

A178 D SA178 D Sec 6 460 Sec 4-E-TS460-1

A210 C SA210 C

A556 C2 SA556 C2

Alloy Steel Boiler and Heat Exchanger Tubes

ASTM ASME JIS G 3462 BS DIN ISO ABS NK LRS DNV

17175 Sec

A209 T1 SA209 T1 STBA 12 3606 243 2604 II TS26 ABS K KSTB 12

15Mo3 4-E-TS380

17177

A250 T1 SA250 T1 3606 245 2604 III TS26

15Mo3

A209 T1a SA209 T1a STBA 13 ABS L

A250 T1a SA250 T1a

17175 Sec

A213 T2 SA213 T2 STBA 20 2604 II TS33

14MoV83 4-E-TS440

A250 T2 SA250 T2

17175 Sec 6 Sec

A213 T12 SA213 T12 STBA 22 3606 620 2604 II TS32 ABS O KSTB 22

13CrMo44 1Cr 1/2Mo-440 4-E-TS410-3

A250 T12 SA250 T12 2604 III TS32

Sec

A213 T11 SA199 T11 STBA 23 3606 621 ABS N KSTB 23

4-E-TS410-4

SA213 T11

17175 Sec 6 Sec

A213 T22 SA199 T22 STBA 24 3606 622 2604 II TS34 ABS P KSTB 24

10CrMo910 2-1/2Cr 1Mo-410 4-E-TS450-2

SA213 T22

Sec

A213 T5 SA199 T5 STBA 25 3606 625 2604 II S37

4-E-TS430

SA213 T5

Sec

A213 T9 SA199 T9 STBA 26 3059-P2 622-490 2604 II S38

4-E-TS500

SA213 T9

17175 Sec 6 Sec

A209 T1b SA209 T1b 3059-P2 243 2604 II S39 ABS M

17Mn4 2-1/2Cr 1Mo-490 4-E-TS450-1

(=A209-

3059-P2 620-460

T1b)

17175 Sec

A250 T1b SA250 T1b 3059-P2 629-470 2604 II S40

14MoV63 4-E-TS460-2

17175 Sec

A250 T11 SA250 T11 3059-P2 629-590

X20CrMoV12 1 4-E-TS590

Sec

A250 T22 SA250 T22 3059-P2 762

4-E-TS610

Sec

A213 T5b SA213 T5b 3059-P2 304S51

4-E-TS690

A213 T5c SA213 T5c 3059-P2 306S51

A213 T17 SA213 T17 3059-P2 316S52

A213 T21 SA213 T21 3059-P2 316S51

A213 T23 SA213 T23 3059-P2 321S51

A213 T91 SA213 T91 3059-P2 347S51

A213 T92 SA213 T92 3059-P2 215S15

Steel Heat Exchanger Tubes for Low Temperature Service

ASTM ASME JIS G 3464 BS DIN ISO ABS NK LRS DNV

A334 1 SA334 1 STBL 380 3603 430LT 17173 TTst35N/V

17174 TTst35N/V

A334 3 SA334 3 STBL 450 3603 503LT 17173 10Ni14 2604 II TS43

A334 8 SA334 8 STBL 690 3603 509LT 17173 X8Ni9 2604 II TS45

A334 6 SA334 6 17173 26CrMo4

A334 7 SA334 7 17173 11MnNi53

17174 11MnNi53

A334 9 SA334 9 17173 13MnNi63

17174 13MnNi63

A334 11 SA334 11 17173 12Ni19

17174 12Ni19

A423 1 SA423 1 (17174 10Ni14)

A423 2 SA423 2 (17174 X8Ni9)

