Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Form 5453E

Caricato da

Anabel Hernández DíazTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Form 5453E

Caricato da

Anabel Hernández DíazCopyright:

Formati disponibili

Emerson Industrial Automation

FORM

7120 New Buffington Road

Florence, KY 41042 5453

Belt Tension Checker Application Engineering: 800 626 2093 Revised

www.emerson-ept.com January 2011

• Read and follow all instructions carefully. • Periodic inspections should be performed. Failure to perform proper maintenance

• Disconnect and lock-out power before installation and maintenance. can result in premature product failure and personal injury.

Working on or near energized equipment can result in severe injury or death. • To avoid damage, supporting structure including shafts and bearings must be

• Do not operate equipment without guards in place. Exposed equipment can designed to handle transmitted loads and belt tension(s).

result in severe injury or death.

Tensioning V-Belt Drives with a Browning® Tension Checker

General rules of tensioning BELT SPAN

1. Ideal tension is the lowest tension at which the belt will not slip under peak load

0 5 10 15 20 2 5 30

conditions.

2. Check tension frequently during the first 24 hours of operation. Check after jog

1 50

start or 1-3 minutes of operation, at 8 hours, 24 hours, 100 hours and periodically

00

1

SPAN

50

INCHES

thereafter are recommended.

5 10 15 20 25 30

3. Over tensioning shortens belt and bearing life.

4. Keep belts free of foreign material which may cause slip.

5. Make v-drive inspection on a periodic basis. Under-tensioned belt drives often

produce audible squeal noise. Tension when slipping. Never apply belt dressing

as this will damage the belt and cause early failure.

Part Number: “Belt Tension Checker”

Tension Measurement Procedure

0

1. Measure the belt span (see sketch).

2. Position bottom of the large o-ring on the span scale at the measured belt span.

3. Set the small o-ring on the deflection force scale to zero.

4. Place the tension checker squarely on one belt at the center of the belt span. Apply

a force on the plunger and perpendicular to the belt span until the bottom of the

large o-ring is even with the top of the adjacent (next) belt or with the bottom of a

straight edge laid across the outside diameters of the v-belt sheaves.

5. Remove the tension checker and read the force applied from the bottom of the

15 20 25 30

small o-ring on the deflection force scale. SMALL

DEFLECTION "O" RING

6. Compare the force you have applied with the values given in the tables on the back FORCE

of this page. The force should be between the minimum and maximum shown. (LBS.)

The maximum value is shown for “New Belt” and new belts should be tensioned

at this value to allow for expected tension loss. “New Belt” tensions should be

used at initial installation and after jog start or 1-3 minutes of operation. Used belts

should be maintained at the minimum value as indicated in the chart. “Used Belt”

tensions should be used for the 8 hour and subsequent checks. If the belt span

was measured in inches, then use the pounds of force values for comparison. If

150

the belt span was measured in centimeters, then use the kilograms of force values

for comparison.

Note: The ratio of deflection to belt span is 1:64 in either units of measurements.

7. Whenever possible, jog start for a few revolutions or preferably run drive for

100

150

approximately 1-3 minutes and then re-tension in accordance with steps 1-6.

SPAN

Running the drive for a few revolutions or minutes will help seat the belt(s) in the

groove(s). This relatively early re-tensioning may reduce or minimize the amount

of re-tensioning required in the first 24 hours of drive service.

100

SPAN

STRAIGHT

EDGE SPAN

50

INCHES

SCALE

INCHES

50

LARGE "O" RING

ADJACENT

V-BELT

V-BELT

Browning, Emerson, Emerson Industrial Automation and EPT Edge are

trademarks of Emerson Electric Co. or one of its affiliated companies.

©2007, 2011 Emerson Power Transmission Corp., All Rights Reserved.

MCIM11003 • Form 5453 • Printed in USA

Note:

1. For gripbands (multiple or banded belts), the belt deflection force in the above tables must be multiplied by the number of ribs in the gripband. Lay a narrow steel bar such

as keystock across the gripband belt and apply the belt deflection force to the bar such that all the individual ribs are deflected evenly.

2. The belt deflection force capacity of the Browning belt tension checker is 33 lbs. or 15 kg. Other means of applying force must be used if force requirement is greater than this.

The above method of tensioning belt drives is to be used when a drive has been selected in accordance with the suggestions listed in the drive selection tables of the Emerson

Components Catalog (Form 8586). For drives with service factor greater than 1.5, consult Browning. For more precise tension calculations, use the EPT EDGE® Online

Selection Program or contact Application Engineering at 1-800-626-2093.

