Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

E924

Caricato da

AthonioMourinhoCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

E924

Caricato da

AthonioMourinhoCopyright:

Formati disponibili

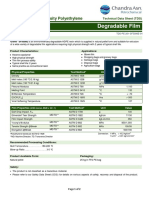

Formolene® E924

High Density Polyethylene High Molecular Weight (HDPE-HMW) Bimodal Resin

Designed For Thin Gauge Film Extrusion Applications

Formolene® E924 is a high molecular weight grade of HDPE designed for high drawdown to produce thin

films with good processing and physical properties. Formolene® E924 is well balanced in overall physical

properties and provides good stiffness for thin gauge film applications.

Formolene® E924 meets all requirements of the U.S. Food and Drug Administration as specified in 21 CFR

177.1520, covering safe use of polyolefin articles intended for direct food contact.

Suggested Applications:

T-Shirt Bags Multi-Wall Bag Liners

Trash Can Liners and Heavy Duty Bags Merchandise Bags

Nominal Physical Properties:

ASTM

TEST

PROPERTY METHOD UNIT VALUE

Typical Resin Properties for E924:

Melt Index D1238 g/10 min. 0.04

HLMI D1238 g/10 min. 8.50

Density D1505 g/cm3 0.949

Melting Point DSC C 131.0

Typical E924 Film Properties:

Dart Drop Impact Strength D1709 g/mil 590

Elmendorf Tear Strength D1922 g/mil 17/210*

Tensile Strength at Break D882 psi. 9,800/7,000*

Tensile Elongation at Break D882 % 290/480*

1% Secant Modulus D882 psi. 74,000/128,000*

* MD / TD

Note: Film properties are not intended to be used as specifications. They represent 0.50 mil film produced in laboratory conditions at

a blow-up ratio of 4.0:1 and a stalk height of 8 times the die diameter. Output: 14.5 Lbs/Hr./In. Die Circumference.

Published 02/01/12, Revised 11/10/16

10/15

Potrebbero piacerti anche

- GRP and Buildings: A Design Guide for Architects and EngineersDa EverandGRP and Buildings: A Design Guide for Architects and EngineersNessuna valutazione finora

- MBA Essays That Worked PDFDocumento170 pagineMBA Essays That Worked PDFAthonioMourinhoNessuna valutazione finora

- Elastomers and Rubber Compounding MaterialsDa EverandElastomers and Rubber Compounding MaterialsI FrantaValutazione: 4.5 su 5 stelle4.5/5 (3)

- Shell and Tube HX Basic CalculationDocumento35 pagineShell and Tube HX Basic Calculationวรศิษฐ์ อ๋องNessuna valutazione finora

- Hempafloor Self-Level 200Documento2 pagineHempafloor Self-Level 200Fadi MagdyNessuna valutazione finora

- FR2375CDocumento1 paginaFR2375CDanitsa Fiorella Silvestre BautistaNessuna valutazione finora

- Formolene FC2304E: Clarity LDPE Resin With 900 PPM Slip and 1200 PPM AntiblockDocumento1 paginaFormolene FC2304E: Clarity LDPE Resin With 900 PPM Slip and 1200 PPM AntiblockHichamSalamaNessuna valutazione finora

- Formolene fl2202c 1Documento1 paginaFormolene fl2202c 1armandoestavanquitoNessuna valutazione finora

- Luban DFDA-7047: Linear Low Density PolyethyleneDocumento2 pagineLuban DFDA-7047: Linear Low Density PolyethyleneJasmine leNessuna valutazione finora

- Luban DFDA-7047: Linear Low Density PolyethyleneDocumento2 pagineLuban DFDA-7047: Linear Low Density PolyethyleneNazmul - Polymet SANessuna valutazione finora

- Certene L.A. LLBF-122D (Sustituto 11PG4) ActualizadaDocumento1 paginaCertene L.A. LLBF-122D (Sustituto 11PG4) ActualizadadianaNessuna valutazione finora

- Exelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingDocumento1 paginaExelene Hdpe: High Density Polyethylene HDPE Copolymer With MWD Thin Injection MoldingOctavio DavidNessuna valutazione finora

- TDS Hpr1018ha AstmDocumento2 pagineTDS Hpr1018ha AstmOsamah JoubsenNessuna valutazione finora

- Tds Dfda 7047 AstmDocumento2 pagineTds Dfda 7047 Astmhafidz 35Nessuna valutazione finora

- TDS Pe 201 Sf5008eDocumento2 pagineTDS Pe 201 Sf5008eOktaviandri SaputraNessuna valutazione finora

- Linear Low Density Polyethylene Film PropertiesDocumento2 pagineLinear Low Density Polyethylene Film PropertiesOsamah JoubsenNessuna valutazione finora

- HMW 700 High Density Polyethylene Data SheetDocumento1 paginaHMW 700 High Density Polyethylene Data SheetJosué GutiérrezNessuna valutazione finora

