Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

TP2016 001 Rev01 (Padeye Guide)

Caricato da

kazdanoDescrizione originale:

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

TP2016 001 Rev01 (Padeye Guide)

Caricato da

kazdanoCopyright:

Formati disponibili

Padeye Design Guidelines TP2016-001-Rev01

The following guide gives an overview of padeye design based on DNV design rules and common industry

practice.

For any manufactured equipment, the geometry of the padeye must match the size of shackle to be used to

ensure a rated connection between the equipment and the lifting set.

DNV states two key sizing rules which are of importance:

• The diameter of the holes in the padeye shall match the shackle used, clearance between shackle pin and

padeye hole shall not exceed 6% of the shackle pin diameter.

• The thickness of the padeye at the hole shall not be less than 75% of the inside width of the joining

shackle

The correct design of padeye should be selected based on the particular load application. For straight lifting

angles a symmetric padeye design should be used, for a multi-point lift as in a offshore container or frame then

a nonsymmetric design can be used. If required plated supports can be added to the symmetric design to

increase the lateral stiffness of the padeye, useful when the padeye will be subjected to dynamic load angles.

BOLT TYPE ANCHOR LIFTING SHACKLE WITH

NUT & SPLIT PIN (CROSBY OR VAN BEEST)

60° LOAD ANGLE

TYPICALLY 30°

PADEYE Symmetric Padeye Nonsymmetric Padeye Symmetric Padeye

(Supported)

For a multi-point lift it is essential that the padeyes point directly to the lift point centre to prevent lateral

bending moments on the padeyes, DNV suggest a tolerances of 2.5 degrees as an allowable misalignment.

For padeyes rated above 2000kg capacity cheek plates must be fitted to reduce the play in the shackle-padeye

connection. These must be fitted as additional plates welded onto the padeye profile and not a single boss as

shown below.

Padeye Materials x

For equipment used in a marine environment, all padeye materials are to be S335J2 (BS EN 10025) supplied with

3.1 material inspection certificates to BS EN 10204.

Padeye Welding

All padeyes must be welded to the primary struture by use of full penetration welds. It is good practure to extend

the base of the padeye to pass it completely through the structural member which it is connected to. If welding

directly onto horizontal plate then the plate must be specified as EMZ grade to prevent delamination of the plate

under tensile load.

When sizing the correct padeye for your application consider the following:

• Maximum foreseen gross load

• Load test requirements

• Dynamic amplification factor (DAF)

• Drag load on equipment when lifting through water

• Potential captured water weight when lifting equipment out of water

This document has been created as a guide and should not be used as a substitute to correct design calculations.

All lifting frames including padeye design should be checked by calculation and ideally independently checked

and approved prior to manufacturing. Post manufacture load testing must be performed prior to equipment use.

www.technikdesign.co.uk sales@technikdesign.co.uk Page 1 of 3

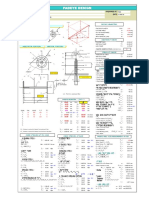

Padeye Design Guidelines TP2016-001-Rev01

R17.5

R15 +0.2

+0.2 10 0

8 0

40

35

10 TYP

10 TYP

65 10 75 12

500KG PADEYE 750KG PADEYE

R25

+0.2

+0.2 R20 13.2 0

11.5 0

50

45

100 15

15 TYP

12 TYP

85 15

1,000KG PADEYE 1,500KG PADEYE

4 TYP

4 TYP

+0.2 R32

+0.2 R30

20 0

16.8 0

50 TYP

45 TYP

60

55

15 TYP

20 TYP

110 12 120 15

2,000KG PADEYE 3,250KG PADEYE

4 TYP

+0.2 R45

4 TYP 26 0

+0.2 R35

23 0

70 TYP

60 TYP

75

65

130 20

20 TYP

160 25

20 TYP

4,750KG PADEYE 6,500KG PADEYE

www.technikdesign.co.uk sales@technikdesign.co.uk Page 2 of 3

Padeye Design Guidelines TP2016-001-Rev01

6 TYP

6 TYP

+0.2 R55

+0.2 R55 33 0

30 0

80 TYP

80 TYP

90

85

25 TYP

195 25 200 30

25 TYP

8,500KG PADEYE 9,500KG PADEYE

10 TYP

8 TYP R60

+0.2

+0.2 R55 40 0

36 0

90 TYP

80 TYP

100

95

30 TYP

30 TYP

210 30 230 30

12,000KG PADEYE 13,500KG PADEYE

10 TYP

R75 10 TYP +0.2 R85

52 0

+0.2

43 0

130 TYP

110 TYP

130

115

40 TYP

300 40

40 TYP

260 30

17,000KG PADEYE 25,000KG PADEYE

15 TYP

Notes:

