Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Key Facts Typical Wire Analysis: - Bossweld 71T-1

Caricato da

cj elec techTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Key Facts Typical Wire Analysis: - Bossweld 71T-1

Caricato da

cj elec techCopyright:

Formati disponibili

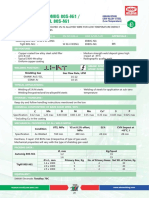

Flux Cored Mig Wires

| Bossweld 71T-1

Key Facts Typical Wire Analysis

• General purpose E71T-1 Flux core wire Mn - Si - Cr -

C - Carbon

• Designed for Co2 gas for lower operating cost Manganese Silicon Chromium

< 0.18 < 1.75 < 0.90 < 0.20

• Smooth welding arc

Mo - P-

Ni - Nickel S - Sulphur

• Low spatter levels Molybdenum Phosphorus

< 0.50 < 0.30 < 0.03 < 0.03

Cu - V-

Description Copper Vanadium

A general purpose, precision layer wound, flux cored

mild steel MIG wire for use with CO2 gas. < 0.35 < 0.08

Recommended for single or multiple pass welding of

mild and carbon steels. Welding positions; all

positions Typical Weld Mechanical Properties

0.2% Proof Stress: > 400N/mm2

Classifications, Approvals &

Conformances Tensile Strength: 490 – 670N/mm2

AWS A5.20, E71T-1

ABS - American Bureau of Shipping Elongation: > 22%

DNV - Det Norske Veritas

Lloyd’s Register of Shipping Diffusible

6.5ppm

JIS Z3313, YFW -C50DR Hydrogen:

DIN 8559 SGR-CY 4232

Impact Strength: 27J @ -18oC

Recommended Shielding Gas

CO2 or Ar/CO2 10-15 Lit./min.

100%CO2 ora75–25% Argon / CO2 mixture Packaging & Ordering Information

Size Packet Part Number

Welding Positions 1.2mm 15kg 200250

All positions except vertical down 1.6mm 15kg 200251

Applications

Most suitable in production or general fabrication

where highest deposition rates and low spatter is

required including farm machinery, construction

equipment and carbon steel fabrication.

• Structural steel fabrication

• Construction of rural equipment

• Pressure vessels

• Earth moving equipment

Disclaimer: The above information is provided as a guide; actual welding current and voltage will depend on the welding machine characteristics, which will vary from model to model. Other

variables include run length and size, plate thickness, operator technique and gas type (if used). The user must evaluate the process, application and recommended professional advice. Under no

circumstance will Dynaweld or its affiliates be liable for misuse or application of products this is entirely up to the user’s ability.

www.bossweld.com

Bossweld

is a registered trademark of Dynaweld Industrial Supplies Pty Ltd | +61 2 9772 1144

Potrebbero piacerti anche

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDa EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNessuna valutazione finora

- Merit S-6: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit S-6: Lincoln Electric China Gmaw Solid Wirelovaldes62Nessuna valutazione finora

- CSF-71T en 2014Documento1 paginaCSF-71T en 2014Yousab CreatorNessuna valutazione finora

- CSF-71T en 2014Documento1 paginaCSF-71T en 2014HoangNessuna valutazione finora

- Bohler Dcms T-MCDocumento1 paginaBohler Dcms T-MCFlaviu-Andrei AstalisNessuna valutazione finora

- FLR6Y-B CablesDocumento1 paginaFLR6Y-B CablesKristaNessuna valutazione finora

- Cu Zn 15 alloy properties and applicationsDocumento2 pagineCu Zn 15 alloy properties and applicationsPetrus UngureanuNessuna valutazione finora

- Diamondspark 52 MC: Seamless Metal-Cored WireDocumento2 pagineDiamondspark 52 MC: Seamless Metal-Cored WireDavid RodriguesNessuna valutazione finora

- Filler Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysDocumento8 pagineFiller Metals: High Purity Solutions For Creep Resistant Steels - B2 SC and B3 SC AlloysimreNessuna valutazione finora

- Diamondspark Ni1 RC: Seamless Cored WireDocumento2 pagineDiamondspark Ni1 RC: Seamless Cored Wiresanul mulyNessuna valutazione finora