Steel Tubes for Fired Heater

ASTM ASME JIS G 3467 ABS NK LRS DNV

A210 A1 SA210 A1 STFA 10

A209 T1 SA209 T1 STFA 12

A213 T12 SA213 T12 STFA 22

A213 T11 SA213 T11 STFA 23

A213 T22 SA213 T22 STFA 24

A213 T5 SA213 T5 STFA 25

A213 T9 SA213 T9 STFA 26

Alloy Steel Tubes for Generator Boiler

ASTM ASME KA ABS NK LRS DNV

KA-STBA 21

A213 T23 SA213 T23 KA-STBA 24J1

A213 T91 SA213 T91 KA-STBA 28

Carbon Steel Pipes for Pressure Service

ASTM ASME JIS G 3454 BS DIN ISO ABS NK LRS DNV

A53 A SA53 A STPG 370 3601 320 1626 ust37.0 2604 II TW4 ABS 2 KSTPG 38 Sec 2 320 Sec 4-B-TS360

2604 III TS4 Sec 2 360

A135 A SA135 A 3601 360 1626 st37.0 2604 II TS5 ABS 8 Sec 3 320 Sec 4-B-TW360

2604 III TW5 Sec 3 360

1629 st37.0 2604 II TS6

2604 III TW6

A53 B SA53 B STPG 410 3601 430 1626 st44.0 2604 II TS9 ABS 3 KSTPG 42 Sec 2 410 Sec 4-B-TS410

2604 III TW9 Sec 4-B-TW410

A135 B SA135 B 1629 st44.0 2604 II TS10 ABS 9 Sec 3 410 Sec 4-B-TS430

2604 III TW10 Sec 4-B-TW430

1626 st52.0 2604 II TS13 Sec 2 460 Sec 4-B-TS500

2604 III TW13 Sec 4-B-TW500

1629 st52.0 2604 II TS14 Sec 2 490

2604 III TW14 Sec 3 460

Carbon Steel Pipes for High Pressure Service

ASTM ASME JIS G 3455 BS DIN ISO ABS NK LRS DNV

STS 370 1630 st37.4 KSTS 38

STS 410 1630 st44.4 2604 II TS15 KSTS 42

STS 480 1630 st52.4 2604 II TS18 KSTS 49

Carbon Steel Pipes for High Temperature Service

ASTM ASME JIS G 3456 BS DIN ISO ABS NK LRS DNV

A106 A SA106 A STPT 370 3602 P1 360 17175 st35.8 ABS 4 KSTPT 38

17177 st37.8

A106 B SA106 B STPT 410 3602 P1 430 17175 st45.8 ABS 5 KSTPT 42

17177 st42.8

A106 C SA106 C STPT 480 3602 P1 500Nb 17175 17Mn4 KSTPT 49

17175 19Mn5

Alloy Steel Pipes for High Temperature Service

ASTM ASME JIS G 3458 BS DIN ISO ABS NK LRS

17175

A335 P1 SA335 P1 STPA 12 2604 II TS26 ABS 6 KSTPA 12

15Mo3

17177

2604 III TW26

15Mo3

A335 P2 SA335 P2 STPA 20 3604 P1 660 2604 II TS32 ABS 7

2604 III TW32

17175 Sec 2

A335 P12 SA335 P12 STPA 22 3604 P1 620-440 ABS 12 KSTPA 22

13CrMo44 1Cr 1/2Mo440

Sec 3

1Cr 1/2Mo440

A335 P11 SA335 P11 STPA 23 3604 P1 621 ABS 11 KSTPA 23

17175 Sec 2

A335 P22 SA335 P22 STPA 24 3604 P1 622 2604 II TS34 ABS 13 KSTPA 24

10CrMo910 2-1/4Cr1Mo410

A335 P5 SA335 P5 STPA 25 3604 P1 625 2604 III TS37 ABS 14

A335 P9 SA335 P9 STPA 26 3604 P1 629-470 2604 II TS38

17175 Sec 2

A335 P5b/P5c SA335 P5b/P5c 3604 P1 591 2604 II TS33

14MoV63 2-1/2Cr1Mo490

17175 Sec 2

A335 P15 SA335 P15 3604 P1 629-590 2604 II TS39

X20CrMoV12 1 /2Cr1/2Mo1/4V460

A335 P21 SA335 P21 3604 P1 762 2604 II TS40

A335 P91 SA335 P91

A335 P92 SA335 P92

Steel Pipes for Low Temperature Service

ASTM ASME JIS G 3460 BS DIN ISO ABS NK LRS DNV

Sec 4 Sec

A333 1 SA333 1 STPL 380 3603 430LT 17173 TTst35N ABS 1L KLP A

