Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Flintkote

Caricato da

Dhim1312670 valutazioniIl 0% ha trovato utile questo documento (0 voti)

254 visualizzazioni2 pagineFlintkote 3

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoFlintkote 3

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

254 visualizzazioni2 pagineFlintkote

Caricato da

Dhim131267Flintkote 3

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

a.b.e.

® Construction Chemicals

flintkote 3

BINDER FOR ABE.®CO FLOORING SYSTEM

AND HEAVY DUTY BITUMINOUS COATING

DESCRIPTION PROPERTIES OF WET MATERIAL

Thixotropic water dispersed bitumen emulsion. Density (typical) 1,0 g/cm³

Colour Brown, drying to black

USES

Finish Matt

flintkote 3 is a general purpose bituminous coating and

vapor barrier and flooring system binder. See abe.®co and Flash point None

tank base mastic. Dilution Clean water

Consistency Smooth thixotropic paste

ADVANTAGES

Toxicity Mildly toxic while liquid

• Waterproof coating and vapor barrier

• Easy, cost effective

PROPERTIES DURING APPLICATION

• Waterproof binder for mastic flooring which is Volume solids (typical) 55%

easily repairable

Recommended average dft

• Suitable for waterproofing membrane (with fabric and 550 µm

per coat

UV protection) Theoretical coverage for

1 m²/L on smooth surfaces

• Potable water containment above dft

Wet film thickness at above 1 mm

COLOUR Maximum recommended wft 1,25 mm

Black. 24 hours but determine

Drying time @ 25°C by inspection

Rub film with wet finger

SURFACE PREPARATION

Overcoating time @ 25°C 24 hours

Steel – must never be coated directly with flintkote 3.

abe® bitu.®prime should be used as a first coat and Application temperature range 5°C to 50°C

preparation of the steel must be as specified for the primer. Surface is less than 2°C

Do not apply if

above dew point

Galvanised steel – must be free of oil, grease and anti-

white rust treatment. Scrub the surface thoroughly with Fire resistance of wet film Non-flammable

a paste made from abe® super brush cleaner and an

abrasive soap. This may be applied with a cleaning pad PROPERTIES OF DRY FILM

(e.g. Scotchbrite). Thoroughly wash away all residues using Service temperature Maximum dry: 60°C

clean water. Minimum: -10°C

Solvent resistance Not resistant

Concrete and other porous surfaces – must be free of all

dust and laitance. Toxicity Non-toxic

Water tainting Non-tainting

The first coat of flintkote 3 should be’ diluted 1:1 with clean

water. See data sheet ‘

a.b.e.® is an ISO 9001:2008 registered company

PO Box 5100, Boksburg North, 1461, South Africa

Website: www.abe.co.za | Tel: +27(0) 11 306 9000

Durban | Johannesburg | Cape Town | Port Elizabeth | East London | Bloemfontein | George

DATE UPDATED: 25/10/12

BONDING/PRIMING PACKAGING

Dilute 1:1 with water for porous surfaces. Use bitu. prime

®

flintkote 3 is supplied in 5L, 25L and 200L yield

on steel. metal containers.

MIXING HANDLING & STORAGE

Stir flintkote 3 well before use, using a flat paddle. flinkote 3 has a shelf life of 12 months if kept in a dry, cool

place in the original, unopened container. If stored at high

COVERAGE temperatures and/or high humidity conditions, the shelf life

1,25 m²/L as coating; 7L/m² as binder. may be reduced.

APPLICATION HEALTH & SAFETY

flintkote 3 is normally applied by brush and generally flinkote 3 is mildly toxic and non-flammable. Ensure the

should not be applied thicker than specified. A coat should working area is well ventilated during application and

be thoroughly dry before application of a second coat. This drying. Avoid inhalation of dust and contact with skin and

can be easily determined by rubbing the surface with a wet eyes. Suitable protective clothing, gloves, eye protection

finger. If the finger remains clean, the surface is dry enough and respiratory protective equipment should be worn. The

to overcoat. flintkote 3 can be used in conjunction with use of barrier creams provides additional skin protection. If

a glass fibre membrane to build up and reinforce thicker contact with skin occurs, wash with water and soap. Splashes

coats. The membrane must be set into the still wet film of into eyes should be washed immediately with plenty of clean

flintkote 3 and ideally all bubbles and wrinkles should be water and medical advice sought.

removed by means of a laminating roller.

