Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Tungsten Slip Traces Revealed by In-Situ Microcompression

Caricato da

MartinAlfonsTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Tungsten Slip Traces Revealed by In-Situ Microcompression

Caricato da

MartinAlfonsCopyright:

Formati disponibili

OPEN {110} Slip with {112} slip traces in bcc

SUBJECT AREAS:

Tungsten

MECHANICAL Cecile Marichal1,2, Helena Van Swygenhoven1,2, Steven Van Petegem1 & Camelia Borca3

PROPERTIES

CHARACTERIZATION AND

1

ANALYTICAL Materials Science and Simulation, NUM/ASQ, Paul Scherrer Institut, CH-5232 Villigen PSI, Switzerland, 2Neutrons and X-rays for

TECHNIQUES Mechanics of Materials, IMX, École Polytechnique Fédérale de Lausanne, CH-1012 Lausanne, Switzerland, 3Beamline MicroXAS,

Paul Scherrer Institut, CH-5232 Villigen PSI, Switzerland.

Received

24 July 2013 While propagation of dislocations in body centered cubic metals at low temperature is understood in terms

of elementary steps on {110} planes, slip traces correspond often with other crystallographic or

Accepted non-crystallographic planes. In the past, characterization of slip was limited to post-mortem electron

1 August 2013 microscopy and slip trace analysis on the sample surface. Here with in-situ Laue diffraction experiments

during micro-compression we demonstrate that when two {110} planes containing the same slip direction

Published experience the same resolved shear stress, sharp slip traces are observed on a {112} plane. When however the

30 August 2013 {110} planes are slightly differently stressed, macroscopic strain is measured on the individual planes and

collective cross-slip is used to fulfill mechanical boundary conditions, resulting in a zig-zag or broad slip

trace on the sample surface. We anticipate that such dynamics can occur in polycrystalline metals due to

Correspondence and local inhomogeneous stress distributions and can cause unusual slip transfer among grains.

requests for materials

D

should be addressed to islocations are line defects in a crystal characterized by their slip plane, their Burgers vector and the

H.V.S. (helena. orientation of the Burgers vector relative to the dislocation line. In metals with a face centered crystal

vanswygenhoven@psi. lattice (fcc) the strain field of dislocations is confined in a {111} plane and the resistance to glide, the

ch) Peierls-Nabarro resistance1,2, is small. Dislocation response to stress is easy predictable and usually controlled by

the resolved shear stress on the slip plane as described by Schmid’s law3. That is why computational models for fcc

plasticity experienced enormous progress in the last decennia.

The body-centered cubic crystal lattice (bcc) has no real closed packed planes and the strain field of screw

dislocations is non-planar4. Dislocation slip depends on the loading axis and the sense of shearing in the

crystallographic plane. The nature of this anisotropy is still under debate. Slip has been reported in pure metals

on {110} and {112} planes5–8. Many particular aspects of the deformation characteristics in bcc metals are ascribed

to the 3-dimensional core structure of screw dislocations, which is consequently anchored in the lattice9,10. Most of

the details on the core structure of screw and on the slip mechanisms are obtained from atomistic simulations4,11–15

revealing aspects such as the role of stresses other than the resolved shear stress that break the symmetry of the

core structure16 or the role of other particular orientations corresponding with a high Peierls stress17. These new

aspects form important input for higher-lengthscale models such as discrete dislocation simulation models used to

investigate the yield and plastic behavior of a bcc single crystal17–22. So far, these computational efforts have

provided much more details than what currently has been validated experimentally, but the extrapolation towards

larger lengthscales remains difficult because of a lack in understanding of the full dynamic picture of dislocation

plasticity.

It is now generally believed that a screw dislocation moves in the lattice potential by thermal activated

nucleation of a pair of kinks in {110} crystal planes23, bringing a segment of the dislocation over the potential

hill of the lattice. The kinks can rapidly propagate in the ,111. direction along the dislocation line advancing the

whole dislocation to the next equilibrium Peierls valley9,10. An open questions is whether a {112} slip trace on the

surface of a crystal results from a composition of slip on several{110} planes.

For instance, consider uniaxial compression performed at room temperature along a crystallographic direction

[155]. Figure 1a shows the compression axis in stereographic projection together with some crystallographic

directions and the projections of the normal of crystallographic planes of interest. In this orientation, the Schmid

factor m, which relates the resolved shear stress for a particular slip system to the applied stress, equals its maximal

value of 0.5 for slip on the (211) plane in the [1-1-1] direction, meaning that the resolved shear stress is highest on

the (211) plane. The (101) and (110) planes are the planes of the {110} family that have the highest Schmid values,

for both m 5 0.43, in the same [1-1-1] direction. Assuming that elementary slip occurs on {110} planes, screw

dislocations will propagate in this loading direction with equal amounts of elementary steps on the (101) and

SCIENTIFIC REPORTS | 3 : 2547 | DOI: 10.1038/srep02547 1

www.nature.com/scientificreports

100

a b

211

110

211

c

101

211

111

112

122

256

155

011

001

012

010 d

211

-111

Figure 1 | Presentation of the [155] and [256] compression axis in stereographic projection (a); schematic presentation of elementary slip steps on

(110) and (101) in equal portions (b), in elementary steps proportional to the resolved shear stress (c) and producing macroscopic slip on the

individual (110) and (101) planes (d).

(110) plane, as is schematically presented in Figure 1b. When reach- Results

ing the surface of the sample, the slip trace would be composed of Compression along the [155] axis confirms that slip can be described

elementary {110} steps that are experimentally however not observ- with elementary steps on {110} planes. Figure 2a provides the stress-

able. What can be measured is the averaged orientation of the slip strain curve obtained from a pillar with a diameter of 1.9 mm. The

trace, which corresponds in this orientation with the (211) plane6,7,24. numbers figuring on the plot correspond with snapshots of Laue

For an orientation of the compression axis slightly different such diffraction patterns taken continuously during the load. The scatter

as [256], keeping the Schmid factor highest (m 5 0.49) for the (211) on the stress-strain curve is due to the open-air working conditions,

plane but slightly different for the (101) and (110), respectively m 5 which is required for operating in-situ.