360 4-D-TS6

Sec

17173 TTst35V KLP B

4-D-TW6

Sec

A334 1 SA334 1 17174 TTst35N KLP C

4-D-TS10

Sec

17174 TTst35V

4-D-TW10

Sec 4 Sec

A333 3 SA333 3 STPL 450 3603 503LT 17173 10Ni14 2604 TS43 ABS 4L KLP 3

3.5Ni440 4-D-TS43

Sec 4 Sec

A333 8 SA333 8 STPL 690 3603 509LT 17173 X8Ni9 2604 TS45 ABS 5L KLP 9

9Ni690 4-D-TS45

Sec 4 Sec

A333 4, A334 3 SA333 4, SA334 3 17173 26CrMo4 ABS 2L KLP 2

410 4-D-TS15

Sec

4-D-TW15

Sec 4 Sec

A333 6, A334 6 SA333 6, SA334 6 17173 11MnNi53 ABS 3L

60 4-D-26CrMo4

Sec

17174 11MnNi53

4-D-TW43

Sec

A333 7, A334 7 SA333 7, SA334 7 17173 13MnNi63 ABS 6L

4-D-11MnNi53

Sec

17174 13MnNi63

4-D-TW45

Sec

A333 9, A334 8 SA333 9, SA334 8 17173 12Ni19

4-D-13MnNi63

17174 12Ni19

Sec

A333 10, A334 9 SA333 10, SA334 9 17174 10Ni14

4-D-12Ni19

A333 11, A334 11 SA333 11, SA334 11 17174 X8Ni9

Alloy Steel Pipes for Generator Piping

ASTM ASME KA BS DIN ISO ABS NK LRS DNV

A335 P23 SA335 P23 KA-STPA 24J1

A335 P91 SA335 P91 KA-STPA 28

Potrebbero piacerti anche

- PIPE AND TUBE - Comparison of SpecificationsDocumento4 paginePIPE AND TUBE - Comparison of Specificationsnate anantathatNessuna valutazione finora

- Tube ComparisonDocumento2 pagineTube ComparisonCong SonNessuna valutazione finora

- Tube and Pipe Material Comparison ChartDocumento2 pagineTube and Pipe Material Comparison Chartvalli rajuNessuna valutazione finora

- Class 125/250 Globe Type Silent Check ValveDocumento1 paginaClass 125/250 Globe Type Silent Check ValveNam ĐỗNessuna valutazione finora

- Material Standard Equivalent PDFDocumento5 pagineMaterial Standard Equivalent PDFpicnarukNessuna valutazione finora

- Tabela de Correlação de Normas PDFDocumento5 pagineTabela de Correlação de Normas PDFFABRICIONessuna valutazione finora

- Special Alloy Steel MaterialsDocumento8 pagineSpecial Alloy Steel Materialsbhavin178Nessuna valutazione finora

- Welding ConsumablesDocumento1 paginaWelding ConsumablesBalakumarNessuna valutazione finora

- Imp-Comparison of SpecificationsDocumento7 pagineImp-Comparison of SpecificationsKetan PatelNessuna valutazione finora

- Steel Grade Equivalency TableDocumento2 pagineSteel Grade Equivalency TableBudy GedhaBlackNessuna valutazione finora

- Astm A632 PDFDocumento5 pagineAstm A632 PDFgaminNessuna valutazione finora

- Material EquilentDocumento16 pagineMaterial EquilentShoaib JadoonNessuna valutazione finora

- Comparison of Steel Tube SpecificationsDocumento2 pagineComparison of Steel Tube SpecificationsDedy WahyudiNessuna valutazione finora

- Spring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)Documento4 pagineSpring Loaded Safety Valve: SRV1 (Open Bonnet) / SRV2 (Closed Bonnet)cmpuckNessuna valutazione finora