+0.2 R90

58 0 1. The padeye sizes have been created for

compatibility with Crosby Bolt Type Standard,

Crosby Bolt Type Alloy, Van Beest Green Pin

Standard and Van Beest Green Pin Super shackles

150 TYP

incorporating all dimensional differences and

manufacturing tolerances within the shackle types.

2. For padeyes subjected to side loading fit additional

plates to increase the lateral stiffness of the padeye.

150

3. Line bore holes through padeye and cheek plates

when possible.

50 TYP

4. Do not apply paint system top toat within through

hole on padeye.

5. Load test all padeyes/equipment prior to use.

320 40

6. All drawings views not to the same scale.

35,000KG PADEYE

www.technikdesign.co.uk sales@technikdesign.co.uk Page 3 of 3

Potrebbero piacerti anche

- DNV Good and Bad Design of PadeyesDocumento30 pagineDNV Good and Bad Design of Padeyese2566601100% (2)

- EC3 - Offshore Padeye DesignDocumento4 pagineEC3 - Offshore Padeye Designscaricatutto100% (1)

- Offshore PadeyeDocumento2 pagineOffshore PadeyeFAR_A_DAYNessuna valutazione finora

- Padeye CalculationDocumento11 paginePadeye CalculationMarvan100% (2)

- 17 Padeye - Spreadsheet Rev ADocumento12 pagine17 Padeye - Spreadsheet Rev Aoluomo1Nessuna valutazione finora

- PADEYE-AISC-360-2005 CalculationDocumento6 paginePADEYE-AISC-360-2005 CalculationsaswattNessuna valutazione finora

- 17 TonsDocumento8 pagine17 Tonsabuzahrau100% (3)

- Padeye Calculation Calculations To Determine The Pad Eye Thickness Is Based On DNV 2Documento1 paginaPadeye Calculation Calculations To Determine The Pad Eye Thickness Is Based On DNV 2Zulham Chandra100% (1)

- Lifting PadeyeDocumento16 pagineLifting PadeyeLưu XuânNessuna valutazione finora

- Pad Eye Calculation DNV 2-7.3.Documento9 paginePad Eye Calculation DNV 2-7.3.Jacek75% (4)

- Padeye DesignDocumento32 paginePadeye DesignMuhammad Iqbal100% (1)

- CALCULATIONS Pad Eye DesignDocumento5 pagineCALCULATIONS Pad Eye DesignVijay Verma100% (1)

- Pad Eye Design CalculationDocumento7 paginePad Eye Design CalculationLưu Xuân0% (1)

- Calculation Sheet Lifting Set DNV 2.7-1 FOR 20ft PDFDocumento3 pagineCalculation Sheet Lifting Set DNV 2.7-1 FOR 20ft PDFNguyễn Quốc Phượng100% (1)

- Padeye Design CheekDocumento3 paginePadeye Design CheekBolarinwa89% (9)

- Lifting Lug DesignDocumento27 pagineLifting Lug Designmramico100% (1)

- Pad Eye New ReleaseDocumento10 paginePad Eye New ReleaseEnrique BarajasNessuna valutazione finora

- 4 Design (Compatibility Mode) - tcm153-474863Documento65 pagine4 Design (Compatibility Mode) - tcm153-474863Gautam Vijay100% (2)

- Padeye Calculation LatestDocumento10 paginePadeye Calculation LatestPavan RayNessuna valutazione finora

- Padeye8t (Without Cheek Plate)Documento2 paginePadeye8t (Without Cheek Plate)Mohd Khir Johari100% (1)

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDocumento5 pagineCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaNessuna valutazione finora

- Twenty Five Ton Padeye - SpreadsheetDocumento4 pagineTwenty Five Ton Padeye - Spreadsheetoluomo1Nessuna valutazione finora

- Design Calculation Offshore BasketDocumento14 pagineDesign Calculation Offshore BasketAnnas Triyoni67% (6)

- Offshore Pad EyesDocumento8 pagineOffshore Pad EyesNhut100% (1)