0.45 and m 5 0.39, one assumes elementary steps on each plane Figure 2b shows the (-3-10) Laue reflection before deformation.

occurring proportional to the ratio of the Schmid factors, as schem- The projected lines correspond with the expected rotation directions

atically presented in Figure 1c. This is the common philosophy for slip on particular crystallographic planes. Figure 2c shows the

behind the interpretation of slip traces observed on the surface of path followed by the center of mass of the (-3-10) reflection in

single crystals but there are no experiments reported in these orien- detector units during compression; the numbers correspond with

tations confirming the above concept behind the interpretation of those shown on the stress-strain curve in Figure 2a. During the elastic

slip traces. In the past, experiments were mainly limited to surface loading the peak moves away from its initial position. This rotation is

slip trace analysis and post-mortem transmission electron micro- caused by elastic distortion of the crystal and accommodation

scopy (TEM). Today’s advanced in-situ techniques can however go between the pillar top and the compression anvil. Load-unload

further. experiments formerly carried out on pillars with similar diameter

Here we use micro-compression testing during in-situ Laue dif- demonstrated that after unloading peak broadening and position

fraction performed on single crystal tungsten (W) pillars in different recover entirely when the load in these pillars did not exceed

crystallographic orientations. Since Tc equals 527uC in tungsten25, 600 MPa (pattern 30). Taking into account all other reflections

experiments performed at room temperature are far below the crit- and using the Taylor model, the movement of the Laue spots corre-

ical temperature. For details on the setup we refer to Methods section. sponds with a rotation of 0.50 degree around the [211] direction.

Laue diffraction is very sensitive to changes in orientation of the Upon further rotation, the path of the Laue spot stays clearly parallel

crystal planes26–29. During micro-compression experiments, the sin- to the rotation direction for slip on the (211) plane which also corre-

gle crystal pillar is constrained during the load. Consequently, the sponds with that for composed slip on (101) and (110). This path is

planes where the dislocations are moving are rotating to accommod- rather smooth and up to pattern 40 no individual jumps are

ate the stress21. During elastic loading, minor rotation can be observed. Between pattern 40 and 58 some of the steps can be also

observed due to distortion of the unit cell. During plastic deforma- assigned to an excess of slip on one of the {110} planes. After pattern

tion, using the Taylor model, the observed rotation can be assigned to 58, which corresponds with the major bursts in the stress-strain

the activated plane(s) by considering the rotation axis as the cross curve, the (211) rotation direction is followed again. Figure 2d shows

product between the compression axis and the normal of the slip the scanning electron microscopy (SEM) image of the pillar after

plane. In other words, the path followed by the Laue spots during deformation, evidencing a well-defined slip trace corresponding with

deformation provides information on the activated slip system. the (211) plane schematically presented in red.

SCIENTIFIC REPORTS | 3 : 2547 | DOI: 10.1038/srep02547 2

www.nature.com/scientificreports

Figure 2 | In-situ results of W single crystal with [155] compression axis. (a) Stress-strain curve (b) Two dimensional representation of the (-3-10)

diffraction spot plotted together with the lines corresponding to rotation directions for slip on particular planes. (c) Zoom-in and path followed by the

(-3-10) spot during the compression, the numbers correspond to the stress stages in (a); (d) Slip trace visible on a SEM picture taken after deformation

corresponding with (211) plane indicated in red. The green and blue lines correspond with (110) and (101) plane orientation on which no traces

are observed.

So far the Laue results confirm that in the athermal regime slip can 35), the (101) Laue peak moves slightly in a direction that does not

be described as composed of elementary steps on {110} planes. This is correspond with any crystallographic slip.

however not the case in orientations for which the Schmid factors on Taking into account all other reflections and using the Taylor

the most stressed {110] planes differ slightly. The character of slip model, the movement of the Laue spots corresponds with a rotation

changes drastically when a [256] oriented pillar is compressed. of 0.75 degree around an axis in between the [110] and the [211]

Figure 3a shows the stress-strain curve of such a pillar, Figure 3b direction. Such a small rotation does not change the values of the

the (101) Laue reflection as well as the possible rotation directions Schmid factors (only the third decimal). Loading till 900 MPa (pat-

plotted with white lines. A zoom-in of the orange square is shown on tern 45) causes the Laue spot to follow the line for rotation according

Figure 3c, where the path followed by the (101) spot during loading is to slip on the (110) plane. From pattern 45 to 48, the path of the Laue

presented by the yellow line. The numbers along the Laue path spot changes direction suggesting equal slip on the (110) and (101)

correspond with the numbers shown on the stress-strain curve. plane resulting in a rotation along the (211) line. Upon further load-

During initial loading till 650 MPa (corresponding with pattern ing the (101) spot jumps discontinuously and some of the directions

Figure 3 | In-situ results of a W single crystal with [256] compression axis. (a) Stress-strain curve (b) Two dimensional representation of the (101)

diffraction spot. The white lines present the expected rotation direction for slip on the indicated planes. (c) Zoom-in on the path followed by the (101)

spot during the compression, the pattern numbers correspond to the stress values shown in (a). (d) Zoom-in of the very jerky part of the spot path

surrounded in green on (c). (e) this back and forward movement of the peak along the rotation direction for (101) and (110) slip is shown in more detail

for the (013) diffraction spot and with a different viewing angle. (f) Two views of the slip trace visible on SEM pictures taken after deformation.

SCIENTIFIC REPORTS | 3 : 2547 | DOI: 10.1038/srep02547 3

www.nature.com/scientificreports

Figure 4 | In-situ result of a second W micro-pillar with a compression axis along [256]. (a) Stress-strain curve (b) Two dimensional representation of

the (101) diffraction spot. The white lines present the expected rotation direction for slip on the indicated planes. (c) Zoom-in on the path followed

by the (101) spot during the compression, the numbers correspond to the stress values shown in (a); (d) Two views on the slip trace visible on SEM

pictures taken after deformation.

correspond with slip on (110) others with slip on (101) as for instance combined slip on (110) and (101). Note that at pattern 85, the global

the strain produced between pattern 52 and pattern 54. The latter can rotation evidenced by Laue corresponds to a rotation along the (211)

be viewed in more detail in the further zoom-in region of Figure 3d line.

(green frame). This back and forward movement of the peak along The load sequence ends with an important strain burst appearing

the rotation direction for (101) and (110) slip is shown in more detail at 1800 MPa during which only a minor additional rotation along

in Figure 3e for the (013) Laue reflection. Here the viewing angle is the (211) line is observed. Inspection of the surface of the sample after

perpendicular to the rotation direction for slip on (110). At the end of deformation revealed one very broad slip trace corresponding with a

the loading path a moderate burst is recorded at 1550 MPa, which (211) plane, visible on Figure 4d. In this case, no substructure can be

corresponds in the Laue patterns with a rotation for slip on (110). observed.

