Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Guidance: Process Audit Checklist

Caricato da

nadeemkarimiTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Guidance: Process Audit Checklist

Caricato da

nadeemkarimiCopyright:

Formati disponibili

Process Audit Checklist

Guidance

Scoring Criteria

The following audit scoring criteria have been used to identify the level of compliance with each requirement that is set out in the standard. In the 'Opportunities for

Improvement' field, note down any situation or condition of the management system that may be weak, cumbersome, redundant, overly complex, or in some other manner,

may, in the opinion of the auditor, offer an opportunity for the organization to improve its current status. In the 'Audit Evidence' field, fill in the evidence that you saw and your

thoughts about the implementation and documentation. If any of the requirements are not applicable, please type 'N/A' to denote that the particular requirement is not

applicable to the organization.

Compliant: Yes, requirement fully documented and implemented. Adherence with the requirements of the standard or specification. No major or

minor non-conformances found.

Opportunity for Improvement (OFI): Minor gap, mostly documented and implemented The management system that may be weak, cumbersome, redundant, overly

complex, or in some other manner, may, in the opinion of the auditor, offer an opportunity for an organization to improve its current

status.

Minor Non-conformance: Requirement partially implemented but no documentation or partially documented but not implemented. A non-conformity that,

based on the judgment and experience of the auditor, is not likely to result in the failure of the management system or reduce its

ability to assure controlled processes or products. It may be either a failure in some part of the supplier's management system relative

to a specified requirement or a single observed lapse in following one item of a company's management system.

Major Non-conformance: No provision, requirement not documented or implemented. The absence (omission, not addressed) or total breakdown (commission,

failure, not implemented) of a system to meet a specified requirement. A number of minor non-conformities against one requirement

can represent a total breakdown of the system and thus be considered a major non-conformity. Any non-compliance that would result

in the probable shipment of a non-conforming product. Conditions that may result in the failure of or materially reduce the usability of

the products or services for their intended purpose. A non-compliance that, in the judgment and experience of the auditor, is likely to

either to result in the failure of the management system or to materially reduce its ability to assure controlled processes and products.

Requirements

An audit of customer related processes should be conducted at planned intervals in order to determine whether the process conforms to planned arrangements in order to

determine whether the process is properly implemented and maintained and to provide process performance information to top management. Effective auditing requires the

auditor to identify and record audit trails that will make a difference to the organization. The audit should begin with the process owner in order to understand how the process

Auditor Name (print): Initials: Date:

Process Audit Checklist

interacts with the other process inputs, outputs, suppliers and/or customers. The auditor should be able to determine whether the outputs are complete and that process

measurements demonstrate whether all of the outputs are consistently fit for purpose and are efficiently managed. Do the customers agree with the outputs and the

measures?

An audit of customer related processes is conducted at planned intervals to:

Determine whether the process conforms to planned arrangements

Determine whether the process is properly implemented and maintained

Provide information on process performance to Top Management

Consider these points during the audit:

Is there continuity between the various support processes?

Is the task done consistently on a person-to-person or day-to-day basis?

Do the interfaces between the departments operate smoothly?

Does product information flow freely?

Is the procedure right?

Does it meet the requirements of the standard or specification?

Is it helping the organization effectively?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Process Audit Turtle Diagram

EQUIPMENT & FACILITIES: PERSONNEL: CONTROL PROCESSES:

What equipment and resources are required? Review employee skill lists for the process. Are there How is the process defined and who is responsible?

Is equipment suitable and properly maintained? lists of skills for each position? Do they show enough How are customer requirements defined?

Is the work environment maintained? detail? This is often a finding, where lists are generic What specifications apply defined?

Is there evidence of appropriate maintenance of all with inadequate detail. Training is a key process of any What objectives and targets apply process?

equipment used by this process? system. Are there particular skills you want to What controls/check points are there?

evaluate? What acceptance criteria exist?

PROCESS INPUTS: PROCESS NAME/DESCRIPTION: PROCESS OUPUTS:

What triggers the process? What steps are involved in the process? What is the product produced by this process?

What inputs are required? What happens at each step in the process? Are product measures in place to ensure that product

Where do the inputs come from? What documents and records are generated? meets requirements?

Are they received in a timely manner? Is the process implemented in accordance with How are processes measured?

