Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TDTO

Caricato da

AndresCorreaCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TDTO

Caricato da

AndresCorreaCopyright:

Formati disponibili

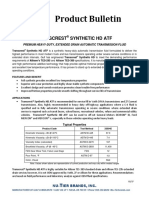

® PREVENTIVE MAINTENANCE PRODUCTS

Transmission/Drive Train Oil

Unique formula for improved life and performance

Comparative Tests

Cat Transmission/Drive Train Oil (TDTO) is formulated for use in Cat equipment

friction devices—power shift transmissions, clutches, and brakes—and in other Cat TO-4 defines a minimum level of performance for the

equipment drive train components like final drives, bevel gears, and differentials. industry that is acceptable for use in Cat transmissions and

It provides a balance between static and dynamic friction characteristics with both final drives. Cat TDTO is the only oil required by Caterpillar

metallic and nonmetallic materials, ensuring increased load-carrrying capacity and to exceed this minimum standard.

component durability. Cat TDTO TO–4

TDTO utilizes an additive technology developed for Caterpillar that provides optimum

Chemical and Physical Properties:

balance between clutch friction disc characteristics and gear wear requirements. This

unique additive significantly improves gear wear performance. Fluoroelastomer/Elastomer

compatibility

Cat TDTO also: Oxidation stability

Rust control

• eliminates transmission slippage caused Copper corrosion

by many CD/TO-2 commerical engine oils. Homogeneity

Foaming

• increases clutch disc life up to 45%. Compatibility

• controls brake chatter. Viscosity:

• increases machine break-out force. SAEJ300

• provides greater machine rim pull. Shear stability (35VQ25)

Wear Test:

Fluid analysis for early detection FZG Gear Wear

35VQ25 Vane Pump Test

We recommend protecting your investment by using a scheduled fluid sampling program. Friction Performance Properties:

Wear,Pressure,Speed,EnergyLimit

Our S·O·SSM analysis program is the ultimate detection and diagnostic tool for your

equipment. Our S·O·S program helps you head off potential problems before they can Bronze

Paper (Brake)

lead to major failures and costly unscheduled downtime. Paper (Transmission)

Paper (Steering Brake)

Elastomeric (Transmission)

Proper use for health and safety F-37

Rayflex

According to toxicology information, Cat Transmission/Drive Train Oil has little or Full-Scale Vehicle Test

no adverse effects if handled and used properly. No special precautions are suggested

beyond attending to good personal hygiene and avoiding prolonged, repeated skin Full-Scale Final Drive

contact. For more information, refer to the “Material Safety Data Sheet,” SEFV1602. Wear Test

Full-Scale Transmission

Endurance Test

980C Brake Noise & Stopping

Distance Test

PEHP7506-06 © 1996 Caterpillar Printed in U.S.A.

® PREVENTIVE MAINTENANCE PRODUCTS

Transmission/Drive Train Oil SAE 10W

SAE 30

For all Cat® transmissions, final drives, and wet brake components SAE 50

Developed, tested, and approved by Caterpillar,

Typical Characteristics*

Cat Transmission/Drive Train Oil (TDTO)

ensures optimum life and performance when

used as recommended in Cat transmissions, SAE Viscosity Grade 10W 30 50

final drives, and wet brake components. Cat

Manufacturer’s Test

TDTO is standard factory fill for Caterpillar®

machines worldwide. CAT TO-4 TO-4 TO-4

Allison C-4, C-3 C-4, C-3 C-4, C-3

Recommended use ISO Viscosity Grade (ISO) 32 100 220

Gravity, °API ( ASTM D287) 29.3 27.0 25.9

Cat Transmission/Drive Train Oil is Color ASTM (ASTM D1500) 4.0 5.0 7.5

recommended for use in all Caterpillar Appearance (Visual) Clear & Bright Clear & Bright Clear & Bright

transmissions, final drives, and wet brake

Flash Point, °C (°F) (ASTM D92) 204 (399) 252 (486) 250 (482)

components (or other OEM non-engine

components that specify use of TO-4, Pour Point, °C (°F) (ASTM D97) -29 (-20) min. -15 (5) min. -12 (10) min.