- Hyundai Welding Handbook (12th)Documento664 pagineHyundai Welding Handbook (12th)Patricia PoggiNessuna valutazione finora

- Technical Manual: VanessaDocumento7 pagineTechnical Manual: VanessaAnonymous LLLK3pqNessuna valutazione finora

- Astm A249 PDFDocumento5 pagineAstm A249 PDFgaminNessuna valutazione finora

- Breather Parts 18-04-2020Documento12 pagineBreather Parts 18-04-2020GUIDO ALONSO VASQUEZ QUIROZNessuna valutazione finora

- ASTM A688 Soldadura de Acero Austenitico PDFDocumento5 pagineASTM A688 Soldadura de Acero Austenitico PDFLeonardo RodriguezNessuna valutazione finora

- Ca 50 50Documento2 pagineCa 50 50Adrian MartinNessuna valutazione finora

- Summary-Costing Sheet For Shell & Tube Heat ExchangerDocumento19 pagineSummary-Costing Sheet For Shell & Tube Heat ExchangerAnonymous LKi1w1uNessuna valutazione finora

- Steel Plate Comparision PDFDocumento2 pagineSteel Plate Comparision PDFchandakweNessuna valutazione finora

- Stainless Steel Grade Composition ChartDocumento6 pagineStainless Steel Grade Composition Charteusufiqbal100% (1)

- SVT - Casting Valve-Compressed PDFDocumento32 pagineSVT - Casting Valve-Compressed PDFHoang Mai HoaNessuna valutazione finora

- Maganetic Material PDFDocumento2 pagineMaganetic Material PDFpremnath RNessuna valutazione finora

- Aluminium Radiator IndexDocumento39 pagineAluminium Radiator IndexArpit VermaNessuna valutazione finora

- Material Grades Match ChartDocumento3 pagineMaterial Grades Match ChartFiras BEN HMIDANessuna valutazione finora

- Material P Group Table 4 PDFDocumento1 paginaMaterial P Group Table 4 PDFshantilalNessuna valutazione finora

- Astrica Laboratories PVT LTD.Documento20 pagineAstrica Laboratories PVT LTD.mathesis-2Nessuna valutazione finora

- Metal Standard ConverterDocumento2 pagineMetal Standard ConverterRadaNessuna valutazione finora

- Equivalent ASTM MaterialDocumento21 pagineEquivalent ASTM MaterialStefanus Laga SubanNessuna valutazione finora

- Equivalent GradesDocumento37 pagineEquivalent GradesUmesh SakhareliyaNessuna valutazione finora

- EN# EN Name SAE UNS DIN Carbon SteelsDocumento16 pagineEN# EN Name SAE UNS DIN Carbon Steelsumesh sengarNessuna valutazione finora

- Farrisone: Home Notices Sales and Marketing Technical Documents Training Order InformationDocumento1 paginaFarrisone: Home Notices Sales and Marketing Technical Documents Training Order InformationAlexander Charry GiraldoNessuna valutazione finora

- Allowable Stress and Welding Efficiency TablesDocumento3 pagineAllowable Stress and Welding Efficiency TablesYuliana SyNessuna valutazione finora

- 1190 Materials SheetDocumento7 pagine1190 Materials SheetjacksonNessuna valutazione finora

- Hoshizaki Kmd-270aaDocumento29 pagineHoshizaki Kmd-270aaMua bán Đồ cũNessuna valutazione finora

- Material Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberDocumento3 pagineMaterial Specifications Tradename Astm Specification UNS Werkstoff DIN Barstock Forging Casting Diversity Rpa Key Pipe Fittings Number NumberErcan YilmazNessuna valutazione finora

- 6 - Material Substitution ListDocumento1 pagina6 - Material Substitution ListLeonardo SarriaNessuna valutazione finora

- Carbon Steel Seamless TubesDocumento8 pagineCarbon Steel Seamless TubesFahim AkhtarNessuna valutazione finora