Are they fit for purpose? procedures, instructions or plans? Are product and process measures achieved?

Are controls applied as described? What feedback is received from customers?

INSTRUCTIONS & PROCEDURES: SUPPORT PROCESSES: KEY PERFORMANCE INDICATORS:

Review the documents that describe and control the As you audit, you will see how it connects and Review metrics and performance with Managers,

process. Review all the important steps and activities interacts with other processes. Interactions with other Supervisors and operators. They should know how

of the process being audited. This info must be processes are always important. As you audit the, you things are running, objectives, customer issues,

documented within the QMS. Evaluate how effectively will see how it connects and interacts with other problem areas. If they do not, the requirements were

the process flows through the steps. Do you see processes. Audit the relevant links to related not met. Is there evidence that quality objectives and

roadblocks or issues? processes and support processes. targets affected by this process are being achieved?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Process Audit Questions

Process Definition

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

Improvement (OFI)

COMPLIANT

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

1 Is the process defined and documented?

Is the process owner identified? (Process map, procedure or

2

work instruction, etc.)

Is there evidence that process inputs are accurately defined and

3

understood by all employees involved?

Is there evidence that process activities are accurately defined

4

and understood by all employees involved?

Is there evidence that process outputs are accurately defined

5

and understood by all employees involved?

6 Are inputs defined and prioritized based on risk?

Have procedures, instructions, and forms been established as

7

needed to control the process?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

Improvement (OFI)

COMPLIANT

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

Are procedures, instructions and forms used in controlling the

8

process readily available?

Do procedures, instructions and forms accurately reflect the

9

practices? (Note: Requires the auditor review and observation!)

10 Are there adequate plans in place to achieve the objectives?

Is relevant customer feedback available? (Feedback from

11

subsequent processes)

12 Are documents understood by process participants?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Process Resources

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

Is there evidence of management commitment, involvement

13

and allocation of resources?

How many people participate in the process, is this adequate to

14

achieve process requirements?

Are participants adequately trained to carry out roles,

15

responsibilities, and authorities?

Is equipment (e.g. manufacturing, measuring & monitoring

16 equipment; transport/logistics; hardware/software; PPE; etc.)

adequate for its intended use?

Is equipment identified to allow participants to determine its

17

readiness for safe use prior to and during the operation?

Are process owners accountable for the performance and

18

compliance of their processes?

19 Are employees satisfied with their work area?

20 Is the work area clean and safe?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

21 Is there adequate equipment/tools/IT support?

Are employees motivated and encouraged to make suggestions

22

for process improvement?

Are all employees aware of the organizational objectives and the

23

current status of these measurements?

Are all employees aware of who their customers are and

24

whether they are satisfied?

Are employees aware of the process metrics which their

25

activities can affect?

Are they aware of the current data analysis related to these

26

metrics and the plans in place to achieve them?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Process Execution

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

Is the observed process activity consistent with approved plans

27

and procedures?

Is the process flow constructed to avoid unnecessary movement

28

of materials and personnel?

29 Are redundant and non-value adding activities minimized?

30 Is material usage maximized to avoid waste?

Is waste material effectively removed and segregated from the

31

process?

Are unused materials returned to the correct location in

32

conditions suitable to allow re-use?

Are process outputs passed on to subsequent processes only

33

when all planned process activities are completed?

Is there evidence of continuity between the various support

34

processes?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

35 Do the interfaces between the departments operate smoothly?

Does product information flow freely between the support

36

processes?

Is there evidence for the reduction in measurement system and

37

process variation?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Process Monitoring

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

38 Is the process monitored, measured, analyzed and improved?

Are monitoring activities carried out according to approved

39

plans and procedures?

Is process monitoring compared against standards to determine

40

the current status of the process?

Is process status communicated to appropriate members of the

41

process team?

Are records of process monitoring maintained according to

42

approved procedures?

Have key performance indicators (KPI) been established to allow

43

the effectiveness of the process to be evaluated?

44 Are KPI consistent with quality and business objectives?

45 Are KPI consistent with customer requirements?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

Are KPI reviewed and communicated to the process team, as

46

appropriate, by process leaders?

47 Is the process measured for effectiveness and efficiency?

When a process is not performing, is there evidence of data

48

analysis to determine the root cause?