The SEM pictures in Figure 3f show a broad unsharp slip trace with It needs to be remarked that the differences in flow stress between

an envelope that corresponds with a (211) plane. The amount of the discussed pillars at a same strain value can be assigned to the

strain accommodated by the slip trace is higher than the strain pro- differences in size (for details see Table 1), a phenomenon that is well

duced in the strain burst. When zooming in on the slip trace, it is known30 but no matter of interest in this paper.

clear that this broad trace consists of several smaller traces which

together form wavy substructures. The direction of the substructures Discussion

reflects slip traces produced by the (101) and (110) slip planes as The Laue diffraction experiments on W at room temperature show

suggested by the colored lines on the SEM picture. In other words, that dislocation slip occurs on {110} planes. This is in line with the

slip trace and the Laue analysis demonstrate slip to occur on the two double kink model for the propagation of screw dislocations in the

(110) planes with highest Schmid factor, however macroscopic strain bcc lattice in the athermal regime (i.e. below the critical temperature).

is produced on the individual slip planes. The important jumps of the In an orientation where two {110} planes have the same resolved

Laue reflections together with the zig-zag slip trace suggest collective shear stress, slip can be described by alternating elementary steps

cross-slip used as mechanism to fulfill the mechanical boundary on both planes so that the overall rotation is similar to effective slip

conditions imposed by compression along [256]. on (211). This is also reflected in the (211) slip trace on the sample

Among the pillars studied, other combinations of collective cross- surface. The situation is however different when the resolved shear

slip have been observed. Figure 4a shows the stress-strain curve of stress on the {110} planes is non-equal. Our experiments dem-

another [256] oriented pillar together with numbers of correspond- onstrate that slip does not occur anymore by frequent alternation

ing Laue patterns. The path of the (101) diffraction spot is shown in of elementary steps proportional to the resolved shear stress of the

Figure 4b together with a projection of the possible rotation direc- two most stressed {110} planes. Instead dislocations can propagate

tions. The region of interest is zoomed in Figure 4c. Till pattern 32 on one of the highly stressed {110} planes, produce macroscopic

corresponding with 600 MPa Laue spots broaden and simulta- strain and cross-slip collectively as schematically represented in

neously rotate about 0.36u degree this time in the direction corres- Figure 1d. Collective cross-slip is the mechanism that allows fulfilling

ponding to slip in the (110) plane. Between pattern 30 and 40 there is the mechanical boundary conditions here represented by a highest

a discontinuous change of rotation direction indicating a rotation resolved shear stress on the (211) plane. The slip trace corresponds to

corresponding with (211) i.e. resulting from composed slip on the the plane expected according to the mechanical boundary condi-

(110) and (101) planes. Between pattern 40 and 60 the Laue peak tions, loses however its sharpness revealing eventual substructures

moves predominantly according to slip on (110) after which the spot that reflect the individual slip systems.

clearly changes direction and rotates predominantly according to slip In a micro-compression experiment the single crystal sample usu-

on (101), suggesting collective cross-slip. At pattern 83 until the end ally experiences an inhomogeneous stress distribution. This is also

of the load, the peak changes again and follows a direction suggesting the case in our experiments. During elastic compression, the Laue

SCIENTIFIC REPORTS | 3 : 2547 | DOI: 10.1038/srep02547 4

www.nature.com/scientificreports

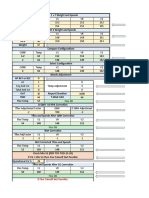

Figure 5 | Overview of the properties of the tungsten pillars under investigation, including pillar geometry and Schmid factors of relevant slip systems.

The last column provides SEM images of the pillars prior to deformation.

peaks do not always rotate along the predicted direction for the composed slip. Instead of progressing with elementary steps using

particular reflection but often rotate in a non-crystallographic dir- frequent cross-slip, slip continues on the chosen {110} plane and

ection. This rotation is minor and in most cases less then 0.75u so that produces macroscopic strain. Our experiments suggest that strain

it has no major influence on the ratio of the resolved shear stresses. It is produced on this system as long as mechanical compatibility

is however an indication for local inhomogeneous stresses as was requirements allow, after which collective cross-slip operates and

already reported earlier31. The role played by these inhomogeneous slip on the secondary {110} system provides the mechanically

stresses in bcc metals is observed to have much more important required crystal rotation.

consequences than in fcc single crystals. Misalignments up to 2u What are the important consequences of these observations?

induce initial slip activity of geometrically less favorable slip systems Inhomogeneous stress distributions within a plastifying volume are

in fcc pillars31 but already after 1 to 2% macroscopic strain slip is unavoidable. In a single crystal, this can occur as a result of, for

taken over fully as expected and predicted by Schmid rules. In bcc instance, boundary constraints of the experimental setup such as

crystals this is also the case for the [155] orientation where the two here in a compression experiment31, or thermal or elastic mismatch

{110} planes are equally stressed however in the [256] orientation the between a thin film and its substrate32. In single-phase polycrystals

small difference in resolved shear stress combined with the presence the interplay between individual grain orientation, size and shape,

of heterogeneous stress distribution disturbs the mechanism of and deformation properties such as elastic-plastic anisotropy and

Figure 6 | Schematic view of the in situ Laue microdiffraction setup installed at the MicroXAS beam line of the Swiss Light Source. The inset displays

the custom-built micro-compression device, consisting of various translation, tilting and rotation stages for alignment and a 1D Hysitron transducer to

perform the actual compression experiment.

SCIENTIFIC REPORTS | 3 : 2547 | DOI: 10.1038/srep02547 5

www.nature.com/scientificreports

strain hardening mechanisms are known to be at the origin of the 10. Hirth, J. P. & Lothe, J. in Theory of dislocations, eds Krieger (1982).

grain-to grain differences in average grain stresses. Slip incompat- 11. Groeger, R., Bailey, A. G. & Vitek, V. Multiscale modeling of plastic deformation

of molybdenum and tungsten: I. Atomistic studies of the core structure and glide

ibilities at interfaces and triple junctions create inhomogeneous of K,111. screw dislocations at 0 K. Acta Mat. 56, 5401 (2008).

stresses and stress gradients at the subgrain scale. The role of such 12. Kang, K., Bulatov, V. V. & Cai, W. Singular orientations and faceted motion

local stress concentrations has been recognized in deformation twin- of dislocations in body-centered cubic crystals. Proc. Nat. Acad. Science 109,

ning in hexagonal close packed metals. The observed diversity in 15174–15178 (2012).

