Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

M147

Caricato da

FRANZ RICHARD SARDINAS MALLCOCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

M147

Caricato da

FRANZ RICHARD SARDINAS MALLCOCopyright:

Formati disponibili

M 147 SPECIFICATIONS FOR MATERIALS

Standard Specification for

Materials for Aggregate and Soil-Aggregate Subbase, Base and Surface Courses

AASHTO DESIGNATION: M 147-65

1. SCOPE fraction passing the 0.425-mm sieve shall and 3 for gradings C, D, E, or F. The

have a liquid limit not greater than 25 and gradings desired shall be specified.

a plasticity index not greater than 6.

1.1 This specification covers the quality NOTE 4-Where it is planned that the soil

and grading of sand-clay mixtures; 2.3 All material shall be free from aggregate surface course is to be maintained

gravel, stone or slag screenings; or sand, vegetable matter and lumps or balls of for several years without bituminous surface

clay. The soil-aggregate material shall treatment or other superimposed impervious

crusher run coarse aggregate consisting

conform to the grading requirements of surfacing, the engineer should specify a

of gravel, crushed stone or slag with or minimum of 8 percent passing 0.075mm (Nº

without soil mortar or any combination of Table 1. The grading requirements for

200) sieve in lieu of the minimum percentages

these materials for use in the construction composite aggregate material will be shown in Table 1 for grading C, D, or E, and

of subbase, base and surface courses. The specified by the engineer. should specify a maximum liquid limit of 35

requirements are intended to cover only and plasticity index range of 4 to 9 in lieu of

materials having normal or average the limits given in Section 2.2.2.

3. SUBBASE MATERIALS

specific gravity, absorption and gradation

characteristics. Where other materials are 6. MOISTURE CONTENT

to be used, appropriate limits suitable to 3.1 Materials for subbase shall conform

their use must be specified. to the requirements of sections 2 and 3

1.2 The values stated SI units are to be for gradings, A, B, C, D, E. or F. The 6.1 All materials shall contain moisture

regarded as the standard. type and grading desired shall be equal to or slightly below the optimum

specified. necessary to insure that the design

NOTE 2-Where local experience has shown

density requirements are obtained when

2. GENERAL REQUIREMENTS that lower percentages passing the 0.075-mm materials are compacted.

(Nº 200) sieve than are required in Table 1 are

necessary for subbase materials in order to

2.1 Coarse Aggregate: 7. ADMIXTURE

prevent damage by frost action, the engineer

2.1.1 Coarse aggregate retained on the should specify such lower percentages.

2.00-mm (Nº 10) sieve shall consist of 7.1 Calcium chloride used for the control

hard, durable particles or fragments of of moisture shall meet the requirements

stone, gravel or slag. Materials that break 4. BASE COURSE MATERIALS of Standard Specifications for Calcium

up when alternately frozen and thawed or Chloride (AASHTO M 144).

wetted and dried shall not be used.

4.1 Materials for base course shall

2.1.2 Coarse aggregate shall have a conform to the requirements of section 2

percentage of wear, by the Los Angeles 8. METHODS OF SAMPLING AND

for gradings A, B, C, D, E, or F. The

test, AASHTO T 96, of not more than 50. TESTING

grading desired shall be specified.

NOTE 1-A higher or lower percentage of NOTE 3-Where local experience has shown

wear may be specified by the engineer, that lower percentages passing the 0.075-mm 8.1 Sampling and testing shall be in

depending upon the materials available for the (Nº 200) sieve than are required in Table 1 are accordance with the following standard

work. necessary for base course materials in order to methods of the American Association of

prevent damage by frost action, the engineer State Highway and Transportation

2.2 Fine Aggregate: should specify such lower percentages. Officials:

2.2.1 Fine aggregate passing the 2.00- Sampling T2

mm (Nº 10) sieve shall consist of natural Sieve analysis T 27 or T 88

or crushed sand, and fine mineral 5. SURFACE COURSE Surveying and sampling soils for

