Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

CHE531 2012-Jan

Caricato da

BiLL ShAmSCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

CHE531 2012-Jan

Caricato da

BiLL ShAmSCopyright:

Formati disponibili

CONFIDENTIAL EH/JAN 2012/CHE531

UNIVERSITI TEKNOLOGI MARA

FINAL EXAMINATION

COURSE CHEMICAL PROCESS PRINCIPLES II

COURSE CODE CHE531

EXAMINATION JANUARY 2012

TIME 3 HOURS

INSTRUCTIONS TO CANDIDATES

1. This question paper consists of five (5) questions.

2. Answer ALL questions in the Answer Booklet. Start each answer on a new page.

3. Do not bring any material into the examination room unless permission is given by the

invigilator.

Please check to make sure that this examination pack consists of:

i) the Question Paper

ii) an Answer Booklet - provided by the Faculty

iii) a three - page Appendix

DO NOT TURN THIS PAGE UNTIL YOU ARE TOLD TO DO SO

This examination paper consists of 6 printed pages

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL 2 EH/JAN 2012/CHE531

QUESTION 1

(P06, C01.C2, C4)

a) Explain how a dew point at a given point on the psychrometric chart can be determined.

(3 marks)

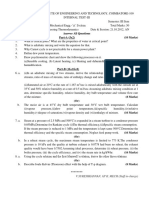

b) The water content of a wet clay pottery is to be reduced from 60 wt % to 10 wt % by a

two-stage process as shown in Figure 1. Wet clay pottery enters a centrifuge at a rate of

240 kg/h in which 30 kg/h of water is removed. The clay then flows from the centrifuge to

a hot air dryer which reduces the water content of the clay to its final value of 10 % by

mass. Fresh air (stream 5) at 20°C and 40 % relative humidity will be heated and fed to

the dryer. The exhaust gas from the dryer (stream 7) is at a temperature of 35°C and a

dew point of 18°C. All air streams are at an absolute pressure of 1 atm.

i) Determine the absolute humidity and enthalpy of the air for the above process

(streams 5, 6 and 7) and show these points in the psychrometric chart provided.

Attach and submit the chart together with your answer script.

(4 marks)

ii) Calculate the mass flow rate of the fresh air into the heater in kg/h.

(5 marks)

iii) Calculate the mass flow rate of the exhaust air stream from the dryer in kg/h.

(3 marks)

iv) Determine the temperature of the air leaving the heater (stream 6).

(2 marks)

v) Determine the amount of heat required to heat the fresh air.

(3 marks)

Wet clay, 2 40kg/h

60 wt % vrater 0 Centrifuge © +

Water

30 kg/h

©

Heater © , 'r

Dryer

© Exhaust air

35°C,

dew point

F r p ^ h air

18°C

20°C, 40% rel.

humidity

1 atm.

tQin

©

1r

Dried clay

10 wt% water

Figure 1 Wet clay drying

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL 3 EH/JAN 2012/CHE531

QUESTION 2

(P06, C03, C2, C5)

a) Explain when a continuous system becomes transient.

(2 marks)

b) For the system shown in Figure 2:

v,= 50 m3/min

v 0 = 50 m3/min

C A i - 12 kg/m3

C Ao , kg/m3

p, kg/m3 V, m3

• P, kg/m3 p, kg/m3

CA, kg/m3

At t = 0, Vo = 100m 3

and CAo = 40 kg/m3

Figure 2 Transient process

i) Write a total mass balance on the tank contents and use it to obtain an expression for

dV/dt, where V is the volume of liquid in the tank at any time t. Density of the liquid is

assumed constant.

(7 marks)

ii) Write a mass balance on A and derive an expression for CA(t) and state its initial

conditions. Concentrations of A in outlet stream and in the tank are assumed to be

the same.

(8 marks)

iii) Find the concentration of A in the tank after 5 minutes,

(2 marks)

iv) Find the concentrations of A in the tank at steady state.

(1 mark)

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL 4 EH/JAN 2012/CHE531

QUESTION 3

(P01.C01.C1)

a) Define closed system and batch processes and give an example for each definition.