twins in similar oriented grains has triggered the development of a 13. Weinberger, C. R., Tucker, G. J. & Foiles, S. M. Peierls potential of screw

dislocations in bcc transition metals: Predictions from density functional theory.

probabilistic twin nucleation model33. The role of local fluctuations Phys. Rev. B 87, 054114 (2013).

in stress or stress gradients are also the focus of attention in studies on 14. Cereceda, D. et al. Assessment of interatomic potentials for atomistic analysis of

nucleation of damage or size dependent strengthening34–36. static and dynamic properties of screw dislocations in W. J. of Phys. Cond. Mat. 25,

Our results add a previously unrevealed aspect of non uniform 085702 (2013).

local stress fluctuations: they can change the character of composed 15. Woodward, C. & Rao, S. I. Ab-initio simulation of isolated screw dislocations in

bcc Mo and Ta. Phil. Mag A 81, 1305–1316 (2001).

slip from frequently alternating elementary steps proportional to the 16. Gröger, R., Bailey, A. G. & Vitek, V. Multiscale modeling of plastic deformation of

resolved shear stress into slip producing macroscopic strain on one molybdenum and tungsten: I. Atomistic studies of the core structure and glide of

particular {110} plane followed by the second system to fulfill the K,111. screw dislocations at 0 K. Acta Mat. 56, 5401–5411 (2008).

boundary conditions. In polycrystalline structures, this can have 17. Kang, K., Bulatov, V. V. & Cai, W. Singular orientations and faceted motion

major impact on the transfer of strain with possible transmission of dislocations in body-centered cubic crystals. Proc. Nat. Acad. Science 109,

15174–15178 (2012).

of unexpected slip systems, having consequences for further plas- 18. Ariza, M. P., Tellechea, E., Menguiano, A. S. & Ortiz, M. Double kink mechanisms

ticity and development of damage. This work advocates for future for discrete dislocations in BCC crystals. Int J Fract 174, 29–40 (2012).

research into the influence of local stress distributions on composed 19. Weinberger, C. R., Battaile, C. C., Buchheit, T. E. & Holm, E. A. Incorporating

slip as well as the parameterization of slip mechanism by the for- atomistic data of lattice friction into BCC crystal plasticity models. Int. Jnl of

mulation of cross-slip rules in discrete dislocation models. Plasticity 37, 16–30 (2012).

20. Srivastava, K., Groger, R., Weygand, D. & Gumbsch, P. Dislocation motion in

tungsten: atomistic input to discrete dislocation simulations. Int J Plast. 47, 126

(2013).

Methods

21. Chaussidon, J., Robertson, C., Rodney, D. & Fivel, M. Dislocation dynamics

Pillars fabrication. For the Laue micro-diffraction experiments free-standing micro-

pillars have been prepared. Two foils of single crystal tungsten in a [155] and [256] simulations of plasticity in Fe laths at low temperature. Acta Mater. 56, 5466–5476

crystallographic orientation with initial thickness of 100 mm have been obtained from (2008).

Mateck Company ensuring a 5N purity. They have both been thinned down to a final 22. Li, D., Zbib, H., Sun, X. & Khaleel, M. Predicting plastic flow and irradiation

thickness of approximately 30 mm by electropolishing in an electrolyte of 250 mL of hardening of iron single crystal with mechanism-based continuum dislocation

distilled water with 25 g of sodium hydroxide applying a current of 6 V. This step dynamics. Int. J. Plast. In Press, Corrected Proof, Available online 4 February

allows removing the thin defects layer introduced during production and to 2013. (2013).

economize FIB time. Conventional high-resolution focused ion beam coupled with a 23. Caillard, D. Kinetics of dislocations in oure Fe. Part I. In situ straining experiments

scanning electron microscope has been used to fabricate the presented micro-pillars at room temperture. Acta Mat 58, 3493 (2010).

at the thin foil extremity. Ion currents in the range from 6.5 nA to 40 pA have been 24. Han, S. M. et al. Critical-temperature/Peierls-stress dependent size effects in body

applied sequentially with an accelerating voltage of 30 kV. First a pillar base of 10 3 centered cubic nanopillars. Appl. Phys. Lett. 102, 041910 (2013).

10 mm2 is created using a current of 6.5 nA. Then this is reduced to a base with a 25. Sestak, B. & Seeger, A. Gleitung und verfestigung in kubisch-raumzentrierten

diameter of three times the final pillar diameter. The step milling process to create the Metallen und Legierungen. Z. Metallkde 69, 195–202 (1978).

final pillar employs very low currents down to 40 pA. The square pillars exhibit no 26. Hosford, W. F. in The Mechanics of Crystals and Textured Polycrystals, eds. Oxford

taper whereas the round pillars have a taper angle of approximately 2u. To ensure a University Press (1993).

flat top the pillars are cut with a current of 10 pA. An overview of the properties of the 27. Van Swygenhoven, H. & Van Petegem, S. The use of Laue microdiffraction to

tungsten pillars is provided in Figure 5. Note that the actual compressions axis are up study small-scale plasticity. JOM 62, 36–43 (2010).

to 0.7u off from the nominal [155] and [256] direction, as determined by x-ray Laue 28. Barabash, R. I., Ice, G. E., Kumar, M. & Belak, J. l. Polychromatic microdiffraction

diffraction. The tabulated Schmid factors are therefore calculated with these corrected analysis of defect self-organization in shock deformed single crystals. Int J Plast 25,

values. 2081–2093 (2009).

29. Larson, B. C. & Levine, L. E. Submicrometre-resolution polychromatic three-

In situ Laue diffraction. In-situ Laue micro-compression experiments are performed dimensional X-ray microscopy. J. Appl Crystallogr 46, 153–164 (2013).

at the MicroXAS beam line of the Swiss Light Source. Figure 6 displays a schematic 30. Uchic, M. D., Dimiduk, D. M., Florando, J. N. & Nix, W. D. Sample dimensions

view of the setup. The sample is illuminated by a polychromatic x-ray beam (5– influence strength and crystal plasticity. Science 305, 986–989 (2004).