When a process is not performing, is there evidence that the

49

cause(s) are dealt with in accordance with procedure?

Are records of process monitoring reviewed regularly to

50

determine opportunities for corrective and preventive action?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Process Improvement

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

Is the performance of the process reviewed at an appropriate

51

frequency by top management?

Are process improvement objectives aligned with organizational

52

objectives, e.g. the business plan?

53 Is there evidence of an effective PDCA cycle?

Can the process owner demonstrate how PDCA applies to their

54

process?

Can the process owner to show examples of improvements

55

driven by their PDCA cycle?

Can employees demonstrate areas of previous continual

56

improvement?

Are records of process upsets and actions taken reviewed to

57

determine the need for corrective/preventive action?

Where corrective/preventive actions have been implemented,

58

have the action(s) taken been demonstrated as effective?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Finding (Tick)

Opportunities for

QUESTION No.

Audit Evidence

COMPLIANT

Improvement (OFI)

MAJOR N/C

MINOR N/C

Audit Question

OFI

Provide reference to documentation or Provide suggestions for process

records that justify the finding improvement

Where opportunities for improvement have been implemented,

59

have the action(s) taken been demonstrated as effective?

Are all process participants encouraged to be involved in

60

identifying improvements?

Auditor Name (print): Initials: Date:

Process Audit Checklist

Findings Summary

Non-conformance

No. ISO/Specification Ref. Summary Root Cause NCR No. Rectification Date

Corrective Action

No. ISO/Specification Ref. Summary Root Cause CAR No. Rectification Date

Preventive Action & OFI

No. ISO/Specification Ref. Summary Root Cause PAR No. Implementation Date

Auditor Name (print): Initials: Date:

Process Audit Checklist

Observations, Comments & Notes

Auditor Name (print): Initials: Date:

Process Audit Checklist

Auditor Name (print): Initials: Date:

Potrebbero piacerti anche

- Process Approach A Complete Guide - 2019 EditionDa EverandProcess Approach A Complete Guide - 2019 EditionNessuna valutazione finora

- Alabama Specialty Products, Inc.Documento24 pagineAlabama Specialty Products, Inc.qmicertificationNessuna valutazione finora

- Quality Management System Software A Complete Guide - 2019 EditionDa EverandQuality Management System Software A Complete Guide - 2019 EditionNessuna valutazione finora

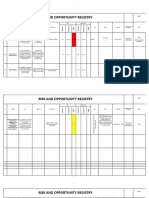

- Risk Registry Sample - PUBLICDocumento8 pagineRisk Registry Sample - PUBLICMelissa CruzNessuna valutazione finora

- Good Distribution Practices A Complete Guide - 2021 EditionDa EverandGood Distribution Practices A Complete Guide - 2021 EditionNessuna valutazione finora

- Project: Dr. Muhammad AjmalDocumento14 pagineProject: Dr. Muhammad AjmalAyesha AbbasNessuna valutazione finora

- Quality Manual, IsO 13485 and MDR, Free TemplateDocumento13 pagineQuality Manual, IsO 13485 and MDR, Free TemplateNADJAH YOUSFINessuna valutazione finora

- Anatomy of ContaminationControlDocumento19 pagineAnatomy of ContaminationControlVinay PatelNessuna valutazione finora

- How Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementDocumento3 pagineHow Can ISO 13485 Clause 7.4, Purchasing, Enhance ProcurementPavan MujawdiyaNessuna valutazione finora

- Checklist ISO45001Documento9 pagineChecklist ISO45001sg_lexNessuna valutazione finora

- Quality Manual Policy ObjectivesDocumento5 pagineQuality Manual Policy ObjectivesImane AaNessuna valutazione finora

- Iso 9001 2015Documento10 pagineIso 9001 2015sharmaramesh34735170% (1)

- Part 2 - EQMS ValidationDocumento7 paginePart 2 - EQMS ValidationIza TobolskaNessuna valutazione finora

- As Iso 10015-2006Documento25 pagineAs Iso 10015-2006АлексейNessuna valutazione finora

- Iso13485 QM06 MngResponsibilityDocumento9 pagineIso13485 QM06 MngResponsibilityQuality and Safety Consultants Co.Nessuna valutazione finora

