Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Assignment 4

Caricato da

Manjunath Nadarajan0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

12 visualizzazioni4 pagineAssignment 4

Copyright

© © All Rights Reserved

Formati disponibili

DOCX, PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoAssignment 4

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

12 visualizzazioni4 pagineAssignment 4

Caricato da

Manjunath NadarajanAssignment 4

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato DOCX, PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 4

ASSIGNMENT-4

Vishnu Harikumar

18

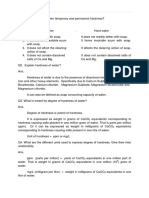

1. What is Poisson’s ratio?

Poisson's ratio, named after Siméon Poisson, also known as the

coefficient of expansion on the transverse axial, is the negative ratio of

transverse to axial strain. If the material is stretched in a direction, it usually

tends to contract in the directions transverse to the direction of stretching. This

phenomenon is called the Poisson effect. Poisson's ratio is a measure of this

effect. The Poisson ratio is the fraction (or percent) of expansion divided by

the fraction (or percent) of compression, for small values of these changes. The

Poisson's ratio of a stable, isotropic, linear elastic material cannot be less than

−1.0 nor greater than 0.5 due to the requirement that Young's modulus,

the shear modulus and bulk modulus have positive values. Most materials

have Poisson's ratio values ranging between 0.0 and 0.5. A perfectly

incompressible material deformed elastically at small strains would have a

Poisson's ratio of exactly 0.5.

Poisson’s ratio of some of materials are:

Steel 0.27-0.3

Cast iron 0.21-0.26

Stainless steel 0.3-0.31

Rubber 0.499

Titanium 0.265-0.34

One area in which Poisson's effect has a considerable influence is in

pressurized pipe flow. When the air or liquid inside a pipe is highly pressurized

it exerts a uniform force on the inside of the pipe, resulting in a radial stress

within the pipe material. Due to Poisson's effect, this radial stress will cause

the pipe to slightly increase in diameter and decrease in length. The decrease

in length, in particular, can have a noticeable effect upon the pipe joints, as the

effect will accumulate for each section of pipe joined in series. A restrained

joint may be pulled apart or otherwise prone to failure.

2. What is Tensor?

Tensor is a linear mapping. Tensors, defined mathematically, are simply arrays

of numbers, or functions that transform according to certain rules under a

change of coordinates. A tensor may consist of a single number, in which case

it is referred to as a tensor of order zero, or simply a scalar. For reasons which

will become apparent, a scalar may be thought of as an array of dimension zero.

The next most complicated tensor is the tensor of order one, otherwise known

as a vector. Just as tensors of any order, it may be defined at a point, or points,

or it may vary continuously from point-to-point, thereby defining a vector field.

In ordinary three dimensional space, a vector has three components (contains

three numbers, or three functions of position). In four dimensional space-time,

a vector has four components. And, generally, in an n-dimensional space, a

vector (tensor of order one) has n components. A vector may be thought of as

an array of dimension one. This is because the components of a vector can be

visualized as being written in a column or along a line, which is one

dimensional.

Next above a vector are tensors of order 2, which are often referred to as

matrices. As might also be guessed, the components of a second order tensor

can be written as a two dimensional array. Just as vectors represent physical

properties more complex than scalars, so too matrices represent physical

properties yet more complex than can be handled by vectors.

3. What is principal stresses and stress invariants?

At every point in a stressed body there are at least three planes,

called principal planes, with normal vectors, called principal directions, where

the corresponding stress vector is perpendicular to the plane, i.e., parallel or in

the same direction as the normal vector, and where there are no normal shear

stresses . The three stresses normal to these principal planes are

called principal stresses.

The components of the stress tensor depend on the orientation of the

coordinate system at the point under consideration. However, the stress tensor

itself is a physical quantity and as such, it is independent of the coordinate

system chosen to represent it. There are certain invariants associated with

every tensor which are also independent of the coordinate system.

For a state of stress

𝜎𝑥𝑥 𝜎𝑥𝑦 𝜎𝑥𝑧

𝜎 = 𝜎𝑦𝑥 𝜎𝑦𝑦 𝜎𝑦𝑧

𝜎𝑧𝑥 𝜎𝑧𝑦 𝜎𝑧𝑧

The invariants are

𝐼1 =𝜎𝑥𝑥 + 𝜎𝑦𝑦 + 𝜎𝑧𝑧

𝜎𝑦𝑦 𝜎𝑥𝑦 𝜎𝑥𝑥 𝜎𝑥𝑧 𝜎𝑥𝑥 𝜎𝑥𝑦

𝐼2 =| 𝜎 𝜎𝑧𝑧 | + | 𝜎𝑧𝑥 𝜎𝑧𝑧 | + | 𝜎𝑥𝑦 𝜎𝑦𝑦 |

𝑦𝑧

𝐼3 = det (σ)