23 keV) with a spot size of 1 mm. The diffracted beam is recorded with a 16-bit CCD- 31. Maass, R. et al. Smaller is stronger: the effect of strain hardening. Acta Mat. 57,

detector (Photonic Science). Sample alignment is done with the help of two high- 5996–6005 (2009).

resolution optical microscopes and an x-ray fluorescence detector. 32. Nicola, L., Van der Giessen, E. & Needleman, A. Discrete dislocation analysis of

The micropillars are compressed at a constant load rate of 5.5 mm/s by a 1D size effects in thin films. J. Appl. Phys. 93, 5920–5928 (2003).

transducer (Hysitron Incorp.), which is mounted in a frame consisting of multiple 33. Beyerlein, I. J. & Tomé, C. N. A probabilistic twin nucleation model for HCP

translation, tilting and rotation stages. Diffraction patterns are recorded every 10 s. polycrystalline metals. Proc. R. Soc. A 466, 2517–2544 (2010).

Indexation and peak analysis were performed with a custom-written software- 34. Rollett, A. D., Lebensohn, R. A., Groeber, M., Choi, Y., Li, J. & Rohrer, G. S. Stress

package coded with Matlab. For more details we refer to27. hot spots in viscoplastic deformation of polycrystals. Modelling Simul. Mater. Sci.

Eng. 18, 074005 (2010).

35. Wilkinson, A. J. & Randman, D. Determination of elastic strain fields and

1. Peierls, R. The size of a dislocation. Proc Phys Soc 52, 34–43 (1940). geometrically necessary dislocation distributions near nanoindents using electron

2. Nabarro, F. R. N. Dislocations in a simple cubic lattice. Proc Phys Soc 59, 256–272 back scatter diffraction. Philos Mag 90, 1159–1177 (2010).

(1947). 36. Chakrawarthy, S. S. & Curtin, W. A. Stress-gradient plasticity. Proc. Nat. Acad.

3. Schmid, E. & Boas, W. Kristallplastizität., Springer, Berlin (1935), translated in Science 108, 15716–15720 (2011).

English: Plasticity of Crystals by F. A. Hughes & Co. (1950).

4. Vitek, V. Structure of dislocation cores in metallic materials and its impact on

their plastic behavior. Prog. Mater. Sci. 36, 1–27 (1992).

5. Christian, J. W. Some surprising features of the plastic deformation of Body-

Centered Cubic metals and alloys. Met. Trans. A 14A, 1237 (1983). Acknowledgements

6. Spitzig, W. A. & Keh, A. S. The effect of orientation and temperature on the plastic Authors are grateful to S. Pierret, M. Weisser, C. Le Bourlot, A. Irastorza, S. Zabihzadeh,

flow properties of iron single crystals. Acta Met. 18, 611 (1970). Z. Sun for help during beam time at the Swiss Light Source. H.V.S., C.M. and S.V.P. thank

7. Hull, D., Byron, J. F. & Noble, F. W. Orientation dependence of yield in body- the Swiss National Science Foundation for the financial support.

centered cubic metals. Can J Phys. 45, 1091–1099 (1967).

8. Seeger, A. Peierls berriers, kinks, and flow stress: recent progress. Z. Metallkd 93,

760 (2002). Author contributions

9. Argon, A. in Strengthening Mechanisms in Crystal Plasticity, Oxford Series on H.V.S., S.V.P. designed research, C.M., S.V.P., C.B. performed experiment, C.M., H.V.S.,

Materials Modelling (2008). S.V.P. analyzed data and wrote the manuscript.

SCIENTIFIC REPORTS | 3 : 2547 | DOI: 10.1038/srep02547 6

www.nature.com/scientificreports

Additional information This work is licensed under a Creative Commons Attribution-

Competing financial interests: The authors declare no competing financial interests. NonCommercial-ShareAlike 3.0 Unported license. To view a copy of this license,

How to cite this article: Marichal, C., Van Swygenhoven, H., Van Petegem, S. & Borca, C. visit http://creativecommons.org/licenses/by-nc-sa/3.0

{110} Slip with {112} slip traces in bcc Tungsten. Sci. Rep. 3, 2547; DOI:10.1038/srep02547

(2013).

SCIENTIFIC REPORTS | 3 : 2547 | DOI: 10.1038/srep02547 7

Potrebbero piacerti anche

- Mahajan 2002Documento14 pagineMahajan 2002Sandeep RakholiyaNessuna valutazione finora

- Deformation of Pure Metals IIDocumento21 pagineDeformation of Pure Metals IISaurabh ManralNessuna valutazione finora

- Cyclic Voltammetry at Gold Single-Crystal Surfaces 2Documento9 pagineCyclic Voltammetry at Gold Single-Crystal Surfaces 2Azucena osornio villaNessuna valutazione finora

- Slabs (LENSCHOW and SOZEN) jl64-27Documento8 pagineSlabs (LENSCHOW and SOZEN) jl64-27Pastor PachecoNessuna valutazione finora

- Mse 255 Lecture 3Documento36 pagineMse 255 Lecture 3percydziksNessuna valutazione finora

- Finite Element Analysis of Von-Mises Stress DistriDocumento7 pagineFinite Element Analysis of Von-Mises Stress DistriAnonymous P8Bt46mk5INessuna valutazione finora

- Dislocation TheoryDocumento37 pagineDislocation TheoryAbbireddy Siva Ganesh100% (1)

- Breakdown of The Schmid Law in BCC Molybdenum Related To The Effect of Shear Stress Perpendicular To The Slip Direction, V. VitekDocumento4 pagineBreakdown of The Schmid Law in BCC Molybdenum Related To The Effect of Shear Stress Perpendicular To The Slip Direction, V. VitekErsin KeserNessuna valutazione finora

- Kounadis RocikngDocumento20 pagineKounadis RocikngDimvoulg CivilNessuna valutazione finora

- Lapping of Single Crystal Diamond ToolsDocumento4 pagineLapping of Single Crystal Diamond ToolsCristian castroNessuna valutazione finora

- Undercut anchors in uncracked concrete load behaviorDocumento3 pagineUndercut anchors in uncracked concrete load behaviorAnonymous YW5mvpNessuna valutazione finora

- Experimental Approaches To The CompressiDocumento10 pagineExperimental Approaches To The CompressiKarishma NazimiNessuna valutazione finora

- Load-Bearing Brickwork Stability After Accidental DamageDocumento6 pagineLoad-Bearing Brickwork Stability After Accidental DamageMarvin MessiNessuna valutazione finora

- Soil Dynamics and Earthquake Engineering: Emre Abalı, Eren Uc - KanDocumento11 pagineSoil Dynamics and Earthquake Engineering: Emre Abalı, Eren Uc - KanAnonymous GFeyDVVNessuna valutazione finora

- Design of Vertical Wall Caisson BreakwatersDocumento14 pagineDesign of Vertical Wall Caisson BreakwatersHRCNessuna valutazione finora

