Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

GSP 01 PDF

Caricato da

arielTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

GSP 01 PDF

Caricato da

arielCopyright:

Formati disponibili

NGL / LPG RECOVERY

Gas Subcooled Process

Ortloff invented the Gas Subcooled Process (GSP) in

the late 1970’s. Since then, Ortloff’s GSP

technology has become a workhorse in the gas process

industry, providing significantly higher ethane or

propane recovery from natural gas streams than the

industry standard single stage (ISS) expander design.

The GSP design incorporates the addition of a reflux

stream generated from a portion of the inlet gas which

is fed as reflux to the top of the Demethanizer.

A PPLICATIONS

The GSP technology is flexible, and can operate as

either an ethane recovery or a propane recovery

process. The GSP technology overcomes two key

limitations of the ISS design. With GSP, the expander

feed separator operates at a warmer temperature,

which eliminates instabilities when operating too close

to the phase envelope, commonly referred to as the

“snow-ball effect”. GSP also incorporates an

additional reflux stream feeding the Demethanizer

column above the expander feed. This enables GSP to Typical applications for the GSP process include:

achieve significantly higher recoveries than the

conventional ISS design. High ethane recovery from natural gas

streams with almost no loss of propane and

Another key feature of the GSP technology is the heavier components.

ability to retrofit existing ISS plants thereby increasing

ethane or propane recovery and improving over-all High propane recovery from natural gas

streams while rejecting lighter components to

plant economics. Ortloff has provided retrofit designs

meet liquid product specifications.

for numerous plants, both in the U.S. and abroad.

Gas processing plants where varying economic

conditions may favor operating in either

ethane recovery or ethane rejection mode.

GSP technology can be installed in a new facility or

retrofit into an existing facility where high recoveries,

increased throughput, and/or plant operational flexibility

are desired.

F EEDSTOCK AND P RODUCTS

The GSP process can accommodate most natural gas

compositions. Richer gas compositions may require the

addition of a refrigeration system. Inlet pressures above

600 PSI are generally preferred.

F EEDSTOCK AND P RODUCTS ( CONT .) E XPERIENCE

In ethane recovery mode the GSP process produces a Ortloff’s GSP technology was developed in the late

mixed NGL product stream, typically meeting a 1970’s and has been utilized successfully throughout the

maximum methane in ethane liquid product industry for over 30 years. Ortloff’s GSP continues to

specification. In propane recovery mode a mixed LPG be the technology of choice for plants where high

product stream is produced, typically meeting a recovery and flexibility are of great importance.

maximum ethane in propane liquid product specification.

The residue gas product stream will contain methane

or methane and ethane, depending on the mode of

operation.

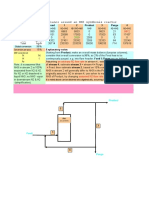

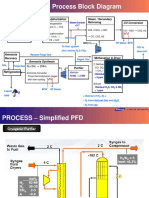

Ortloff’s GSP Process

Residue

Gas

Residue Gas

Compressor

Inlet Expander /

Gas Compressor

Demethanizer /

Deethanizer

NGL or LPG Product

F OR M ORE I NFORMATION

For more information about this or any other Ortloff

process, contact Ortloff Engineers, Ltd. at:

Phone: (432) 685-0277

Fax: (432) 685-0258

E-mail: oel@ortloff.com

Web: http://www.ortloff.com

© 2010 Ortloff Engineers, Ltd. All rights reserved.

This information is not to be taken as a warranty or representation for which Ortloff Engineers, Ltd.

assumes legal responsibility, nor as permission or recommendation to practice any patented invention

415 W. Wall St., Suite 2000

without a license. It is offered solely for your consideration. Midland, TX 79701-4438

USA

OEL FORM PDS-GSP-01 14JUL2010

Potrebbero piacerti anche

- UOP Selexol Technology For Acid Gas RemovalDocumento33 pagineUOP Selexol Technology For Acid Gas Removalganeshdhage100% (1)

- ChemTherm 550Documento2 pagineChemTherm 550jifarinaNessuna valutazione finora

- Uop Par-Isom Process: Nelson A. CusherDocumento6 pagineUop Par-Isom Process: Nelson A. CusherBharavi K S100% (1)

- UOP Integration of Membranes For CO2 Removal Tech Paper PDFDocumento15 pagineUOP Integration of Membranes For CO2 Removal Tech Paper PDFghasem_726990287Nessuna valutazione finora