particles passing the 0.075-mm (Nº 200) MATERIALS highway subgrades T 86

sieve. Preparing samples T 87

Liquid limit T 89

2.2.2 The fraction passing the 5.1 Materials for surface course shall Plastic limit and plasticity index T 90

0.075mm (Nº 200) sieve shall not be conform to the requirements of sections 2 Percentage of wear T 96

greater than two-thirds of the fraction Passing 0.075-mm (Nº 200 sieve) T 11

passing the 0.425-mm (Nº 40) sieve. The

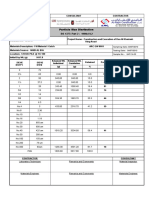

TABLE 1 Grading Requirements for Soil-Aggregate Materials

Sieve Designation Mass Percent Passing

Standard mm Alternate Grading A Grading B Grading C Grading D Grading E Grading F

50.0 2 in. 100 100 - - - -

25.0 1 in. - 75-95 100 100 100 100

9.5 1/8 in. 30-65 40-75 50-85 60-100 - -

4.75 Nº 4 25-55 30-60 35-65 50-85 55-100 70-100

2.00 Nº 10 15-40 20-45 25-50 40-70 40-100 55-100

0.425 Nº 40 8-20 15-30 15-30 25-45 20-50 30-70

0.075 Nº 200 2-8 5-20 5-15 5-20 6-20 8-25

111

Potrebbero piacerti anche

- ASTM D6926 Standard Practice For Preparation of Asphalt Mixture Specimens Using Marshall ApparatusDocumento8 pagineASTM D6926 Standard Practice For Preparation of Asphalt Mixture Specimens Using Marshall ApparatusRafael EstradaNessuna valutazione finora

- Wis 4 08 02 PDFDocumento6 pagineWis 4 08 02 PDFbkarabasevicNessuna valutazione finora

- Is2720 Part09Documento6 pagineIs2720 Part09anvesh_kumar_16Nessuna valutazione finora

- ACI 325.10R-95: Reported by ACI Committee 325Documento32 pagineACI 325.10R-95: Reported by ACI Committee 325edgomurNessuna valutazione finora

- Astm C845 PDFDocumento3 pagineAstm C845 PDFJohn Richard NelsonNessuna valutazione finora

- Construction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsDocumento7 pagineConstruction and Execution of Ras Al Khaimah Ring Road Fill Material Particle Size and Compaction Test ResultsamesbNessuna valutazione finora

- Base Course Aggregates StandardsDocumento5 pagineBase Course Aggregates Standardsprobook450_ehsanNessuna valutazione finora

- (BS 1881-124) - Testing Concrete. Part 124. Methods For Analysis of Hardened Concrete PDFDocumento45 pagine(BS 1881-124) - Testing Concrete. Part 124. Methods For Analysis of Hardened Concrete PDFsidiq733% (3)

- C94C94M-15 Standard Specification For Ready-Mixed Concrete PDFDocumento14 pagineC94C94M-15 Standard Specification For Ready-Mixed Concrete PDFdiego rodriguezNessuna valutazione finora

- ACI 116R Admixture Effects Setting TimeDocumento3 pagineACI 116R Admixture Effects Setting TimeRavi Ayyavu100% (1)

- ASTM C 260 Standard Specification For Air-Entraining Admixtures For ConcreteDocumento3 pagineASTM C 260 Standard Specification For Air-Entraining Admixtures For ConcreteRyan LasacaNessuna valutazione finora

- ASTM D 1557 - 02 Proctor ModificadoDocumento10 pagineASTM D 1557 - 02 Proctor ModificadoPaolaNessuna valutazione finora

- M 80-87 (2003) Coarse Aggregate For PCCDocumento5 pagineM 80-87 (2003) Coarse Aggregate For PCCWalticoZegarraHerrera100% (1)

- C595C595M.20555 Blended Hydraulic CementsDocumento8 pagineC595C595M.20555 Blended Hydraulic CementsSabine Alejandra Kunze HidalgoNessuna valutazione finora