Sheave Diameter - Inches Sheave Diameter - Millimeters

Deflection Force - Lbs. Deflection Force - Kg.

Belt Deflection Force Belt Deflection Force

Super Gripnotch Super Gripnotch

Smallest Gripbelts Belts Smallest Gripbelts Belts

Belt Belt

Sheave RPM and and Sheave RPM and and

Cross Cross Diameter

Diameter Range Unnotched Notched Section Range Range Unnotched Notched

Section Gripbands Gripbands

Range Gripbands Gripbands

Used New Used New Used New Used New

Belt Belt Belt Belt Belt Belt Belt Belt

1000-2500 3.7 5.5 4.1 6.1 1000-2500 1.7 2.5 1.9 2.8

3.0 - 3.6 75 - 90

2501-4000 2.8 4.2 3.4 5.0 2501-4000 1.3 1.9 1.5 2.3

1000-2500 4.5 6.8 5.0 7.4 1000-2500 2.0 3.1 2.3 3.4

A,AX 3.8 - 4.8 A,AX 91 - 120 2501-4000 1.7 2.6 2.0 2.9

2501-4000 3.8 5.7 4.3 6.4

1000-2500 5.4 8.0 5.7 8.4 1000-2500 2.4 3.6 2.6 3.8

5.0 - 7.0 121 - 175 2

2501-4000 4.7 7.0 5.1 7.6 501-4000 2.1 3.2 2.3 3.4

860-2500 - - 4.9 7.2 860-2500 - - 2.2 3.3

3.4 - 4.2 85 - 105

2501-4000 - - 4.2 6.2 2501-4000 - - 1.9 2.8

860-2500 5.3 7.9 7. 1 10.5

B,BX 4.4 - 5.6 B,BX 106 - 140 2856001--24500000 2.4

2.0

3.6

3.0

3.2 4.8

2501-4000 4.5 6.7 6.1 9.1 2 .8 4.1

860-2500 6.3 9.4 8.5 12.6

5.8 - 8.6 141 - 220 2856001--24500000 2.9

2.7

4.3

4.0

3.9

3.3

5.7

4.9

2501-4000 6.0 8.9 7.3 10.9

500-1740 11.5 17.0 14.7 21.8

7.0 - 9.0 175 - 230 1570401--13704000 5.2

4.3

7.7

6.3

6.7

5.4

9.9

7.9

1741-3000 9.4 13.8 11.9 17.5

C,CX C,CX

500-1740 14.1 21.0 15.9 23.5

9.5 - 16.0 231 - 400 1570401--13704000 6.4

5.7

9.5

8.4

7.2

6.6

10.7

9.8

1741-3000 12.5 18.5 14.6 21.6

12.0 - 200-850 24.9 37.0 - - 200-850 11.3 16.8 - -

305 - 400

16.0 851-1500 21.2 31.3 - - 851-1500 9.6 14.2 - -

D D

18.0 - 200-850 30.4 45.2 - - 200-850 13.8 20.5 - -

401 - 510 851-1500 11.6 17.2 - -

20.0 851-1500 25.6 38.0 - -

1000-2500 - - 3.3 4.9 1000-2500 - - 1.5 2.2

2.2 - 2.4 55 - 60 2501-4000 - - 1.3 2.0

2501-4000 - - 2.9 4.3

2.65 - 1000-2500 3.6 5.1 4.2 6.2 1000-2500 1.6 2.3 1.9 2.8

3V,3VX 3V,3VX 61 - 90 2501-4000 1.4 2.0 1.7 2.5

3.65 2501-4000 3.0 4.4 3.8 5.6

4.12 - 1000-2500 4.9 7 .3 5.3 7.9 1000-2500 2.2 3.3 2.4 3.6

91 - 175 2501-4000 2.0 3.0 2.2 3.3

6.90 2501-4000 4.4 6.6 4.9 7.3

500-1749 - - 10.2 15.2 5 00-1749 - - 4.6 6.9

4.4 - 6.7 1750-3000 - - 8.8 13.2 110 - 170 1750-3000 - - 4.0 6.0

3001-4000 - - 5.6 8.5 3001-4000 - - 2.5 3.9

5V,5VX 500-1740 12.7 18.9 14.8 22.1 5V,5VX

7.1 - 10.9 171 - 275 1570401--13704000 5.8

5.1

8.6

7.6

6.7

6.2

10.0

9.1

1741-3000 11.2 16.7 13.7 20.1

11.8 - 500-1740 15.5 23.4 17.1 25.5

276 - 400 1570401--13704000 7.0

6.6

10.6

9.9

7.8

7.6

11.6

11.3

16.0 1741-3000 14.6 21.8 16.8 25.0

12.5 - 200-850 33.0 49.3 - - 200-850 15.0 22.4 - -

315 - 430 851-1500 12.2 18.1 - -

17.0 851-1500 26.8 39.9 - -

8V 8V

18.0 - 200-850 39.6 59.2 - - 200-850 18.0 26.8 - -

431 - 570

22.4 851-1500 35.3 52.7 - - 851-1500 16.0 23.9 - -

