Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Greenbarge 1 Greenbarge 2 Greenbarge 3 Greenbarge 4: Standard North Sea Barge 300x90 FT

Caricato da

Ganesh FakatkarTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Greenbarge 1 Greenbarge 2 Greenbarge 3 Greenbarge 4: Standard North Sea Barge 300x90 FT

Caricato da

Ganesh FakatkarCopyright:

Formati disponibili

Greenbarge 1

Greenbarge 2

Greenbarge 3

Greenbarge 4

Standard North Sea Barge 300x90 ft

Greenbarge 1 Greenbarge 1 – 4 are flattop oceangoing heavy deck

cargo barges with the following special features:

Point loads :

Longitudinal bulkheads / sideshell and transverse frames : 700 tonnes

Greenbarge 2

Longitudinal bulkheads / sideshell and transverse bulkheads : 200 tonnes

• improved hull shape for reduced towing resistance Mid on transverse frames : 240 tonnes

obtaining a higher towing speed with less fuel

Mid on transeverse bulkheads : 100 tonnes

consumption.

Greenbarge 3 • diesel-electric power system and automated

ballasting and valve control system with Eltorque

Greenbarge 4

electric actuators.

• first offshore barges to have built-in ballast water

treatment system (BWTS), the Type-Approved

BALPURE® ballast water treatment system from

Severn Trent De Nora.

Built: 2012 BWTS:

Yard: Dalian Shipyard Capacity: 600m3/hour

Class: DNV +1A1

Flag: Greenbarge 1 Singapore Type-approved BALPURE® ballast water treatment system

Greenbarge 2 Singapore is a reliable and economical ballast water treatment

Greenbarge 3 Norway approach, which has been proven to surpass IMO D-2

Greenbarge 4 Norway standards. The system utilizes electrolytic disinfection

technology treatment during uptake of the ballast water.

Dimensions :

Lenght overall: 91,440 m ( 300`) Towing arrangement :

Breadth overall: 27,432 m ( 90`) DNV certified Smit towing brackets both forward and aft

Depth: 6,096 m ( 20`) (recessed). Certified towing bridle consisting of 2 x 3,8m

Draft forward: 1,308 m chafing chains, 2 x 17m steel wire ropes, forged Deltaplate

Draft aft: 0,894 m and shackles, all with SWL 85T.

Loaded draft: 4,840 m

Frame Spacing: 2286 mm

Emergency towing arrangement :

DNV certified Smit towing bracket connected to a 4m

Arrangement and form : chafing chain and 103m steel wire rope with SWL 85T+,

Bulkheads: 3 longitudinal, stretcher, messenger line and floating buoy.

4 transverse

pumproom bulkhead.

Double bottom: In pumproom Mooring-/ Anchor arrangement :

Ballast tanks: 20 Emergency anchor: 1 x Spek anchor 4000 kg

Bow: Raked - sloped bottom plate Anchor wire: 610m dia. 38 mm

Stern: Raked - sloped bottom plate Windlass: Hydraulic driven in pumproom

and 2 skegs Capstan: Hydraulic driven PS forward

Bollards: Recessed mooring bollards NS2584

Fenders: 2 x tiers horizontal steel

Capacities : fenders each side.

Deadweight: 9025 tonnes 1 x tier steel fender each end.

Lightship weight: 2361 tonnes

Reg. Tonnage: 4050 GRT / 1215 NRT

Deck area: 2508 m2 Navigational equipment:

Uniform deck load: 25 tonnes per m2

2

Daylight signals, LED and gas driven navigational lights.

Machinery and ballasting equipment:

Generator: Caterpillar 200kw

Ballast pumps: 2 x 600 m3/hour

Tank Sounding: Kockum Sonics Levelmaster Disclaimer :

All information in this brochure

Valve actuators: Eltorque QT800/QT250 is believed to be correct,

but not guaranteed.

