Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aluminium Alloy Guide and Proof Stress

Caricato da

muniCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aluminium Alloy Guide and Proof Stress

Caricato da

muniCopyright:

Formati disponibili

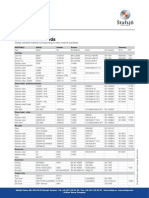

ALUMINIUM

National Distributors of Stainless Steel and Aluminium

GUIDE TO COMMON SOUTH AFRICAN ALUMINIUM ALLOYS (for more detail refer to the alloy specification sheets)

CHEMICAL COMPOSITION (mass %)

ALLOY TYPICAL 2% STOCK RANGE TYPICAL APPLICATION / USAGE

Al Fe Si Cu Mn Mg Zn Ti Cr TEMPER Proof

Stress

(MPa)

1050A 99,5 0,4 0,25 0,05 0,05 0,5 0,7 0,05 O / Hx4 35 / 105 Sheet, coil, foil, General sheet work where moderate strength is

(0.2 - 6.35 mm) adequate, packaging for food and chemicals, radiator

Extrusions. tubes, insulation foils, automotive trim, light

reflectors, architecture.

1200 99,0 Fe & Si = 1.0 0,05 0,05 - 0,1 0,05 O / Hx4 40 / 150 Sheet, coil, General sheet work where moderate strength is

circles, plate, adequate, packaging for food and chemicals,

tread architectural flashings, hollowware, automotive trim.

sheet/plate

1350 99,5 0,40 0,10 0,05 0,01 0,03 0,05 0,01 O / Hx4 75 /110 Extrusions, Electrical conductors, busbars, transformer coils.

(UTS) sheet and plate

2024 Bal. 0,5 0,5 3,8 - 0,3 - 1,2 - 0,25 0,15 0,1 T3, T8 340 / 450 Bar, sheet. High strength fabricated or machined items.

AlCu4Mg1 4,9 0,9 1,8 Imported Mechanical joining

3003 Bal. 0,15 0,5 0,10 - 1,70 – Mill temper On Treadbright, 1 - 5 Decorative & architectural, non-slip flooring for boats,

Special 0,5 2,40 only. request bar sheet & coil vehicles, lifts, offices, factories.

3004 Bal. 0,7 0,3 0,25 1,0 – 0,8 – 0,25 O / Hx4 / 75 / 200 / Sheet, coil General purpose sheet of high strength used for

AlMnMg 1,5 1,3 Hx8 250 (0,2 – 6,35 mm) roofing, cladding, gutters, packaging, containers,

transport, architectural, cans.

4043 Bal. 0,8 4,5 – 0,3 0,05 0,05 0,10 0,2 - n/a Wire and rods Welding filler, commonly used for castings and for

AlSi5 6,0 welding 1xxx to 5xxx and 6xxx, and 6xxx to 6xxx.

5083 Bal. 0,4 0,4 0,1 0,4 – 4,0 – 0,25 0,15 0,05 – O / Hx2 / 145 / 240 Sheet, plate Commercial transport, marine plate, structural plate

AlMg4,5 1,0 4,9 0,25 Hx4 / 275 (0,25 – 6,35 – for mining, pressure vessels, storage tanks, tooling

Mn0,7 150 mm) plate, railway wagons, general sheet metal.

5251 Bal. 0,5 0,4 0,15 0,1 – 1,7 – 0,15 0,15 0,15 O / Hx2 / 80 / 165 / Sheet, plate, As for 5083, but a medium to high strength alloy

AlMg2Mn 0,5 2,4 Hx4 190 coil, tread sheet

5454 Bal. 0,4 0,25 0,1 0,5 – 2,4 – 0,25 0,20 0,05 – O / Hx2 / 110 / 205 Sheet, plate. As for 5083, but good strength in temperature range

AlMg3Mn 1,0 3,0 0,2 Hx4 / 235 65 – 160o C.

© 2006 Euro Steel. All rights reserved.

ALUMINIUM

National Distributors of Stainless Steel and Aluminium

GUIDE TO COMMON SOUTH AFRICAN ALUMINIUM ALLOYS cont’d

CHEMICAL COMPOSITION (mass %)

ALLOY TYPICAL 2% STOCK RANGE TYPICAL APPLICATION / USAGE

Al Fe Si Cu Mn Mg Zn Ti Cr TEMPER Proof

Stress

(MPa)

5356 Bal. 0,4 0,25 0,1 0,05 – 4,5 – 0,1 0,06 – 0,05 – n/a Wire and rods Welding filler commonly used for welding 5xxx series

AlMg5 0,20 5,5 0,2 0,2 to 5xxx and 6xxx series alloys.