- FLUXOFIL 42 Cored Wires for High-strength SteelsDocumento1 paginaFLUXOFIL 42 Cored Wires for High-strength SteelskarthiksaadhanaNessuna valutazione finora

- Shield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresDocumento1 paginaShield-Bright 2209: Gas-Shielded Flux-Cored Wires (Fcaw) Stainless Steel WiresvallirajuNessuna valutazione finora

- Cored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDDocumento3 pagineCored Wires For CMN & Low Alloy Steels: Oerlikon Fluxofil 14 HDBranko FerenčakNessuna valutazione finora

- Stainless Steel Mig 316LSI WireDocumento1 paginaStainless Steel Mig 316LSI WireAli TalebiNessuna valutazione finora

- Union TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20Documento2 pagineUnion TG 55 M: Classifications EN ISO 17632-A EN ISO 17632-B AWS A5.20brunizzaNessuna valutazione finora

- Boehler CN 23 12 PW-FDDocumento1 paginaBoehler CN 23 12 PW-FDbrayanNessuna valutazione finora

- Union MV Mo and RV 71 Flux Cored WiresDocumento1 paginaUnion MV Mo and RV 71 Flux Cored WiresAnghelache RazvanNessuna valutazione finora

- Cw008a Cu-Of Version1Documento1 paginaCw008a Cu-Of Version1Gaka RtaNessuna valutazione finora

- Bohler-Welding-Germany 207Documento1 paginaBohler-Welding-Germany 207Anghelache RazvanNessuna valutazione finora

- AUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-ADocumento1 paginaAUTOMIG 80S-Ni1 / TIGFIL 80S-Ni1: AWS A/SFA 5.28 EN ISO 14341-A EN ISO 636-AsatnamNessuna valutazione finora

- Merit RM-56: Lincoln Electric China Gmaw Solid WireDocumento2 pagineMerit RM-56: Lincoln Electric China Gmaw Solid WirejuanchepeinNessuna valutazione finora

- TNI2TIDocumento2 pagineTNI2TIKureiNessuna valutazione finora

- CWC-BookletF1 24Documento1 paginaCWC-BookletF1 24Jagannath SahuNessuna valutazione finora

- Pr01, Pr02, Pr03: Vishay BccomponentsDocumento19 paginePr01, Pr02, Pr03: Vishay BccomponentsGabriel pedrosaNessuna valutazione finora

- GBTDocumento1 paginaGBTRaviTeja BhamidiNessuna valutazione finora

- Flux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless SteelDocumento1 paginaFlux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless Steelmohamed AdelNessuna valutazione finora

- NiCu-7 solid wire for welding nickel-copper alloysDocumento1 paginaNiCu-7 solid wire for welding nickel-copper alloyssatnamNessuna valutazione finora

- Barrettetig Catalogo Oerlikon 35035Documento44 pagineBarrettetig Catalogo Oerlikon 35035mp303Nessuna valutazione finora

- B - Boehler NiMo 1-IG - de - en - 5Documento1 paginaB - Boehler NiMo 1-IG - de - en - 5cristian popescuNessuna valutazione finora

- Fluxofil M42: Cored Wires High-Strength SteelsDocumento1 paginaFluxofil M42: Cored Wires High-Strength SteelsCristian BoselliNessuna valutazione finora

- Ficha Técnica CarborodDocumento1 paginaFicha Técnica CarborodAndres NuñezNessuna valutazione finora

- Domex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelDocumento2 pagineDomex 650 MC Hot Rolled, Extra High Strength, Cold Forming SteelHugo RodriguezNessuna valutazione finora

- Sm-309Lmo: Special Metal Korea Co., LTDDocumento1 paginaSm-309Lmo: Special Metal Korea Co., LTDWelli E SNessuna valutazione finora

- Böhler Eas 2 PW-FDDocumento1 paginaBöhler Eas 2 PW-FDHAKANNessuna valutazione finora

- Naval BrassDocumento1 paginaNaval BrassAugusto Gabriel Flores ManzanedaNessuna valutazione finora