(4 marks)

b) Give the definition of heat capacity and state the relation between Cvdan Cp

(3 marks)

c) Expression for the heat capacity at constant pressure of hydrogen sulfide is given by

J

C

P

= 0.0252 + 1.547 x 10~s71- 3.012 JC 10^T\°C)

mol • °C

Assuming ideal gas behavior, calculate the heat that must be transferred in each of

the following cases.

i) A stream of hydrogen sulfide at a rate of 100 mol/min is heated from 25°C to.

100°C.

(6 marks)

ii) Hydrogen sulfide contained in a 5 liter flask at initial pressure of 3 bars is

cooled from 85°C to 35°C.

(7 marks)

QUESTION 4

(P06, C02, C3.C3.C3, C5)

Styrene (C6H5CHCH2) is produced from dehydrogenation reaction of ethylbenzene

(C6H5CH2CH3).

C6H5CH2CH3 (g) -» C6H5CHCH2 (g) + H2 (g)

Ethylbenzene in gaseous phase is mixed with steam at a ratio of 1:6 as feed to an

isothermal catalytic reactor at a temperature of 600°C and pressure of 1 bar. The steam

acts as an inert and removes carbon deposited on the catalyst surface. Given that, the feed

entering the reactor contains 100 mol/h of ethylbenzene and that 70% conversion of

ethylbenzene to styrene is achieved.

a) Calculate the flow rate of components at the product stream.

(5 marks)

b) Determine the standard heat of reaction (AH°) for the reaction. Indicate whether it is

endothermic or exothermic.

(3 marks)

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL 5 EH/JAN 2012/CHE531

c) Calculate the rate of heat supplied or released in order to maintain the reaction

temperature of 600°C.

(10 marks)

d) Suppose the reaction is reversible and taking place in an adiabatic reactor. The

ethylbenzene to steam ratio is then increased to 1: 16. Explain why the amount of the

steam is increased further.

(2 marks)

Given data:

Ethylbenzene (C6CH5CH2CH3): Cp(l) = 185.6 J/mol°C

Cp(g) = 118 + 0.30T J/mol°C

AH}{g)= 29.92 kJ/mol

A//;(l) = -12.5kJ/mol

A # v = 36.0kJ/molat136°C

Styrene(C6H5CHCH2) : Cp (I) = 182.6 J/mol°C

Cp (g) = 115 + 0.27TJ/mol°C

A//;(g) = 147.4 kJ/mol

AH}(\) = 103.5 kJ/mol

A # „ =37.1 kJ/mol at 145°C

Hydrogen: Cp (g) = 28.658 + 0.00162T J/mol°C

QUESTION 5

(P06, C02, C3)

Flue gas desulfurization may be achieved by passing the flue gas through a cold aqueous

solution of sodium sulfite(Na2S03) and the S0 2 reacts to form sodium bisulfite(NaHS03):

Na2S03(aq) + S0 2 (g)+H 2 0(l) -*2NaHS0 3 (aq)

Flue gas from a power plant boiler containing 0.35% S0 2 by volume enters a scrubber at a

rate of 60,000 mol/h at 60°C. The gas is bubbled through an aqueous solution containing

10 mol% sodium sulfite that enters the scrubber from the top at 25°C. The gas and liquid

effluents from the scrubber both emerge at 40°C. The scrubber is capable of removing 95%

of the incoming S0 2 . The effluent liquid is analysed and is found to contain 2.5 moles

Na 2 S0 3 per mole of NaHS0 3 .

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL 6 EH/JAN 2012/CHE531

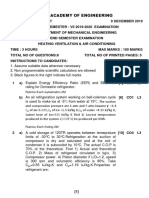

Sodium Sulfite Solution Effluent Gas

10mol% Na 2 S0 3 S0 2

N2

Tm = 25°C Tout = 40°C

Gas

Scrubber

Flue Gas ,r Effluent Liguid Solution

0.35 % vol S0 2 Na 2 S0 3

N2 NaHS0 3

i in — 60°C

uu w H 0

n22v-» Tout —

40 C

Figure 3 Flue gas desulfurization process

a) Determine the molar flow rate of the incoming sodium sulfite solution, components of the

effluent gas and effluent liquid solution; and the extent of reaction, t, (mol/h).

(6 marks)

b) Calculate the standard heat of reaction (AH° ) for the reaction.

(2 marks)

c) Calculate the rate of heat transferred to/from the scrubber in kW. Neglect evaporation of

water in the calculation.