6061 Bal. 0,7 0,4 – 0,15 – 0,15 0,8 – 0,25 0,15 0,04 – O / T4 / T6 55 / 140 / Extrusions, bar, Heavy duty structural sections, road, rail, marine,

AlMgSiCu 0,8 0,4 1,2 0,35 / sheet T651 270 plate, sheet. bridges, pylons, rivets, hydraulic components.

6063 Bal. 0,35 0,2 – 0,1 0,1 0,45 – 0,1 0,1 0,1 O / T4 / T6 50 / 90 / Extrusions – all Structural, transport, architectural, agricultural,

AlMg0,7Si 0,6 0,90 210 shapes general engineering, tubing, intricate profiles.

6082 Bal. 0,5 0,7 - 0,1 0,4 – 0,6 – 0,2 0,1 0,25 O / T4 / T6 60 / 170 / Extrusions, Stressed and heavy duty structural applications,

AlSiMnMg 1,3 1,0 1,2 / sheet T651 310 sheet, plate. machinery, towers, roof trusses, cranes, bridle plates.

6463 Bal. 0,15 0,2 – 0,2 0,05 0,45 – 0,05 - - T4 / T6 75 / 160 Extrusions Especially good for bright anodising of architectural

AlSiMg 0,6 0,90 sections and trim.

7075 Bal. 0,5 0,4 1,2 – 0,3 2,1 – 5,1 – 0,2 0,18 – T6 sheet & 480 & Bar, extrusions, Very high strength for structural components,

AlZnMgCu 2,0 2,9 6,1 0,28 T6 plate 460 plate. Imported machine parts & tools. (Mechanical joining)

44100 Bal. 0,65 10,5 – 0,15 0,55 0,10 0,15 0,2 - Sand / chill / 65 / 75 / Castings – sand, Marine ‘on deck’, manifolds, thin section & intricate

AlSi12 13,5 die casts 120 chill and die. castings, large castings & castings to be welded.

46500 Bal. 1,3 8 – 11 2-4 0,55 0,05 – 3,0 0,25 - High press. 140 High pressure Automotive and electrical components, household

AlSi9Cu3 0,55 die cast, ‘F’ die castings appliances.

© 2006 Euro Steel. All rights reserved.

Potrebbero piacerti anche

- Question Bank 1Documento194 pagineQuestion Bank 1kishore babu50% (2)

- Aluminium Matrix Composites: Challenges and OpportunitiesDocumento16 pagineAluminium Matrix Composites: Challenges and OpportunitiesRajanikantJadhavNessuna valutazione finora

- Aluminium EtchingDocumento3 pagineAluminium EtchingaliNessuna valutazione finora

- Failure PDFDocumento101 pagineFailure PDFManuel GasparNessuna valutazione finora

- Data Sheet AluminaDocumento10 pagineData Sheet AluminaXin EnNessuna valutazione finora

- Boronizing AVIONDocumento37 pagineBoronizing AVIONManwi Khandelwal100% (1)

- DC16 Engine 478kWDocumento4 pagineDC16 Engine 478kWmuniNessuna valutazione finora

- Age Hardening Aluminium AlloyDocumento31 pagineAge Hardening Aluminium AlloyMhd. Didi Endah PranataNessuna valutazione finora

- Astm B 171 B M .04Documento7 pagineAstm B 171 B M .04FrengkiNessuna valutazione finora

- MCM AllDocumento7 pagineMCM AllPalanisamy RajaNessuna valutazione finora

- Stainless Steels: and Specialty Alloys For Pulp, Paper and Biomass ConversionDocumento144 pagineStainless Steels: and Specialty Alloys For Pulp, Paper and Biomass ConversionIndra NainggolanNessuna valutazione finora

- Bor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelDocumento12 pagineBor1991 - Effect of Pearlite Banding On Mechanical Properties of Perlitic SteelAlejandroAcuñaMaureiraNessuna valutazione finora

- Equivalent Materials GradeDocumento2 pagineEquivalent Materials GradeSatyamEng80% (5)

- Studying The Effect of Tramp Elements inDocumento7 pagineStudying The Effect of Tramp Elements inmohit madaviNessuna valutazione finora

- Tesla SYSTEM AND METHOD FOR FACILITATING PULSED SPRAY QUENCH OF EXTRUDED OBJECTSDocumento20 pagineTesla SYSTEM AND METHOD FOR FACILITATING PULSED SPRAY QUENCH OF EXTRUDED OBJECTSJoey KlenderNessuna valutazione finora