- 8 Padeye - Spreadsheet Check1Documento4 pagine8 Padeye - Spreadsheet Check1oluomo1Nessuna valutazione finora

- Lifting Sets Calculation - API RP 2ADocumento11 pagineLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Padeye DolphinDocumento38 paginePadeye DolphinMuhammad FadelNessuna valutazione finora

- Padeye Design GuidelinesDocumento4 paginePadeye Design GuidelineskazdanoNessuna valutazione finora

- Padeye Calculation For Lifting AnalysisDocumento3 paginePadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- DNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDocumento2 pagineDNV 2.7-3 Pad Eye Calculations For 15k Debris CatcherDhanraj VasanthNessuna valutazione finora

- Lifting LugsDocumento2 pagineLifting LugsAdi Cahyoko82% (11)

- Pad Eye Designwww - Thenavalarch.com Rev B SI UnitsDocumento10 paginePad Eye Designwww - Thenavalarch.com Rev B SI UnitsndesigngmailNessuna valutazione finora

- SWI PadeyeDocumento11 pagineSWI PadeyeFian ArdiyanaNessuna valutazione finora

- Mathcad - Spreader Bar FinalDocumento4 pagineMathcad - Spreader Bar FinalOkondu Chiedu100% (3)

- Lifting Lug Calc-Single CPI - RFDocumento7 pagineLifting Lug Calc-Single CPI - RFRustam RiyadiNessuna valutazione finora

- Jacket Padeye Design PDFDocumento37 pagineJacket Padeye Design PDFolomu100% (1)

- SkyCiv Sample DNV 2 7 1 Design Report Example Integrated PDFDocumento11 pagineSkyCiv Sample DNV 2 7 1 Design Report Example Integrated PDFCarlos Eduardo Alvarez SantiagoNessuna valutazione finora

- SC-292 - Lift Point DesignDocumento39 pagineSC-292 - Lift Point DesignSantanu100% (2)

- Design Calculation LiftingDocumento19 pagineDesign Calculation LiftingAbu Al Sayyid100% (1)

- Calculation Sheet: Padeye Calculations LoadsDocumento28 pagineCalculation Sheet: Padeye Calculations Loadsghoshamit4100% (5)

- Spreader Beam CalculationDocumento2 pagineSpreader Beam Calculationhombre.muerto595977% (13)

- Series: Static Three Wheel RollerDocumento2 pagineSeries: Static Three Wheel RollerFahri Alvian NoorNessuna valutazione finora

- Series: Static Three Wheel RollerDocumento2 pagineSeries: Static Three Wheel Rolleragus yuliantoNessuna valutazione finora

- Dynapac Soil CompactorsDocumento20 pagineDynapac Soil Compactorsjorgemorales416Nessuna valutazione finora

- Flexible Lab Automation With The MOTOMAN CSDA10FDocumento4 pagineFlexible Lab Automation With The MOTOMAN CSDA10FIulia CostacheNessuna valutazione finora

- All-Black Cs6K-270 - 275 - 280 M: Linear Power Output Warranty Key FeaturesDocumento2 pagineAll-Black Cs6K-270 - 275 - 280 M: Linear Power Output Warranty Key FeaturesRemarcos PachecoNessuna valutazione finora

- Canadian Solar Datasheet MaxPower CS6U M V5.51naDocumento2 pagineCanadian Solar Datasheet MaxPower CS6U M V5.51naStenio ArcelinoNessuna valutazione finora

- Dynapac Soil CompactorsDocumento20 pagineDynapac Soil CompactorsAchmad PrayogaNessuna valutazione finora

- A Polyhydron Group Company: DescriptionDocumento2 pagineA Polyhydron Group Company: DescriptionRenjithSivaNessuna valutazione finora

- Grinding Cost Calculation - Summary: Annual Production Quantity Annual Consumption - QuantityDocumento6 pagineGrinding Cost Calculation - Summary: Annual Production Quantity Annual Consumption - QuantitynanthaidNessuna valutazione finora

- SANSHING Tooling BrochureDocumento11 pagineSANSHING Tooling BrochureAnonymous w13t9bNessuna valutazione finora

- Sp20 DescripcionDocumento2 pagineSp20 DescripcionJuan Pablo Moreno Téllez Moreno TéllezNessuna valutazione finora

- 1 - E-1 - Rev RADocumento1 pagina1 - E-1 - Rev RAavinashkeswaniNessuna valutazione finora