CD/TO-2, or TO-2). This oil should not Viscosity,

be used in engines because it can shorten cP @ -20°C (ASTM D2602) 2700 — —

engine life. cSt @ 40°C (ASTM D445) 38.2 107.4 219

We can help you determine the right oil for cSt @ 100°C ( ASTM D445) 6.0 11.6 18.5

your Cat machines, or you can refer to your Viscosity Index (ASTM D2270) 100 95 93

“Operation and Maintenance Manual” or

Calcium, % wt. .308 .308 .308

Service Publication SEBU6250 (“Caterpillar

Machine Lubricant Recommendations”). Sulfated Ash, % wt. (ASTM D874) 1.2 1.2 1.2

Zinc, % wt. (ASTM D1549) .124 .124 .124

Phosphorous, % wt. (ASTM D1091) .110 .110 .110

Nitrogen, % wt. .02 .02 .02

TBN (ASTM D2896) 7.1 7.1 7.1

* The values shown are typical values and should not be used as quality control parameters to either

accept or reject product. Specifications are subject to change without notice.

Potrebbero piacerti anche

- Cat TDTODocumento4 pagineCat TDTOalexanderNessuna valutazione finora

- Cat Oil Fdao SynDocumento2 pagineCat Oil Fdao SynDesta 77Nessuna valutazione finora

- TDTO Pehp7506Documento4 pagineTDTO Pehp7506ngilaNessuna valutazione finora

- Cat-Tdto-10 30 50 PDFDocumento4 pagineCat-Tdto-10 30 50 PDFEduardo Zamora100% (1)

- Cat Oil Filtros CodPartDocumento2 pagineCat Oil Filtros CodPartKaly7Nessuna valutazione finora

- Cat Tdto-Tms: Caterpillar. The Difference CountsDocumento2 pagineCat Tdto-Tms: Caterpillar. The Difference CountsMarcelo Monteiro Da CorreggioNessuna valutazione finora

- Vecton 15W-40 CI-4 Plus/E7: DescriptionDocumento2 pagineVecton 15W-40 CI-4 Plus/E7: Descriptionkuruvillaj2217Nessuna valutazione finora

- Shell Advance 4T Ultra 15W-50 (SM MA2) (en-GB) TDSDocumento2 pagineShell Advance 4T Ultra 15W-50 (SM MA2) (en-GB) TDSantvilaNessuna valutazione finora

- Technical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Documento2 pagineTechnical Data Sheet (TDS) : Puma Premium Motor Oil 15W-40Mohamed IsmailNessuna valutazione finora

- Shell Rimula Ultra 5W-30Documento2 pagineShell Rimula Ultra 5W-30Aaron ChanNessuna valutazione finora

- Cat Deo-Uls: Recommended UseDocumento2 pagineCat Deo-Uls: Recommended Useanon_828943220Nessuna valutazione finora

- GPCDOC Local TDS Switzerland Shell Advance 4T AX7 10W-40 (SL MA2) (en-CH) TDSDocumento2 pagineGPCDOC Local TDS Switzerland Shell Advance 4T AX7 10W-40 (SL MA2) (en-CH) TDSBernad BearNessuna valutazione finora

- Cat Tdto PDSDocumento2 pagineCat Tdto PDSMOHAMED GamalNessuna valutazione finora

- Shell Advance 4T AX5 10W-30 (SL/MA) : Performance, Features & Benefits Specifications, Approvals & RecommendationsDocumento2 pagineShell Advance 4T AX5 10W-30 (SL/MA) : Performance, Features & Benefits Specifications, Approvals & RecommendationsandriNessuna valutazione finora

- Shell Spirax S3 G80WDocumento2 pagineShell Spirax S3 G80WNokiabhre WijayaNessuna valutazione finora

- Shell Argina X 40 - TDSDocumento2 pagineShell Argina X 40 - TDSHUM CIREBON DFLTS100% (1)

- TDS - Advance 4T AX5 15W-40 (SLMA)Documento2 pagineTDS - Advance 4T AX5 15W-40 (SLMA)hanafiajaNessuna valutazione finora

