Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Manufacturing and Mass Balance of Copper Phthalocyanine (CPC) Blue and Green Pigments

Caricato da

Advanced Research PublicationsCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Manufacturing and Mass Balance of Copper Phthalocyanine (CPC) Blue and Green Pigments

Caricato da

Advanced Research PublicationsCopyright:

Formati disponibili

Journal of Drug Discovery and Development

Volume 2, Issue 1 - 2018, Pg. No. 18-23

Peer Reviewed & Open Access Journal

Research Article

Manufacturing and Mass Balance of

Copper Phthalocyanine (CPC) Blue and

Green Pigments

Ashok K Rathoure1, Savita Goyal Aggarwal2

1

Eco Group of Companies, New Civil Road, Surat (GJ) India.

2

Dept. of Chemistry, GRD Institute of Management and Technology, 12, Rajpur Road, Dehradun, Uttarakhand, India.

Abstract

Organic pigments are cost-effective, non-toxic, and possess good color strength, which makes them good

choice for their use across various end-use sectors. Copper phthalocyanine (CPC) blue is the copper (II)

complex of tetra aza tetra benzoporphine (CPC) whereas phthalocyanine green is its chlorinated derivative.

The brominated derivatives of CPC provide a yellowish green shade. The specific crystal modification

decides the hue of the product as in Alpha Blue-red shade copper phthalocyanine (Pigment Blue 15) and

in Beta Blue-green shade blue (Pigment Blue 15:3). CPC Blue is an upstream product and is a raw material

used for the manufacture of our Pigment Blue and Pigment Green products. CPC Blue is also sold to other

manufacturers of pigments including a related party for the manufacture of textile dyestuffs. Here we have

presented the manufacturing process of two organic pigments – CPC Green and Blue.

Keywords: CPC Green, Beta Blue, Ink, Manufacturing, Textile, Tint

Introduction phthalocyanine (Pigment Blue 15), and in Beta Blue – green

shade blue (Pigment Blue 15:3). The alpha modification is

Manufacture of organic pigments with good light fastness phase stabilized by partial chlorination called solvent stable

property is gaining traction among global manufacturers. Alpha Blue or Pigment Blue 15:1. The alpha modification

Besides, developing countries such as China and India are which is stabilized towards flocculation and the phase

shifting towards becoming the center of global organic change is registered as Pigment Blue 15:2. These pigments

pigments market, both from the demand and supply side. find use in paints. Pigment Blue is a cyclic product of copper

The manufacturing of organic pigment is in a cautious and reaction between phthalic anhydride and urea. Alpha

phase as API bulk drug.3 The information sheet for organic Blue and Beta Blue are variations of Phthlocyanine Blues.

pigments is listed in Table 1. Alpha Blue is redder in shade and of smaller particle size

and is available as crystallizing type and non-crystallizing

Copper Phthalocyanine (CPC) Blue is the copper (II) non-flocculating type. Beta Blue yields bright greenish

complex of tetra aza tetra benzoporphine (CPC) whereas blue shades with slightly lower tintorial strength. Beta

Phthalocyanine Green is its chlorinated derivative. The Blue is of a more stable crystal formulation than Alpha

brominated derivatives of CPC provide a yellowish green Blue and is available as the non-crystallizing type and the

shade. The specific crystal modification decides the non-crystallizing non-flocculating type.

hue of the product as in Alpha Blue – red shade copper

Corresponding Author: Ashok K Rathoure, Eco Group of Companies, New Civil Road, Surat (GJ) India.

E-mail Id: asokumr@gmail.com

Orcid Id: https://orcid.org/0000-0001-9131-1346

How to cite this article: Rathoure AK, Aggarwal SG. Manufacturing and Mass Balance of Copper Phthalocyanine (CPC) Blue and

Green Pigments. J Durg Dis Dev 2018; 2(1): 18-23.

Copyright (c) 2018 Journal of Drug Discovery and Development

Rathoure AK et al.

19 J. Durg. Dis. Dev. 2018; 2(1)

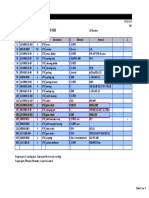

Table 1.Information Sheet for Organic Pigments

Particular Copper Phthalocyanine (CPC) Green CPC Beta Blue

Physical state Solid Solid

CAS No. 1328-53-6 147-14-8

Formula C32Cl16CuN8 CuC32H16N8

MW (g/mol) 1127.154 576.0690

Uses Inks, coatings and many plastics, in manufacturing of other pigments in the category

Toxicity Serious birth defects in developing embryos; non-bio-degradable

LD50 >3 g per kg body weight >5 g per kg body weight

LC50 >250 mg/L for 48 h >100 mg/L for 48 h

Reference Sandor et al. 1

OECD SIDS, 1990

Raw Material

The list of raw material required for the manufacturing of two organic pigments is shown in Table 2.

Table 2.Raw Material Consumption (per ton of product)

Organic Pigments Raw Material Physical State Raw Material Consumption (per ton of product)

CPC Green Aluminum Chloride Solid 1.928

Salt Solid 0.3

CPC Blue Solid 0.571

Cupric Chloride Solid 0.085

Chlorine Gas Liquid/Gas 1.265

MCB (Recovered) Liquid 2.97

MCB (Fresh) Liquid 0.03

Caustic lye Liquid 0.16

Emulsifier Liquid 0.02

Oleic Acid Liquid 0.02

Beta Blue CPC Blue Solid 1.02

Salt Solid 0.15

Xylene (Recovered) Liquid 2.940

Xylene (Fresh) Liquid 0.06

Emulsifier Liquid 0.025

Caustic Liquid 0.05

Manufacturing Process for Copper Phthalocyanine green crude wet cake.

