Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

716 Check Valve

Caricato da

locoombreDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

716 Check Valve

Caricato da

locoombreCopyright:

Formati disponibili

IPS CARBON STEEL PIPE – GROOVED VALVES 08.

08

VICTAULIC® IS AN ISO 9001 CERTIFIED COMPANY

Series 716 Vic-Check® Valves

PRODUCT DESCRIPTION

The Series 716 check valve is a product of computer-assisted innovative engineering with quality features

including a new hydrodynamically efficient profile. Available in sizes 2 1/2 - 12"/65 - 300 mm, the Vic-

Check® valve utilizes a spring-assisted, single-disc design that achieves a leak-free seal with as little as

5 ft./1.5 m of head. The valve can be installed in both horizontal and vertical positions.

Series 716 check valves are engineered for long life and seize-free sealing. In sizes 2 1/2 and 3"/65 and

80 mm, the elastomeric seal, mounted on the aluminum bronze disc, seats against the machined area of

the body, which is completely coated with polyphenylene sulphide (PPS). Sizes 4 - 12"/100 - 300 mm

feature an elastomer-encapsulated disc and a welded-in nickel seat. Every valve is factory tested to its

working pressure of 300 psi/2065 kPa. Drains are provided both upstream and downstream of the disc.

Sizes 21/2 & 3"

Grooved ends allow fast, easy installation with just two Victaulic couplings. The valve may also be

connected to flanged (ANSI Class 150) components using Style 741 Vic-Flange adapters on either end.

Sizes 4 - 12"

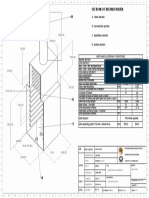

DIMENSIONS

A

R 3

A

P C

P C

DE

D E

K 2

A B 1 2

B J K 1

B J

➀ ¹⁄₂" NPT Upstream Drain (Optional)

C ➁ ¹⁄₂" NPT Downstream Drain (Optional) ➀ ¹⁄₂" NPT Upstream Drain (Optional)

➂ 2" NPT (Drain Optional) ➁ ¹⁄₂" NPT Downstream Drain (Optional)

Typical 21/2 - 3" Typical 4 - 8" Typical 10 - 12"

Actual Dimensions- Inches/millimeters

Nom. Outside Approx.

Size Dia. E-E Overall Width Wgt. Ea.

In./mm In./mm A B C D E J K P R Lbs./kg

21/2 2.875 3.88 4.25 3.60 – – – – – – 3.6

65 73.0 99 108 91 – – – – – – 1.6

3.000 3.88 4.25 3.60 – – – – – – 3.6

76,1 mm 76.1 99 108 91 – – – – – – 1.6

3 3.500 4.25 5.06 4.19 – – – – – – 4.5

80 88.9 108 129 106 – – – – – – 2.0

4 4.500 9.63 6.00 3.90 2.75 3.50 2.00 4.50 3.50 3.35 16.0

100 114.3 245 152 99 70 89 51 114 89 85 7.3

5 5.563 10.50 6.80 4.50 4.17 4.17 2.15 5.88 4.08 4.02 20.0

125 141.3 267 173 114 106 106 55 149 104 102 9.1

5.500 10.50 6.80 4.50 4.17 4.17 2.15 5.88 4.08 4.02 27.0

139,7 mm 139.7 267 173 114 106 106 55 149 104 102 12.3

6 6.625 11.50 8.00 5.00 4.50 4.50 2.38 6.67 4.73 3.89 28.0

150 168.3 292 203 127 114 114 61 169 120 99 12.7

6.500 11.50 8.00 5.00 4.50 4.50 238 6.67 4.73 3.89 28.0

165,1 mm 165.1 292 203 127 114 114 61 169 120 99 12.7

8 8.625 14.00 9.88 6.10 5.05 5.65 2.15 8.75 5.70 5.75 40.0

200 219.1 356 251 155 128 144 55 222 145 146 18.1

10 10.750 17.00 12.00 7.10 5.96 6.69 2.15 10.92 6.93 – 100.0

250 273.0 432 305 180 151 170 55 277 176 – 45.4

12 12.750 19.50 14.00 8.10 6.91 7.64 2.51 12.81 7.93 – 140.0

300 323.9 495 356 206 176 194 64 325 201 – 63.5

® REGISTERED TRADEMARK OF VICTAULIC – © COPYRIGHT 2005 VICTAULIC – PRINTED IN U.S.A. – SKU #WCAS-6AYRNC 1473 REV D

United States • Phone: 1-800-PICK-VIC (1-800-742-5842) • Fax: 610-250-8817 • e-mail: pickvic@victaulic.com