- Shell Advance 4T Ultra 15W-50: Performance, Features & BenefitsDocumento2 pagineShell Advance 4T Ultra 15W-50: Performance, Features & Benefitsfmj_moncanoNessuna valutazione finora

- Transmission Synthetic CAT OilDocumento4 pagineTransmission Synthetic CAT OilGolbert GolbiNessuna valutazione finora

- TDS - Advance 4T AX5 Scooter 10W-30 (MB)Documento2 pagineTDS - Advance 4T AX5 Scooter 10W-30 (MB)hanafiajaNessuna valutazione finora

- Shell AgDocumento2 pagineShell AgAndrei30Nessuna valutazione finora

- R2 30 (CF 10TBN) TDSDocumento2 pagineR2 30 (CF 10TBN) TDSMozesTobingNessuna valutazione finora

- TDS - Advance 4T AX5 Scooter 15W-40 (MB)Documento2 pagineTDS - Advance 4T AX5 Scooter 15W-40 (MB)hanafiajaNessuna valutazione finora

- TDS - Advance 4T AX7 10W-40 (SLMA2)Documento2 pagineTDS - Advance 4T AX7 10W-40 (SLMA2)hanafiajaNessuna valutazione finora

- Helix Ultra Professional AG 5W-30 (Dexos 2)Documento2 pagineHelix Ultra Professional AG 5W-30 (Dexos 2)rstec pyNessuna valutazione finora

- Lubrex Guide BookDocumento209 pagineLubrex Guide BookPawel PawelNessuna valutazione finora

- Shell Advance 4T AX7 10W-40: Performance, Features & BenefitsDocumento2 pagineShell Advance 4T AX7 10W-40: Performance, Features & BenefitsPoser HarvesterNessuna valutazione finora

- Tema 5. Motores de Corriente AlternaDocumento2 pagineTema 5. Motores de Corriente AlternaRichard ZapataNessuna valutazione finora

- Tds en Puma Motor Oil Sae 30Documento2 pagineTds en Puma Motor Oil Sae 30Dilhara PinnaduwageNessuna valutazione finora

- Premium Protection Synthetic Motor Oils (AMO & ARO)Documento2 paginePremium Protection Synthetic Motor Oils (AMO & ARO)brian5786Nessuna valutazione finora

- TDTO 10W Ulei Transmisie CaterpillarDocumento2 pagineTDTO 10W Ulei Transmisie CaterpillarCorina Stanculescu0% (1)

- Cat Arctic TDTO: Synthetic Blend Transmission and Drive Train OilDocumento2 pagineCat Arctic TDTO: Synthetic Blend Transmission and Drive Train Oilanon_828943220Nessuna valutazione finora

- Shell Advance 4T Ultra 10W-40Documento2 pagineShell Advance 4T Ultra 10W-40Anonymous oAbjbl4HNessuna valutazione finora

- TDS - Advance 4T AX5 10W-30 (SLMA)Documento2 pagineTDS - Advance 4T AX5 10W-30 (SLMA)hanafiajaNessuna valutazione finora

- Shell Spirax S3 G 80W90Documento2 pagineShell Spirax S3 G 80W90Jorge Arrieta TorresNessuna valutazione finora

- Shell Rimula Ultra 5W-30Documento2 pagineShell Rimula Ultra 5W-30Jorge Arrieta TorresNessuna valutazione finora

- AmsoilSyntheticOilProductInfo SheetsDocumento2 pagineAmsoilSyntheticOilProductInfo Sheetsapi-19921780Nessuna valutazione finora

- Cat DEO Performance 15w-40 PDFDocumento2 pagineCat DEO Performance 15w-40 PDFАртемNessuna valutazione finora

- Gulf Transcrest Synthetic HD ATFDocumento1 paginaGulf Transcrest Synthetic HD ATFchandan sahooNessuna valutazione finora

- PDS Castrol Trans C 10wDocumento2 paginePDS Castrol Trans C 10wepesanoNessuna valutazione finora