- Astm C76M-16Documento12 pagineAstm C76M-16bestoon RamadhanNessuna valutazione finora

- AASHTO Testing ProceduresDocumento224 pagineAASHTO Testing Proceduresmudassirbaqer979Nessuna valutazione finora

- BS 812-109 1990 (Moisture Content)Documento12 pagineBS 812-109 1990 (Moisture Content)Kartika Setia RiniNessuna valutazione finora

- ASTM C94 C94M Standard Specification For Ready-Mixed ConcreteDocumento1 paginaASTM C94 C94M Standard Specification For Ready-Mixed ConcreteAmanda Ariesta ApriliaNessuna valutazione finora

- Previews-ACI 301 10 PreDocumento4 paginePreviews-ACI 301 10 PreAroldo Vega Urriola40% (5)

- ACI 301 Specifications UpdateDocumento33 pagineACI 301 Specifications Updateeros100% (1)

- Soil testing methods guideDocumento2 pagineSoil testing methods guideDr Wong Kim YuenNessuna valutazione finora

- M 43-05 Aggregate For Road & Bridge ConstructionDocumento2 pagineM 43-05 Aggregate For Road & Bridge ConstructionWalticoZegarraHerreraNessuna valutazione finora

- Highway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsDocumento75 pagineHighway Materials Manual: Kingdom of Saudi Arabia Ministry of CommunicationsAyman KandeelNessuna valutazione finora

- Astm C33 C33M-16Documento11 pagineAstm C33 C33M-16haval100% (2)

- BS 6076.1996Documento19 pagineBS 6076.1996Yaser Al ShabasyNessuna valutazione finora

- Astm C869-91 PDFDocumento7 pagineAstm C869-91 PDFAlfonso PatuktokNessuna valutazione finora

- BS 6717 - 2001Documento34 pagineBS 6717 - 2001Ahmad Khreisat100% (1)

- Aci 221R-96Documento3 pagineAci 221R-96farhadamNessuna valutazione finora

- Astm c33Documento11 pagineAstm c33Kiko Nobre100% (1)

- Graded Aggregate Material For Bases or Subbases For Highways or AirportsDocumento3 pagineGraded Aggregate Material For Bases or Subbases For Highways or AirportsNyimas Febrika100% (1)

- SoilsDocumento180 pagineSoilsAyman KandeelNessuna valutazione finora

- Bs12 PDFDocumento15 pagineBs12 PDFraed waheebNessuna valutazione finora

- Soil Worksheets (OSAF22)Documento120 pagineSoil Worksheets (OSAF22)Lloyd R. Ponce100% (1)

- ACI 301 05 SpecsDocumento4 pagineACI 301 05 Specsnb_6049755660% (1)

- British Standard Mixing Water For ConcreteDocumento23 pagineBritish Standard Mixing Water For ConcreteDaniela GonzalezNessuna valutazione finora

- Concrete 70TMSS03R1Documento38 pagineConcrete 70TMSS03R1azeemmet9924Nessuna valutazione finora

- Aashto T26Documento2 pagineAashto T26filipe33% (6)

- M 82-75 (2004) Cutback Asphalt (MC Type)Documento2 pagineM 82-75 (2004) Cutback Asphalt (MC Type)WalticoZegarraHerrera100% (1)

- Rocker Pipe PDFDocumento8 pagineRocker Pipe PDFMahmoud GwailyNessuna valutazione finora

- Astm D25-12Documento8 pagineAstm D25-12Kim Kenneth AsiaNessuna valutazione finora

- Aashto T 99-81Documento7 pagineAashto T 99-81ORUSNessuna valutazione finora

- Properties Concrete Dune SandDocumento6 pagineProperties Concrete Dune SandAlanSamNessuna valutazione finora

- Aashto T 84Documento10 pagineAashto T 84alicarlos1350% (2)

- 02525Documento3 pagine02525uddinnadeem0% (1)

- Reclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForDocumento5 pagineReclamation of Recycled Aggregate Base (RAB) Material: Standard Practice ForRed RedNessuna valutazione finora