- Bulk Water SeparationDocumento1 paginaBulk Water SeparationSean MiddletonNessuna valutazione finora

- Amine Loading To SystemDocumento6 pagineAmine Loading To SystemRathinavel PerumalNessuna valutazione finora

- UOP Oleflex ProcessDocumento2 pagineUOP Oleflex ProcessssslayerNessuna valutazione finora

- 50 Olefin ReductionDocumento2 pagine50 Olefin ReductiondimkuhNessuna valutazione finora

- Minimise Amine Losses in Gas and Liquid TreatingDocumento10 pagineMinimise Amine Losses in Gas and Liquid Treatings k kumar100% (2)

- 2-HG17G Operating and Maintenance HandbookDocumento48 pagine2-HG17G Operating and Maintenance HandbookarielNessuna valutazione finora

- WGM GasTech Presentation PDFDocumento25 pagineWGM GasTech Presentation PDFariel100% (1)

- ScoreDocumento2 pagineScoreEdgar HuancaNessuna valutazione finora

- RSV PDFDocumento2 pagineRSV PDFhoseinNessuna valutazione finora

- Honeywell Uop Ortloff NGL Recovery BrochureDocumento4 pagineHoneywell Uop Ortloff NGL Recovery BrochureDiego1980bNessuna valutazione finora

- Next generation NGL/LPG recovery processesDocumento14 pagineNext generation NGL/LPG recovery processesEdgar HuancaNessuna valutazione finora

- UOP Ortloff NGL LPG and Sulfur Recovery Technologies Tech PresentationDocumento30 pagineUOP Ortloff NGL LPG and Sulfur Recovery Technologies Tech PresentationAlfredo Ledezma100% (1)

- Natural Gas Liquids Recovery Processes in Natural Gas ProcessingDocumento27 pagineNatural Gas Liquids Recovery Processes in Natural Gas ProcessingVictor Ali MentaNessuna valutazione finora

- Comparison of Present Day Peakshaving Liquefaction TechnologiesDocumento18 pagineComparison of Present Day Peakshaving Liquefaction Technologiesfericoolabiss100% (1)

- Process DescriptionDocumento6 pagineProcess Descriptionافكر اشتري كورياNessuna valutazione finora

- H2 PSA SlidesDocumento16 pagineH2 PSA SlidesCristian TorrezNessuna valutazione finora

- 245 NGL Deethanizer Capacity ExpansionDocumento1 pagina245 NGL Deethanizer Capacity ExpansionRafeek Emad AbdElkader0% (1)

- Technical PaperDocumento6 pagineTechnical PaperCJ CHNessuna valutazione finora

- A200 Amine System English A4 PDFDocumento4 pagineA200 Amine System English A4 PDFMuhammad ZubairNessuna valutazione finora

- Catacarb Section, Dawood Hercules Fertilizers LimitedDocumento16 pagineCatacarb Section, Dawood Hercules Fertilizers LimitedMuddassar Sultan100% (1)

- Ammonia Synthesis Material Balence CalulDocumento1 paginaAmmonia Synthesis Material Balence CalulDhruv RanaNessuna valutazione finora

- Amine Gas SweeteningDocumento2 pagineAmine Gas SweeteningCameron Kashani0% (1)

- PSA GeneralDocumento17 paginePSA GeneralMohammed AhmedNessuna valutazione finora

- Flare Gas Recovery PDFDocumento13 pagineFlare Gas Recovery PDFSadad MohamadNessuna valutazione finora

- Amine Re Circulation Pump Min CirculationDocumento2 pagineAmine Re Circulation Pump Min CirculationajaysapruNessuna valutazione finora

- Product Data Sheet - MDEADocumento4 pagineProduct Data Sheet - MDEACHANADAS100% (1)

- Hydrogen from refinery offgas: Three schemes comparedDocumento3 pagineHydrogen from refinery offgas: Three schemes comparedkulaspiro100% (1)

- Teg ContactorDocumento4 pagineTeg ContactorrepentinezNessuna valutazione finora

- Ammonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEODocumento33 pagineAmmonia Plant - Methanation Operations: By: Gerard B. Hawkins Managing Director, CEOAkil PrabhuNessuna valutazione finora

- Atmospheric CO2 To MethanolDocumento16 pagineAtmospheric CO2 To MethanolMUTHU KESHAV KNessuna valutazione finora

- Amine Acid and Sour Gas Plant ExperiencesDocumento16 pagineAmine Acid and Sour Gas Plant ExperiencescymyNessuna valutazione finora