Cured flintkote 3 is inert and harmless.

The film is allowed to dry and then a second coat is applied

at a sufficient thickness to completely obliterate the weave IMPORTANT NOTE

and pattern of the membrane. Where the flintkote 3 film This data sheet is issued as a guide to the use of the

is finally to be exposed to the effects of sunlight and ultra- product(s) concerned. Whilst a.b.e.® Construction

violet radiation, it is recommended that, some 3 - 4 weeks Chemicals endeavors to ensure that any advice,

after being applied, it be overcoated with silvakote. recommendation, specification or information is accurate

and correct, the company cannot - because a.b.e.® has no

CLEANING direct or continuous control over where and how a.b.e.®

Ordinary clean water or abe® super brush cleaner. products are applied - accept any liability either directly

or indirectly arising from the use of a.b.e.® products,

PROTECTION ON COMPLETION whether or not in accordance with any advice, specification,

Protect against traffic and spillage until cured. If exposed to recommendation, or information given by the company.

direct extensive sunlight, overcoat with abe® silvakote.

FURTHER INFORMATION

TEMPERATURE AND RELATIVE HUMIDITY Where other products are to be used in conjunction with

High humidity slows evaporation of water dispersant. this material, the relevant technical data sheets should

be consulted to determine total requirements. a.b.e.®

MODEL SPECIFICATION Construction Chemicals has a wealth of technical and

practical experience built up over years in the company’s

Water dispersed single-component, general purpose bitumen

pursuit of excellence in building and construction technology.

emulsion supplied by a.b.e.® Construction Chemicals,

installed to manufacturer’s instructions.

a.b.e.® is an ISO 9001:2008 registered company

PO Box 5100, Boksburg North, 1461, South Africa

Website: www.abe.co.za | Tel: +27(0) 11 306 9000

Durban | Johannesburg | Cape Town | Port Elizabeth | East London | Bloemfontein | George

DATE UPDATED: 25/10/12

Potrebbero piacerti anche

- Minimum Edge Distance Table AISC ANSI 360 10 Specifications For Structural Steel BuildingsDocumento1 paginaMinimum Edge Distance Table AISC ANSI 360 10 Specifications For Structural Steel BuildingsDean Anders100% (7)

- Minimum Edge Distance Table AISC ANSI 360 10 Specifications For Structural Steel BuildingsDocumento1 paginaMinimum Edge Distance Table AISC ANSI 360 10 Specifications For Structural Steel BuildingsDean Anders100% (7)

- Cameron TC14111maintenance Manual311 PDFDocumento20 pagineCameron TC14111maintenance Manual311 PDFJess TobiasNessuna valutazione finora

- SMAW Welding Guidelines for Safety and ProceduresDocumento28 pagineSMAW Welding Guidelines for Safety and ProceduresD S Sagar TripuramalluNessuna valutazione finora

- Guidelines for U-Bolt DesignDocumento16 pagineGuidelines for U-Bolt DesigntylerstearnsNessuna valutazione finora

- Material Grade Comparison Chart PDFDocumento1 paginaMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

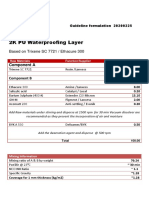

- 2K Solvent Free Waterproofing FormulationDocumento2 pagine2K Solvent Free Waterproofing FormulationM Idrees100% (2)

- Petroleum WaxesDocumento18 paginePetroleum WaxesChandra Kant100% (1)

- Room Decontamination With Hydrogen Peroxide VaporDocumento8 pagineRoom Decontamination With Hydrogen Peroxide VaporMohammad IsmailNessuna valutazione finora

- Consumer Guide CementDocumento2 pagineConsumer Guide CementDoobeng DudsNessuna valutazione finora

- Everest PEB Brochure - Leader in PEB StructuresDocumento28 pagineEverest PEB Brochure - Leader in PEB StructuresBikramdevPadhiNessuna valutazione finora

- Ral ChartDocumento10 pagineRal ChartShravan ThangallapalliNessuna valutazione finora