Canada • Phone: 905-884-7444 • Fax: 905-884-9774 • e-mail: viccanada@victaulic.com

Europe • Phone: 32-9-381-1500 • Fax: 32-9-380-4438 • e-mail: viceuro@victaulic.be

UK • Phone: 44(0)1438741100 • Fax: 44(0)1438313883 • e-mail: viceuro@victaulic.be

Central and South America • Phone: 610-559-3300 • Fax: 610-559-3608 • e-mail: vical@victaulic.com

Australasia • Phone: 86-21-54253300 • Fax: 86-21-54253671 • e-mail: vicap@victaulic.com

08.08

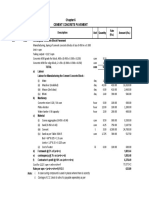

PERFORMANCE

Formulas for CV Values:

Vic-Check valves combine

high pressure capabilities with Q2

ΔP = --------- Where:

low pressure drop 2

performance. The grooved

CV Q = Flow (GPM) CV = Flow Coefficient

end design permits fast, easy Q = C V × ΔP ΔP = Pressure Drop (psi)

installation.

The seat provides leak-free

sealing under conditions as Actual Actual Actual

Nom. Outside CV Nom. Outside CV Nom. Outside CV

low as five feet of head. Size Dia. (Full Size Dia. (Full Size Dia. (Full

CV values for flow of water at In./mm In./mm Open) In./mm In./mm Open) In./mm In./mm Open)

+60°F/+16°C with a fully open 21/2 2.875 5.500 8§ 8.625

65 73.0

140 139.7 mm 139.7

700 200 219.1

1800

valve are shown in the table at

right. 3.000 5 5.563 10 § 10.750

76,1 mm 76.1

140 125 141.3

700 250 273.0

3000

3 3.500 6.500 12 § 12.750

80 88.9

250 165.1 mm 165.1

1000 300 323.9

4200

4 4.500 6 6.625

100 114.3

390 150 168.3

1000

NOTE: Placement of check valves SERIES 716

6.0

too close to sources of unstable flow 5.0

will shorten the life of the valve and FLOW OF WATER

4.0 AT 60F (16C)

potentially may damage the system. THROUGH VALVE

To extend valve life, valves should be 3.0

m

installed a reasonable distance

mm

mm

6m

"

12

downstream from pumps, elbows,

&7

65

139

expanders, reducers or other similar 2.0

&1

"

5" &

devices. Sound piping practices

2¹⁄₂

PRESSURE DROP – P.S.I.

8"

3"

4"

6"

10"

dictate a minimum of five (5) times

the pipe diameter for general use.

Distances between three (3) and five 1.0

(5) diameters are allowable provided 0.9

0.8

the flow velocity is less than eight (8) 0.7

feet per second (2.4 mps). Distances 0.6

less than three (3) diameters are not 0.5

recommended and will violate the 0.4

Victaulic product warranty.

0.3

0.2

0.1

10 20 30 40 60 80 100 200 300 400 600 1,000 2,000 4,000 6,000 10,000

800 3,000 8,000

FLOW RATE – G.P.M.

2 Series 716 Vic-Check® Valves

08.08

MATERIAL SPECIFICATIONS

Body: Ductile iron conforming to ASTM A-536, grade 65-45-12. Ductile iron conforming to ASTM A-395,

grade 65-45-15, is available upon special request. 2 1/2 - 3"/65 - 80 mm sizes PPS coated, UL classified in

accordance with ANSI/NSF 61 for potable water service. 4 - 12"/100 - 300 mm sizes painted black

enamel.

Body Seat: Sizes 21/2 - 3"/65 - 80 mm machined surfaces PPS coated. 4 - 12"/100 - 300 mm integrally

welded-on nickel alloy.