- 1 - E-1 - Rev RADocumento1 pagina1 - E-1 - Rev RAavinashkeswaniNessuna valutazione finora

- Sbpa - Rnav Dakat 1b Rwy 29 - Star - 20230810Documento1 paginaSbpa - Rnav Dakat 1b Rwy 29 - Star - 20230810CMDT MatheusNessuna valutazione finora

- Roata PDFDocumento1 paginaRoata PDFBadica Marius NicolaeNessuna valutazione finora

- Roata: Universitatea "Petrol - Gaze" PloiestiDocumento1 paginaRoata: Universitatea "Petrol - Gaze" PloiestiBadica Marius NicolaeNessuna valutazione finora

- Brochure Gearless INDIA June22Documento12 pagineBrochure Gearless INDIA June22Pritesh NaikNessuna valutazione finora

- Canadian 395wDocumento2 pagineCanadian 395wagnieszkaNessuna valutazione finora

- Cover Housing: All Sharp Edges C0.3-0.5Documento1 paginaCover Housing: All Sharp Edges C0.3-0.5Arief FibonacciNessuna valutazione finora

- LB-Buch-Conventional-Hardness (Rockwel Shore)Documento23 pagineLB-Buch-Conventional-Hardness (Rockwel Shore)kazdanoNessuna valutazione finora

- KTF-standard ENGDocumento60 pagineKTF-standard ENGkazdanoNessuna valutazione finora

- Earth Boss: - Provides Preferential Equipotential Bonding Connection PointDocumento1 paginaEarth Boss: - Provides Preferential Equipotential Bonding Connection PointkazdanoNessuna valutazione finora

- ISO 3601 G Measurements in Millimeters Measurements in Inches ISO 3601 G Size ID CS ID CS SizeDocumento8 pagineISO 3601 G Measurements in Millimeters Measurements in Inches ISO 3601 G Size ID CS ID CS SizekazdanoNessuna valutazione finora

- ComprehensiverangeDocumento4 pagineComprehensiverangekazdanoNessuna valutazione finora

- SCM Torque and Power 151019Documento12 pagineSCM Torque and Power 151019kazdanoNessuna valutazione finora

- High Strength Fine Grained Structural Steel, Quenched and TemperedDocumento6 pagineHigh Strength Fine Grained Structural Steel, Quenched and TemperedkazdanoNessuna valutazione finora

- GE - SX-GE - AX Thrust Plain Spherical BearingsDocumento1 paginaGE - SX-GE - AX Thrust Plain Spherical BearingskazdanoNessuna valutazione finora

- SCM Torque and Power 151019Documento12 pagineSCM Torque and Power 151019kazdanoNessuna valutazione finora

- SCM 012-130 SaeDocumento12 pagineSCM 012-130 SaekazdanoNessuna valutazione finora

- CH3 1 Welding Joint SymbolsDocumento32 pagineCH3 1 Welding Joint SymbolskazdanoNessuna valutazione finora

- Product: CatalogueDocumento38 pagineProduct: CataloguekazdanoNessuna valutazione finora

- SCM Efficiency Curves SCM Efficiency CurvesDocumento12 pagineSCM Efficiency Curves SCM Efficiency CurveskazdanoNessuna valutazione finora

- SCM 025-108 M2Documento8 pagineSCM 025-108 M2kazdanoNessuna valutazione finora

- 42 CR Mo 4Documento4 pagine42 CR Mo 4kazdanoNessuna valutazione finora

- Class Equip Lifting Mach enDocumento9 pagineClass Equip Lifting Mach enerzengenhariaNessuna valutazione finora

- G G GE EEN N NE EER R RA Aalll P PPU U UR R RP PPO O OS SSE EE E EEN N NC C Clllo O OS SSU U UR R RE EES SSDocumento37 pagineG G GE EEN N NE EER R RA Aalll P PPU U UR R RP PPO O OS SSE EE E EEN N NC C Clllo O OS SSU U UR R RE EES SSkazdanoNessuna valutazione finora

- Applied Mechanics I Tutorials and AssignmentDocumento34 pagineApplied Mechanics I Tutorials and AssignmentaayushNessuna valutazione finora

- Expanding The Limits of SPCDocumento23 pagineExpanding The Limits of SPCswap dNessuna valutazione finora