- Randy Kelana: UHAMKA - Agustus 2022Documento24 pagineRandy Kelana: UHAMKA - Agustus 2022diinipermanaNessuna valutazione finora

- Conformity Assessment (Management System Certification)Documento5 pagineConformity Assessment (Management System Certification)Talal AhmedNessuna valutazione finora

- Referenced Procedure # Procedure Name Included Form# Included Form NameDocumento2 pagineReferenced Procedure # Procedure Name Included Form# Included Form NameAngelo SantiagoNessuna valutazione finora

- ISO 13485 2003 Vs FDA QSR 42 69Documento28 pagineISO 13485 2003 Vs FDA QSR 42 69Ancuta FeierNessuna valutazione finora

- Rms Quality CounterfeitDocumento24 pagineRms Quality CounterfeitFrancis LewahNessuna valutazione finora

- As 9100 9110 QMDocumento27 pagineAs 9100 9110 QMAMINE ABASSINessuna valutazione finora

- NABL 600 Directory of Accredited Medical Testing Laboratories As On 01 05 2015 PDFDocumento100 pagineNABL 600 Directory of Accredited Medical Testing Laboratories As On 01 05 2015 PDFektasharma123Nessuna valutazione finora

- 2 Mapping ProcessesDocumento73 pagine2 Mapping ProcessesIr Moise MatabaroNessuna valutazione finora

- CustomerDocumento5 pagineCustomervg_vvgNessuna valutazione finora

- AAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Documento28 pagineAAMI Quality Systems White Paper: Comparison of 21 CFR Part 820 To ISO 13485:2016Hong XuyenNessuna valutazione finora

- Context & Strategy Analysis: ISO 9001:2015 QMSDocumento3 pagineContext & Strategy Analysis: ISO 9001:2015 QMSshailendra singhNessuna valutazione finora

- Iso 15194 2009Documento11 pagineIso 15194 2009Safaa MasoudNessuna valutazione finora

- What Is A Document?: Tips On ISO 9001 Quality Management System DocumentationDocumento5 pagineWhat Is A Document?: Tips On ISO 9001 Quality Management System DocumentationMohammad Jaid AlamNessuna valutazione finora

- Iso13485 QM06 MngResponsibilityDocumento9 pagineIso13485 QM06 MngResponsibilityhitham shehataNessuna valutazione finora

- Iso13485 QM01 Scope PDFDocumento4 pagineIso13485 QM01 Scope PDFQuality and Safety Consultants Co.Nessuna valutazione finora

- Audit Report TemplateDocumento2 pagineAudit Report TemplateSiti Zulaikha Johari AffandiNessuna valutazione finora

- 21 CFR Part 11 RegulationsDocumento25 pagine21 CFR Part 11 RegulationsVinita SharmaNessuna valutazione finora

- CDC UP Requirements Traceability Matrix TemplateDocumento2 pagineCDC UP Requirements Traceability Matrix TemplateFelicia GhicaNessuna valutazione finora

- Quality Manual 9001-2015 06-10-2021Documento27 pagineQuality Manual 9001-2015 06-10-2021Geoff EricksonNessuna valutazione finora

- White Paper On UNIDO's GMP Roadmap ConceptDocumento24 pagineWhite Paper On UNIDO's GMP Roadmap Conceptiabureid7460Nessuna valutazione finora

- WI - Case HandlingDocumento32 pagineWI - Case HandlingYosep GunawanNessuna valutazione finora

- Guide To Agile Design and Development For Medical Devices-AMDD-Greenlight-GuruDocumento40 pagineGuide To Agile Design and Development For Medical Devices-AMDD-Greenlight-Gururemliw101Nessuna valutazione finora

- IAF - MD08 - 2020 - App ISO-IEC 17011 - ISO 13485Documento19 pagineIAF - MD08 - 2020 - App ISO-IEC 17011 - ISO 13485Leonardo Navarro100% (1)

- Clause 8 - ExplanationDocumento33 pagineClause 8 - Explanations_agali2413Nessuna valutazione finora

- 424 Software Testing PDFDocumento102 pagine424 Software Testing PDFawneesh tiwariNessuna valutazione finora