Greenway Shipping AS, PO box 1226, Pirsenteret, 7462 Trondheim, Norway

Tel +47 477 00 222, chartering@greenwayshipping.no www.greenwayshipping.no

Potrebbero piacerti anche

- Atlantic Eagle - Infos, GA Plan PDFDocumento4 pagineAtlantic Eagle - Infos, GA Plan PDFArief KurniawanNessuna valutazione finora

- Saipem 3000Documento8 pagineSaipem 3000Nkechi KokoNessuna valutazione finora

- Ceona - Normand Pacific Datasheet - EU Low PDFDocumento2 pagineCeona - Normand Pacific Datasheet - EU Low PDFHugo Vco RvaNessuna valutazione finora

- Specifications Laguna StarDocumento2 pagineSpecifications Laguna StarVictor RamosNessuna valutazione finora

- 2019 Fairplayer FactsheetDocumento4 pagine2019 Fairplayer Factsheetnoorul786Nessuna valutazione finora

- M/V PRIDE - Advanced DP-3 Offshore Construction VesselDocumento2 pagineM/V PRIDE - Advanced DP-3 Offshore Construction VesselMiguel Angel FriasNessuna valutazione finora

- Havila Venus PDFDocumento5 pagineHavila Venus PDFFrds123Nessuna valutazione finora

- Boabarge 21-22 Rev 2007Documento6 pagineBoabarge 21-22 Rev 2007Agi NugrohoNessuna valutazione finora

- HLV UGLEN Heavy Lift Crane Vessel 800-Ton CapacityDocumento6 pagineHLV UGLEN Heavy Lift Crane Vessel 800-Ton CapacityAnwarul Shafiq AwalludinNessuna valutazione finora

- KL Saltfjord 300812Documento12 pagineKL Saltfjord 300812hihihiNessuna valutazione finora

- Suezmax Oil Tanker Tankers 2021Documento22 pagineSuezmax Oil Tanker Tankers 2021Виктор ВладимировичNessuna valutazione finora

- Brochure Armada Condor Rev D3Documento4 pagineBrochure Armada Condor Rev D3rammech85Nessuna valutazione finora

- Skandi ArcticDocumento4 pagineSkandi ArcticnebulaequinoxNessuna valutazione finora

- Executive Summary ASD Tug 3213-12-2015Documento16 pagineExecutive Summary ASD Tug 3213-12-2015Ernesto JuniorNessuna valutazione finora

- Seaway - Alfa Lift-300dpi - Pdf.downloadasset PDFDocumento2 pagineSeaway - Alfa Lift-300dpi - Pdf.downloadasset PDFДимаNessuna valutazione finora

- Gdańsk Shiprepair Yard converts tankers into shuttle tankersDocumento2 pagineGdańsk Shiprepair Yard converts tankers into shuttle tankersCarlos HuancaNessuna valutazione finora

- DP3 Multi-Purpose Offshore Construction Vessel: Toisa ProteusDocumento2 pagineDP3 Multi-Purpose Offshore Construction Vessel: Toisa Proteuslmorsal01Nessuna valutazione finora

- Havila Jupiter PDFDocumento5 pagineHavila Jupiter PDFDodolNessuna valutazione finora

- SLS301 (Launched On 08.05.2015)Documento20 pagineSLS301 (Launched On 08.05.2015)a.msNessuna valutazione finora

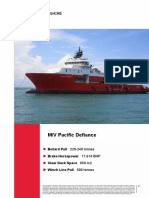

- MV Pacific DefianceDocumento7 pagineMV Pacific DefianceyukosNessuna valutazione finora

- Aker OSCV 06L DSV Skandi Arctic technical overviewDocumento5 pagineAker OSCV 06L DSV Skandi Arctic technical overviewÍcaro ReisNessuna valutazione finora

- BOABARGE 33-34 BrochureDocumento4 pagineBOABARGE 33-34 BrochureLai Quoc0% (1)

- TOS HA LONG PIPE LAY Spec (Updated 30 12 19)Documento3 pagineTOS HA LONG PIPE LAY Spec (Updated 30 12 19)Mr. DNessuna valutazione finora

- Bulk Carriers TypesDocumento11 pagineBulk Carriers TypesJeesonAntonyNessuna valutazione finora

- Normand SubseaDocumento2 pagineNormand SubseaarunnvNessuna valutazione finora

- ECO FREIGHTER 10,000-TON DRY CARGO SHIPDocumento1 paginaECO FREIGHTER 10,000-TON DRY CARGO SHIPshihabafghonyNessuna valutazione finora