- LL0209 AA-shazand PDFDocumento1 paginaLL0209 AA-shazand PDFmohamad mostafaviNessuna valutazione finora

- LLBF 122FDocumento1 paginaLLBF 122FYefrain J. ArzolayNessuna valutazione finora

- Product Sheet Petlin LD N125y - 0Documento2 pagineProduct Sheet Petlin LD N125y - 0Manufaktur Sinar JoyoboyoNessuna valutazione finora

- TDS Pe 002 Uf1810t 03Documento2 pagineTDS Pe 002 Uf1810t 03qc jrpNessuna valutazione finora

- Muehlstein Certene HWF-852BDocumento1 paginaMuehlstein Certene HWF-852BManuel martinezNessuna valutazione finora

- Hdpe HHM TR 144Documento1 paginaHdpe HHM TR 144JagrutNessuna valutazione finora

- Sabic® Ldpe Hp0322Nn: Low Density PolyethyleneDocumento2 pagineSabic® Ldpe Hp0322Nn: Low Density PolyethyleneGabriela Lopez MunozNessuna valutazione finora

- Nf528t Rev.0Documento1 paginaNf528t Rev.0MZY Commercial EnterprisesNessuna valutazione finora

- Product Sheet Petlin LD C150y - 0Documento2 pagineProduct Sheet Petlin LD C150y - 0121221042Nessuna valutazione finora

- Tds DGDX 6097 Astm ButeneDocumento2 pagineTds DGDX 6097 Astm ButeneLakshay UniplarNessuna valutazione finora

- Tricolene HDF10952: High Density Polyethylene ResinDocumento1 paginaTricolene HDF10952: High Density Polyethylene ResinLFCV5Nessuna valutazione finora

- PDS HF09522 Rev0 - EvaleneDocumento2 paginePDS HF09522 Rev0 - EvalenechinchotarngNessuna valutazione finora

- TDS Pe 001 Uf1810Documento2 pagineTDS Pe 001 Uf1810asrilNessuna valutazione finora

- Duraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)Documento4 pagineDuraline - Ficha Técnica Tubería PEAD 4710 (Gas Natural)FrancoNessuna valutazione finora

- TDS DGDZ 6097 ASTM HexeneDocumento2 pagineTDS DGDZ 6097 ASTM HexenegauravmishraanalystNessuna valutazione finora

- Lldpe 22501aa22501kjDocumento2 pagineLldpe 22501aa22501kj李万福Nessuna valutazione finora

- DFDC-7080 Linear Low Density Polyethylene FilmDocumento2 pagineDFDC-7080 Linear Low Density Polyethylene FilmNazmul - Polymet SANessuna valutazione finora

- Lldpe LL0209KJDocumento1 paginaLldpe LL0209KJmohamad mostafaviNessuna valutazione finora

- Product Data: Titanlene Ldf200GgDocumento1 paginaProduct Data: Titanlene Ldf200GgchinchotarngNessuna valutazione finora

- Westlake Polymers LP: Typical Physical PropertiesDocumento1 paginaWestlake Polymers LP: Typical Physical PropertiesGabs GabrielaNessuna valutazione finora

- Qatofin Lotrene Q2018Documento2 pagineQatofin Lotrene Q2018HichamSalamaNessuna valutazione finora

- FORMOLENE LB1810E2 Homotipo Venelene 11pg4Documento1 paginaFORMOLENE LB1810E2 Homotipo Venelene 11pg4Luis Eduardo Julio MovillaNessuna valutazione finora

- LDF201FG R01Documento1 paginaLDF201FG R01Oscar Tan IIINessuna valutazione finora

- Product Data: Titanex Hf0961Documento1 paginaProduct Data: Titanex Hf0961chinchotarngNessuna valutazione finora

- SABIC® LDPE - HP0322N - Global - Technical - Data - SheetDocumento2 pagineSABIC® LDPE - HP0322N - Global - Technical - Data - SheetThamimNessuna valutazione finora

- Lldpe - LL7410D PDSDocumento1 paginaLldpe - LL7410D PDSchinchotarngNessuna valutazione finora

- Formolene E924: Technical Data SheetDocumento1 paginaFormolene E924: Technical Data SheetGabs GabrielaNessuna valutazione finora

- HB5502BDocumento1 paginaHB5502BDe SaripudinNessuna valutazione finora

- TDS Pe 003 Uf1810s1 03Documento2 pagineTDS Pe 003 Uf1810s1 03qc jrpNessuna valutazione finora

- TDS Pe 010 Uf1820t 04Documento2 pagineTDS Pe 010 Uf1820t 04Lenggana SukriaNessuna valutazione finora

- DTM Bonding Primer: Protective & Marine CoatingsDocumento4 pagineDTM Bonding Primer: Protective & Marine CoatingsAna CabreraNessuna valutazione finora

- TDS Pe 200 SF5007Documento2 pagineTDS Pe 200 SF5007Oktaviandri SaputraNessuna valutazione finora