- Solutions of Problem Set 4Documento16 pagineSolutions of Problem Set 4yasin yttNessuna valutazione finora

- Sweeney FinlayDocumento5 pagineSweeney FinlayAmit SharmaNessuna valutazione finora

- I Cce 2002 Exposed JettiesDocumento15 pagineI Cce 2002 Exposed JettiesGauri ChoudhariNessuna valutazione finora

- Basics of Physical Metallurgy MM 2107Documento22 pagineBasics of Physical Metallurgy MM 2107srujan baluNessuna valutazione finora

- The Structure of Silicon Surfaces From (001) To (111)Documento17 pagineThe Structure of Silicon Surfaces From (001) To (111)skpasha26Nessuna valutazione finora

- Viscous DissipationDocumento63 pagineViscous DissipationDustin SalasNessuna valutazione finora

- Slip-System Cal PDFDocumento13 pagineSlip-System Cal PDFVanaja JadapalliNessuna valutazione finora

- Stability of Rock Slopes: Dr. R.S.Banshtu Associate Professor Civil Engineering Department NIT HamirpurDocumento89 pagineStability of Rock Slopes: Dr. R.S.Banshtu Associate Professor Civil Engineering Department NIT HamirpurAastha SoniNessuna valutazione finora

- Thin-Walled Structures: Jianguo Gong, Weisheng Cui, Sheng Zeng, Tao JinDocumento6 pagineThin-Walled Structures: Jianguo Gong, Weisheng Cui, Sheng Zeng, Tao JinAnonymous wWOWz9UnWNessuna valutazione finora

- Seismic Design of Tunnels: Wang', MunfakhzDocumento10 pagineSeismic Design of Tunnels: Wang', MunfakhzGabriel SanchezNessuna valutazione finora

- Reliability Analysis and Optimal Design of Monolithic Vertical Wall BreakwatersDocumento8 pagineReliability Analysis and Optimal Design of Monolithic Vertical Wall BreakwatersDinar IstiyantoNessuna valutazione finora

- On The Galloping Instability of Two-Dimensional Bodies Having Elliptical Cross-SectionsDocumento11 pagineOn The Galloping Instability of Two-Dimensional Bodies Having Elliptical Cross-SectionsAndreea MunteanuNessuna valutazione finora

- Shear-flexible beam elementDocumento19 pagineShear-flexible beam elementnevinkoshyNessuna valutazione finora

- Simulating 3D Submerged Jet Flow Around a PileDocumento14 pagineSimulating 3D Submerged Jet Flow Around a Pileshuntao fanNessuna valutazione finora

- Analysis of Shell StructureDocumento37 pagineAnalysis of Shell StructureDave Mark AtendidoNessuna valutazione finora

- Modelling Expansive Soil FEMDocumento10 pagineModelling Expansive Soil FEMmed AmineNessuna valutazione finora

- Crystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversityDocumento7 pagineCrystal-Plasticity Fundamentals: Henry R. Piehler, Carnegie Mellon UniversitybluecreteNessuna valutazione finora

- Application of Nonlinear Fluid-Structure Interaction Methods To Seismic Analysis of Anchored and Unanchored TanksDocumento15 pagineApplication of Nonlinear Fluid-Structure Interaction Methods To Seismic Analysis of Anchored and Unanchored TanksRAKSHITH NNessuna valutazione finora

- Drop-Shock Stability of A Thin Shallow Arch Considering The Effects of Variations in ShapeDocumento10 pagineDrop-Shock Stability of A Thin Shallow Arch Considering The Effects of Variations in Shapenjm001Nessuna valutazione finora

- M54 Unit 10 Skew Deck & Intergral BridgesDocumento25 pagineM54 Unit 10 Skew Deck & Intergral BridgesPhilip YapNessuna valutazione finora

- Orientation Dependence of Plastic Deformation in Nickel-Based Single Crystal Superalloys: Discrete-Continuous Model SimulationsDocumento14 pagineOrientation Dependence of Plastic Deformation in Nickel-Based Single Crystal Superalloys: Discrete-Continuous Model SimulationsIonut CristeaNessuna valutazione finora

- Modelling Macrosegregation in A 2.45 Ton Steel IngotDocumento9 pagineModelling Macrosegregation in A 2.45 Ton Steel IngotsambitsahooNessuna valutazione finora

- Fbcabeb6 8930 4a01 BDBD 4b468e2f1e3d PDFDocumento2 pagineFbcabeb6 8930 4a01 BDBD 4b468e2f1e3d PDFManzoor NoumanNessuna valutazione finora

- Geometric description of folds and their shapesDocumento2 pagineGeometric description of folds and their shapesManzoor NoumanNessuna valutazione finora

- Fbcabeb6 8930 4a01 BDBD 4b468e2f1e3d PDFDocumento2 pagineFbcabeb6 8930 4a01 BDBD 4b468e2f1e3d PDFManzoor NoumanNessuna valutazione finora

- Slope InstabilityDocumento37 pagineSlope InstabilityGorkem AktasNessuna valutazione finora

- Naval Engineering Modeling and Optimization Program (NEMO)Documento54 pagineNaval Engineering Modeling and Optimization Program (NEMO)Leandro MeiliNessuna valutazione finora

- 7845 SeismicDocumento8 pagine7845 SeismicnehaNessuna valutazione finora

- Flow Separation and Secondary Flow PDFDocumento12 pagineFlow Separation and Secondary Flow PDFMahmoud Abd El LateefNessuna valutazione finora

- 1 s2.0 S0889974606001253 MainDocumento21 pagine1 s2.0 S0889974606001253 Mainaysenurpektas97Nessuna valutazione finora

- Model For The Lateral Behavior of RCC Columns - Setzler and Sezen PDFDocumento19 pagineModel For The Lateral Behavior of RCC Columns - Setzler and Sezen PDFSaurabh Bansal BansalNessuna valutazione finora

- Behavior of Beams With Dowel ActionDocumento5 pagineBehavior of Beams With Dowel ActioncustomerxNessuna valutazione finora

- Understanding Vibration of Simple StructuresDocumento38 pagineUnderstanding Vibration of Simple StructuresMakaraSoyNessuna valutazione finora

- Rocker Pipe PDFDocumento8 pagineRocker Pipe PDFMahmoud GwailyNessuna valutazione finora

