Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Solutionstainlesssteelweldinspection 170124181624

Caricato da

NDTInstructor0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

10 visualizzazioni13 paginestainless welding solution

Titolo originale

solutionstainlesssteelweldinspection-170124181624 (1)

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentostainless welding solution

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

10 visualizzazioni13 pagineSolutionstainlesssteelweldinspection 170124181624

Caricato da

NDTInstructorstainless welding solution

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 13

Stainless Steel

Weld Inspection

Application Solution

© Zetec Inc. All rights reserved 1

Overview

• Inspection Challenge

• Recommended Phased Array Ultrasonic (PA UT)

Solution

• Results

• Benefits of Zetec Solution

© Zetec Inc. All rights reserved 2

Inspection Challenge

• Various industries want to use PA UT for manufacturing

inspection (“in lieu of RT”) and for in-service inspection of

stainless steel (SS) and other austenitic welds : dissimilar

metal, Inconel, Corrosion-Resistant alloy (CRA)

• These welds are challenging for UT examination, because of

sound propagation issues in the coarse-grain austenitic weld

structure (see next slide)

• Reliable examination of austenitic welds requires careful

selection of inspection techniques

• Most elements of a “successful” inspection solution for

austenitic material are known to UT experts, but implementation

is still perceived as laborious and expensive (requires high-end

equipment and software, or multiple software packages)

© Zetec Inc. All rights reserved 3

Inspection Challenge

Propagation issues caused by anisotropic coarse-grain

structure of stainless steel and austenitic welds :

• High, and variable attenuation

LW

• High noise level, caused by

reflection on individual grains

• Low-pass filtering effect

SW

• Beam skewing and distortion

• Local variations of material

structure

© Zetec Inc. All rights reserved 4

Recommended PA UT Solution

• Low-frequency 2D matrix array probes, to generate both

LW and SW beams, for complete weld coverage

• High-performance portable PA UT unit, with

fully integrated support of 2D matrix arrays :

– On-board setup and adjustment of probe

and wedge configuration

– Visual feedback on focal laws

– Volumetric Merge for efficient data analysis

• Efficient deployment on-site, compatible with

automated and manually driven encoded

scanners

© Zetec Inc. All rights reserved 5

Inspection Technique

• Examination for circumferential flaws using dual 2D matrix

arrays (TRL mode), with frequencies between 1.5 and 3.5 MHz:

– Better sensitivity and SNR due to the “convolution” of T and R beams

– No dead zone or wedge echoes

• Refracted angles from 30° to 85°LW, covering the full thickness

• Effective inspection through coarse-grain weld material

© Zetec Inc. All rights reserved 6

Inspection Technique

• Detection of axial cracks (e.g. IGSCC) in austenitic welds with

weld cap in place

• Single 2D matrix array probe, operating in pulse-echo mode,

generating skewed SW beams through base material

• Multiple skew angles and probe orientations to optimize detection

and coverage

© Zetec Inc. All rights reserved 7

2D Matrix Array Probes

• Standard dual 2D matrix array probes: frequency and active

surface optimized for material attenuation and wall thickness

• Element configuration optimized for maximum steering

capability without side lobes

• Exchangeable wedge assemblies, contoured to match pipe OD

© Zetec Inc. All rights reserved 8

Zetec Instrument

• Fully integrated, portable unit

• 64-bit computer, 2 x faster

• PA UT 32/128PR + 2 UT at 200 V

UltraVision TouchTM

Advanced software

• On-board support of 2D arrays

• « Propose Setup » tool

• Visual feedback on focal laws

• On-line Volumetric Merge

• Full data analysis capability

• 2GByte data files on-board

© Zetec Inc. All rights reserved 9

Results – SS Weld with Cap

PA UT data (30° to 85°LW) from 304 SS weld (T = 25 mm) :

all flaws detected from a single side with 2.25 MHz, 10x3 matrix array (TRL)

© Zetec Inc. All rights reserved 10

Results – Axial Flaws

Merged PA UT data (SW) from axial ID crack in SS pipe weld (T = 23 mm):

Reliable detection using beams with multiple skews,

and accurate positioning of the crack in cylindrical geometry

© Zetec Inc. All rights reserved 11

Benefits of Zetec Solution

• Standard 2D matrix array probes with proven design for

a wide range of austenitic weld configurations

• integrated portable PA UT system,

capable of performing 2-sided weld inspection using

TRL probes (32T/32R):

– High performance from on-board 64-bit computer

– Capability to record large data files (up to 2 GBytes)

• Efficient setup and optimization of inspection techniques

using only the on-board UltraVision Touch software

• Easy to deploy:

– Dynamic Merge views for on-line monitoring of inspection data

– Complete data analysis capability

– Indication Table & Report Generation

© Zetec Inc. All rights reserved 12

Thank You!