- User Access PermissionsDocumento8 pagineUser Access PermissionsSihle Crystal GaselaNessuna valutazione finora

- PresH - ISO 14971Documento20 paginePresH - ISO 14971William Salgado0% (1)

- ISO 9001 and ISO 10007 Quality Management - Guidance For CM Relative To CMIIDocumento8 pagineISO 9001 and ISO 10007 Quality Management - Guidance For CM Relative To CMIImsaadi717Nessuna valutazione finora

- Canadian Safety and Effectiveness Requirements (Cser)Documento9 pagineCanadian Safety and Effectiveness Requirements (Cser)aymohamad2020Nessuna valutazione finora

- Standard Operation Procedure Production ProcessDocumento2 pagineStandard Operation Procedure Production ProcessHarits As SiddiqNessuna valutazione finora

- ISO 9001 Internal Audit ChecklistDocumento14 pagineISO 9001 Internal Audit ChecklistEsterNTNessuna valutazione finora

- NIST SP 800-171r1Documento125 pagineNIST SP 800-171r1Fabio MartinezNessuna valutazione finora

- Annex IV Part IV Audit Report Template v4.1 PDFDocumento6 pagineAnnex IV Part IV Audit Report Template v4.1 PDFMichael FadjarNessuna valutazione finora

- Quality Manual 9001-2008 Elsmar 1Documento13 pagineQuality Manual 9001-2008 Elsmar 1luis miguel perez cruzNessuna valutazione finora

- Procedure For Designing and Developing ProjectDocumento3 pagineProcedure For Designing and Developing ProjectMalu Paras LacsonNessuna valutazione finora

- Achieving Quality Production: Textbook, Chapter 19 (PG 235-239)Documento4 pagineAchieving Quality Production: Textbook, Chapter 19 (PG 235-239)Vincent ChurchillNessuna valutazione finora

- Introduction To ISO 9001 2015Documento11 pagineIntroduction To ISO 9001 2015chrisNessuna valutazione finora

- 3rd ISO 90012015 Internal Audit ReportDocumento40 pagine3rd ISO 90012015 Internal Audit Reportmohammed kurkuruNessuna valutazione finora

- All Processes ChecklistDocumento9 pagineAll Processes ChecklistAndy Le GrangeNessuna valutazione finora

- LQMS-SIP Checklist Final v1 - Jan 12 2016 PDFDocumento48 pagineLQMS-SIP Checklist Final v1 - Jan 12 2016 PDFrasimc9475Nessuna valutazione finora

- Pub100373 PDFDocumento12 paginePub100373 PDFedgelcer100% (1)

- Selecting, Implementing, and Using QMS Software SolutionsDocumento24 pagineSelecting, Implementing, and Using QMS Software SolutionsSireesha100% (1)

- The Much Anticipated: ISO/IEC 27701:2019Documento6 pagineThe Much Anticipated: ISO/IEC 27701:2019Clement ChanNessuna valutazione finora

- Sanofi Application Strategy Framework DraftDocumento16 pagineSanofi Application Strategy Framework DraftfzNessuna valutazione finora

- Sample SoP For Vigilance SystemDocumento9 pagineSample SoP For Vigilance Systemhitham shehataNessuna valutazione finora

- Supplier Audit ChecklistDocumento21 pagineSupplier Audit ChecklistAnonymous W2gdmMVhoM100% (2)

- Intekhab e Naat Vol2Documento448 pagineIntekhab e Naat Vol2nadeemkarimi100% (2)

- B 17Documento47 pagineB 17nadeemkarimiNessuna valutazione finora

- Martin Gibson QIS 3 June 2014Documento13 pagineMartin Gibson QIS 3 June 2014nadeemkarimiNessuna valutazione finora

- Previews AIAG SPC 3 Pre PDFDocumento6 paginePreviews AIAG SPC 3 Pre PDFnadeemkarimiNessuna valutazione finora

- Advanced Product Quality Planning and Control Plan: Second EditionDocumento5 pagineAdvanced Product Quality Planning and Control Plan: Second EditionDavid Sigalingging36% (11)

- Chap3f Secure PDFDocumento195 pagineChap3f Secure PDFnadeemkarimiNessuna valutazione finora