- LNG ExampleDocumento48 pagineLNG ExampleHeat.MotionNessuna valutazione finora

- The Rose Process: Tayseer Abdel-Halim and Raymond FloydDocumento14 pagineThe Rose Process: Tayseer Abdel-Halim and Raymond FloydBharavi K SNessuna valutazione finora

- Liquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessDocumento8 pagineLiquefaction of Natural Gas Using Single Stage Mixed Refrigerant PRICO ProcessHaru MasaNessuna valutazione finora

- Gbhe Ammonia Co2 Removal Systems WSV PDFDocumento20 pagineGbhe Ammonia Co2 Removal Systems WSV PDFAaserElkenanyNessuna valutazione finora

- ACETONADocumento6 pagineACETONAvanesaNessuna valutazione finora

- Understanding Carbon Formation in Reforming ProcessesDocumento26 pagineUnderstanding Carbon Formation in Reforming ProcessesBilalNessuna valutazione finora

- 92015BASF Molecular Sieve Brochure USL 190411 110814Documento8 pagine92015BASF Molecular Sieve Brochure USL 190411 110814FrankNessuna valutazione finora

- 04 NGL Fractionation Train PDFDocumento23 pagine04 NGL Fractionation Train PDFcarolynNessuna valutazione finora

- Sweetening LPG With AminesDocumento8 pagineSweetening LPG With AminessizwehNessuna valutazione finora

- Hydrotreater Revamps MUSTANG PTQDocumento4 pagineHydrotreater Revamps MUSTANG PTQDavid SmithNessuna valutazione finora

- Peerless Separation & Filtration SolutionsDocumento2 paginePeerless Separation & Filtration SolutionsJose Rodrigo Salguero DuranNessuna valutazione finora

- Aspen EDR FamilyDocumento10 pagineAspen EDR Familyrtrajan_mech5408Nessuna valutazione finora

- 3 3 MR Robert PardemannDocumento47 pagine3 3 MR Robert Pardemannhoremheb1Nessuna valutazione finora

- Siemens Zimpro - Wet Air OxidationDocumento8 pagineSiemens Zimpro - Wet Air OxidationGorden DryginNessuna valutazione finora

- Reciprocating Compressors in A Hydrogen Plant 2016Documento5 pagineReciprocating Compressors in A Hydrogen Plant 2016Lucas SondreNessuna valutazione finora

- Amine Sweetening With DEADocumento14 pagineAmine Sweetening With DEARoza SavitriNessuna valutazione finora

- Uhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaDocumento6 pagineUhde Dual-Pressure Process For Large-Scale Ammonia Plants: - Saskferco Ammonia-Urea Complex, CanadaMUHAMMAD USMAN0% (1)

- Complete PFDDocumento5 pagineComplete PFDAriff FikriNessuna valutazione finora

- Nitrogen RejectionDocumento7 pagineNitrogen RejectionOmar TocmoNessuna valutazione finora

- FCC GCU Stripper RevampDocumento5 pagineFCC GCU Stripper RevampRavi NookalaNessuna valutazione finora

- Condensate Stabilizer English A4Documento2 pagineCondensate Stabilizer English A4wisnu_bayusaktiNessuna valutazione finora

- AT 03943 JSG Acid Gas Cleaning Aspen HYSYS PDFDocumento17 pagineAT 03943 JSG Acid Gas Cleaning Aspen HYSYS PDFAkhmadi WaridyantoNessuna valutazione finora

- Hydrogen and Syngas Production and Purification TechnologiesDa EverandHydrogen and Syngas Production and Purification TechnologiesNessuna valutazione finora

- SRC Supplemental Rectification With CompressionDocumento2 pagineSRC Supplemental Rectification With Compressionquocthuong1988 leNessuna valutazione finora

- Vdocuments - MX Supplemental Rectification With Reflux Ortloff LPG Recovery Supplemental RectificationDocumento2 pagineVdocuments - MX Supplemental Rectification With Reflux Ortloff LPG Recovery Supplemental Rectificationquocthuong1988 leNessuna valutazione finora

- Single Column Overhead Recycle Process (SCORE) : NGL / LPG RDocumento2 pagineSingle Column Overhead Recycle Process (SCORE) : NGL / LPG RAhmed Khamees ShatlaNessuna valutazione finora

- Retrofits Applications Worth ConsideringDocumento7 pagineRetrofits Applications Worth ConsideringBharti FamilyNessuna valutazione finora