4. What is von-mises stress?

The von Mises yield criterion suggests that the yielding of materials begins

when the second deviatoric stress invariant 𝐽2 reaches a critical value. For this

reason, it is sometimes called the 𝐽2 plasticity or 𝐽2 flow theory. In materials

science and engineering the von Mises yield criterion can be also formulated

in terms of the von Mises stress or equivalent tensile stress, , a scalar stress

value that can be computed from the Cauchy stress tensor. In this case, a

material is said to start yielding when its von Mises stress reaches a critical

value known as the yield strength, . The von Mises stress is used to predict

yielding of materials under any loading condition from results of simple

uniaxial tensile tests. The von Mises stress satisfies the property that two

stress states with equal distortion energy have equal von Mises stress.

Von-mises stress in terms of principal stress is given by

(𝜎1 −𝜎2 )2 +(𝜎2 −𝜎3 )2 +(𝜎3 −𝜎1 )2

𝜎𝑣 = √

2

5. A stress analysis of space craft structural member gives the state of stress as

follows

200 30 0

𝑇𝑖𝑗 = [ 30 100 0 ]

0 0 −50

If the part is made of aluminium alloy with strength 500MPa

Find

Stress invariants

Principal stresses

Von-mises stress

𝐼1 = 𝜎𝑥𝑥 + 𝜎𝑦𝑦 + 𝜎𝑧𝑧

=250

𝜎𝑦𝑦 𝜎𝑥𝑦 𝜎𝑥𝑥 𝜎𝑥𝑧 𝜎𝑥𝑥 𝜎𝑥𝑦

𝐼2 =| 𝜎 𝜎𝑧𝑧 | + | 𝜎𝑧𝑥 𝜎𝑧𝑧 | + | 𝜎𝑥𝑦 𝜎𝑦𝑦 |

𝑦𝑧

= -5000-10000+19100 = 4100

𝐼3 = det (σ)

=-955000

Characteristic equation is given by

𝜎 3 − 250 𝜎 2 + 4100𝜎 + 955000 = 0

Principal stresses are

𝜎1 = -50 MPa

𝜎2 = 208.309 MPa

𝜎3 = 91.690 MPa

Von-mises stress

(𝜎1 −𝜎2 )2 +(𝜎2 −𝜎3 )2 +(𝜎3 −𝜎1 )2

𝜎𝑣 = √

2

=224.0531 MPa

Potrebbero piacerti anche

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Different Failure TheoriesDocumento4 pagineDifferent Failure TheoriesManjunath NadarajanNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- GECBH Students Placed 2013 Pass OutDocumento5 pagineGECBH Students Placed 2013 Pass OutManjunath NadarajanNessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- 8.1. Campusinfrastructureandfacility (10) : Hostels No. of Rooms No. of Students AccommodatedDocumento6 pagine8.1. Campusinfrastructureandfacility (10) : Hostels No. of Rooms No. of Students AccommodatedManjunath NadarajanNessuna valutazione finora

- 13.804 Compter Integrated Manufacturing (MU)Documento2 pagine13.804 Compter Integrated Manufacturing (MU)Manjunath NadarajanNessuna valutazione finora

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- Course Outcomes (CO) : Course: Instructors: Manjunath N Sl. NODocumento2 pagineCourse Outcomes (CO) : Course: Instructors: Manjunath N Sl. NOManjunath NadarajanNessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- s7 Mechnical Strem Production Eng1479454356Documento59 pagines7 Mechnical Strem Production Eng1479454356Manjunath NadarajanNessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- 08.804 Product Design and DevelopmentDocumento4 pagine08.804 Product Design and DevelopmentManjunath NadarajanNessuna valutazione finora

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Me Machine DesignDocumento86 pagineMe Machine DesignManjunath NadarajanNessuna valutazione finora

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- 08.804 Product Design and DevelopmentDocumento4 pagine08.804 Product Design and DevelopmentManjunath NadarajanNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Guide To Water TechnologyDocumento29 pagineGuide To Water TechnologyManjunath NadarajanNessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Classical Approach of ManagementDocumento57 pagineClassical Approach of ManagementManjunath NadarajanNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Wastewater Study GuideDocumento46 pagineWastewater Study GuideManjunath NadarajanNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Tumor Ablation ClinicalDocumento16 pagineTumor Ablation ClinicalManjunath NadarajanNessuna valutazione finora

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- CANCER DictionaryDocumento79 pagineCANCER DictionaryManjunath NadarajanNessuna valutazione finora

- The Garuda PuranaDocumento51 pagineThe Garuda Puranajothi11Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- 107 2 EM Midterm 2 SolDocumento2 pagine107 2 EM Midterm 2 SolAn ChaikekeNessuna valutazione finora