- 7000 SpecDocumento21 pagine7000 SpecChristopher ThomasNessuna valutazione finora

- Deep Explorer: Purpose-Designed Diving Support and Heavy Construction VesselDocumento2 pagineDeep Explorer: Purpose-Designed Diving Support and Heavy Construction Vesselkyle krugerNessuna valutazione finora

- The Demise of EL FARO - A Wake Up Call For The World Merchant MarineDocumento18 pagineThe Demise of EL FARO - A Wake Up Call For The World Merchant Marineshakeer tNessuna valutazione finora

- Parsifal 2263Documento2 pagineParsifal 2263maritim2k16Nessuna valutazione finora

- Liquefied Natural Gas PDFDocumento16 pagineLiquefied Natural Gas PDFwasita wadariNessuna valutazione finora

- Deepwater Pipelay Capabilities: Company UpdateDocumento21 pagineDeepwater Pipelay Capabilities: Company Updatecontenido100% (1)

- Developments in The Design of Specialised Marine TransportDocumento40 pagineDevelopments in The Design of Specialised Marine TransporttyuNessuna valutazione finora

- Subsea Pipe Laying Ships: S-Lay Systems & Solitaire VesselDocumento8 pagineSubsea Pipe Laying Ships: S-Lay Systems & Solitaire VesselMostafa Shawky El ShenawyNessuna valutazione finora

- 5,480 BHP DP ROV Support Vessel SpecificationDocumento6 pagine5,480 BHP DP ROV Support Vessel SpecificationDestaRifkyAldaraNessuna valutazione finora

- Low-Emission Diesel-Electric PSV with 30% Greater CargoDocumento6 pagineLow-Emission Diesel-Electric PSV with 30% Greater Cargozpoker49417Nessuna valutazione finora

- Data SheetDocumento2 pagineData SheetRaymundo AlarconNessuna valutazione finora

- MV Pacific HarrierDocumento8 pagineMV Pacific HarrierdafoozzNessuna valutazione finora

- Sea AaryanDocumento2 pagineSea AaryanMohammed Rizwan KhanNessuna valutazione finora

- Atlantic Raven: Registration MachineryDocumento3 pagineAtlantic Raven: Registration MachineryArief KurniawanNessuna valutazione finora

- Offshore World - Track Record - Swiber LimitedDocumento9 pagineOffshore World - Track Record - Swiber LimitedTip RendahNessuna valutazione finora

- SeaBoats ID1558 PDFDocumento6 pagineSeaBoats ID1558 PDFSonyNessuna valutazione finora

- Suez Canal Transit MiniguideDocumento34 pagineSuez Canal Transit MiniguideNikhilVinayNessuna valutazione finora

- Holmen Arctic Updated On 2011-08-03Documento2 pagineHolmen Arctic Updated On 2011-08-03HASHMI MAHMOODNessuna valutazione finora

- Ocean Tow GuidelinesDocumento35 pagineOcean Tow Guidelinesfajee_faridNessuna valutazione finora

- Anchor Handling Tug SupplyDocumento12 pagineAnchor Handling Tug Supplyapi-231764268Nessuna valutazione finora

- Seven ChampionDocumento2 pagineSeven Championlalit67% (3)

- Ballast Free ShipsDocumento18 pagineBallast Free ShipsassddfNessuna valutazione finora

- 03 DAMEN SY - High Speed in Severe Waves PDFDocumento35 pagine03 DAMEN SY - High Speed in Severe Waves PDFjohn kasichNessuna valutazione finora

- Sapura Ônix - Panama Flagged DP2 Pipelay VesselDocumento2 pagineSapura Ônix - Panama Flagged DP2 Pipelay VesselRodrigo Luis Cintra RosaNessuna valutazione finora

- BulkDocumento7 pagineBulkbigbang182Nessuna valutazione finora

- Shippaxguide16: Extract From The Annual Publication Shippax Guide 16. Presentation of ACL's ATLANTIC STARDocumento68 pagineShippaxguide16: Extract From The Annual Publication Shippax Guide 16. Presentation of ACL's ATLANTIC STARЕгор Лядов100% (1)

- Datenblatt Natalie English WebDocumento5 pagineDatenblatt Natalie English WebNMHaNessuna valutazione finora