- Gpcdoc Local Tds Pakistan Shell Advance 4t Ax3 20w-40 (SG Ma) (Ur-Pk) TdsDocumento2 pagineGpcdoc Local Tds Pakistan Shell Advance 4t Ax3 20w-40 (SG Ma) (Ur-Pk) TdsRoxanne ObleroNessuna valutazione finora

- Shell IVeco 1811Documento2 pagineShell IVeco 1811Jorge Arrieta TorresNessuna valutazione finora

- Catalogo Aceites CaterpillarDocumento87 pagineCatalogo Aceites CaterpillarsergioNessuna valutazione finora

- Shell Rimula R3 Turbo 15W-40Documento2 pagineShell Rimula R3 Turbo 15W-40HUM CIREBON DFLTSNessuna valutazione finora

- Shell Spirax S6 ATF A668: Performance, Features & BenefitsDocumento2 pagineShell Spirax S6 ATF A668: Performance, Features & BenefitsMUHAMMAD LUTHFINessuna valutazione finora

- Pennzoil 5W-20 Motor Oil: Technical Data SheetDocumento2 paginePennzoil 5W-20 Motor Oil: Technical Data SheetKlaudio Perez CarvajalNessuna valutazione finora

- Traxon 80W90Documento4 pagineTraxon 80W90Prabhakar SinhaNessuna valutazione finora

- Castrol Transmax CVT: DescriptionDocumento2 pagineCastrol Transmax CVT: Descriptionautomaticosbrasil100% (1)

- Castrol Power 1 4T 10W-30: DescriptionDocumento2 pagineCastrol Power 1 4T 10W-30: DescriptionRajesh ShettyNessuna valutazione finora

- Axle EPX 80W-90-pds-EngDocumento2 pagineAxle EPX 80W-90-pds-EngVusal HasanovNessuna valutazione finora

- GPCDOC GTDS Shell Advance 4T Ultra Scooter 5W-40 (SM MB) (En) TDSDocumento2 pagineGPCDOC GTDS Shell Advance 4T Ultra Scooter 5W-40 (SM MB) (En) TDSMythic GloryNessuna valutazione finora

- Premium Protection Synthetic Motor OilDocumento2 paginePremium Protection Synthetic Motor OilmindsNessuna valutazione finora

- Amsoil MetricDocumento2 pagineAmsoil MetricHoàng Quang MạnhNessuna valutazione finora

- Cat Deo 15W40 - Pehj0059-02 PDFDocumento2 pagineCat Deo 15W40 - Pehj0059-02 PDFpaolo88Nessuna valutazione finora

- Machinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityDa EverandMachinery Oil Analysis & Condition Monitoring : A Practical Guide to Sampling and Analyzing Oil to Improve Equipment ReliabilityValutazione: 3 su 5 stelle3/5 (4)

- Automotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionDa EverandAutomotive Buzz, Squeak and Rattle: Mechanisms, Analysis, Evaluation and PreventionValutazione: 5 su 5 stelle5/5 (3)

- Aviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BDa EverandAviation Maintenance Technician Handbook—Powerplant (2024): FAA-H-8083-32BNessuna valutazione finora

- UntitledDocumento939 pagineUntitledAndresCorreaNessuna valutazione finora

- Operation and Maintenance Manual: CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsDocumento166 pagineOperation and Maintenance Manual: CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsAndresCorrea100% (1)

- TDTODocumento2 pagineTDTOAndresCorrea100% (1)

- Drum and Blade Attachment Under Platform: CS56B, CP56B, CS68B, and CP68B Hydraulic System Vibratory Soil CompactorsDocumento2 pagineDrum and Blade Attachment Under Platform: CS56B, CP56B, CS68B, and CP68B Hydraulic System Vibratory Soil CompactorsAndresCorreaNessuna valutazione finora

- Operation and Maintenance Manual: CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsDocumento166 pagineOperation and Maintenance Manual: CP56B, CP68B, CP74B, CS56B, CS68B, CS74B, CS78B and CS79B Vibratory Soil CompactorsAndresCorrea100% (1)