- The Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesDocumento2 pagineThe Use of Titanium in Family Automobiles: Current Trends: K. Faller and F.H. (Sam) FroesAmol HawaldarNessuna valutazione finora

- Buehler Summet, Sample Prep and AnalysisDocumento136 pagineBuehler Summet, Sample Prep and AnalysisSebastian RiañoNessuna valutazione finora

- B 275 - 02 - Qji3ns1sruqDocumento8 pagineB 275 - 02 - Qji3ns1sruqmalika_00100% (1)

- Porous Anodic Metal OxidesDocumento20 paginePorous Anodic Metal Oxidescargetoianu2357Nessuna valutazione finora

- Castings, Austenitic, For Pressure-Containing PartsDocumento7 pagineCastings, Austenitic, For Pressure-Containing Partsist93993100% (1)

- EU Homologation 2018R0858 PDFDocumento218 pagineEU Homologation 2018R0858 PDFmuniNessuna valutazione finora

- Austenitizing Heat Treatment PDFDocumento20 pagineAustenitizing Heat Treatment PDFsivajirao70100% (1)

- Casting and Fabrication of High-Damping Manganese-Copper AlloysDocumento28 pagineCasting and Fabrication of High-Damping Manganese-Copper Alloysbrad209Nessuna valutazione finora

- Controlling The Chemistry and The and The Section Size Is Very ImportantDocumento2 pagineControlling The Chemistry and The and The Section Size Is Very ImportantHeuzerGomesNessuna valutazione finora

- BMP FI-RevA-1-8.xerDocumento1.590 pagineBMP FI-RevA-1-8.xerbharathyNessuna valutazione finora

- Excercise Sheet Lecture 3Documento30 pagineExcercise Sheet Lecture 3Mohamed ZaitoonNessuna valutazione finora

- PREN Number Effect On AlloyDocumento6 paginePREN Number Effect On AlloyVed JoshiNessuna valutazione finora

- Handbook of Quenchants and Quenching TechnologyDocumento518 pagineHandbook of Quenchants and Quenching TechnologyDiego mena contrerasNessuna valutazione finora

- EMC '91 - Non-Ferrous Metallurgy-Present and FutureDocumento483 pagineEMC '91 - Non-Ferrous Metallurgy-Present and FutureRao Gari AbbaiNessuna valutazione finora

- Metallurgical Achievements: Selection of Papers Presented at the Birmingham Metallurgical Society's Diamond Jubilee Session, 1963-1964Da EverandMetallurgical Achievements: Selection of Papers Presented at the Birmingham Metallurgical Society's Diamond Jubilee Session, 1963-1964W. O. AlexanderNessuna valutazione finora

- Ti 6al 4v Grade 5Documento1 paginaTi 6al 4v Grade 5Angga Kurniawan DharmaNessuna valutazione finora

- Metal Matrix CompositesDocumento30 pagineMetal Matrix CompositesRoger LaraNessuna valutazione finora

- Aluminium Insight 2011-02 Lomag Mag RemovalDocumento1 paginaAluminium Insight 2011-02 Lomag Mag Removalnabeel1981Nessuna valutazione finora

- Investigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueDocumento4 pagineInvestigation On Mechanical Properties of Aluminum (6065) With Copper by PM TechniqueVinoth KumarNessuna valutazione finora

- 01 Introduction To Aluminum and Aluminum AlloysDocumento12 pagine01 Introduction To Aluminum and Aluminum AlloysAlex KozayaNessuna valutazione finora

- Danes HM A Nesh 2003Documento6 pagineDanes HM A Nesh 2003Rina OktapianiNessuna valutazione finora

- Weathering of Anodized AluminiumDocumento7 pagineWeathering of Anodized AluminiumShahid PerwezNessuna valutazione finora

- Zn-Fe-Al Phase Diagram Low TempDocumento16 pagineZn-Fe-Al Phase Diagram Low Tempbdavis33100% (1)

- Titanium AlloysDocumento4 pagineTitanium Alloyswsjouri2510Nessuna valutazione finora

- The Behaviour of The Secondary Metallurgy Slag Into The EAF. How To Create A Good Foamy Slag With The Appropriate Basicity Using A Mix of Lime and Recycled Ladle Slag As EAF Slag FormerDocumento1 paginaThe Behaviour of The Secondary Metallurgy Slag Into The EAF. How To Create A Good Foamy Slag With The Appropriate Basicity Using A Mix of Lime and Recycled Ladle Slag As EAF Slag FormerRavindra Kashyap0% (1)

- Ybco Superconductor Characterization Under Shear StrainDocumento4 pagineYbco Superconductor Characterization Under Shear StrainRiddhesh PatelNessuna valutazione finora