- Comparison Table Between Steel Grades in GOST and Other Countries, International Standard. GOST Nearest Equivalents, GOST Steel Grade AnaloguesDocumento6 pagineComparison Table Between Steel Grades in GOST and Other Countries, International Standard. GOST Nearest Equivalents, GOST Steel Grade Analoguesdhineshbabu rNessuna valutazione finora

- Steel GradesDocumento12 pagineSteel GradesDidar Singh Thethi100% (1)

- Welding ProcessesDocumento28 pagineWelding ProcessesAnaswarpsNessuna valutazione finora

- JIS-ASTM contrast list of relative materials standardsDocumento1 paginaJIS-ASTM contrast list of relative materials standardsSrhosseini30% (1)

- Standard Allowable Stress Table: Material P No. UNS No. Allowable Stress, Ksi Min. Yield Stress, KsiDocumento2 pagineStandard Allowable Stress Table: Material P No. UNS No. Allowable Stress, Ksi Min. Yield Stress, KsiGospel OgwuNessuna valutazione finora

- Tabella Corrispondenza Acciai Inox: UNI 8317 EN 10088-2 DIN 17440 Aisi ASTM A240 BS 1449 pt2 AFNOR NFA35-573 JISDocumento1 paginaTabella Corrispondenza Acciai Inox: UNI 8317 EN 10088-2 DIN 17440 Aisi ASTM A240 BS 1449 pt2 AFNOR NFA35-573 JISMauro CostaNessuna valutazione finora

- GOST & OthersDocumento6 pagineGOST & OthersSuseprianus PatumbaNessuna valutazione finora

- Mounting BearingDocumento4 pagineMounting Bearingoka100% (1)

- Steel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardDocumento8 pagineSteel Grades For GB Standard - JIS Standard - ASTM Standard - DIN StandardElumalai Srinivasan75% (8)

- Sabater Fundimol Catalog p10 11Documento2 pagineSabater Fundimol Catalog p10 11Mario BarbarićNessuna valutazione finora

- Materials Data for Cyclic Loading: Low-Alloy SteelsDa EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsValutazione: 5 su 5 stelle5/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonDa EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNessuna valutazione finora

- Materials Data for Cyclic Loading: Cast and Welded MetalsDa EverandMaterials Data for Cyclic Loading: Cast and Welded MetalsNessuna valutazione finora

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysDa EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysValutazione: 1 su 5 stelle1/5 (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDa EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNessuna valutazione finora

- PED Universal AnalyzersDocumento132 paginePED Universal AnalyzersKarthikeyan ShanmugavelNessuna valutazione finora

- U.S. Department of Labor Occupational Safety and Health AdministrationDocumento71 pagineU.S. Department of Labor Occupational Safety and Health AdministrationSAYEDNessuna valutazione finora

- Safe Distance Stored Energy Calculator - Pneumatic TestingDocumento3 pagineSafe Distance Stored Energy Calculator - Pneumatic TestingKarthikeyan ShanmugavelNessuna valutazione finora

- Ship Loose Spools Packing DetailsDocumento2 pagineShip Loose Spools Packing DetailsKarthikeyan ShanmugavelNessuna valutazione finora

- ASME Section I and VIII-Div-1 Training Course OutlineDocumento2 pagineASME Section I and VIII-Div-1 Training Course OutlineKarthikeyan ShanmugavelNessuna valutazione finora

- Astm A565-1Documento4 pagineAstm A565-1MICHELNessuna valutazione finora

- Rietu To: TR TR Saving CurrentDocumento2 pagineRietu To: TR TR Saving CurrentKarthikeyan ShanmugavelNessuna valutazione finora

- H 2010Documento40 pagineH 2010Haotian DuanNessuna valutazione finora

- PED Universal AnalyzersDocumento132 paginePED Universal AnalyzersKarthikeyan ShanmugavelNessuna valutazione finora

- Pipe BendsDocumento23 paginePipe BendsabhisheknharanghatNessuna valutazione finora

- KT-100/ KT-200 Series Ultrasonic Thickness GaugesDocumento1 paginaKT-100/ KT-200 Series Ultrasonic Thickness GaugesKarthikeyan ShanmugavelNessuna valutazione finora