- Paint Calculation: Factor To Consider AreDocumento1 paginaPaint Calculation: Factor To Consider AreKalyanasundaram ThirugnanasambandamNessuna valutazione finora

- Perlite Sproule1200 Data SheetDocumento2 paginePerlite Sproule1200 Data Sheetkresimir.mikoc9765Nessuna valutazione finora

- Catenary Sag-Tension Calculator (Even and Uneven)Documento2 pagineCatenary Sag-Tension Calculator (Even and Uneven)mohsin160Nessuna valutazione finora

- High Temperature Grease: DescriptionDocumento2 pagineHigh Temperature Grease: Descriptionvicky kNessuna valutazione finora

- Article - Waste Glass in The Production of Cement and Concrete - A ReviewDocumento35 pagineArticle - Waste Glass in The Production of Cement and Concrete - A ReviewAnonymous OG8ApT4go100% (1)

- GER3620L 1 Oct 19 2010 1Documento60 pagineGER3620L 1 Oct 19 2010 1carlitos8022Nessuna valutazione finora

- GD 1020 BandlockDocumento12 pagineGD 1020 BandlockashuadbnelNessuna valutazione finora

- Welding CrackingDocumento8 pagineWelding CrackingjensdcvNessuna valutazione finora

- Lab Report Absorption ColumnDocumento18 pagineLab Report Absorption ColumnArina Hazirah100% (1)

- Et 0000 0 000 04 750Documento83 pagineEt 0000 0 000 04 750RenatoNessuna valutazione finora

- Construction Chemical Floor HardenerDocumento2 pagineConstruction Chemical Floor HardenerAndy100% (1)

- Work Smarter with Kovax's Cutting-Edge Finishing ProductsDocumento28 pagineWork Smarter with Kovax's Cutting-Edge Finishing ProductsViraj AmleNessuna valutazione finora

- Patchroc RSPDocumento46 paginePatchroc RSPvietpineNessuna valutazione finora

- Jotun-Penetrating Sealer-TDS PDFDocumento3 pagineJotun-Penetrating Sealer-TDS PDFmark jade moratilloNessuna valutazione finora

- TDS Conbextra EP10M IndiaDocumento2 pagineTDS Conbextra EP10M Indiasyed AffanNessuna valutazione finora

- Technical - Emx-120 Quickmaster With ConveyorDocumento14 pagineTechnical - Emx-120 Quickmaster With ConveyorJenriel CatulingNessuna valutazione finora

- 6DLDocumento1 pagina6DLAnonymous NxpnI6jCNessuna valutazione finora

- SPF 1K - MDU4075 Clear Coat - WBF 19 - 26 PDFDocumento2 pagineSPF 1K - MDU4075 Clear Coat - WBF 19 - 26 PDFsriatul2006100% (1)

- Bitumen Modified With SBS Thermoplastic For Roofing ApplicationDocumento9 pagineBitumen Modified With SBS Thermoplastic For Roofing ApplicationResearch and Development100% (1)

- Basf Masterpolyheed 8118 TdsDocumento2 pagineBasf Masterpolyheed 8118 Tdsaji arafat100% (2)

- Auracast 4115Documento2 pagineAuracast 4115zerzoumiaNessuna valutazione finora

- Mix Design - M25 - CSDocumento5 pagineMix Design - M25 - CSsatishNessuna valutazione finora

- Evonik Sunmide CX 1151 UploadDocumento6 pagineEvonik Sunmide CX 1151 UploadEpox by Epx polymers pvt ltdNessuna valutazione finora

- Inter Penertrating Polymer Network CBRI Paper PDFDocumento8 pagineInter Penertrating Polymer Network CBRI Paper PDFRadha KrishnanNessuna valutazione finora

- INDUSTRIAL FLOORING SOLUTIONSDocumento24 pagineINDUSTRIAL FLOORING SOLUTIONSchengkkNessuna valutazione finora

- Cmci Cmci: Epoxy Grout System For Equipment BasesDocumento2 pagineCmci Cmci: Epoxy Grout System For Equipment Basespravi3434Nessuna valutazione finora

- Masterrheobuild 890 tds-2 PDFDocumento2 pagineMasterrheobuild 890 tds-2 PDFBnbdbbdbhhbbbvvffffnhebrbbrNessuna valutazione finora