- Aboriginal Perspectives: A Guide To The Teacher's ToolkitDocumento12 pagineAboriginal Perspectives: A Guide To The Teacher's ToolkitbmvoNessuna valutazione finora

- Drill Site Audit ChecklistDocumento5 pagineDrill Site Audit ChecklistKristian BohorqzNessuna valutazione finora

- Summary Scholten's GroupsDocumento8 pagineSummary Scholten's GroupsLily Samardzic-Rafik100% (4)

- For Hand Grip Strength: NormsDocumento7 pagineFor Hand Grip Strength: NormsPraneethaNessuna valutazione finora

- Community Medicine DissertationDocumento7 pagineCommunity Medicine DissertationCollegePaperGhostWriterSterlingHeights100% (1)

- Compensation ManagementDocumento2 pagineCompensation Managementshreekumar_scdlNessuna valutazione finora

- Perioperative Care For CABG PatientsDocumento32 paginePerioperative Care For CABG PatientsAya EyadNessuna valutazione finora

- MSDS Lubriplate 105Documento2 pagineMSDS Lubriplate 105mackyyo0% (1)

- Test Questions For Oncologic DisordersDocumento6 pagineTest Questions For Oncologic Disorderspatzie100% (1)

- Module 2: Environmental Science: EcosystemDocumento8 pagineModule 2: Environmental Science: EcosystemHanna Dia MalateNessuna valutazione finora

- Cape 2 Biology - Homeostasis &excretionDocumento9 pagineCape 2 Biology - Homeostasis &excretionTamicka BonnickNessuna valutazione finora

- Consent CertificateDocumento5 pagineConsent Certificatedhanu2399Nessuna valutazione finora

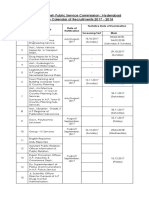

- APPSC Calender Year Final-2017Documento3 pagineAPPSC Calender Year Final-2017Krishna MurthyNessuna valutazione finora

- Effect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventDocumento8 pagineEffect of Moisture Content On The Extraction Rate of Coffee Oil From Spent Coffee Grounds Using Norflurane As SolventMega MustikaningrumNessuna valutazione finora

- AQ-101 Arc Flash ProtectionDocumento4 pagineAQ-101 Arc Flash ProtectionYvesNessuna valutazione finora

- VOC & CO - EnglishDocumento50 pagineVOC & CO - EnglishAnandKumarPNessuna valutazione finora

- Crime Free Lease AddendumDocumento1 paginaCrime Free Lease AddendumjmtmanagementNessuna valutazione finora

- Bakery Ind HygieneDocumento104 pagineBakery Ind Hygienelabie100% (1)

- FNCP Improper Waste DisposalDocumento2 pagineFNCP Improper Waste DisposalKathleen Daban RagudoNessuna valutazione finora

- MSU-Iligan Institute of TechnologyDocumento5 pagineMSU-Iligan Institute of TechnologyYuvi Rociandel LUARDONessuna valutazione finora

- Richard Teerlink and Paul Trane - Part 1Documento14 pagineRichard Teerlink and Paul Trane - Part 1Scratch HunterNessuna valutazione finora

- Subquery ProblemDocumento9 pagineSubquery ProblemAbhi RamNessuna valutazione finora

- Rotary Screw Gas: CompressorsDocumento2 pagineRotary Screw Gas: CompressorsLucas SilvestreNessuna valutazione finora

- TelfastDocumento3 pagineTelfastjbahalkehNessuna valutazione finora

- MelatoninaDocumento32 pagineMelatoninaCodrut GeorgescuNessuna valutazione finora

- Aseptic TechniquesDocumento3 pagineAseptic TechniquesMacy MarianNessuna valutazione finora

- Presentation - Factors Affecting ClimateDocumento16 paginePresentation - Factors Affecting ClimateAltoverosDihsarlaNessuna valutazione finora

- 4th Summative Science 6Documento2 pagine4th Summative Science 6brian blase dumosdosNessuna valutazione finora

- Polikanov 2019-05-14 Curriculum Vitae YuryDocumento6 paginePolikanov 2019-05-14 Curriculum Vitae Yuryapi-460295531Nessuna valutazione finora

- Cooling Tower (Genius)Documento7 pagineCooling Tower (Genius)JeghiNessuna valutazione finora