Learn more at: www.zetec.com

© Zetec Inc. All rights reserved 13

Potrebbero piacerti anche

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Documento242 pagineNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Forging DefectsDocumento1 paginaForging DefectsNDTInstructorNessuna valutazione finora

- New Holland Ec25 Mini ExcavatorDocumento153 pagineNew Holland Ec25 Mini ExcavatorJack StinerNessuna valutazione finora

- The BBTT Program REV PDFDocumento40 pagineThe BBTT Program REV PDFBianca Lacramioara Florea100% (3)

- PAUT Vs RadiographyDocumento1 paginaPAUT Vs RadiographyNDTInstructorNessuna valutazione finora

- ASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFDocumento89 pagineASME-PTC-18-Hydraulic Turbines and Pump Turbines-2002 PDFFabiano Lebkuchen100% (2)

- Surge Arrester Function and Working PrinciplesDocumento25 pagineSurge Arrester Function and Working PrinciplesMidhun Varghese100% (1)

- Vakri Grahas - Effects of Retrograde Planets in Hindu AstrologyDocumento4 pagineVakri Grahas - Effects of Retrograde Planets in Hindu AstrologyBailvan100% (1)

- Vision CertificateDocumento1 paginaVision CertificateNDTInstructorNessuna valutazione finora

- 526Documento13 pagine526jeas grejoy andrewsNessuna valutazione finora

- Cat Marine Engine ProgramDocumento4 pagineCat Marine Engine ProgramRobert BeddingfieldNessuna valutazione finora

- Polyester MicrofiberDocumento37 paginePolyester Microfiberpsyish80% (5)

- TunisiaDocumento4 pagineTunisiaNDTInstructorNessuna valutazione finora

- Job Description NDTDocumento4 pagineJob Description NDTNDTInstructorNessuna valutazione finora

- Color Vision TestDocumento1 paginaColor Vision TestNDTInstructorNessuna valutazione finora

- Color Vision TestDocumento1 paginaColor Vision TestNDTInstructorNessuna valutazione finora

- NigieriaDocumento12 pagineNigieriaNDTInstructorNessuna valutazione finora

- Piping 4Documento1 paginaPiping 4NDTInstructorNessuna valutazione finora

- Api 580Documento1 paginaApi 580NDTInstructorNessuna valutazione finora

- Piping 3Documento1 paginaPiping 3NDTInstructorNessuna valutazione finora

- H300 Introduction (Si Units) : Para. 304.3.3Documento2 pagineH300 Introduction (Si Units) : Para. 304.3.3NDTInstructorNessuna valutazione finora

- Measuring Residual Magnetic Fields with Field Indicators and Gauss MetersDocumento1 paginaMeasuring Residual Magnetic Fields with Field Indicators and Gauss MetersNDTInstructorNessuna valutazione finora

- (A) Elastic Behavior. The Assumption That DisplaceDocumento1 pagina(A) Elastic Behavior. The Assumption That DisplaceNDTInstructorNessuna valutazione finora

- Piping 4Documento1 paginaPiping 4NDTInstructorNessuna valutazione finora

- A309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2Documento1 paginaA309 Bolting: Appendix F Para. F309 Paragraph 309.1 Para. 309.1 Para. A335.2NDTInstructorNessuna valutazione finora

- Eddify Lyft Presentation DocumentDocumento4 pagineEddify Lyft Presentation DocumentBernardo FariasNessuna valutazione finora

- 344.2 Visual Examination: Para. 344.7Documento1 pagina344.2 Visual Examination: Para. 344.7NDTInstructorNessuna valutazione finora

- Shell Settlement EvaluationDocumento1 paginaShell Settlement EvaluationNDTInstructorNessuna valutazione finora

- Job Hazard AnalysisDocumento5 pagineJob Hazard AnalysisNDTInstructorNessuna valutazione finora

- Tank Inspection SolutionDocumento7 pagineTank Inspection SolutionNDTInstructorNessuna valutazione finora

- General TankDocumento2 pagineGeneral TankNDTInstructorNessuna valutazione finora

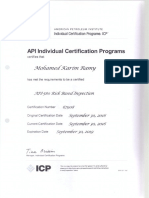

- API Individual Certification Programs: Mohamed Karim RamyDocumento1 paginaAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNessuna valutazione finora