- Nitoflor SL2050: Constructive SolutionsDocumento4 pagineNitoflor SL2050: Constructive SolutionsNishant VasuNessuna valutazione finora

- Iterlene in 400-s Green Rev 00-14 en TDocumento2 pagineIterlene in 400-s Green Rev 00-14 en TPeroy PomaNessuna valutazione finora

- Nitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsesDocumento4 pagineNitoflor SL1000: Flow Applied, 0.5 - 1.5mm Thick Epoxy Resin Based Floor Topping UsestalatzahoorNessuna valutazione finora

- تحليل اسعار جميع البنودDocumento68 pagineتحليل اسعار جميع البنودhaytham saadNessuna valutazione finora

- Cmci Cmci: CEMTEC 227 P.UDocumento2 pagineCmci Cmci: CEMTEC 227 P.Upravi3434Nessuna valutazione finora

- Volume - 1 TSM-02.08.18 PDFDocumento251 pagineVolume - 1 TSM-02.08.18 PDFruhul01Nessuna valutazione finora

- General Catalogue - Waterfalls Manufacturing - 2022 EditionDocumento16 pagineGeneral Catalogue - Waterfalls Manufacturing - 2022 Editionmuhammad nurochmanNessuna valutazione finora

- BASF Introduces Smart Dynamic ConcreteDocumento4 pagineBASF Introduces Smart Dynamic ConcreteNurul Hidayati100% (1)

- TDS Conplast Crystalline India PDFDocumento2 pagineTDS Conplast Crystalline India PDFAarish KhanNessuna valutazione finora

- ESTOP TDS - Estogard CS Lining R002.i.21Documento2 pagineESTOP TDS - Estogard CS Lining R002.i.21Dewi OktoraNessuna valutazione finora

- National Road Marker: Decorative Coatings Technical Data SheetDocumento1 paginaNational Road Marker: Decorative Coatings Technical Data SheetFirst ChoiceNessuna valutazione finora

- Tds - Polpox Ep Hs 942Documento3 pagineTds - Polpox Ep Hs 942hemantrulzNessuna valutazione finora

- CONCRETE MIX DESIGN FOR M55 GRADE CONCRETEDocumento1 paginaCONCRETE MIX DESIGN FOR M55 GRADE CONCRETELegendary GamingNessuna valutazione finora

- Iso 1811 1 en PDFDocumento3 pagineIso 1811 1 en PDFmahmoued mohamed100% (1)

- TDS Nitoflor TF10000 Saudi ArabiaDocumento3 pagineTDS Nitoflor TF10000 Saudi ArabiaCynthia Miller100% (1)

- Product Data Sheet: Hempafloor Durable 300Documento2 pagineProduct Data Sheet: Hempafloor Durable 300Fadi MagdyNessuna valutazione finora

- Carbomastic 15 PDSDocumento2 pagineCarbomastic 15 PDSAnonymous 4fVUDODNessuna valutazione finora

- Setseal B - TDSDocumento4 pagineSetseal B - TDShussam jumah100% (1)

- Fenomastic Pure Colours Enamel MattDocumento4 pagineFenomastic Pure Colours Enamel MattAslam KhanNessuna valutazione finora

- Cicocure WBDocumento2 pagineCicocure WBMQSWT100% (2)

- DS - 645 - Pro Anticarb HB Elastomeric CoatingDocumento2 pagineDS - 645 - Pro Anticarb HB Elastomeric CoatingRay EngineeringNessuna valutazione finora

- Tuffkote Protective CoatingsDocumento2 pagineTuffkote Protective CoatingsioginevraNessuna valutazione finora

- Conplast SP423Documento2 pagineConplast SP423Tori SmallNessuna valutazione finora

- Determining properties of AAC blocksDocumento7 pagineDetermining properties of AAC blocksindrajit sodhaNessuna valutazione finora

- Fosroc Nitocote EM 300 protects concrete from corrosionDocumento2 pagineFosroc Nitocote EM 300 protects concrete from corrosionAarish Khan100% (1)

- BASF MasterGlenium 3889 - SuperplasticizerDocumento2 pagineBASF MasterGlenium 3889 - SuperplasticizerHJ100% (2)