(12 marks)

Given Data:

Na2S03(aq): AH} (aq): -1090.3 kJ/mol

NaHS03(aq): AH} (aq): - 990 kJ/mol

H20(l): AH} (I): -285.84 kJ/mol

S02(g): AH}(g): -296.81 kJ/mol

Cp = 38.91 x 10"3 + 3.904x 10~5 T - 3.104x10"8 T2 kJ/mol

C_ for all liquid solutions = 119.5 J/mol°C

END OF QUESTION PAPER

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

APPENDIX 1 EH/JAN 2012/CHE531

Properties of Superheated Steam

/'(bar) Temperature (•Q-

(rs.„.'C) 400 450 500 550 600 650 700 750

0.0 ft 3280 3384 3497 3597 3706 3816 3929 4043

(-) 0 2969 3050 3132 3217 3303 3390 3480 3591

V

0.1. ft 3280 3384 3489 3596 3706 3816 3929 4043

(45.8) 0 2969 3050 3132 321.7 3303 3390 3480 3571

V 21.1 33.3 35.7 38.0 40.3 42.6 44.8 47.2

0.5 ft 3279 3383 3489 3596 3705 381.6 3929 4043

(81.3) V 2969 3049 3132 3216 3302 3390 3480 3571

V 6.21 6.67 7.14 7.58 8.06 8.55 9.01 9.43

1.0 ft 3278 3382 3488 3596 3705 3816 3928 4042

(99.6) 0 2968 3049 3132 3216 3302 3390 3479 3570

V 3.1.1 3.33 3.57 3.80 4.03 4.26 4.48 4.72

5.0 ft 3272 337S 3484 3592 3702 3813 3926 4040

(151.8) 0 2964 3045 3128 3213 3300 3388 3477 3569

V 0.617 0.664 0.711 0.758 0.804 0.850 0.897 0.943

10 ft 3264 3371 3478 3587 3697 3809 3923 4038

(179.9) 0 2958 3041 3124 3210 3296 3385 3475 3567

V 0.307 0.330 0.353 0.377 0.402 0.424 0.448 0.472

20 fi 3249 3358 3467 3578 3689 3802 3916 4032

(212.4) 0 2946 3031 3115 3202 3290 3379 3470 3562

V 0.151 0.163 0.175 0.188 0.200 .0211 0.223 0.235

40 ft 3216 3331 3445 3559 3673 3788 3904 4021

(250.3) 0 2922 3011 3100 3188 3278 3368 3460 3554

V 0.0734 0.0799 0.0864 0.0926 0.0987 0.105 0.111 0.117

60 ft 3180 3303 3422 3539 3657 3774 3892 40.11

(275.6) 0 2896 2991 3083 3174 3265 3357 3451 3545

V 0.0474 0.0521 0.0566 0.0609 0.0652 0.0693 0.0735 0.0776

80 ft 3142 3274 3399 3520 3640 3759 3879 4000

(295.0) 0 2867 2969 3065 3159 3252 3346 3441 3537

V 0.0344 0.0382 0.0417 0.0450 0.0483 0.0515 0.0547 0.0578

100 ft 3100 3244 3375 3500 3623 3745 3867 3989

(311.0) 0 2836 2946 3047 3144 3240 3335 3431 3528

V 0.0264 0.0298 0.0328 0.0356 0.0383 0.0410 0.0435 0.0461

1.50 it 2975 3160 3311 3448 3580 3708 3835 3962

(342.1) 0 2744 2883 2999 3105 3207 3307 3407 3507

V 0.0157 0.0185 0.0208 0.0229 0.0249 0.0267 0.0286 0.0304

200 ft 2820 3064 3241 3394 3536 3671 3804 3935

(365.7) 0 2622 2810 2946 3063 3172 3278 3382 3485

V 0.009950 0.0127 0.0148 0.0166 0.0182 0.197 0.211 0.0225

22l.2(P,.) ft 2733 3020 3210 3370 3516 3655 3790 3923

(374.15)(rt) 0 2553 2776 2922 3045 3157 3265 3371 3476

V 0.008157 0.0110 0.0130 0.0147 0.0162 0.0176 0.0190 0.0202

250 fi 2582 2954 3166 3337 3490 3633 3772 3908

(—) 0 2432 2725 2888 3019 3137 3248 3356 3463