- Maersk GallantDocumento8 pagineMaersk GallantAarón CespedesNessuna valutazione finora

- 30mt Multi Purpose Vessel SpecDocumento2 pagine30mt Multi Purpose Vessel Specmariners123Nessuna valutazione finora

- 20-Lampiran 1 Ship ParticularDocumento1 pagina20-Lampiran 1 Ship ParticularAkun Gocar100% (1)

- Semi Submersible Heavy Lift VesselDocumento12 pagineSemi Submersible Heavy Lift VesselmailokeNessuna valutazione finora

- Maximising Efficiency of New Multipurpose VesselsDocumento3 pagineMaximising Efficiency of New Multipurpose VesselsthugsdeiNessuna valutazione finora

- Rig ErikDocumento8 pagineRig Eriksuraj pandeyNessuna valutazione finora

- POSH-Conquest HighResDocumento2 paginePOSH-Conquest HighResRamos KristinouvNessuna valutazione finora

- Seminar 4 Oil SpillDocumento12 pagineSeminar 4 Oil SpillGanesh FakatkarNessuna valutazione finora

- CO Sensor For Ocean Acidification StudiesDocumento6 pagineCO Sensor For Ocean Acidification StudiesGanesh FakatkarNessuna valutazione finora

- Comrel 9.50 Demo - (Demo - Bti)Documento4 pagineComrel 9.50 Demo - (Demo - Bti)Ganesh Fakatkar0% (1)

- 3 Moment EqnDocumento18 pagine3 Moment EqnRahul GaikwadNessuna valutazione finora

- SpaceClaim2017 SP0 UsersGuideDocumento1.342 pagineSpaceClaim2017 SP0 UsersGuideVietnhut Phan0% (1)

- 3 Moment EqnDocumento18 pagine3 Moment EqnRahul GaikwadNessuna valutazione finora

- Comrel 9.50 Demo - (Demo - Bti)Documento4 pagineComrel 9.50 Demo - (Demo - Bti)Ganesh Fakatkar0% (1)

- Moment DistributionDocumento153 pagineMoment DistributionHerbert P. BacosaNessuna valutazione finora

- 3 Moment EqnDocumento18 pagine3 Moment EqnRahul GaikwadNessuna valutazione finora

- Calculation For Hull Strength Construction in Offshore Structures PDFDocumento10 pagineCalculation For Hull Strength Construction in Offshore Structures PDFcxb07164Nessuna valutazione finora

- A Ship Propeller Design MethodologyDocumento14 pagineA Ship Propeller Design MethodologyGanesh FakatkarNessuna valutazione finora

- A Ship Propeller Design MethodologyDocumento34 pagineA Ship Propeller Design MethodologyGanesh FakatkarNessuna valutazione finora

- A Ship Propeller Design MethodologyDocumento14 pagineA Ship Propeller Design MethodologyGanesh FakatkarNessuna valutazione finora

- Barge - Ship SFD BMD PDFDocumento12 pagineBarge - Ship SFD BMD PDFGanesh FakatkarNessuna valutazione finora

- 222222222222222Documento47 pagine222222222222222Ganesh FakatkarNessuna valutazione finora

- Barge - Ship SFD BMD PDFDocumento12 pagineBarge - Ship SFD BMD PDFGanesh FakatkarNessuna valutazione finora

- Marine Offshore BrochureDocumento8 pagineMarine Offshore BrochureGanesh FakatkarNessuna valutazione finora

- USS Carl Vinson Deck Logs May 1, 2011 To May 7, 2011Documento97 pagineUSS Carl Vinson Deck Logs May 1, 2011 To May 7, 2011Mossad NewsNessuna valutazione finora

- Contract of Sales of Goods Groupwork 01 DanielPuznyDocumento4 pagineContract of Sales of Goods Groupwork 01 DanielPuznyMark Ramirez0% (1)

- Topics in Contemporary Mathematics 10th Edition Bello Test BankDocumento35 pagineTopics in Contemporary Mathematics 10th Edition Bello Test Bankbiforous.feuter.v79dv100% (29)

- Smc-Chaguy 1Documento1 paginaSmc-Chaguy 1Rafael González MonascalNessuna valutazione finora