- Levicast ProcessDocumento5 pagineLevicast ProcessMuha KimNessuna valutazione finora

- Review of Magnesium Metal Matrix CompositesDocumento19 pagineReview of Magnesium Metal Matrix CompositesGokulraju RangasamyNessuna valutazione finora

- High Entropy AlloysDocumento8 pagineHigh Entropy AlloysTeka KamNessuna valutazione finora

- Aluminum Extrusion Process OverviewDocumento4 pagineAluminum Extrusion Process Overviewken_desNessuna valutazione finora

- Gas Fron Green SandDocumento13 pagineGas Fron Green Sandjose.figueroa@foseco.comNessuna valutazione finora

- Image Analysis in Quantitative Metallography: National Metallurgical Laborator Y, Jamshedpur-831007Documento16 pagineImage Analysis in Quantitative Metallography: National Metallurgical Laborator Y, Jamshedpur-831007nantha kumarNessuna valutazione finora

- Non-Ferrous Process Principles and Production Technologies: H.Y. SohnDocumento1 paginaNon-Ferrous Process Principles and Production Technologies: H.Y. SohnCarlosNessuna valutazione finora

- Effect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIDocumento6 pagineEffect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIgiokniessNessuna valutazione finora

- Aluminizing Nickel Foam by A Slurry Coating ProcessDocumento3 pagineAluminizing Nickel Foam by A Slurry Coating ProcessFatih BozkurtNessuna valutazione finora

- Aluminium Alloy Applications PDFDocumento3 pagineAluminium Alloy Applications PDFKhanHasibKaisarNessuna valutazione finora

- SEMINAR REPORT - PXFGDFDocumento28 pagineSEMINAR REPORT - PXFGDFig200100% (3)

- 55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Documento2 pagine55 Aluminum-Zinc Alloy Coated Steel Technical Bulletin 6 - Cut Edge Protection v20153Syed Raja AdeelNessuna valutazione finora

- Sound Insulation - NRCDocumento372 pagineSound Insulation - NRCKhader Abu-daggaNessuna valutazione finora

- Aluminium and Aluminium AlloysDocumento3 pagineAluminium and Aluminium AlloysCherie DiazNessuna valutazione finora

- Technical Information of Icr18650 S3 (2200mah)Documento9 pagineTechnical Information of Icr18650 S3 (2200mah)Rolland ButterNessuna valutazione finora

- Diamond Like Amorphous Carbon PDFDocumento153 pagineDiamond Like Amorphous Carbon PDFமாத்தி யோசிப்பேன்Nessuna valutazione finora

- Etchant Selection Guide (SS Superalloy) 11-2015Documento3 pagineEtchant Selection Guide (SS Superalloy) 11-2015Malik Ansar HayatNessuna valutazione finora

- New Metallic Materials-Al-Li AlloysDocumento23 pagineNew Metallic Materials-Al-Li AlloyszorazhrNessuna valutazione finora

- EMEA14 Alcoa Wood EnablingStartupOperationalImprovementUsingthePISystemDocumento25 pagineEMEA14 Alcoa Wood EnablingStartupOperationalImprovementUsingthePISystemAshish DasNessuna valutazione finora

- Uts Material SuperplastisDocumento10 pagineUts Material SuperplastisHandrizaHanifAsyrafiNessuna valutazione finora

- Monotectic AlloysDocumento8 pagineMonotectic Alloysandrea usugaNessuna valutazione finora

- Barekar2014P Overview of Twin Roll Casting of Al AlloysDocumento12 pagineBarekar2014P Overview of Twin Roll Casting of Al AlloyskishoreNessuna valutazione finora

- Continuous casting The Ultimate Step-By-Step GuideDa EverandContinuous casting The Ultimate Step-By-Step GuideNessuna valutazione finora

- Modelling and Simulation in The Design ProcessDocumento13 pagineModelling and Simulation in The Design ProcessmuniNessuna valutazione finora

- RAM 3500/4500/5500 Chassis Cab SpecsDocumento5 pagineRAM 3500/4500/5500 Chassis Cab SpecsmuniNessuna valutazione finora

- Hydraulic Steel Tubing and FittingsDocumento11 pagineHydraulic Steel Tubing and FittingsmuniNessuna valutazione finora

- Tech Brief Heat Treating Copper Beryllium PartsDocumento6 pagineTech Brief Heat Treating Copper Beryllium PartsFELIPENessuna valutazione finora

- UNS N06002, UNS N06230, UNS N12160, and UNS R30556 Plate, Sheet, and StripDocumento3 pagineUNS N06002, UNS N06230, UNS N12160, and UNS R30556 Plate, Sheet, and StripLemir LopezNessuna valutazione finora