- Transmision D6D PDFDocumento72 pagineTransmision D6D PDFJose Luis Garcia Blanco100% (3)

- CS-583D Vibratory Compactor 3GZ00001-UP (MACHINE) POWERED by 3116 Engine (KEBP0214 - 46) - Por Número de PiezaDocumento3 pagineCS-583D Vibratory Compactor 3GZ00001-UP (MACHINE) POWERED by 3116 Engine (KEBP0214 - 46) - Por Número de PiezaAndresCorreaNessuna valutazione finora

- Alert Indicator Description: Systems OperationDocumento28 pagineAlert Indicator Description: Systems OperationEd Calhe100% (5)

- Transmision D6D PDFDocumento72 pagineTransmision D6D PDFJose Luis Garcia Blanco100% (3)

- Transmision D6D PDFDocumento72 pagineTransmision D6D PDFJose Luis Garcia Blanco100% (3)

- 4-Cylinder Injection Engine (2.0 L Direct InjectionDocumento259 pagine4-Cylinder Injection Engine (2.0 L Direct Injectiongordonjairo60% (5)

- Transmision D6D PDFDocumento72 pagineTransmision D6D PDFJose Luis Garcia Blanco100% (3)

- Course Drive Train Works Wears Heavy Equipment Caterpillar PDFDocumento114 pagineCourse Drive Train Works Wears Heavy Equipment Caterpillar PDFBruno Cecatto93% (28)

- Transmision D6D PDFDocumento72 pagineTransmision D6D PDFJose Luis Garcia Blanco100% (3)

- Serp4874 11 2Documento728 pagineSerp4874 11 2AndresCorrea100% (1)

- Nehs1032 03 PDFDocumento12 pagineNehs1032 03 PDFAndresCorreaNessuna valutazione finora

- Parts Manual: 320D & 320D L ExcavatorsDocumento603 pagineParts Manual: 320D & 320D L ExcavatorsAnonymous QzcMDyLcNessuna valutazione finora

- Mack GraniteDocumento125 pagineMack GraniteNarciso Martinez100% (1)

- Serp4874 11 2Documento728 pagineSerp4874 11 2AndresCorrea100% (1)

- FormatoDocumento1 paginaFormatoAndresCorreaNessuna valutazione finora

- Toyota Prius C Aqua All Products GuideDocumento3 pagineToyota Prius C Aqua All Products GuideAndresCorreaNessuna valutazione finora

- Parts Manual: 320D & 320D L ExcavatorsDocumento603 pagineParts Manual: 320D & 320D L ExcavatorsAnonymous QzcMDyLcNessuna valutazione finora

- Sebp4874 11 1Documento812 pagineSebp4874 11 1Timothy Mcbride100% (1)

- STOU SAE 10W 30 - 701 08aDocumento2 pagineSTOU SAE 10W 30 - 701 08aAndresCorreaNessuna valutazione finora

- 120H Motor Grader 5FM000... - 92) - by Part NumberDocumento4 pagine120H Motor Grader 5FM000... - 92) - by Part NumberAndresCorreaNessuna valutazione finora

- 588 392 100 1Nz-Fxe: NHW20 AugDocumento2 pagine588 392 100 1Nz-Fxe: NHW20 AugAndresCorreaNessuna valutazione finora

- 120H Motor Grader 5FM000... - 92) - by Part NumberDocumento4 pagine120H Motor Grader 5FM000... - 92) - by Part NumberAndresCorreaNessuna valutazione finora

- 2010 Mitsubishi Lancer Evolution Brochures (US)Documento4 pagine2010 Mitsubishi Lancer Evolution Brochures (US)Jandy Aditya Pratisto100% (2)

- Measuring InstrumentsDocumento45 pagineMeasuring InstrumentsRavinder Minhas100% (1)

- AAR - G Section 2 - WHEEL & AXLE MANUALDocumento200 pagineAAR - G Section 2 - WHEEL & AXLE MANUALManoj KumarNessuna valutazione finora

- GM STG 15004 50 2 Introduction To ABSDocumento116 pagineGM STG 15004 50 2 Introduction To ABSBill NucleusNessuna valutazione finora