- ACI Manual ListingsDocumento6 pagineACI Manual ListingswikoboyNessuna valutazione finora

- Proportioning Concrete Mixtures With Graded AggregatesDocumento86 pagineProportioning Concrete Mixtures With Graded AggregatesM HAFEEZ RAJA100% (1)

- Quality Management System For Concrete Construction: ACI 121R-04Documento33 pagineQuality Management System For Concrete Construction: ACI 121R-04askarah100% (1)

- Optimal Mix Design For Pervious ConcreteDocumento9 pagineOptimal Mix Design For Pervious ConcretejanakarajNessuna valutazione finora

- 05-15 QCS 2014Documento14 pagine05-15 QCS 2014Raja Ahmed Hassan100% (2)

- M 195-06 Lightweight Aggregates PDFDocumento6 pagineM 195-06 Lightweight Aggregates PDFWalticoZegarraHerreraNessuna valutazione finora

- ASTM C 305 Standard Practice For Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic ConsistencyDocumento3 pagineASTM C 305 Standard Practice For Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic ConsistencyPaola Vargas100% (1)

- Unbound Aggregates in RoadsDa EverandUnbound Aggregates in RoadsR.H. JonesNessuna valutazione finora

- Supervising Highway Engineer: Passbooks Study GuideDa EverandSupervising Highway Engineer: Passbooks Study GuideNessuna valutazione finora

- M 147Documento2 pagineM 147Katerin HernandezNessuna valutazione finora

- D1241-07 Standard Specification For Materials For Soil-Aggregate Subbase, Base, and Surface CoursesDocumento3 pagineD1241-07 Standard Specification For Materials For Soil-Aggregate Subbase, Base, and Surface CoursesAlabbas FadhelNessuna valutazione finora

- M 147-65 (2004) Materials For Aggregate Soil-Agg SB B & SCDocumento3 pagineM 147-65 (2004) Materials For Aggregate Soil-Agg SB B & SCFranz Richard Sardinas MallcoNessuna valutazione finora

- Cement Pavement Aeronautics - P-304 - 282161 - 7Documento5 pagineCement Pavement Aeronautics - P-304 - 282161 - 7Mog GomNessuna valutazione finora