- Cooker ManualDocumento2 pagineCooker ManualKarthikeyan ShanmugavelNessuna valutazione finora

- Iob Service Charges 01012019Documento4 pagineIob Service Charges 01012019Karthikeyan ShanmugavelNessuna valutazione finora

- COMPARISON OF MATERIAL STANDARDS FOR TUBESDocumento1 paginaCOMPARISON OF MATERIAL STANDARDS FOR TUBESKarthikeyan ShanmugavelNessuna valutazione finora

- Sanicro 38 PDFDocumento4 pagineSanicro 38 PDFJose Luis Gomez Ortiz100% (1)

- Sanicro 38 PDFDocumento4 pagineSanicro 38 PDFJose Luis Gomez Ortiz100% (1)

- Itp PTTDocumento3 pagineItp PTTKarthikeyan ShanmugavelNessuna valutazione finora

- AISI 1015 Carbon Steel (UNS G10150) : Topics CoveredDocumento3 pagineAISI 1015 Carbon Steel (UNS G10150) : Topics CoveredKarthikeyan ShanmugavelNessuna valutazione finora

- X10CrMoVNb9 1 PropertiesDocumento2 pagineX10CrMoVNb9 1 PropertiesKarthikeyan ShanmugavelNessuna valutazione finora

- Ammonia Vaporizer ITPDocumento2 pagineAmmonia Vaporizer ITPKarthikeyan ShanmugavelNessuna valutazione finora

- China GB Plate (Update)Documento10 pagineChina GB Plate (Update)lipicolsmNessuna valutazione finora

- CH4 2 Welding Joint PreparationDocumento46 pagineCH4 2 Welding Joint PreparationMatija BušićNessuna valutazione finora

- Ammonia Vaporizer ITPDocumento2 pagineAmmonia Vaporizer ITPKarthikeyan ShanmugavelNessuna valutazione finora

- ITPDocumento2 pagineITPKarthikeyan Shanmugavel100% (1)

- IS: 73 - 1992 Paving Bitumen - SpecificationDocumento7 pagineIS: 73 - 1992 Paving Bitumen - SpecificationKarthikeyan Vedi83% (6)

- Empy Health PDFDocumento2 pagineEmpy Health PDFKarthikeyan ShanmugavelNessuna valutazione finora

- Us Navy Practical Guide Flame Bending PipeDocumento102 pagineUs Navy Practical Guide Flame Bending PipeBrian DohertyNessuna valutazione finora

- Flow Chart - QCDocumento2 pagineFlow Chart - QCKarthikeyan Shanmugavel100% (1)

- 1Cr2Mo MechanicalDocumento2 pagine1Cr2Mo MechanicalKarthikeyan ShanmugavelNessuna valutazione finora

- Heating Element ArticleDocumento10 pagineHeating Element ArticleFrea Kent-Dazze D'DrughiNessuna valutazione finora

- IR Inspection Program For Fired Heater Mechanical Integrity: New Product!Documento1 paginaIR Inspection Program For Fired Heater Mechanical Integrity: New Product!bazil17Nessuna valutazione finora

- Charles Law ExplainedDocumento3 pagineCharles Law ExplainedKaren May UrlandaNessuna valutazione finora

- The Effect of Different Alkalinity Levels On Litopenaeus Vannamei Reared With Bio Oc Technology (BFT)Documento17 pagineThe Effect of Different Alkalinity Levels On Litopenaeus Vannamei Reared With Bio Oc Technology (BFT)Manu MorpheusNessuna valutazione finora

- Polyisobutylene SuccinicamideDocumento9 paginePolyisobutylene Succinicamideperqs BeautyisjoyNessuna valutazione finora

- Protect and seal concrete floors with PAVIMYC HB 2/CDocumento6 pagineProtect and seal concrete floors with PAVIMYC HB 2/CDory KiblawiNessuna valutazione finora