V 0.006013 0.009174 0.0111 0.0127 0.0141 0.0143 0.0.166 0.01.78

?(K) it 2162 2826 3085 3277 3443 3595 3740 3880

(—) 0 2077 2623 2825 2972 3100 3218 3330 3441

V 0.002830 0.006734 0.008680 0.0102 0.0114 0.0126 0.0136 0.0147

500 ft 1878 2293 2723 3021 3248 3439 3610 3771

( ) 0 1791 2169 2529 2765 2946 3091 3224 3350

V 0.001726 0.002491 0.003882 0.005112 0.006112 0.007000 0.007722 0.008418

1000 ft 1798 2051 2316 2594 2857 3105 3324 3526

( ) 0 1653 1888 2127 2369 2591 2795 2971 3131

V 0.00.1446 0.001628 0.001893 0.002246 0.002668 0.003106 0.003536 0.003953

Unit for J?(kJ/kg), 5(kJ/kg), £(m3/kg)

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

CONFIDENTIAL APPENDIX 2 E H / J A N 20 12/CHE531

Specific Enthalpies of Selected Gases

//(kJ/mol)

Reference state: Gas, Pref = 1 atm, Tcet = 25°C

7" Air o2 N2 H2 CO co 2 H20

0 -0.72 -0.73 -0.73 -0.72 -0.73 -0.92 -0.84

25 0.00 0.00 0.00 0.00 0.00 0.00 0.00

100 2.19 2.24 2.19 2.16 2.19 2.90 2.54

200 5.15 5.31 5.13 5.06 5.16 7.08 6.01

300 8.17 8.47 8.12 7.96 8.17 11.58 9.57

400 11.24 11.72 11.15 10.89 11.25 16.35 13.23

500 14.37 15.03 14.24 13.83 14.38 21.34 17.01

600 17.55 18.41 17.39 16.81 17.57 26.53 20.91

700 20.80 21.86 20.59 19.81 20.82 31.88 24.92

800 24.10 25.35 23.86 22.85 24.13 37.36 29.05

900 27.46 28.89 27.19 25.93 27.49 42.94 33.32

1000 30.86 32.47 30.56 29.04 30.91 48.60 37.69

1100 34.31 36.07 33.99 32.19 34.37 54.33 42.18

1200 37.81 39.70 37.46 35.39 37.87 60.14 46.78

1300 41.34 43.38 40.97 38.62 41.40 65.98 51.47

1400 44.89 47.07 44.51 41.90 44.95 71.89 56.25

1500 48.45 50.77 48.06 45.22 48.51 77.84 61.09

© Hak Cipta Universiti Teknologi MARA CONFIDENTIAL

z

LU

Q

Lu

z

o

o

/7/T?/:

o

o

'&_

*-•

0)

E

o

.C

o

>.

(/)

Q.

<

<

s

o

o

c

4>

2

>

c

\10 3

\ 0.80 Df 8uln

y Temperature, "C 0,8S a.

0.75

O

Below 0°C Properties and Enthalpy Deviation Lines Are For Ice Humid Volume, m 3 /kg Dry Air ra

X

©

Potrebbero piacerti anche

- Assignment L01 (Thursday, 11.30 Am)Documento9 pagineAssignment L01 (Thursday, 11.30 Am)MawareNessuna valutazione finora

- CHE263 FA July 2022Documento3 pagineCHE263 FA July 2022Muhd FirdausNessuna valutazione finora

- Number of Printed Pages-6: EightDocumento6 pagineNumber of Printed Pages-6: EightAmiya singhaNessuna valutazione finora

- End Sem Questions CLPC 11 Process CalculationsDocumento2 pagineEnd Sem Questions CLPC 11 Process CalculationsSujalNessuna valutazione finora

- QP - MID III Exam - Regular Mode - MTO1Documento2 pagineQP - MID III Exam - Regular Mode - MTO1Chandra SekharNessuna valutazione finora

- Bkf1333-Thermodynamics 11415 PDFDocumento17 pagineBkf1333-Thermodynamics 11415 PDFrushdiNessuna valutazione finora