Disc Seal or Coating: (Specify Choice)

• Grade “E” EPDM

EPDM (Green color code). Temperature range –30°F to +230°F/–34°C to +110°C. Recommended for

hot water service within the specified temperature range plus a variety of dilute acids, oil-free air and

many chemical services. UL classified in accordance with ANSI/NSF 61 for for cold +86°F/+30°C and

hot +180°F/+82°C potable water service. NOT RECOMMENDED FOR PETROLEUM SERVICES.

• Grade “T” nitrile

Nitrile (Orange color code). Temperature range –20°F to +180°F/–29°C to +82°C. Recommended for

petroleum products, air with oil vapors, vegetable and mineral oils within the specified temperature

range; except hot, dry air over +140°F/+60°C and water over +150°F/+66°C. NOT RECOMMENDED

FOR HOT WATER SERVICES.

• Grade “O” fluoroelastomer

Fluoroelastomer (Blue color code). Temperature range +20°F to +300°F/–7°C to +149°C. Recom-

mended for many oxidizing acids, petroleum oils, halogenated hydrocarbons, lubricants, hydraulic

fluids, organic liquids and air with hydrocarbons to +300°F/+149°C.

*Services listed are General Service Recommendations only. It should be noted that there are services for

which these disc liners are not recommended. Reference should always be made to the latest Victaulic

Gasket Selection Guide for specific liner service recommendations and for a listing of services which are

not recommended.

Discs: 21/2 - 3"/65 - 80 mm Aluminum bronze conforming to ASTM B-148. 4 - 12"/100 - 300 mm ductile iron

conforming to ASTM A-536 Grade 65-45-12, fully encapsulated in Grade “E”, “T”, or “O” elastomer. (See

Disk Seal)

Shaft: 21/2 - 3"/65 - 80 mm Type 416 stainless steel. 4 - 12"/100 - 300 mm Type 316 stainless steel.

Spring: All sizes Type 302/304 stainless steel.

Shaft Plug: 21/2 - 3"/65 - 80 mm only; SAE Hex Socket Type conforming to ASTM A-576, cadmium plated

to military specifications QQ-P-416A, class 3 type 2.

Pipe Plug: 4 - 12"/100 - 300 mm only; carbon steel zinc plated to ASTM B-633.

This product shall be manufactured by Victaulic or to Victaulic specifications. All products to be installed in accordance with current Victaulic installation/assembly instructions.

Victaulic reserves the right to change product specifications, designs and standard equipment without notice and without incurring obligations.

Series 716 Vic-Check® Valves 3

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- Frosio - Exam Questions - SampleDocumento3 pagineFrosio - Exam Questions - SampleAnte Bosancic86% (7)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Sandvik-Seamless SMLS Stainless Tubes PDFDocumento10 pagineSandvik-Seamless SMLS Stainless Tubes PDFInnov8 OilNessuna valutazione finora

- Steam Generator Boiler - 2Documento1 paginaSteam Generator Boiler - 2ToniNessuna valutazione finora

- Floline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit ValueDocumento3 pagineFloline (3-W) Triple Wall Profiled Hdpe Culvert: Physical Properties Test Method Unit Valuejerryruki71Nessuna valutazione finora

- Consolis Technical Guide & Product ManualDocumento68 pagineConsolis Technical Guide & Product ManualAndrej DunovskijNessuna valutazione finora

- How To Build A Screened-In Porch From ScratchDocumento6 pagineHow To Build A Screened-In Porch From ScratchRi SovannaphumiNessuna valutazione finora

- 1 s2.0 S0950061821027239 MainDocumento13 pagine1 s2.0 S0950061821027239 MainExe TommasielloNessuna valutazione finora

- Admixture Technical Sheet - ATS 12 Pumping Admixtures: 1 FunctionDocumento2 pagineAdmixture Technical Sheet - ATS 12 Pumping Admixtures: 1 FunctionDileepa DissanayakeNessuna valutazione finora

- AOR Conc Blocks 450x300x150 M30Documento1 paginaAOR Conc Blocks 450x300x150 M30Daljeet SidhuNessuna valutazione finora

- Durability and Corrosion Studies in Prestressed Concrete Made With Blended CementDocumento10 pagineDurability and Corrosion Studies in Prestressed Concrete Made With Blended CementAshfaq AhmedNessuna valutazione finora