- Time Table MED-UW Summer 2022 Rev-4Documento1 paginaTime Table MED-UW Summer 2022 Rev-4Muhammad Nouman khanNessuna valutazione finora

- Timoshenko Beam Theory - WikipediaDocumento8 pagineTimoshenko Beam Theory - WikipediaaapennsylvaniaNessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Newton's Method On A System of Nonlinear EquationsDocumento14 pagineNewton's Method On A System of Nonlinear EquationsBiswajit PaleiNessuna valutazione finora

- Generating FunctionDocumento2 pagineGenerating Functionzkchong0% (1)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Vibration AnalysisDocumento14 pagineVibration AnalysisHarish KumarNessuna valutazione finora

- Mathematics - 2Documento168 pagineMathematics - 2Infi Coaching CenterNessuna valutazione finora

- G10 Q1 Summative Test Week 1-2Documento3 pagineG10 Q1 Summative Test Week 1-2Mark A. SolivaNessuna valutazione finora

- Dielectric Image MethodsDocumento14 pagineDielectric Image Methodssh1tty_cookNessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Wideband Array Processing Using A Two-Sided Correlation TransformationDocumento13 pagineWideband Array Processing Using A Two-Sided Correlation TransformationSuyash SinghNessuna valutazione finora

- Zill PPT CH 01Documento21 pagineZill PPT CH 01Kenneth Rodriguez HerminadoNessuna valutazione finora

- Arithmetic Sequences of Higher Order: U U U U 1 N n+1-3Documento6 pagineArithmetic Sequences of Higher Order: U U U U 1 N n+1-3Charlie PinedoNessuna valutazione finora

- 7 Space TrussesDocumento3 pagine7 Space TrussesVincent Kong100% (1)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- Gamma Swap: Roger Lee University of Chicago December 29, 2008Documento3 pagineGamma Swap: Roger Lee University of Chicago December 29, 2008Lisa SmithNessuna valutazione finora

- Common Derivatives IntegralsDocumento4 pagineCommon Derivatives Integralsjaytech O. kerim100% (1)

- Electromagnetic Forces in COMSOLDocumento10 pagineElectromagnetic Forces in COMSOLAlkalin100% (1)

- Solution of Differential Equations With MATLABDocumento20 pagineSolution of Differential Equations With MATLABÖmer KayaNessuna valutazione finora

- Maths QP Set-1Documento6 pagineMaths QP Set-1Zam NaizamNessuna valutazione finora

- The 29th Nordic Mathematical Contest: Tuesday, March 24, 2015Documento1 paginaThe 29th Nordic Mathematical Contest: Tuesday, March 24, 2015xpgongNessuna valutazione finora

- Laplace TransformDocumento5 pagineLaplace TransformjohnNessuna valutazione finora

- Unit IIDocumento17 pagineUnit IISivapriya SNessuna valutazione finora

- Revision Test - 1 (MATHS) ON 28-12-17Documento2 pagineRevision Test - 1 (MATHS) ON 28-12-17RG PlaytechNessuna valutazione finora

- Fixed End Moments PDFDocumento1 paginaFixed End Moments PDFEdrian DiazNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- GRHW 1Documento2 pagineGRHW 1Kastalia Delaporta0% (1)

- Dirac AlgebraDocumento29 pagineDirac AlgebraDaniel Julián Cárdenas OrtizNessuna valutazione finora

- Form 5 Additional Maths Note2022Documento10 pagineForm 5 Additional Maths Note2022indahinsyirahNessuna valutazione finora

- From The Point of View of Inter-Universal Teichmuller TheoryDocumento24 pagineFrom The Point of View of Inter-Universal Teichmuller TheoryAdrián López CrucesNessuna valutazione finora

- Stability Theory For Nonlinear Systems: Giuseppe OrioloDocumento47 pagineStability Theory For Nonlinear Systems: Giuseppe OriolomaryamNessuna valutazione finora

- EE351Chap3-2.0 - Transfer FTN & SFGsDocumento19 pagineEE351Chap3-2.0 - Transfer FTN & SFGsSardar Hamid ullahNessuna valutazione finora

- 02 Review of Mathematical FoundationDocumento32 pagine02 Review of Mathematical FoundationHahahahahahahahahaNessuna valutazione finora

- Basic Math & Pre-Algebra Workbook For Dummies with Online PracticeDa EverandBasic Math & Pre-Algebra Workbook For Dummies with Online PracticeValutazione: 4 su 5 stelle4/5 (2)

- The ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemDa EverandThe ISO 45001:2018 Implementation Handbook: Guidance on Building an Occupational Health and Safety Management SystemNessuna valutazione finora