- Mpact D143: Metallocene Linear Low Density PolyethyleneDocumento1 paginaMpact D143: Metallocene Linear Low Density PolyethyleneJulio GarcíaNessuna valutazione finora

- POLYMER C150Y - Jan15 - New - Rev1Documento2 paginePOLYMER C150Y - Jan15 - New - Rev1W I Prayogo100% (1)

- LDPE C2923 - Con AditivosDocumento1 paginaLDPE C2923 - Con Aditivosedinson100% (1)

- TDS - TR144 - Astm (Eng)Documento2 pagineTDS - TR144 - Astm (Eng)Darwin Lenin Iza PradoNessuna valutazione finora

- Low Density Polyethylene: Lamination Film ApplicationsDocumento1 paginaLow Density Polyethylene: Lamination Film ApplicationsMahadi Bachar MahamatNessuna valutazione finora

- Delrin - Mechanical PropertyDocumento1 paginaDelrin - Mechanical PropertyGovarthanan GovaNessuna valutazione finora

- Delrin SpecsDocumento1 paginaDelrin SpecsGrimmo1979Nessuna valutazione finora

- Delrin SpecsDocumento1 paginaDelrin SpecsabhijitNessuna valutazione finora

- Marlex D139 Polyethylene: Nominal Resin Properties English SI MethodDocumento1 paginaMarlex D139 Polyethylene: Nominal Resin Properties English SI MethodGabriela Lopez MunozNessuna valutazione finora

- Hanwha LLDPE 7635Documento1 paginaHanwha LLDPE 7635M. Kürşad ArslanNessuna valutazione finora

- M6007LDocumento1 paginaM6007LempacNessuna valutazione finora

- Sabicr Ldpe Hp4023wnDocumento2 pagineSabicr Ldpe Hp4023wnFarah bennourNessuna valutazione finora

- Novapol TF 0338 e NovaDocumento2 pagineNovapol TF 0338 e NovaJulio GarcíaNessuna valutazione finora

- kopelen jh-350 (1)Documento2 paginekopelen jh-350 (1)AthonioMourinhoNessuna valutazione finora

- HD5403AA_new_revision september 2020Documento2 pagineHD5403AA_new_revision september 2020AthonioMourinhoNessuna valutazione finora

- Trilen 9500G40Documento2 pagineTrilen 9500G40AthonioMourinhoNessuna valutazione finora

- tds-hd5403pdfDocumento2 paginetds-hd5403pdfAthonioMourinhoNessuna valutazione finora

- Oq TDS Ep2340lDocumento2 pagineOq TDS Ep2340lAthonioMourinhoNessuna valutazione finora

- Oq TDS Ep2348rDocumento2 pagineOq TDS Ep2348rAthonioMourinhoNessuna valutazione finora

- Leaflet BI6200 ENDocumento1 paginaLeaflet BI6200 ENAthonioMourinhoNessuna valutazione finora

- Oq TDS Ep2340pDocumento2 pagineOq TDS Ep2340pAthonioMourinhoNessuna valutazione finora

- Oq TDS HP2100LDocumento2 pagineOq TDS HP2100LAthonioMourinhoNessuna valutazione finora

- 4710c24e-0c54 ZA HKR102 EN-ZADocumento2 pagine4710c24e-0c54 ZA HKR102 EN-ZABanupriya BalasubramanianNessuna valutazione finora

- 150506T01 PVC NIC GMBHDocumento15 pagine150506T01 PVC NIC GMBHAthonioMourinhoNessuna valutazione finora

- Oq TDS Ep2340pDocumento2 pagineOq TDS Ep2340pAthonioMourinhoNessuna valutazione finora

- ZA - Polymers - LDPE OverviewDocumento4 pagineZA - Polymers - LDPE OverviewKai Yuan TeoNessuna valutazione finora

- ECM6: Homework # 1 (2012) : GuidelinesDocumento3 pagineECM6: Homework # 1 (2012) : GuidelinesAthonioMourinhoNessuna valutazione finora

- 0 C 960537234 e 247 A 70000000Documento12 pagine0 C 960537234 e 247 A 70000000AthonioMourinhoNessuna valutazione finora

- 09 e 4150 A 380 FCF 1 Da 3000000Documento9 pagine09 e 4150 A 380 FCF 1 Da 3000000AthonioMourinhoNessuna valutazione finora

- New Microsoft Word DocumentDocumento4 pagineNew Microsoft Word DocumentAthonioMourinhoNessuna valutazione finora

- Solution to HW3 Minimizes Disturbance and SensitivityDocumento9 pagineSolution to HW3 Minimizes Disturbance and SensitivityAthonioMourinhoNessuna valutazione finora

- Estimating biomass and growth rate from oxygen uptake dataDocumento3 pagineEstimating biomass and growth rate from oxygen uptake dataAthonioMourinhoNessuna valutazione finora

- Solution to HW3 Minimizes Disturbance and SensitivityDocumento9 pagineSolution to HW3 Minimizes Disturbance and SensitivityAthonioMourinhoNessuna valutazione finora