- Mooring Arrangement DiagramDocumento37 pagineMooring Arrangement Diagramdinar rosandy100% (1)

- Launching of ShipDocumento55 pagineLaunching of ShipNasrul SetiawanNessuna valutazione finora

- Gupta SirDocumento54 pagineGupta Sirshiwani sharmaNessuna valutazione finora

- Intertanko'S Standard Tanker Chartering Questionnaire 88 (Q88) 1. Vessel DescriptionDocumento7 pagineIntertanko'S Standard Tanker Chartering Questionnaire 88 (Q88) 1. Vessel DescriptionAkram HossainNessuna valutazione finora

- Maneuvering Information For U.S.C.G. (286010)Documento2 pagineManeuvering Information For U.S.C.G. (286010)viperovNessuna valutazione finora

- Class Notations PDFDocumento32 pagineClass Notations PDFIgnatius FernandesNessuna valutazione finora

- ASM Masters Solved Past Question Papers Solved Numericals From Sept16 Till Nov21Documento302 pagineASM Masters Solved Past Question Papers Solved Numericals From Sept16 Till Nov21arivarasanNessuna valutazione finora

- Regulations on compulsory pilotage and pilot exemption certificatesDocumento26 pagineRegulations on compulsory pilotage and pilot exemption certificatesSergiyNessuna valutazione finora

- q209 Deck GeneralDocumento18 pagineq209 Deck Generalandesvan gumayNessuna valutazione finora

- S.L. 234.51 - MLCDocumento94 pagineS.L. 234.51 - MLCJoseph Alexander BorgNessuna valutazione finora

- 1914 - BritannicDocumento28 pagine1914 - BritannicTom Bates100% (2)

- PRC Form DAVEDocumento1 paginaPRC Form DAVEDave Sayson33% (3)

- GLDD-585-BH - Vessel ParticularsDocumento6 pagineGLDD-585-BH - Vessel ParticularsShailendra KumarNessuna valutazione finora

- Monitor The Loading, Stowage, Securing, Care During The Voyage and The Unloading.060717Documento25 pagineMonitor The Loading, Stowage, Securing, Care During The Voyage and The Unloading.060717Farizky AlamNessuna valutazione finora

- Curriculum Vitae: TH TH THDocumento1 paginaCurriculum Vitae: TH TH THBeni KristyanNessuna valutazione finora

- Selected List of Iranian-Linked Ships Marked by US Treasury DeptDocumento3 pagineSelected List of Iranian-Linked Ships Marked by US Treasury DeptShurat HaDin - Israel Law CenterNessuna valutazione finora

- Past Question Papers Theory Solved Jan 12 To Jan 15 Capt. Saujanya SinhaDocumento282 paginePast Question Papers Theory Solved Jan 12 To Jan 15 Capt. Saujanya Sinhabasheer shaik100% (2)

- Baltic Questionnaire - Taizhou Pioneer - 2021Documento10 pagineBaltic Questionnaire - Taizhou Pioneer - 2021S. Kumar JagannathNessuna valutazione finora

- Seaman'S Employment Application Form: Personal ParticularsDocumento1 paginaSeaman'S Employment Application Form: Personal ParticularsFuckboy /Nessuna valutazione finora

- Oris Princess Ship Particulars - NEWDocumento3 pagineOris Princess Ship Particulars - NEWLasha ZoidzeNessuna valutazione finora

- Draft Survey Manual CalculationDocumento14 pagineDraft Survey Manual CalculationKuco NotNessuna valutazione finora

- Greek Island Ferries Sea Schedules December 09Documento60 pagineGreek Island Ferries Sea Schedules December 09SeaSchedulesNessuna valutazione finora

- Kiribati CanoeDocumento9 pagineKiribati CanoeSándor Tóth100% (1)

- Sea Project Sample!Documento53 pagineSea Project Sample!Ivan Ariate Gualberto100% (2)

- Safety InductionDocumento1 paginaSafety InductionMandeep KumarNessuna valutazione finora

- M O Monthly Publications Check List For Med Black Red SeaDocumento3 pagineM O Monthly Publications Check List For Med Black Red SeaMarian VisanNessuna valutazione finora