- Numerical Study of The Three-Dimensional Flow Around A Vertical Submerged Cylinder S. Umeda, M.Yuhi & H. Ishida & L. Cheng PDFDocumento7 pagineNumerical Study of The Three-Dimensional Flow Around A Vertical Submerged Cylinder S. Umeda, M.Yuhi & H. Ishida & L. Cheng PDFGrant HosieNessuna valutazione finora

- Iabse20142014 01 22Documento9 pagineIabse20142014 01 22Giovanni FaiazzaNessuna valutazione finora

- Underpotential Deposition of Lead On Single Crystal FacesDocumento14 pagineUnderpotential Deposition of Lead On Single Crystal FacesAzucena osornio villaNessuna valutazione finora

- Axisymmetric Solids AnalysisDocumento13 pagineAxisymmetric Solids AnalysisPanchoMiyamotoNessuna valutazione finora

- 05. Dislocation TheoryDocumento55 pagine05. Dislocation Theoryhsy5478Nessuna valutazione finora

- O 06 Dcty DFLCTNDocumento9 pagineO 06 Dcty DFLCTNCarlos Rene Mamani TrujilloNessuna valutazione finora

- Stability of StructuresDocumento83 pagineStability of StructuresmchilwesaNessuna valutazione finora

- Mellman - The Transverse Motion of Solids in Rotating Cylinders-Forms of Motion and Transitions BehaviorDocumento20 pagineMellman - The Transverse Motion of Solids in Rotating Cylinders-Forms of Motion and Transitions BehaviorBrenno FerreiraNessuna valutazione finora

- Winkler Modulus For Axially Loaded Piles: Géotechnique January 2001Documento8 pagineWinkler Modulus For Axially Loaded Piles: Géotechnique January 2001Jhomar Jara del RosarioNessuna valutazione finora

- Fault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionDa EverandFault and Joint Development in Brittle and Semi-Brittle Rock: The Commonwealth and International Library: Geology DivisionNessuna valutazione finora

- A Jumping Shape Memory Alloy Under Heat 2015Documento6 pagineA Jumping Shape Memory Alloy Under Heat 2015MartinAlfonsNessuna valutazione finora

- A Jumping Shape Memory Alloy Under Heat 2015Documento6 pagineA Jumping Shape Memory Alloy Under Heat 2015MartinAlfonsNessuna valutazione finora

- Maxwell-Like Equations for Dirac ElectronsDocumento6 pagineMaxwell-Like Equations for Dirac ElectronsMartinAlfonsNessuna valutazione finora

- 2011 Argatov Wire Rope Strands Axial and Torsional LoadsDocumento11 pagine2011 Argatov Wire Rope Strands Axial and Torsional LoadsMartinAlfonsNessuna valutazione finora

- Clifford Algebra PDFDocumento68 pagineClifford Algebra PDFMartinAlfonsNessuna valutazione finora

- 2007 Curvatures of Smooth and Discrete SurfacesDocumento14 pagine2007 Curvatures of Smooth and Discrete SurfacesMartinAlfonsNessuna valutazione finora

- 100 Years of Work FunctionDocumento18 pagine100 Years of Work FunctionMartinAlfonsNessuna valutazione finora

- Cold Plasma Treatment of FoodsDocumento21 pagineCold Plasma Treatment of FoodsMartinAlfonsNessuna valutazione finora

- 3dscanningtechniquesofmechanicalobjects Piperi EtalDocumento8 pagine3dscanningtechniquesofmechanicalobjects Piperi Etalel_conejasNessuna valutazione finora

- Origin of Induction PDFDocumento3 pagineOrigin of Induction PDFMartinAlfonsNessuna valutazione finora

- Clifford Algebra PDFDocumento68 pagineClifford Algebra PDFMartinAlfonsNessuna valutazione finora

- Clifford Algebra and The Projective Model of Hyperbolic Spaces PDFDocumento11 pagineClifford Algebra and The Projective Model of Hyperbolic Spaces PDFMartinAlfons100% (1)

- A Key To The Projective Model of Homogeneous Metric SpacesDocumento30 pagineA Key To The Projective Model of Homogeneous Metric SpacesMartinAlfonsNessuna valutazione finora

- 2017kobelev Unification Proposals For Fatigue Crack Propagation LawsDocumento31 pagine2017kobelev Unification Proposals For Fatigue Crack Propagation LawsMartinAlfonsNessuna valutazione finora

- A Model of Comprehensive Unification: Physics Letters B June 2017Documento6 pagineA Model of Comprehensive Unification: Physics Letters B June 2017MartinAlfonsNessuna valutazione finora

- 2012-Dislocations Riemann-Cartan Geometry of Nonlinear Dislocation Mechanics Arash YavariDocumento61 pagine2012-Dislocations Riemann-Cartan Geometry of Nonlinear Dislocation Mechanics Arash YavariMartinAlfonsNessuna valutazione finora

- A Study On Treatment of Surface Water Using Cold Plasma For Domestic Water SupplyDocumento18 pagineA Study On Treatment of Surface Water Using Cold Plasma For Domestic Water SupplyMartinAlfonsNessuna valutazione finora

- Category Theory Approach to Algebraic Quantum Field TheoryDocumento38 pagineCategory Theory Approach to Algebraic Quantum Field TheoryMartinAlfonsNessuna valutazione finora

- Alshits Magnetoplastic Effect Basic Properties and Physical Mechanisms PDFDocumento29 pagineAlshits Magnetoplastic Effect Basic Properties and Physical Mechanisms PDFMartinAlfonsNessuna valutazione finora

- C. F. Gauß 1818 Elliptische Ring MassenverteilungDocumento20 pagineC. F. Gauß 1818 Elliptische Ring MassenverteilungMartinAlfonsNessuna valutazione finora

- 2012-Dislocations Riemann-Cartan Geometry of Nonlinear Dislocation Mechanics Arash YavariDocumento61 pagine2012-Dislocations Riemann-Cartan Geometry of Nonlinear Dislocation Mechanics Arash YavariMartinAlfonsNessuna valutazione finora

- Cauchy Vs Gaussian DistributionDocumento2 pagineCauchy Vs Gaussian DistributionMartinAlfonsNessuna valutazione finora

- 1 Induction Fundamentals LEP FurnacesDocumento29 pagine1 Induction Fundamentals LEP FurnacesMartinAlfonsNessuna valutazione finora

- A Brief Look On Gaussian Integrals Quantum Field Theory William O. StraubDocumento8 pagineA Brief Look On Gaussian Integrals Quantum Field Theory William O. StraubMartinAlfonsNessuna valutazione finora