- PET Resin Technical Data SheetsDocumento6 paginePET Resin Technical Data SheetsEsteban FloreanoNessuna valutazione finora

- Elastopor H 1221/92: Technical Data SheetDocumento2 pagineElastopor H 1221/92: Technical Data SheetLassad ZitouniNessuna valutazione finora

- Hydropower BasicsDocumento102 pagineHydropower BasicsMai SharafNessuna valutazione finora

- Chemical Resistant Epoxy GroutDocumento2 pagineChemical Resistant Epoxy GroutBalasubramanian AnanthNessuna valutazione finora

- SmartCare TechnoPlast S 300Documento2 pagineSmartCare TechnoPlast S 300raviteja036100% (1)

- Fosroc Nitoflor TF120 UB: Constructive SolutionsDocumento4 pagineFosroc Nitoflor TF120 UB: Constructive SolutionstalatzahoorNessuna valutazione finora

- الآثار البيئية والاقتصادية لبعض المخلفات الصناعيةDocumento256 pagineالآثار البيئية والاقتصادية لبعض المخلفات الصناعيةWafa HabibNessuna valutazione finora

- Flintkote 3 Binder for Flooring SystemsDocumento2 pagineFlintkote 3 Binder for Flooring Systemsengramir07Nessuna valutazione finora

- PDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKDocumento2 paginePDS Optimum Flex 18 KG - 9 SQ.M PER GAL 1MMTHKRoemaric AguasNessuna valutazione finora

- Watertite PU 35Documento2 pagineWatertite PU 35Alexi ALfred H. Tago100% (1)

- Operation Manual: Dual Plate Wafer Check ValvesDocumento3 pagineOperation Manual: Dual Plate Wafer Check ValvesDhim131267Nessuna valutazione finora

- NewGRP CatalogueDocumento43 pagineNewGRP CatalogueDhim131267Nessuna valutazione finora

- Bellows Gate Valve/Globevalve Din Valves SeriesDocumento20 pagineBellows Gate Valve/Globevalve Din Valves SeriesDhim131267Nessuna valutazione finora

- Full Bore Ball Valve: Technicial Specifications General FeaturesDocumento3 pagineFull Bore Ball Valve: Technicial Specifications General FeaturesDhim131267Nessuna valutazione finora

- Bs Flange PDFDocumento7 pagineBs Flange PDFPelin RoxanaNessuna valutazione finora

- U Bolt Guide PDFDocumento1 paginaU Bolt Guide PDFAhmad Dzulfiqar RahmanNessuna valutazione finora

- Co 2Documento11 pagineCo 2Lucious LightNessuna valutazione finora

- Precautions in Handling and Use of Valves: 1. Notes For Pipe DesignDocumento4 paginePrecautions in Handling and Use of Valves: 1. Notes For Pipe DesignDhim131267Nessuna valutazione finora

- U-bolt pipe attachments for carbon steel, PVC, and stainless steelDocumento1 paginaU-bolt pipe attachments for carbon steel, PVC, and stainless steelDhim131267Nessuna valutazione finora

- U-clamp technical sheet for pipes up to DN 600Documento2 pagineU-clamp technical sheet for pipes up to DN 600Dhim131267Nessuna valutazione finora

- A72-A79 - Clamps U-Bolts - EN PDFDocumento11 pagineA72-A79 - Clamps U-Bolts - EN PDFMarian Valentin MitreaNessuna valutazione finora

- U Bolt Guide PDFDocumento1 paginaU Bolt Guide PDFAhmad Dzulfiqar RahmanNessuna valutazione finora

- Tie in OperationDocumento20 pagineTie in OperationChijioke ObiNessuna valutazione finora

- Co 2Documento11 pagineCo 2Lucious LightNessuna valutazione finora

- Mechanical Properties of Steel Bolts Screws StudsDocumento3 pagineMechanical Properties of Steel Bolts Screws StudsSOMSUBHRA DENessuna valutazione finora

- Tech Paper Fat PDFDocumento14 pagineTech Paper Fat PDFTratortudor14Nessuna valutazione finora

- Wrapidbond: Anti-Corrosion System For Protection of Steel SubstratesDocumento2 pagineWrapidbond: Anti-Corrosion System For Protection of Steel SubstratesDhim131267Nessuna valutazione finora