- Procedure CFVDocumento13 pagineProcedure CFVNDTInstructorNessuna valutazione finora

- Optimized Performance For Wall Thickness and LiftoffDocumento1 paginaOptimized Performance For Wall Thickness and LiftoffNDTInstructorNessuna valutazione finora

- Olympus Multiscan Ms 5800 Er1uDocumento2 pagineOlympus Multiscan Ms 5800 Er1uNDTInstructorNessuna valutazione finora

- Inspections and Audits For Boilers and Pressure VesselsDocumento2 pagineInspections and Audits For Boilers and Pressure VesselsNDTInstructorNessuna valutazione finora

- API Individual Certification Programs: Mohamed Karim RamyDocumento1 paginaAPI Individual Certification Programs: Mohamed Karim RamyNDTInstructorNessuna valutazione finora

- Pulp Digester FailuredDocumento93 paginePulp Digester FailuredTim Ku100% (1)

- Work Permit SystemDocumento50 pagineWork Permit SystemBin khammash and sons Co.Nessuna valutazione finora

- CS410 Series and CS417: User's GuideDocumento209 pagineCS410 Series and CS417: User's Guident11Nessuna valutazione finora

- Latihan Akuntansi Perusahaan DagangDocumento3 pagineLatihan Akuntansi Perusahaan DagangTheresya HutajuluNessuna valutazione finora

- 10 1108 - JPBM 07 2022 4070Documento19 pagine10 1108 - JPBM 07 2022 4070erikNessuna valutazione finora

- Leadership Theory Application and Skill Development 5th Edition Lussier Test Bank 1Documento36 pagineLeadership Theory Application and Skill Development 5th Edition Lussier Test Bank 1douglasbrownyipsmrgkob100% (29)

- Anggraeni Kusuma Dewi Xii Iis Bahasa Inggris (UH 4/SOAL REPORT TEXT)Documento7 pagineAnggraeni Kusuma Dewi Xii Iis Bahasa Inggris (UH 4/SOAL REPORT TEXT)prabaswara xxNessuna valutazione finora

- R/C Soaring Digest - May 2009Documento80 pagineR/C Soaring Digest - May 2009Aviation/Space History LibraryNessuna valutazione finora

- Um Centuris Pro Li900b1 - enDocumento70 pagineUm Centuris Pro Li900b1 - enOsires Ferreira100% (1)

- Training Programmers. Reniforcementptx145525Documento9 pagineTraining Programmers. Reniforcementptx145525nkalaiNessuna valutazione finora

- Acid Dissociation ConstantDocumento4 pagineAcid Dissociation ConstantJair RangelNessuna valutazione finora

- 51-11-15-001-Data Recording of Allowable Damage and Repairs-A320Documento6 pagine51-11-15-001-Data Recording of Allowable Damage and Repairs-A320FredNessuna valutazione finora

- Manual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Documento53 pagineManual Direct Fired 160h Through 800h PN 54000 07-12-13 - 1Fer YamashitaNessuna valutazione finora

- Assignment On Computer HardwareDocumento9 pagineAssignment On Computer HardwareMuktadirhasan100% (1)

- SAP Sales Order Store Returns (Intercompany)Documento2 pagineSAP Sales Order Store Returns (Intercompany)Donny CorleonNessuna valutazione finora

- Engineering Declaration Unit # 2 JindalDocumento16 pagineEngineering Declaration Unit # 2 JindalVIBHAV100% (1)

- CT AC 72A<INV=<90A 70A<REC=<135A Part SpecDocumento7 pagineCT AC 72A<INV=<90A 70A<REC=<135A Part SpecEdwin Mosos RamosNessuna valutazione finora

- trs5 Key Cho Cac BanDocumento35 paginetrs5 Key Cho Cac BanNguyệt NgôNessuna valutazione finora

- Metrology-Lab-Manual 3 Year 1semDocumento41 pagineMetrology-Lab-Manual 3 Year 1semBHARATH Chandra100% (1)

- Working Principle Iwind Wind TurbinesDocumento25 pagineWorking Principle Iwind Wind TurbinesKarbonKaleNessuna valutazione finora

- Comprehensive Land Use Plan in Municipality of TigbauanDocumento4 pagineComprehensive Land Use Plan in Municipality of TigbauanmaygracedigolNessuna valutazione finora

- EM-PM Hybrid Maglev Conveyor SimulationDocumento7 pagineEM-PM Hybrid Maglev Conveyor SimulationLalbahadur MajhiNessuna valutazione finora