- JPME Volume 17 Issue 1 Pages 17-28Documento12 pagineJPME Volume 17 Issue 1 Pages 17-28Kolo Arnaud SoroNessuna valutazione finora

- LATfeature 1Documento6 pagineLATfeature 1ariel100% (1)

- Case Study 11Documento22 pagineCase Study 11arielNessuna valutazione finora

- Edge NG ManualDocumento90 pagineEdge NG ManualarielNessuna valutazione finora

- Fisher-Enardo Product CatalogDocumento207 pagineFisher-Enardo Product CatalogarielNessuna valutazione finora

- Fan Sound ED300Documento8 pagineFan Sound ED300arielNessuna valutazione finora

- Gmaa00532011 Warranty Storage 1 Year en SP BP 15may08Documento12 pagineGmaa00532011 Warranty Storage 1 Year en SP BP 15may08arielNessuna valutazione finora

- Fan Belt Drives ED1400Documento6 pagineFan Belt Drives ED1400arielNessuna valutazione finora

- Ngineering ATA: Fan Performance Troubleshooting GuideDocumento10 pagineNgineering ATA: Fan Performance Troubleshooting GuidePranpath NarupantawartNessuna valutazione finora

- Fan Protective Coatings ED400Documento7 pagineFan Protective Coatings ED400arielNessuna valutazione finora

- Fan Bearings ED1300 PDFDocumento6 pagineFan Bearings ED1300 PDFJose Luis ChapasNessuna valutazione finora

- From The Wellhead Through The Pipeline Hanover People Perform.Documento12 pagineFrom The Wellhead Through The Pipeline Hanover People Perform.arielNessuna valutazione finora

- Corrosion: EngineeringDocumento149 pagineCorrosion: EngineeringarielNessuna valutazione finora

- Flanged Internal ValveDocumento12 pagineFlanged Internal ValvearielNessuna valutazione finora

- ASTM D2504 Noncondensable Gases in C2 and Lighter Hydrocarbon Products by Gas ChromatDocumento5 pagineASTM D2504 Noncondensable Gases in C2 and Lighter Hydrocarbon Products by Gas ChromatarielNessuna valutazione finora

- Selecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsDocumento5 pagineSelecting Thermodynamic Models For Process Simulation of Organic VLE and LLE SystemsoscarmaumarNessuna valutazione finora

- CNC 670 Series Liquid Level Indicator: DatasheetDocumento2 pagineCNC 670 Series Liquid Level Indicator: DatasheetarielNessuna valutazione finora

- Heat Exchanger and Fin Fan Cooler-FinalDocumento38 pagineHeat Exchanger and Fin Fan Cooler-Finalgabisa100% (2)

- NH3 Process Simplified PFDDocumento4 pagineNH3 Process Simplified PFDarielNessuna valutazione finora

- Gas Compression Control SystemsDocumento45 pagineGas Compression Control SystemsarielNessuna valutazione finora

- Cp226 SpanishDocumento80 pagineCp226 SpanisharielNessuna valutazione finora

- Orifice Plate, Model FLC-OP Orifice Flange, Model FLC-FL Annular Chamber, Model FLC-ACDocumento10 pagineOrifice Plate, Model FLC-OP Orifice Flange, Model FLC-FL Annular Chamber, Model FLC-ACarielNessuna valutazione finora

- API - Bs - Cast Steel Ball Valves WCB A216Documento16 pagineAPI - Bs - Cast Steel Ball Valves WCB A216arielNessuna valutazione finora

- Tutorial On Turbo ExpanderDocumento0 pagineTutorial On Turbo ExpanderMajid Sattar100% (1)

- New NGL Recovery ProcessDocumento9 pagineNew NGL Recovery ProcessEbby Onyekwe100% (1)

- TD 1648 2648 3648 8pg BW OCT2015Documento8 pagineTD 1648 2648 3648 8pg BW OCT2015Ajazuddin MohammedNessuna valutazione finora

- Cryomax Jan2016Documento8 pagineCryomax Jan2016arielNessuna valutazione finora

- The PETROLEUM RULES, 1937 - Josh and Mak InternationalDocumento87 pagineThe PETROLEUM RULES, 1937 - Josh and Mak InternationalQaisar AbbasNessuna valutazione finora

- To Promote Innovation: Uk - Germany - Uae Nigeria - India Aburi Composite LPG CylindersDocumento11 pagineTo Promote Innovation: Uk - Germany - Uae Nigeria - India Aburi Composite LPG CylindersCarlos RondonNessuna valutazione finora