- Product Safety Data Sheet: According To Article 31 and Annex II of The EU REACH RegulationDocumento8 pagineProduct Safety Data Sheet: According To Article 31 and Annex II of The EU REACH RegulationDhim131267Nessuna valutazione finora

- Range of Trim MaterialsDocumento1 paginaRange of Trim MaterialsAbu___AbdullahNessuna valutazione finora

- Distant IereDocumento24 pagineDistant IereAnonymous KeeGB3oxPNessuna valutazione finora

- JFE Pipe Making PDFDocumento20 pagineJFE Pipe Making PDFDhim131267Nessuna valutazione finora

- Val-Matic Rubber-Seated Ball Valve: Operation, Maintenance and Installation ManualDocumento12 pagineVal-Matic Rubber-Seated Ball Valve: Operation, Maintenance and Installation ManualDhim131267Nessuna valutazione finora

- Clark1984 PDFDocumento29 pagineClark1984 PDFMiguel HerreraNessuna valutazione finora

- 2 - 4 - Waste Water CharacteristicsDocumento17 pagine2 - 4 - Waste Water CharacteristicsMala VantoshNessuna valutazione finora

- Removal of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaDocumento3 pagineRemoval of H2S in down-flow GAC biofiltration using sulfide oxidizing bacteriaมาร์ค มัธยมNessuna valutazione finora

- Titration Lab Report 1Documento28 pagineTitration Lab Report 1api-607048551Nessuna valutazione finora

- Flash Point by Abel's ApparatusDocumento3 pagineFlash Point by Abel's ApparatusAbhishek JoshiNessuna valutazione finora

- Umc Technical SpecsDocumento3 pagineUmc Technical SpecsMunir AhmadNessuna valutazione finora

- Optimal DC Cable Selection in PV DesignsDocumento8 pagineOptimal DC Cable Selection in PV DesignsHelena AraujoNessuna valutazione finora

- ASTM D6373 15 Especificacion PGDocumento7 pagineASTM D6373 15 Especificacion PGPedro AlvelaisNessuna valutazione finora

- Chapter 5 HeatsinkDocumento6 pagineChapter 5 HeatsinkRazman RamedanNessuna valutazione finora

- 1singly-Reinforced Beams1Documento29 pagine1singly-Reinforced Beams1Jayson MariNessuna valutazione finora

- Hydac Filter ElementsDocumento30 pagineHydac Filter Elementsatorresh090675Nessuna valutazione finora

- Susianto 2005Documento7 pagineSusianto 2005Diego JesusNessuna valutazione finora

- Analysis of Functional Groups in Organic CompoundsDocumento14 pagineAnalysis of Functional Groups in Organic CompoundsANSH JAINNessuna valutazione finora

- Masterseal 380 TDSDocumento2 pagineMasterseal 380 TDSArasu DonNessuna valutazione finora

- Chapter2 Di Pa TaposDocumento13 pagineChapter2 Di Pa TaposDianne VillanuevaNessuna valutazione finora

- Improvised Power Bank From Torn Out Electronic GadgetsDocumento2 pagineImprovised Power Bank From Torn Out Electronic GadgetsJiya PalomaresNessuna valutazione finora

- Machined Seals: Product RangeDocumento43 pagineMachined Seals: Product RangeAnonymous r3MoX2ZMTNessuna valutazione finora

- Vehicle Body Materials PDFDocumento5 pagineVehicle Body Materials PDFAghil BuddyNessuna valutazione finora

- Li-Ion pd2019 Mot SolutionsDocumento2 pagineLi-Ion pd2019 Mot SolutionsManuel BermudezNessuna valutazione finora

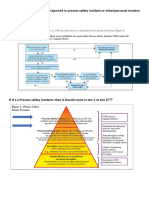

- REPORTING INCIDENTSDocumento6 pagineREPORTING INCIDENTSDivyansh Singh ChauhanNessuna valutazione finora

- Interzinc 22 Application Guidelines UkDocumento10 pagineInterzinc 22 Application Guidelines Ukapde06Nessuna valutazione finora

- SoapsDocumento7 pagineSoapsLucita P. CatarajaNessuna valutazione finora