- Equivalent Material Cross Valve CastDocumento2 pagineEquivalent Material Cross Valve CastsviswaNessuna valutazione finora

- Pneuminics Periodic TableDocumento2 paginePneuminics Periodic TableSomu Yashawant ChaudhariNessuna valutazione finora

- Corrosion Coupons: P/N CO100 P/N CO131Documento2 pagineCorrosion Coupons: P/N CO100 P/N CO131heikelNessuna valutazione finora

- Market Price Graph of South Indian Scrap Prices For IronsDocumento2 pagineMarket Price Graph of South Indian Scrap Prices For IronsR.JayaprakashNessuna valutazione finora

- Minerals Notes Answers.1575292264Documento2 pagineMinerals Notes Answers.1575292264carlierosetalNessuna valutazione finora

- T. J. Kotas (Auth.) - The Exergy Method of Thermal Plant Analysis-Butterworth-Heinemann LTD (1985)Documento45 pagineT. J. Kotas (Auth.) - The Exergy Method of Thermal Plant Analysis-Butterworth-Heinemann LTD (1985)Francisco SanchezNessuna valutazione finora

- QF 450 10 Rev. B Specification Log SheetDocumento11 pagineQF 450 10 Rev. B Specification Log Sheetjianli wangNessuna valutazione finora

- 6th Sem MetallurgyDocumento13 pagine6th Sem Metallurgymtnit07Nessuna valutazione finora

- Duplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)Documento13 pagineDuplex and Super Duplex Stainless Steel Fittings (Amendments/Supplements To Astm A 815)aleeimeran100% (1)

- La Copia Stampata Non E' Soggetta A Controllo: Electrostatic Painting With Epoxy-Polyester Powder PaintsDocumento3 pagineLa Copia Stampata Non E' Soggetta A Controllo: Electrostatic Painting With Epoxy-Polyester Powder PaintsdmejiaNessuna valutazione finora

- Cu-Fe-Ni (Copper-Iron-Nickel) : Ternary Isothermal SectionsDocumento3 pagineCu-Fe-Ni (Copper-Iron-Nickel) : Ternary Isothermal SectionsTrushar ParmarNessuna valutazione finora

- Inconel 625 - Properties, Applications and ProductionDocumento5 pagineInconel 625 - Properties, Applications and ProductionHidden TruthNessuna valutazione finora

- Gasnitriding - Plasmanitriding - SaltbathnitridingDocumento4 pagineGasnitriding - Plasmanitriding - SaltbathnitridingKevin ThomasNessuna valutazione finora

- Stainless Steel CA6NM (J91540) : Material Data SheetDocumento3 pagineStainless Steel CA6NM (J91540) : Material Data SheetAlex007Nessuna valutazione finora

- Inconel Alloy 690Documento8 pagineInconel Alloy 690Zeeshan SajidNessuna valutazione finora

- Ductile IronDocumento2 pagineDuctile Ironpraval84Nessuna valutazione finora

- Sinthesis and Characterization of ClinoptiloliteDocumento191 pagineSinthesis and Characterization of ClinoptilolitealelalelNessuna valutazione finora

- Brick and Paving Retail Price List: Victoria - 1st April 2019Documento4 pagineBrick and Paving Retail Price List: Victoria - 1st April 2019bUZzTEN LATELyNessuna valutazione finora

- 10 Occurrence and Extraction of Metals (Teacher)Documento31 pagine10 Occurrence and Extraction of Metals (Teacher)otto wongNessuna valutazione finora

- Brochure Bohler Benelux PDFDocumento8 pagineBrochure Bohler Benelux PDFBarcelonaNessuna valutazione finora

- Tabelas - IncroperaDocumento31 pagineTabelas - IncroperaOliveira74Nessuna valutazione finora

- Significance of Cold Rolling Reduction On Lüders Band Formation and Mechanical Behavior in Cold-Rolled Intercritically Annealed Medium-Mn Steel PDFDocumento6 pagineSignificance of Cold Rolling Reduction On Lüders Band Formation and Mechanical Behavior in Cold-Rolled Intercritically Annealed Medium-Mn Steel PDFRhushikeshNessuna valutazione finora

- MEISER Grating PDFDocumento122 pagineMEISER Grating PDFabdulloh_99Nessuna valutazione finora

- Cracking Continuous A: in Zinc Layers On Galvanized SheetsDocumento17 pagineCracking Continuous A: in Zinc Layers On Galvanized SheetsAlex GarciaNessuna valutazione finora