- Bank StatmentDocumento10 pagineBank StatmentSivakumar ThangarajanNessuna valutazione finora

- Block Diagram: Feed Inlet CO2 & H2S DehydrationDocumento5 pagineBlock Diagram: Feed Inlet CO2 & H2S DehydrationRandy HassanaliNessuna valutazione finora

- Math Samples PDFDocumento1 paginaMath Samples PDFArwin VillegasNessuna valutazione finora

- MBA Project On CRMDocumento40 pagineMBA Project On CRMsrikanthmogilla1250% (2)

- History: Aviation Is The Practical Aspect or Art ofDocumento3 pagineHistory: Aviation Is The Practical Aspect or Art ofEarle J ZaficoNessuna valutazione finora

- AP Lab Assignment 1Documento30 pagineAP Lab Assignment 1Ahmad AlsharefNessuna valutazione finora

- SurgeTest EPCOSDocumento33 pagineSurgeTest EPCOSSabina MaukoNessuna valutazione finora

- Productguide - Chemicals Aceites FleetriteDocumento12 pagineProductguide - Chemicals Aceites FleetriteJose AlbertoNessuna valutazione finora

- PPE ChecklistDocumento3 paginePPE ChecklistAtique Ur Rehman KhattakNessuna valutazione finora

- Solar Sagm 12 205: Data SheetDocumento2 pagineSolar Sagm 12 205: Data Sheetsofia hernandezNessuna valutazione finora

- Pavan Tools Catalog 2012Documento76 paginePavan Tools Catalog 2012Pavan ToolsNessuna valutazione finora

- Unit 1: Configuration Layout and LoftDocumento45 pagineUnit 1: Configuration Layout and LoftDaxit LodaliyaNessuna valutazione finora

- Torque & Tension Figures SPXDocumento24 pagineTorque & Tension Figures SPXzxpnqxv7vhNessuna valutazione finora

- Mercedes Panaromic Roof Lubrication GuideDocumento1 paginaMercedes Panaromic Roof Lubrication Guidehappy_jonNessuna valutazione finora

- Principles of Motion EconomyDocumento39 paginePrinciples of Motion EconomyNikhil GargNessuna valutazione finora

- Checlist Kelompok Pressure VesselDocumento8 pagineCheclist Kelompok Pressure VesselerniNessuna valutazione finora

- Software Engineering I (02161) Lecture Notes: Assoc. Prof. Hubert Baumeister Spring 2012Documento16 pagineSoftware Engineering I (02161) Lecture Notes: Assoc. Prof. Hubert Baumeister Spring 2012Karthik KeyanNessuna valutazione finora

- Solid Fuel Boiler Control Standard 2: Version 1.0) Version 1.0) Version 1.0) Version 1.0)Documento26 pagineSolid Fuel Boiler Control Standard 2: Version 1.0) Version 1.0) Version 1.0) Version 1.0)Ana Odzaklieska Krste SmileskiNessuna valutazione finora

- Greenlane Biogas Cover Page See Content On Following Page (S)Documento3 pagineGreenlane Biogas Cover Page See Content On Following Page (S)Cibele AlvesNessuna valutazione finora

- Normas Iec - AstmDocumento3 pagineNormas Iec - AstmGregorio Mendoza PolaresNessuna valutazione finora

- Liebherr Fridge ManualDocumento18 pagineLiebherr Fridge ManualJames RavensdaleNessuna valutazione finora

- QAP For Pipes For Hydrant and Sprinkler SystemDocumento3 pagineQAP For Pipes For Hydrant and Sprinkler SystemCaspian DattaNessuna valutazione finora

- Top Secrets of The VedasDocumento54 pagineTop Secrets of The Vedasbiswajit_paulNessuna valutazione finora

- RT-1000 Terex, RT-100 TonDocumento14 pagineRT-1000 Terex, RT-100 TonMaximo CC100% (1)

- Desalter Package 1.2 User ManualDocumento10 pagineDesalter Package 1.2 User ManualPervaiz RizviNessuna valutazione finora

- Introduction of Technical Drawing (Automotive Major)Documento10 pagineIntroduction of Technical Drawing (Automotive Major)Jake Casiple100% (1)

- Introduction To PythonDocumento0 pagineIntroduction To PythonLokesh BhatiaNessuna valutazione finora

- Slope Stability AnalysisDocumento16 pagineSlope Stability AnalysisRajesh KhadkaNessuna valutazione finora