- Cromacore DW 308LP flux cored wire for welding stainless steelDocumento1 paginaCromacore DW 308LP flux cored wire for welding stainless steelRaul GonzaloNessuna valutazione finora

- En 0011 1312 00 Ed5Documento2 pagineEn 0011 1312 00 Ed5cybula.michalNessuna valutazione finora

- SC-71LHM Cored: Hyundai Welding Co., LTDDocumento9 pagineSC-71LHM Cored: Hyundai Welding Co., LTDAmanSharmaNessuna valutazione finora

- B Boehler Ti 80 T-FD Fde en 5Documento1 paginaB Boehler Ti 80 T-FD Fde en 5Valentin Hernández TrianoNessuna valutazione finora

- CWC-BookletF1 15Documento1 paginaCWC-BookletF1 15satnamNessuna valutazione finora

- Automig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalsDocumento1 paginaAutomig 80S-B2 / Tigfil 80S-B2: Classification: ApprovalssatnamNessuna valutazione finora

- Lasting Connections with Seamless Cored WireDocumento2 pagineLasting Connections with Seamless Cored WireEduardo FarfanNessuna valutazione finora

- Boehler HL 75 T-MCDocumento1 paginaBoehler HL 75 T-MCBruno SantosNessuna valutazione finora

- Tigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28Documento1 paginaTigfil 90S-B3 SPL: Classification: Aws A/Sfa 5.28satnamNessuna valutazione finora

- Material No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardsDocumento1 paginaMaterial No. EN Symbol (Short) Aisi/Sae UNS Afnor BS Alloy Registered Work's Labelen StandardschetanNessuna valutazione finora

- AUTOMIG 80S Ni1 - TIGFIL 80S Ni1Documento1 paginaAUTOMIG 80S Ni1 - TIGFIL 80S Ni1Kalyan Chakravathi A GNessuna valutazione finora

- Diamondspark Ni1 MC: Seamless Cored WireDocumento2 pagineDiamondspark Ni1 MC: Seamless Cored WireDavid RodriguesNessuna valutazione finora

- Smooth arc stainless steel electrodeDocumento1 paginaSmooth arc stainless steel electrodeson ambaritaNessuna valutazione finora

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocumento1 paginaCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNessuna valutazione finora

- Covered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesDocumento1 paginaCovered (Stick) Electrodes (Smaw) Low Hydrogen Electrodes: Typical Tensile PropertiesNibin OdukkathilNessuna valutazione finora

- Tiginox 385: Classification: en Iso 14343-ADocumento1 paginaTiginox 385: Classification: en Iso 14343-AJagannath SahuNessuna valutazione finora

- Sandvik 19.9.L Welding Wire DatasheetDocumento3 pagineSandvik 19.9.L Welding Wire Datasheetpedro rojasNessuna valutazione finora

- L1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENDocumento1 paginaL1 8515 en Diamondspark Ni1 MC CU05120F 3241743 ENbrayanNessuna valutazione finora

- Primacore MW 71Documento2 paginePrimacore MW 71rjan7peNessuna valutazione finora

- Low Alloy13Documento5 pagineLow Alloy13Branko FerenčakNessuna valutazione finora

- Features/Benefits Typical Applications: Specification ElectricalDocumento2 pagineFeatures/Benefits Typical Applications: Specification Electricalpaula09Nessuna valutazione finora

- Automig FC 71 T1Documento1 paginaAutomig FC 71 T1Sushil BhansaliNessuna valutazione finora

- CPE-FR CablesDocumento1 paginaCPE-FR CablesVijay KarthikeyanNessuna valutazione finora

- Asme Sa-264 Specification For Stainless Chromiumnickel Steel-Clad Plate, Sheet, and StripDocumento11 pagineAsme Sa-264 Specification For Stainless Chromiumnickel Steel-Clad Plate, Sheet, and Striplucecita1902Nessuna valutazione finora

- Steel Plates For Offshore StructuresDocumento8 pagineSteel Plates For Offshore StructuresYiengeChanYeeNessuna valutazione finora

- Centrifugal Pumps Specification Provides Design RequirementsDocumento20 pagineCentrifugal Pumps Specification Provides Design RequirementsRochdi SahliNessuna valutazione finora