- A. B. C. D.: Answer: ExplanationDocumento73 pagineA. B. C. D.: Answer: ExplanationUpender DhullNessuna valutazione finora

- Techmate Technical Guide ABS SensorsDocumento2 pagineTechmate Technical Guide ABS SensorspepitoNessuna valutazione finora

- NS200 Fi (2023) (Uma 15 - 09 - 2023)Documento92 pagineNS200 Fi (2023) (Uma 15 - 09 - 2023)Juan Diego Rodriguez CedeñoNessuna valutazione finora

- Defender Parts CatalogDocumento14 pagineDefender Parts CatalogBilly FoxNessuna valutazione finora

- Optimized Design and Static, Dynamic Analysis of Disc Brake Using Finite Element AnalysisDocumento5 pagineOptimized Design and Static, Dynamic Analysis of Disc Brake Using Finite Element AnalysisVinayak ImadiNessuna valutazione finora

- MCQ - Diagnosis and Testing of VehicleDocumento59 pagineMCQ - Diagnosis and Testing of VehiclearpanNessuna valutazione finora

- Corsair FSMDocumento894 pagineCorsair FSMDanny MannoNessuna valutazione finora

- Ferrari - Cap9 Specifichetecniche F121618 EDocumento8 pagineFerrari - Cap9 Specifichetecniche F121618 EJoseph VasquezNessuna valutazione finora

- Safety Operator Training HD785-20120910Documento21 pagineSafety Operator Training HD785-20120910mohan100% (2)

- Installation Drawing: Caliper Identification ChartDocumento1 paginaInstallation Drawing: Caliper Identification Chart陈巍Nessuna valutazione finora

- zt310t Euro IVDocumento109 paginezt310t Euro IVEmiliano Arocha CorsoNessuna valutazione finora

- F1 1958 Manual PDFDocumento78 pagineF1 1958 Manual PDFJames OtreblaNessuna valutazione finora

- Brake Technicians Service Guide PDFDocumento28 pagineBrake Technicians Service Guide PDFleonardo cardenasNessuna valutazione finora

- 2022 NC750X BrochureDocumento3 pagine2022 NC750X BrochureaaNessuna valutazione finora

- SportStar Maintenance ManualDocumento135 pagineSportStar Maintenance Manualtipu321Nessuna valutazione finora

- B12B Euro4-5inc Eng Hi PDFDocumento2 pagineB12B Euro4-5inc Eng Hi PDFcamilo reyNessuna valutazione finora

- Pulsar 180 NeonDocumento72 paginePulsar 180 NeondianaaguilaraltamiranoNessuna valutazione finora

- Meyle CatalogDocumento58 pagineMeyle CatalogossoskiNessuna valutazione finora

- Vmoto Monaco HandbookDocumento40 pagineVmoto Monaco HandbookHamish CleghornNessuna valutazione finora

- Prius Front Brake Caliper RattleDocumento5 paginePrius Front Brake Caliper RattleclgutierrezNessuna valutazione finora

- SM Tm3989 Knott A4Documento1 paginaSM Tm3989 Knott A4Marc GlebNessuna valutazione finora

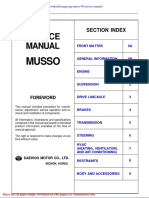

- Ssangyong Musso 99 Service ManualDocumento20 pagineSsangyong Musso 99 Service Manualdominique100% (44)

- Catalogo Brembo Competicion PDFDocumento134 pagineCatalogo Brembo Competicion PDFmushu710% (1)

- Autoexpo 2012 Exhibitors ListDocumento53 pagineAutoexpo 2012 Exhibitors ListNagender100% (1)

- Baja Design Report 2010Documento9 pagineBaja Design Report 2010Aaditeshwar SinghdeoNessuna valutazione finora

- PM - B40D - B35D - ADT - PIN 7.2 IT4 - RevA - Feb2013Documento804 paginePM - B40D - B35D - ADT - PIN 7.2 IT4 - RevA - Feb2013Pieter BothaNessuna valutazione finora