- Che-309: Chemical Engineering Laboratory (I) : Drying of SolidsDocumento12 pagineChe-309: Chemical Engineering Laboratory (I) : Drying of SolidsMohammad KhNessuna valutazione finora

- 13qus DME KecDocumento4 pagine13qus DME KecstrombornNessuna valutazione finora

- 2428 PDFDocumento8 pagine2428 PDFBagusSatriyaNessuna valutazione finora

- Heat and Mass Transfer Unit OperationsDocumento5 pagineHeat and Mass Transfer Unit OperationsFran LeeNessuna valutazione finora

- CPP Assignment 1Documento2 pagineCPP Assignment 1AmandaEdwinNessuna valutazione finora

- Tutorial 9v18sol PDFDocumento4 pagineTutorial 9v18sol PDFSohayb GattousNessuna valutazione finora

- rr310804 Mass Transfer Operations IDocumento8 paginerr310804 Mass Transfer Operations ISRINIVASA RAO GANTANessuna valutazione finora

- II B. Tech I Semester Regular Examinations, Dec - 2015 ThermodynamicsDocumento8 pagineII B. Tech I Semester Regular Examinations, Dec - 2015 ThermodynamicsAshok DaraNessuna valutazione finora

- WWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2016Documento2 pagineWWW - Manaresults.Co - In: B.Tech Ii Year I Semester (R13) Supplementary Examinations June 2016Noor IslamNessuna valutazione finora

- rr222102 Engineering ThermodynamicsDocumento8 paginerr222102 Engineering ThermodynamicsSRINIVASA RAO GANTANessuna valutazione finora

- 25 0 ChE MOCK BOARD 4 4may2016 ANS KEY and SolnDocumento6 pagine25 0 ChE MOCK BOARD 4 4may2016 ANS KEY and SolnFran LeeNessuna valutazione finora

- Btv2213 Thermodynamics s1 0218Documento9 pagineBtv2213 Thermodynamics s1 0218Aswaja313Nessuna valutazione finora

- W17 Process CalculationDocumento4 pagineW17 Process CalculationAmey WankhedeNessuna valutazione finora

- r05222103 ThermodynamicsDocumento8 paginer05222103 ThermodynamicsSRINIVASA RAO GANTANessuna valutazione finora

- Rr310804 Mass Transfer Operations IDocumento8 pagineRr310804 Mass Transfer Operations ISrinivasa Rao GNessuna valutazione finora

- (Template) Chemical Process Calculations-Final Exam PaperDocumento4 pagine(Template) Chemical Process Calculations-Final Exam Papergurumann ssNessuna valutazione finora

- Psychrometrics of DryingDocumento7 paginePsychrometrics of DryingNurul Atikah JapryNessuna valutazione finora

- Semester End Supplementary Examination, Feb 2019 MEDocumento2 pagineSemester End Supplementary Examination, Feb 2019 MEAnonymous uDuusWmdtNessuna valutazione finora

- AR12/AR13 ME 2404: Section IDocumento2 pagineAR12/AR13 ME 2404: Section IAnonymous uDuusWmdtNessuna valutazione finora

- Please Submit The Assignment On - During The Class. Late Submission Will Not Be Evaluated. 4 Person in One GroupDocumento3 paginePlease Submit The Assignment On - During The Class. Late Submission Will Not Be Evaluated. 4 Person in One GroupThurgah VshinyNessuna valutazione finora

- 9a23303-Fluid Flow in Bio ProcessesDocumento4 pagine9a23303-Fluid Flow in Bio ProcessessivabharathamurthyNessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological UniversityShivam PanchalNessuna valutazione finora

- Answer All Questions Part-A (5x2) (10 Marks) : V.SURESHKANNAN, AP II, MECH (Staff In-Charge)Documento1 paginaAnswer All Questions Part-A (5x2) (10 Marks) : V.SURESHKANNAN, AP II, MECH (Staff In-Charge)vsureshkannanmsecNessuna valutazione finora

- Week 6-8Documento32 pagineWeek 6-8siti surayaNessuna valutazione finora

- ME Subjective Paper IESDocumento8 pagineME Subjective Paper IESizharul haqueNessuna valutazione finora

- Refrig 1Documento2 pagineRefrig 1Nabeel SalimNessuna valutazione finora

- Candidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full MarksDocumento2 pagineCandidates Are Required To Give Their Answers in Their Own Words As Far As Practicable. The Figures in The Margin Indicate Full Marksprajwal karkiNessuna valutazione finora