- Flanges Gaskets and Expansion Joints PDFDocumento5 pagineFlanges Gaskets and Expansion Joints PDFichrakNessuna valutazione finora

- General Guidelines For Successful Materials SelectionDocumento5 pagineGeneral Guidelines For Successful Materials SelectionBALARAM S PATTARNessuna valutazione finora

- ExoTec and ExoTec Vero Facade Panel Install Guide Dec 2019 Rev 01Documento24 pagineExoTec and ExoTec Vero Facade Panel Install Guide Dec 2019 Rev 01kakakaNessuna valutazione finora

- Stel Casting Handbook - Sample PagesDocumento5 pagineStel Casting Handbook - Sample PagesBobby WongNessuna valutazione finora

- Oceanic HW 443 Series: Key Benefits DescriptionDocumento2 pagineOceanic HW 443 Series: Key Benefits Descriptions bNessuna valutazione finora

- Built Up Edge (BUE) in Turning Applications Causes & EffectsDocumento4 pagineBuilt Up Edge (BUE) in Turning Applications Causes & EffectsJo MarbeNessuna valutazione finora

- Aathangudi Tile - SubanandheniDocumento6 pagineAathangudi Tile - SubanandheniArchi NandheniNessuna valutazione finora

- ROR BQ Arena 2DEC2022 - LatestDocumento196 pagineROR BQ Arena 2DEC2022 - LatestJay JayNessuna valutazione finora

- Tutorial 6 - Die DesignDocumento40 pagineTutorial 6 - Die DesignMay FadlNessuna valutazione finora

- Cost Estimate For Submersible Boring at Iccc Building AreaDocumento10 pagineCost Estimate For Submersible Boring at Iccc Building AreaShubhankar SharmaNessuna valutazione finora

- FinetekDocumento21 pagineFinetekdenny kanaNessuna valutazione finora

- Oasis - 24 Sales BrochureDocumento14 pagineOasis - 24 Sales BrochureArjun GuptaNessuna valutazione finora

- EnDOtec 310Documento2 pagineEnDOtec 310EdwinNessuna valutazione finora

- Qdoc - Tips Astm A108Documento4 pagineQdoc - Tips Astm A108Israel de Freitas CarvalhoNessuna valutazione finora

- GF, FF, SFDocumento1 paginaGF, FF, SFamit_saxena_10Nessuna valutazione finora

- 0511 Grob PDFDocumento7 pagine0511 Grob PDFJ VeluNessuna valutazione finora

- Procut Catalogue 2010 Procut is an internationally renowned brand of high quality carbide burrs, and forms a key part of ATA Group, a privately owned organisation with over 50 years experience in the supply of metal working solutions to all major industrial sectors. We are committed to providing our customers with high performance products that maximise productivity and reduce costs. Our headquarters and global production centre based in Cavan, Ireland, is accredited to ISO9001:2008 and equipped with the latest CNC technology delivering product of unrivalled quality and consistency.Documento19 pagineProcut Catalogue 2010 Procut is an internationally renowned brand of high quality carbide burrs, and forms a key part of ATA Group, a privately owned organisation with over 50 years experience in the supply of metal working solutions to all major industrial sectors. We are committed to providing our customers with high performance products that maximise productivity and reduce costs. Our headquarters and global production centre based in Cavan, Ireland, is accredited to ISO9001:2008 and equipped with the latest CNC technology delivering product of unrivalled quality and consistency.Sun SunNessuna valutazione finora

- MSS SP45 Bypass and Drain ConnectionsDocumento12 pagineMSS SP45 Bypass and Drain ConnectionsChotiwan Rattanasatien100% (1)

- LP-105 Installation Procedure For Lokring Carbon Steel, Stainless Steel (CRES), and Copper Nickel Pipe and Tube FittingsDocumento64 pagineLP-105 Installation Procedure For Lokring Carbon Steel, Stainless Steel (CRES), and Copper Nickel Pipe and Tube Fittingsdbucks88Nessuna valutazione finora

- Pop A Plug MaterialDocumento2 paginePop A Plug MaterialHijau Auliya Keramat Al-qadiryNessuna valutazione finora