- LPG MonitoringDocumento15 pagineLPG MonitoringTeja SanthoshNessuna valutazione finora

- Fractional Distillation of Crude OilDocumento6 pagineFractional Distillation of Crude OilDavid Ngo83% (6)

- Residential Owners ManualDocumento11 pagineResidential Owners ManualMSILVAJRNessuna valutazione finora

- Guidance Document On BS EN 13565-2 Foam System StandardDocumento8 pagineGuidance Document On BS EN 13565-2 Foam System StandardFernando KatayamaNessuna valutazione finora

- STD 135Documento26 pagineSTD 135Mathan Selva Kumar ANessuna valutazione finora

- Petroleum QuizDocumento62 paginePetroleum Quizchoksi himanshu100% (1)

- EGPC PSM GL 009 Fire and Explosion Risk Assessment FREA GuidelineDocumento58 pagineEGPC PSM GL 009 Fire and Explosion Risk Assessment FREA Guidelinekhaled faragNessuna valutazione finora

- Bharat Emission Standards & Saumitra Chaudhuri CommitteeDocumento11 pagineBharat Emission Standards & Saumitra Chaudhuri CommitteeRajat VarshneyNessuna valutazione finora

- Instrumentation Standards ListDocumento45 pagineInstrumentation Standards ListRajeevNessuna valutazione finora

- Electric Brake SystemDocumento12 pagineElectric Brake Systemamine100% (1)

- Energy Efficiency Design Index (EEDI)Documento23 pagineEnergy Efficiency Design Index (EEDI)SorinBalabanNessuna valutazione finora

- MSDS LPGDocumento3 pagineMSDS LPGSARATH KRISHNAKUMARNessuna valutazione finora

- Economics Material Using Fragmented LearningDocumento52 pagineEconomics Material Using Fragmented Learningshyam mishraNessuna valutazione finora

- Automatic Gas Booking System With Gas LeDocumento13 pagineAutomatic Gas Booking System With Gas LegopinathNessuna valutazione finora

- General 20studies 20 20general 20abilities - KeyDocumento24 pagineGeneral 20studies 20 20general 20abilities - KeysrikanthNessuna valutazione finora

- Arduino Based LPG Gas Monitoring and Automatic Cylinder BookingDocumento24 pagineArduino Based LPG Gas Monitoring and Automatic Cylinder BookingRaghavNessuna valutazione finora

- LNG, CNG and LPG Comparison StudyDocumento15 pagineLNG, CNG and LPG Comparison StudyAli MahmoudNessuna valutazione finora

- Elegant Group BookDocumento8 pagineElegant Group BookTrevor MupasiNessuna valutazione finora

- Petron Malaysia Annual Report 2016Documento131 paginePetron Malaysia Annual Report 2016SharifahNurAinFarahin0% (1)

- Instrumetation Report ClarificationDocumento10 pagineInstrumetation Report ClarificationTayebASherifNessuna valutazione finora

- Harmonized Survey Questions For Monitoring Household Energy Use and SDG Indicators 7.1.1 and 7.1.2Documento9 pagineHarmonized Survey Questions For Monitoring Household Energy Use and SDG Indicators 7.1.1 and 7.1.2monique dianeNessuna valutazione finora

- Power With LPG Fuel Flexible SolutionDocumento24 paginePower With LPG Fuel Flexible SolutionPablo M Ugalde100% (1)

- Combustion and Flame NCERT NotesDocumento4 pagineCombustion and Flame NCERT NotesVinod KumarNessuna valutazione finora

- Asphalt Mixing Plant - AIMIXDocumento8 pagineAsphalt Mixing Plant - AIMIXBahrun NajahNessuna valutazione finora

- SOW For 1451 Total Change MasterDocumento55 pagineSOW For 1451 Total Change MasterVerghese OommenNessuna valutazione finora

- Futuristic Gas System Training ReportDocumento12 pagineFuturistic Gas System Training Reportamazing anythingNessuna valutazione finora

- Electric Cooking: Needs, Challenges and Way ForwardDocumento8 pagineElectric Cooking: Needs, Challenges and Way ForwardChandrashekhar SinghNessuna valutazione finora

- (Please Enumerate Use Separate Sheet, If Necessary) : Petroleum Fuel Station ProjectsDocumento4 pagine(Please Enumerate Use Separate Sheet, If Necessary) : Petroleum Fuel Station ProjectsCharlotte Mae MartinezNessuna valutazione finora