- Gujarat Technological UniversityDocumento2 pagineGujarat Technological UniversityRîkèñ PâtélNessuna valutazione finora

- THERMODYNAMICS Oct-Nov 2019Documento8 pagineTHERMODYNAMICS Oct-Nov 2019Karthik CruiseNessuna valutazione finora

- 2428Documento8 pagine2428kiranin10Nessuna valutazione finora

- Questions Only. Questions (1) and (3) Are Mandatory. QuestionDocumento3 pagineQuestions Only. Questions (1) and (3) Are Mandatory. QuestionElzubair EljaaliNessuna valutazione finora

- Btech Thermodynamics - 2022Documento2 pagineBtech Thermodynamics - 2022Shailesh Singh SuryavanshiNessuna valutazione finora

- Jntuh BT Che 5 Mass-Transfer-Operations-I-2011Documento8 pagineJntuh BT Che 5 Mass-Transfer-Operations-I-2011Sanjeev Kumar SuppalaNessuna valutazione finora

- dtx33 PDFDocumento10 paginedtx33 PDFAiko Rowyena Constantino CruzNessuna valutazione finora

- ME 22 (Industrial Plant Engineering) : Capitol UniversityDocumento14 pagineME 22 (Industrial Plant Engineering) : Capitol UniversityBensoyNessuna valutazione finora

- Chapter 12 PDFDocumento43 pagineChapter 12 PDFMurali MohanNessuna valutazione finora

- 02-JAD States of Matter-HWDocumento2 pagine02-JAD States of Matter-HWVijayNessuna valutazione finora

- 525 PQDocumento7 pagine525 PQPromise OkekeNessuna valutazione finora

- Engineering Thermodynamics Odd Sem End Term 2018-19 (DITUStudentApp)Documento2 pagineEngineering Thermodynamics Odd Sem End Term 2018-19 (DITUStudentApp)Niban IlawurNessuna valutazione finora

- Thermodyamics R07Documento9 pagineThermodyamics R07hhjjNessuna valutazione finora

- NR-310804 - Mass Transfer Operations - IDocumento8 pagineNR-310804 - Mass Transfer Operations - ISrinivasa Rao G100% (1)

- Exp - S10A - Forced Draft Tray DryerDocumento6 pagineExp - S10A - Forced Draft Tray DryerSenthilNathanNessuna valutazione finora

- BE - MECH - Heating Ventilation & Air Conditioning - Dec 2019Documento5 pagineBE - MECH - Heating Ventilation & Air Conditioning - Dec 2019Vishal GaikwadNessuna valutazione finora

- r050210801 Fluid Mechanics For Chemical EngineeringDocumento7 paginer050210801 Fluid Mechanics For Chemical EngineeringSrinivasa Rao GNessuna valutazione finora

- DJJ2093 Questions DIS2016 EditedDocumento8 pagineDJJ2093 Questions DIS2016 EditedAsa Fansuri Abu SamahNessuna valutazione finora

- Thermal TestDocumento11 pagineThermal TestBhavani GujjariNessuna valutazione finora

- Me 8301 EtdDocumento3 pagineMe 8301 Etdsrinithims78Nessuna valutazione finora

- Tutorial 3Documento3 pagineTutorial 3Andrew0% (1)

- Answers - Heat & Mass Transfer - IDocumento8 pagineAnswers - Heat & Mass Transfer - IKTINE08Nessuna valutazione finora

- Assignment 2Documento2 pagineAssignment 2Boy farhanNessuna valutazione finora

- ME - Refrigeration and Air Conditioning 1Documento7 pagineME - Refrigeration and Air Conditioning 1Vijay KumarNessuna valutazione finora

- Groundwater Chemical Methods for Recharge Studies - Part 2Da EverandGroundwater Chemical Methods for Recharge Studies - Part 2Nessuna valutazione finora

- SN200Documento111 pagineSN200tajinder231280% (5)

- Astm A358 A358mDocumento11 pagineAstm A358 A358mShashank SaxenaNessuna valutazione finora