- Novabrite RGB Full Color High Power Led Application Note: R&D CenterDocumento15 pagineNovabrite RGB Full Color High Power Led Application Note: R&D CenterVinu KumarNessuna valutazione finora

- Gas Sweetening TotalDocumento62 pagineGas Sweetening TotalMehdi AlizadNessuna valutazione finora

- S1 2016 330961 BibliographyDocumento6 pagineS1 2016 330961 BibliographyVelda KartikaswastiNessuna valutazione finora

- Chemical Composition of A Fountain Pen InkDocumento4 pagineChemical Composition of A Fountain Pen InkmynamecoolNessuna valutazione finora

- AVENDAÑO, Jay Russell A. Written Report PURUGGANAN, Stephanie Claire SISON, KellyDocumento4 pagineAVENDAÑO, Jay Russell A. Written Report PURUGGANAN, Stephanie Claire SISON, KellyKelly SisonNessuna valutazione finora

- Backup Rings Respaldo de OringsDocumento8 pagineBackup Rings Respaldo de OringsRPINILLA (EICO S.A.)Nessuna valutazione finora

- Corrosion Prevention and ControlDocumento19 pagineCorrosion Prevention and ControlJosa FatyNessuna valutazione finora

- JEE Main 2020 Question Paper Solutions 9 January MorningDocumento45 pagineJEE Main 2020 Question Paper Solutions 9 January MorningDishant ShahNessuna valutazione finora

- SemiconDocumento9 pagineSemiconRealyn PugayNessuna valutazione finora

- FINALDocumento16 pagineFINALdushyanth rajNessuna valutazione finora

- Date Planned: - / - / - Daily Tutorial Sheet-13 Expected Duration: 30 Min Actual Date of Attempt: - / - / - Level-3 Exact DurationDocumento1 paginaDate Planned: - / - / - Daily Tutorial Sheet-13 Expected Duration: 30 Min Actual Date of Attempt: - / - / - Level-3 Exact DurationShahina NasreenNessuna valutazione finora

- Methods For Diffusion Welding The Superalloy Udimet 700Documento9 pagineMethods For Diffusion Welding The Superalloy Udimet 700Enary SalernoNessuna valutazione finora

- Surface TensionDocumento25 pagineSurface TensionIshani Gupta100% (1)

- Psma411-Prelim ReviewerDocumento82 paginePsma411-Prelim ReviewerRebekah EquizNessuna valutazione finora

- Saudi Arabian Standard SASO-443E Plug Pin 220V TestDocumento21 pagineSaudi Arabian Standard SASO-443E Plug Pin 220V TestPusertif PengadaanNessuna valutazione finora

- Urine Analysis I: Chemical Examination: Lenka Fialová & Martin VejražkaDocumento9 pagineUrine Analysis I: Chemical Examination: Lenka Fialová & Martin VejražkaGeffrey S. QuilalaNessuna valutazione finora

- Ultraviolet RaysDocumento17 pagineUltraviolet RaysZUBAIR SHAHNessuna valutazione finora

- API Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Documento5 pagineAPI Gravity of Crude Petroleum and Petroleum Products (Hydrometer Method)Luis Ernesto Marin JaimesNessuna valutazione finora

- High Resolution HAADF Characterization of IrTiO2 Reduced at 500C - Orlando HernándezDocumento7 pagineHigh Resolution HAADF Characterization of IrTiO2 Reduced at 500C - Orlando HernándezOr HdezNessuna valutazione finora

- Astm D 388Documento6 pagineAstm D 388Julian MonroyNessuna valutazione finora

- Special Fiber Optic PDFDocumento18 pagineSpecial Fiber Optic PDFtarluzNessuna valutazione finora

- M MLV Reverse Transcriptase ProtocolDocumento2 pagineM MLV Reverse Transcriptase ProtocolSergio HernandezNessuna valutazione finora

- Chapter 2-The Column in GCDocumento92 pagineChapter 2-The Column in GCkhanhvan2105Nessuna valutazione finora

- Glyphosate Goker MSDS 1Documento7 pagineGlyphosate Goker MSDS 1Bima SitorusNessuna valutazione finora