- Precast Reinforced Concrete Box Sections For Culverts, Storm Drains, and Sewers With Less Than 2 FT of Cover Subjected To Highway LoadingsDocumento8 paginePrecast Reinforced Concrete Box Sections For Culverts, Storm Drains, and Sewers With Less Than 2 FT of Cover Subjected To Highway LoadingsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Evaluating Blast Cleaned Steel SurfacesDocumento1 paginaEvaluating Blast Cleaned Steel SurfacesFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Structural Steel For BridgesDocumento6 pagineStructural Steel For BridgesFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Steel Sheet, Metallic-Coated and Polymer Precoated For Corrugated Steel PipeDocumento3 pagineSteel Sheet, Metallic-Coated and Polymer Precoated For Corrugated Steel PipeFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Corrugated polyethylene drainage tubing specsDocumento4 pagineCorrugated polyethylene drainage tubing specsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Retroreflective Sheeting For Traffic Control: M 268 Specifications For MaterialsDocumento1 paginaRetroreflective Sheeting For Traffic Control: M 268 Specifications For MaterialsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Precast Concrete Box Culvert SpecificationsDocumento14 paginePrecast Concrete Box Culvert SpecificationsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Plain and Laminated Elastomeric Bridge Bearings: Standard Specification ForDocumento4 paginePlain and Laminated Elastomeric Bridge Bearings: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Acrylonitrile-Butadiene-Styrene (ABS) and Poly (Vinyl Chloride) (PVC) Composite Sewer PipingDocumento1 paginaAcrylonitrile-Butadiene-Styrene (ABS) and Poly (Vinyl Chloride) (PVC) Composite Sewer PipingFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Standard Tire For Pavement Frictional Property TestsDocumento3 pagineStandard Tire For Pavement Frictional Property TestsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Corrosion resistant coated dowel bar specificationsDocumento2 pagineCorrosion resistant coated dowel bar specificationsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- White and Yellow Reflective Thermoplastic Striping Material (Solid Form)Documento2 pagineWhite and Yellow Reflective Thermoplastic Striping Material (Solid Form)FRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Heat-Treated Steel Structural Bolts, 150 Ksi Minimum Tensile StrengthDocumento1 paginaHeat-Treated Steel Structural Bolts, 150 Ksi Minimum Tensile StrengthFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- M253MDocumento1 paginaM253MFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- M259MDocumento14 pagineM259MFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Steel Bars, Carbon, Hot-Wrought,. Special Quality, Mechanical PropertiesDocumento3 pagineSteel Bars, Carbon, Hot-Wrought,. Special Quality, Mechanical PropertiesFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Flow table specifications for testing hydraulic cementDocumento4 pagineFlow table specifications for testing hydraulic cementFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Granular Material To Control Pumping Under Concrete PavementDocumento1 paginaGranular Material To Control Pumping Under Concrete PavementFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- M242MDocumento5 pagineM242MFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Field Applied Coating of Corrugated Metal Structural Plate For Pipe, Pipe-Arches, and ArchesDocumento2 pagineField Applied Coating of Corrugated Metal Structural Plate For Pipe, Pipe-Arches, and ArchesFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Distillation Equipment: M 191 Specifications For MaterialsDocumento1 paginaDistillation Equipment: M 191 Specifications For MaterialsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Ready-Mixed White and Yellow Traffic Paints: Standard Specification ForDocumento3 pagineReady-Mixed White and Yellow Traffic Paints: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer PipeDocumento4 pagineReinforced Concrete D-Load Culvert, Storm Drain, and Sewer PipeFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Specifications for Materials M 262Documento2 pagineSpecifications for Materials M 262FRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- High-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingDocumento2 pagineHigh-Yield-Strength, Quenched and Tempered Alloy Steel Plate, Suitable For WeldingFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Concrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForDocumento6 pagineConcrete Made by Volumetric Batching and Continuous Mixing: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Liquid Membrane-Forming Compounds For Curing ConcreteDocumento2 pagineLiquid Membrane-Forming Compounds For Curing ConcreteFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Precast Reinforced Concrete Manhole Sections: Standard Specification ForDocumento5 paginePrecast Reinforced Concrete Manhole Sections: Standard Specification ForFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Corrugated Steel Pipe, Polymer Precoated, For Sewers and DrainsDocumento9 pagineCorrugated Steel Pipe, Polymer Precoated, For Sewers and DrainsFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- SPEC-40: Standard Specification for Preformed Sponge Rubber and Cork Expansion Joint FillersDocumento2 pagineSPEC-40: Standard Specification for Preformed Sponge Rubber and Cork Expansion Joint FillersFRANZ RICHARD SARDINAS MALLCONessuna valutazione finora

- Soil Erosion ProcessesDocumento3 pagineSoil Erosion ProcessesGaurav MallaNessuna valutazione finora

- Expansive Soils TreatmentDocumento13 pagineExpansive Soils Treatmentbkollarou9632Nessuna valutazione finora

- Difference Between Sand and SoilDocumento3 pagineDifference Between Sand and Soillakshmi psNessuna valutazione finora

- EXERCISE 10 Organic Matter DecompositionDocumento3 pagineEXERCISE 10 Organic Matter DecompositionKobe Conrad AbelleraNessuna valutazione finora

- TMW22 - Evaluation of Flow Liquefaction Susceptibility and Liquefied Strength - A Case StudyDocumento12 pagineTMW22 - Evaluation of Flow Liquefaction Susceptibility and Liquefied Strength - A Case StudyMauro P Dos Santos JuniorNessuna valutazione finora

- Itp - RoadDocumento5 pagineItp - RoadBiswajit BarikNessuna valutazione finora

- Eals Lesson 3 RocksDocumento45 pagineEals Lesson 3 RocksMishi Nicole LeonardoNessuna valutazione finora