- Technical Specification Supply Delivery and Installation of Furniture and Fixtures For The MARINA Building in The Cities of Iloilo and Bacolod PDFDocumento5 pagineTechnical Specification Supply Delivery and Installation of Furniture and Fixtures For The MARINA Building in The Cities of Iloilo and Bacolod PDFSusie Vanguardia100% (1)

- Chapter 1 7Documento76 pagineChapter 1 7Ian ReyesNessuna valutazione finora

- Lambda Sensor LSU 4.9: Application Mechanical DataDocumento2 pagineLambda Sensor LSU 4.9: Application Mechanical DataDamirNessuna valutazione finora

- Flare System PDFDocumento41 pagineFlare System PDFAzar Deen100% (1)

- Characteristics, Applications, and Processing of Stress - Strain Behavior (I)Documento7 pagineCharacteristics, Applications, and Processing of Stress - Strain Behavior (I)nelson bessoneNessuna valutazione finora

- The Impact of Sugar On Setting - Time of Ordinary Portland Cement (OPC) Paste and Compressive Strength of ConcreteDocumento8 pagineThe Impact of Sugar On Setting - Time of Ordinary Portland Cement (OPC) Paste and Compressive Strength of ConcreteJarek PlaszczycaNessuna valutazione finora

- Mat Chem Comp GB en PDFDocumento48 pagineMat Chem Comp GB en PDFvzimak2355Nessuna valutazione finora

- UFGS Section 09 97 13.27Documento42 pagineUFGS Section 09 97 13.27crcltcNessuna valutazione finora

- Force Analysis - PPSXDocumento107 pagineForce Analysis - PPSXÖmer Faruk EkizNessuna valutazione finora

- Sikagrout 214-11 PdsDocumento2 pagineSikagrout 214-11 PdscharlessimoNessuna valutazione finora

- Manual de La Ingleteadora BOSCH GCM12SDDocumento164 pagineManual de La Ingleteadora BOSCH GCM12SDChristopher DavisNessuna valutazione finora

- R9500 enDocumento1 paginaR9500 enSwapnil UbaleNessuna valutazione finora

- STADIUM EstimateDocumento13 pagineSTADIUM EstimateRajeswari Ramakrishnan100% (1)

- Types of Chroma To Grap GyDocumento75 pagineTypes of Chroma To Grap GyMohammad RehanNessuna valutazione finora

- Public Area CleaningDocumento16 paginePublic Area Cleaningnitty loveNessuna valutazione finora

- ICI Internship ReportDocumento11 pagineICI Internship ReportKhubaib AsadiNessuna valutazione finora

- EN 1372 765 101a 2017 02 OnlineDocumento204 pagineEN 1372 765 101a 2017 02 Onlineemilio Alons100% (11)

- Food Technology and Biotechnology - StrawberryDocumento8 pagineFood Technology and Biotechnology - StrawberryIfenza HernandaNessuna valutazione finora

- Auma - Gear OperatorsDocumento30 pagineAuma - Gear Operatorsnabil160874100% (1)

- PWD Schedule EM SUB-HEAD-3 NewDocumento11 paginePWD Schedule EM SUB-HEAD-3 NewEmran HusainNessuna valutazione finora

- Generic PID DefinitionsDocumento4 pagineGeneric PID DefinitionsNicoara Stoica Paul FlorinNessuna valutazione finora

- Hot & Cold WorkingDocumento18 pagineHot & Cold WorkingMadushan MadushaNessuna valutazione finora

- Brochure by-Pass-Units 20160216 enDocumento36 pagineBrochure by-Pass-Units 20160216 enHOryshorNessuna valutazione finora

- LCA Methodology ReportDocumento95 pagineLCA Methodology ReportMOHAMEDABBASNessuna valutazione finora

- Kim Lighting LLF Low Level Floodlight Brochure 1990Documento38 pagineKim Lighting LLF Low Level Floodlight Brochure 1990Alan MastersNessuna valutazione finora

- PQR GmawDocumento4 paginePQR GmawEr Sumant Kumar Singh0% (1)

- Carborundum Universal Ltd. (CUMI) : HistoryDocumento3 pagineCarborundum Universal Ltd. (CUMI) : HistoryNavjot SidhuNessuna valutazione finora

- Steel ChemistryDocumento22 pagineSteel ChemistryAmit Kumar UkeNessuna valutazione finora