- 2008 Generalized Peierls-Nabarro Model For Curved DislocationsDocumento19 pagine2008 Generalized Peierls-Nabarro Model For Curved DislocationsMartinAlfonsNessuna valutazione finora

- 2015 Lucat Generalised Einstein Cartan TheoryDocumento89 pagine2015 Lucat Generalised Einstein Cartan TheoryMartinAlfonsNessuna valutazione finora

- A Phenomenological Dislocation Mobility Law For BCC Metals Peierls Stress TungstenDocumento14 pagineA Phenomenological Dislocation Mobility Law For BCC Metals Peierls Stress TungstenMartinAlfonsNessuna valutazione finora

- A Model of Comprehensive Unification: Physics Letters B June 2017Documento6 pagineA Model of Comprehensive Unification: Physics Letters B June 2017MartinAlfonsNessuna valutazione finora

- A Brief Look On Gaussian Integrals Quantum Field Theory William O. StraubDocumento8 pagineA Brief Look On Gaussian Integrals Quantum Field Theory William O. StraubMartinAlfonsNessuna valutazione finora

- Universal Chargers and GaugesDocumento2 pagineUniversal Chargers and GaugesFaizal JamalNessuna valutazione finora

- Department Electrical Engineering Management IV Assignment 1 Semester 1, 2020Documento2 pagineDepartment Electrical Engineering Management IV Assignment 1 Semester 1, 2020samuelNessuna valutazione finora

- Cathodic Disbonding TesterDocumento1 paginaCathodic Disbonding TesterfelavinNessuna valutazione finora

- Strategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFDocumento23 pagineStrategic Marketing Plan For Red Bull - Elvis Asiedu - Academia - Edu PDFThomas Diwo0% (1)

- Systems Analyst Interview Questions GuideDocumento3 pagineSystems Analyst Interview Questions GuidehassanshoaibNessuna valutazione finora

- Mockups Showeet (Standard)Documento46 pagineMockups Showeet (Standard)Palo Alto Turismo y EntretenimientoNessuna valutazione finora

- Quiz 2 ReviewDocumento17 pagineQuiz 2 ReviewabubakkarNessuna valutazione finora

- Design TheoryDocumento2 pagineDesign Theoryhamidreza mohseniNessuna valutazione finora

- George B Dantzig PDFDocumento19 pagineGeorge B Dantzig PDFKeith BoltonNessuna valutazione finora

- Even Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityDocumento2 pagineEven Sem - Odd Sem - MD MS - MA, MSC, MCom - Previous - Final Main Exam Result 2021 - Mahatma Jyotiba Phule Rohilkhand UniversityprashantNessuna valutazione finora

- Article 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocumento13 pagineArticle 680 Swimming Pools, Spas, Hot Tubs, Fountains, and Similar InstallationsDocente 361 UMECITNessuna valutazione finora

- Biocompatibility and HabitabilityDocumento143 pagineBiocompatibility and HabitabilitySvetozarKatuscakNessuna valutazione finora

- Manual de Diagnostico D3E PDFDocumento72 pagineManual de Diagnostico D3E PDFJosé Luis Contreras Calderón100% (3)

- Elements of TQM: Dr. Sanjay MahalingamDocumento7 pagineElements of TQM: Dr. Sanjay Mahalingamuday saiNessuna valutazione finora

- Project Equipment Load AnalysisDocumento54 pagineProject Equipment Load Analysisrajeshmk2002100% (6)

- Energies: Review of Flow-Control Devices For Wind-Turbine Performance EnhancementDocumento35 pagineEnergies: Review of Flow-Control Devices For Wind-Turbine Performance Enhancementkarthikeyankv.mech DscetNessuna valutazione finora

- ISO/TC 46/SC 9/working Group 1Documento4 pagineISO/TC 46/SC 9/working Group 1João Paulo CésarNessuna valutazione finora

- Energy Engineering SyllabusDocumento49 pagineEnergy Engineering SyllabusKarthiik88Nessuna valutazione finora

- A320 Flex CalculationDocumento10 pagineA320 Flex CalculationMansour TaoualiNessuna valutazione finora

- ACI-439.3R-91 Mechanical Connections of Reinforcing BarsDocumento16 pagineACI-439.3R-91 Mechanical Connections of Reinforcing BarsMichi AGNessuna valutazione finora

- General Format Feasibility StudyDocumento7 pagineGeneral Format Feasibility StudyRynjeff Lui-Pio100% (1)

- SUCHANA EANV SANCHAR PRAUDYOGIK (I.C.T.) AADHARIT SHIKSHAN ADHIGAM VYUV RACHANA KA MADHYAMIK STAR PAR ADHYAYANRAT GRAMIN EANV SHAHARI PARIVESH KE VIDHYARTHITON KI GANIT UPLABDHI PAR PRABHAV KA ADHYAYANDocumento9 pagineSUCHANA EANV SANCHAR PRAUDYOGIK (I.C.T.) AADHARIT SHIKSHAN ADHIGAM VYUV RACHANA KA MADHYAMIK STAR PAR ADHYAYANRAT GRAMIN EANV SHAHARI PARIVESH KE VIDHYARTHITON KI GANIT UPLABDHI PAR PRABHAV KA ADHYAYANAnonymous CwJeBCAXpNessuna valutazione finora

- Nordson EFD Ultimus I II Operating ManualDocumento32 pagineNordson EFD Ultimus I II Operating ManualFernando KrauchukNessuna valutazione finora

- 942 FullDocumento9 pagine942 FullZulfah MidahNessuna valutazione finora

- Cities Words and Images From Poe To ScorseseDocumento266 pagineCities Words and Images From Poe To Scorsesejcbezerra100% (2)

- Single Point Loading Working Model Specifications and Parts OverviewDocumento4 pagineSingle Point Loading Working Model Specifications and Parts OverviewAnonymous CYdagI100% (1)

- Regulation of AlternatorDocumento6 pagineRegulation of Alternatorkudupudinagesh100% (1)

- Industrial Wire Cutting Machine: A Senior Capstone Design ProjectDocumento17 pagineIndustrial Wire Cutting Machine: A Senior Capstone Design ProjectTruta IonutNessuna valutazione finora

- Accomplishment Report - English (Sy 2020-2021)Documento7 pagineAccomplishment Report - English (Sy 2020-2021)Erika Ikang WayawayNessuna valutazione finora

- Speech Sound Disorders First Edition Ebook PDF VersionDocumento57 pagineSpeech Sound Disorders First Edition Ebook PDF Versionzelma.bennett128100% (39)