Sheave Diameter - Inches

Deflection Force - Lbs.

Smallest Belt Deflection Force

Belt

Sheave

Cross Used New

Diameter

Section Belt Belt

Range

1.25 - 1.75 3/8 5/8

3L 2.00 - 2.25 3/4 1 1/4 For additional assistance please contact

2.50 - 3.00 1 1 1/2 Application Engineering at 1-800-626-2093.

2.10 - 2.80 5/8 1

4L 3.00 - 3.50 1 5/8 2 1/2

3.70 - 5.00 2 3

3.00 - 4.20 1 1/2 2 5/8

5L

4.50 - 5.20 2 1/2 3 1/2

Browning, Emerson, Emerson Industrial Automation and EPT Edge are

trademarks of Emerson Electric Co. or one of its affiliated companies.

©2007, 2011 Emerson Power Transmission Corp., All Rights Reserved.

2 MCIM11003 • Form 5453 • Printed in USA

Potrebbero piacerti anche

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (74)

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Mining Machinery Nit RourkelaDocumento343 pagineMining Machinery Nit RourkelaNaren Gujjar100% (8)

- HJ AC Servo Motor Technical Data Manual Issue 5.5Documento144 pagineHJ AC Servo Motor Technical Data Manual Issue 5.5sunhuynhNessuna valutazione finora

- Baldor 15 HPDocumento8 pagineBaldor 15 HPAnabel Hernández DíazNessuna valutazione finora

- Belt Weigher CalibrationDocumento3 pagineBelt Weigher CalibrationClint GarciaNessuna valutazione finora

- VLT8000 OperatingDocumento202 pagineVLT8000 OperatingAnabel Hernández DíazNessuna valutazione finora

- Trane Tutorial para Diseño Tuberías 1Documento2 pagineTrane Tutorial para Diseño Tuberías 1Anabel Hernández DíazNessuna valutazione finora

- Lysol Disinfectant SprayDocumento14 pagineLysol Disinfectant SprayAman BaigNessuna valutazione finora

- Installation, Operation and Maintenance Manual: General Safety InformationDocumento12 pagineInstallation, Operation and Maintenance Manual: General Safety InformationAnabel Hernández DíazNessuna valutazione finora

- Brochure Bac-7000 Vav Sb005cDocumento2 pagineBrochure Bac-7000 Vav Sb005cAnabel Hernández DíazNessuna valutazione finora

- Manual IOM Colector Polvo UMA40 A 750Documento1 paginaManual IOM Colector Polvo UMA40 A 750Anabel Hernández DíazNessuna valutazione finora

- Monitoring CO in Wineries: Case Study - Chateau St. JeanDocumento2 pagineMonitoring CO in Wineries: Case Study - Chateau St. JeanAnabel Hernández DíazNessuna valutazione finora

- Installation Instructions Tb7100a1000Documento16 pagineInstallation Instructions Tb7100a1000Anabel Hernández DíazNessuna valutazione finora

- Manual IOM Colector Polvo UMA40 A 750 PDFDocumento28 pagineManual IOM Colector Polvo UMA40 A 750 PDFAnabel Hernández DíazNessuna valutazione finora

- 600P Tubing & FittingDocumento36 pagine600P Tubing & FittingAnabel Hernández DíazNessuna valutazione finora

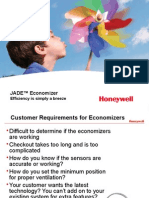

- JADE™ Economizer: Efficiency Is Simply A BreezeDocumento14 pagineJADE™ Economizer: Efficiency Is Simply A BreezeAnabel Hernández DíazNessuna valutazione finora