- Case 1 Prod HartDocumento5 pagineCase 1 Prod Harteldo0% (1)

- Metrode Cryogenic ER316 B-38Documento5 pagineMetrode Cryogenic ER316 B-38Claudia MmsNessuna valutazione finora

- Replacing Materials in Aging Aircraft to Improve Corrosion Resistance and Fatigue PerformanceDocumento22 pagineReplacing Materials in Aging Aircraft to Improve Corrosion Resistance and Fatigue Performancemarin.petre2815100% (1)

- Nptel WeldingDocumento236 pagineNptel WeldingNishankzattNessuna valutazione finora

- Draft WPS Welder R0Documento51 pagineDraft WPS Welder R0R Bernanda Argandhi SaputraNessuna valutazione finora

- Manual Esab 352 CVDocumento28 pagineManual Esab 352 CVJaSon MadridNessuna valutazione finora

- Handbook MetrodeDocumento371 pagineHandbook Metrodejf2587Nessuna valutazione finora

- Method Statement & Risk Assessment For Hot Works WeldingDocumento4 pagineMethod Statement & Risk Assessment For Hot Works Weldingchandanprakash30100% (1)

- Revision Indication for UOP Piping Fabrication StandardDocumento7 pagineRevision Indication for UOP Piping Fabrication Standardasif rahimNessuna valutazione finora

- E1416-96 Radioscopic Exam of WeldmentsDocumento5 pagineE1416-96 Radioscopic Exam of WeldmentssanthakumarNessuna valutazione finora

- Accessories Catalogue - Jan 2024Documento195 pagineAccessories Catalogue - Jan 2024Mary HernandezNessuna valutazione finora

- Steel Beam To Column-Welded ConnectionDocumento2 pagineSteel Beam To Column-Welded ConnectionAbukalam MullaNessuna valutazione finora

- Interview Guidance by S K MondalDocumento16 pagineInterview Guidance by S K MondaljishnuNessuna valutazione finora

- Nowata CapabilitiesDocumento4 pagineNowata CapabilitiesKetan KarandikarNessuna valutazione finora

- McDonald (2003) Tor Considerations For Future Higher Eff Micro TurbinesDocumento25 pagineMcDonald (2003) Tor Considerations For Future Higher Eff Micro TurbinesPieter van der MeerNessuna valutazione finora

- Cara Hitung Kawat LasDocumento12 pagineCara Hitung Kawat LasPrince PrinceNessuna valutazione finora

- Brochure - Valco - Marine Valves - EnglishDocumento8 pagineBrochure - Valco - Marine Valves - EnglishMeet JaniNessuna valutazione finora

- ASME IX Interpretation-Part9Documento36 pagineASME IX Interpretation-Part9kevin herry100% (1)

- Pub 83 Al Bronze Alloys For Industry PDFDocumento24 paginePub 83 Al Bronze Alloys For Industry PDFpbanerjeeNessuna valutazione finora

- Sockolet Gap Control Threaded Joints - PR - 0XXDocumento14 pagineSockolet Gap Control Threaded Joints - PR - 0XXRAMAKRISHNANessuna valutazione finora

- PLANAR DefectDocumento20 paginePLANAR DefectmiladrahimianNessuna valutazione finora

- DIGISTEEL III 420/520 DIGIPULS III 420/520: Cat N°: 8695-1251 Rev: D Date: 02/2018Documento282 pagineDIGISTEEL III 420/520 DIGIPULS III 420/520: Cat N°: 8695-1251 Rev: D Date: 02/2018Công Nghệ HànNessuna valutazione finora

- Cold Bonding LNG TanksDocumento4 pagineCold Bonding LNG TankskaybeeNessuna valutazione finora

- BabbittDocumento4 pagineBabbitthrsreenathNessuna valutazione finora

- R057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpoolDocumento16 pagineR057-Ac-It-002 (C) - Inspection and Test Plan For Pipe SpooldharwinNessuna valutazione finora

- List Applicable WPS StructureDocumento7 pagineList Applicable WPS StructureFerdie OSNessuna valutazione finora

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocumento8 pagineSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289Nessuna valutazione finora