- Factors Affecting Soil ErosionDocumento2 pagineFactors Affecting Soil ErosionYousufain FarazNessuna valutazione finora

- Case Studies in Construction MaterialsDocumento12 pagineCase Studies in Construction MaterialsArham SheikhNessuna valutazione finora

- Hp02ver Endmember AbbreviationsDocumento4 pagineHp02ver Endmember AbbreviationslinkyashuNessuna valutazione finora

- A.V. Watkins Dam Modification Cement-Bentonite Slurry Cutoff WallDocumento13 pagineA.V. Watkins Dam Modification Cement-Bentonite Slurry Cutoff WallMUHAMMAD ALINessuna valutazione finora

- 12 Metamorphic RocksDocumento36 pagine12 Metamorphic RocksAryan YadavNessuna valutazione finora

- ELS - Q1 - Summative Test 1Documento8 pagineELS - Q1 - Summative Test 1Shekaina Faith Cuizon LozadaNessuna valutazione finora

- Geotechnical Engineering ReportDocumento25 pagineGeotechnical Engineering ReportAbdullah YucesoyNessuna valutazione finora

- Process Design Manual For Land Treatment of Municipal WastewaterDocumento488 pagineProcess Design Manual For Land Treatment of Municipal WastewaterihllhmNessuna valutazione finora

- Soil Conservation MeasuresDocumento16 pagineSoil Conservation MeasuresPradeep YadavNessuna valutazione finora

- DLL Science-5 Q4 W3Documento15 pagineDLL Science-5 Q4 W3cristina quiambaoNessuna valutazione finora

- Price List April 2012 - March 2013Documento15 paginePrice List April 2012 - March 2013Sajjad Amin AminNessuna valutazione finora

- Chapter 6 - Sediment and Sedimentary Rocks PDFDocumento45 pagineChapter 6 - Sediment and Sedimentary Rocks PDFmahmoud alawnehNessuna valutazione finora

- Soil Moisture Conservation in Dry Land AgricultureDocumento5 pagineSoil Moisture Conservation in Dry Land AgricultureInternational Journal of Innovative Science and Research TechnologyNessuna valutazione finora

- Garden Loam Potting Soil: John Innes Potting CompostDocumento5 pagineGarden Loam Potting Soil: John Innes Potting CompostHRuEsqNessuna valutazione finora

- معادلات وجداول الكورس الثانيDocumento4 pagineمعادلات وجداول الكورس الثانيMaherNessuna valutazione finora

- Soil Stabilization From Mechanical MethodsDocumento21 pagineSoil Stabilization From Mechanical MethodslazamNessuna valutazione finora

- Chapter 1.4Documento11 pagineChapter 1.4Gie AndalNessuna valutazione finora

- Overturning Resistant Moment Calculation of Directly Burried PoleDocumento5 pagineOverturning Resistant Moment Calculation of Directly Burried PoleALEX BNessuna valutazione finora

- Guidelines for characterising rock massesDocumento48 pagineGuidelines for characterising rock massesTJ NolascoNessuna valutazione finora

- GEOTECHNICAL INVESTIGATION REPORT - Proposed Construction of 13-Storey Green and Iconic Office Building With Roof DeckDocumento21 pagineGEOTECHNICAL INVESTIGATION REPORT - Proposed Construction of 13-Storey Green and Iconic Office Building With Roof DeckMinh Tâm TrầnNessuna valutazione finora

- Geotechnical Investigation Report: Date of Test: 18.09.2020 TO 19.09.2020Documento23 pagineGeotechnical Investigation Report: Date of Test: 18.09.2020 TO 19.09.2020Koustav MajumdarNessuna valutazione finora

- Economical Mixing Method For Cement Deep MixingDocumento10 pagineEconomical Mixing Method For Cement Deep MixingJonathan M.Nessuna valutazione finora

- Soil Properties for LPILE & COM624P AnalysisDocumento2 pagineSoil Properties for LPILE & COM624P Analysiswaleed4631100% (1)