- BELTS - Technical Manual For Ribbed BELTS DrivesDocumento54 pagineBELTS - Technical Manual For Ribbed BELTS DrivesMarkoMikicNessuna valutazione finora

- Maintenance Intervals: Operation and Maintenance Manual ExcerptDocumento43 pagineMaintenance Intervals: Operation and Maintenance Manual ExcerptPramodNessuna valutazione finora

- BV DSG eDocumento18 pagineBV DSG eIulianIonutRaduNessuna valutazione finora

- Masons ConveyorCatalogueDocumento19 pagineMasons ConveyorCataloguesinanduixNessuna valutazione finora

- Diesel Engine Setting/Locking Tool Kit For Vauxhall/Opel: 1. ApplicationDocumento3 pagineDiesel Engine Setting/Locking Tool Kit For Vauxhall/Opel: 1. ApplicationchennieNessuna valutazione finora

- Design and Construction of An Automated Adjustable-Can Foil Sealing MachineDocumento9 pagineDesign and Construction of An Automated Adjustable-Can Foil Sealing Machinepharmafactoryegstore 2021Nessuna valutazione finora

- Lab. Belt FrictionDocumento2 pagineLab. Belt Frictionchem jobs0% (1)

- S 821 - 826 - Manual - 2006Documento174 pagineS 821 - 826 - Manual - 2006Centrifugal SeparatorNessuna valutazione finora

- 5 Timing BeltDocumento8 pagine5 Timing BeltWirote Dewilai100% (1)

- EPSON Technology and Operating PrinciplesDocumento182 pagineEPSON Technology and Operating PrinciplesLukáš KadeřábekNessuna valutazione finora

- Jeep WK Grand Cherokee Section 09 EngineDocumento1.568 pagineJeep WK Grand Cherokee Section 09 EnginePedroParker100% (9)

- Beltomatic Operator's ManualDocumento285 pagineBeltomatic Operator's ManualOrbán ÁrpádNessuna valutazione finora

- Stihl TS 700 Cut-Off Saw Service Repair ManualDocumento20 pagineStihl TS 700 Cut-Off Saw Service Repair Manualshishankaogou4Nessuna valutazione finora

- Manual - Labeling MachineDocumento10 pagineManual - Labeling MachineGilang WijayaNessuna valutazione finora

- Lab Sheet BDA27401 Sem 2 20162017 PDFDocumento82 pagineLab Sheet BDA27401 Sem 2 20162017 PDFNik JaffNessuna valutazione finora

- DRIVE GEARBOX ZC01-FD001-3.7 TPHDocumento1 paginaDRIVE GEARBOX ZC01-FD001-3.7 TPHachmatNessuna valutazione finora

- Case Combine 2388 (2006) Parts Catalog (PDF, RUS, 12 MB) PDFDocumento771 pagineCase Combine 2388 (2006) Parts Catalog (PDF, RUS, 12 MB) PDFVlad Ptashnichenko100% (2)

- Unit 4Documento36 pagineUnit 4hisuresh196Nessuna valutazione finora

- Manual Merge TS4200-150 - o - MDocumento28 pagineManual Merge TS4200-150 - o - MWalter JimenezNessuna valutazione finora

- Yk-X e V5.21Documento360 pagineYk-X e V5.21hexapodo2Nessuna valutazione finora

- Terex Jaques Torrent ScreensDocumento16 pagineTerex Jaques Torrent ScreensKarin AndersonNessuna valutazione finora

- S 831 - 836 - Manual - 2006Documento171 pagineS 831 - 836 - Manual - 2006Centrifugal SeparatorNessuna valutazione finora

- Belt Was Her Maintenance ManualDocumento28 pagineBelt Was Her Maintenance Manualnaser150Nessuna valutazione finora

- Catalog General BaldorDocumento210 pagineCatalog General Baldorvalentinp3Nessuna valutazione finora

- Catalogue 2528k PDFDocumento390 pagineCatalogue 2528k PDFbhushan kalwa100% (1)

- SX4257DT384T - Shacman Tractor GNV CatalogoDocumento523 pagineSX4257DT384T - Shacman Tractor GNV Catalogopercy67% (3)

- AC6000 8000S 8300 UsersManual EDocumento60 pagineAC6000 8000S 8300 UsersManual EInversiones JapesaNessuna valutazione finora