Green • Pigmentation: In a reactor, monochlorobenzene, water

and caustic soda lye are mixed. Now dispersing agents

• Chlorination: In a glass-lined reactor, eutectic mixture are added to it and an emulsion is prepared. The

of aluminum chloride and sodium chloride is prepared wet cake from above stage is taken to it and stirring

and is melted. Now CPC AD blue and cupric chloride are is continued. The mass is then refluxed. Solvent

charged. The chlorine gas is purged till the drawdown monochlorobenzene is then recovered by distillation

is found O.K. The mass is then drowned. and the mass is filtered.

• Drowning: In a vessel, water is taken. The chlorinated • Filtration: The suspended slurry is then filtered and is

mass is then received slowly. The mass is stirred and washed to make it free of alkali.

filtered. • Drying: The wet cake from above filtration is dried in

• Filtration: Drowned mass is filtered and is then washed a spin flash dryer.

to make it free of chloride or aluminum. This gives CPC

Rathoure AK et al.

J. Durg. Dis. Dev. 2018; 2(1) 20

CHEMICAL REACTION COPER PHTHALO CYANINE GREEN

Figure 1.Structure of CPC Green

N C C N

N

C C Cl Cl

+ 16 Cl2

N Cu N (1136)

Cl Cl

C

N C

N C C N

N C C N

Cl

Cl N

Cl C C Cl

N Cu N

Cl C Cl

N C

CuC32H15N8 Cl Cl

N C C

Copper Phthalo Cyanine Blue N

(575.5) + 16 HCl

CuC32Cl15N8

(584)

Cl

Copper Phthalo Cyanine Green Cl

(1127.5)

Cl Cl

Figure 2.Chemical Reaction CPC Green

Rathoure AK et al.

21 J. Durg. Dis. Dev. 2018; 2(1)

MASS BALANCE OF CPC GREEN

Water: 583 kgs

AlCl3 : 1928 kgs

Salt: 300 kgs

CPC Blue: 571 kgs CHLORINATION Unreacted Chlorine gas: 250 kgs Three stage Scrubber

CuCl2 : 85 kgs

Cl2 gas: 1265 kgs

HCl (30%): 833 kgs

DROWNING

Water: 12000 kgs

AlCl3 Soln. (10-12%): 12000 kgs

Water: 22500 kgs FILTERATION & WASHING

Effluent to ETP: 22000 Kgs

MCB: 3000 kgs

Water: 1200 kgs PIGMENTATION

Caustic: 160 kgs MCB recovered: 2970 kgs

Oleic Acid: 20 kgs MCB loss: 30 kgs

Emulsifer: 20 kgs

FILTERATION Effluent to ETP: 23299 kgs

Water: 20000 kgs

& WASHING

SPIN FLASH Evaporation loss: 1500 kgs

DRYER

CPC GREEN: 1000 kgs

Figure 3.Mass Balance of CPC Green

Figure 4.Hazardous Waste Management during Manufacturing of CPC Green

Rathoure AK et al.

J. Durg. Dis. Dev. 2018; 2(1) 22

Manufacturing of CPC Beta Blue with solvent at 90ºC.

• Filtration and Washing: The mass is filtered off in filter

• Ball Milling: Copper Phthalocyanine Blue is milled press, and washed up to neutral pH.

along with vacuum salt below 70ºC. It is unloaded and • Drying: The wet cake is dried in a spin flash drier and

transferred

PROCESS forFLOW

pigmentation.

DIAGRAM WITH MASS BALANCE finally

OF packed.

BETA BLUE PIGMENT 15.3 & 15.4

• Solvent Pigmentation: The milled powder is treated

CPC Blue (98.5%): 1020 kgs

Salt: 150 kgs BALL MILLING

Water: 5000 kgs

Xylene: 3000 kgs Solvent recovered: 2940 kgs

Emulsifier : 25 Kgs PIGMENTATION

Additives : 25 Kgs Solvent loss: 60 kgs

Caustic : 50 kgs

FILTERATION

Water : 25000 kgs Effluent to ETP: 28470 kgs

& WASHING

SPIN FLASH Water Evaporation loss: 1800 kgs

DRYER

PRODUCT : BETA BLUE: 1000 kgs

Figure 5.Process Flow Diagram of Beta Blue Pigment

Figure 6.Hazardous Waste Management during Manufacturing of CPC Blue

There is no chemical reaction taking place, only rearrangement of molecules of Phthalocyanine Blue and Beta Blue are

formed which is stable and has greener blue tone.

Rathoure AK et al.

23 J. Durg. Dis. Dev. 2018; 2(1)

(CuC32H16N8)

Figure 7.Chemical Reaction of Copper Phthalocyanine Beta Blue Pigment

Figure 8.Conversion of Organic Pigments

Conclusion References

The CPC green and blue pigments are used widely in 1. Sandor S, Prelipceanu O, Checiu I. Sulphonated

textile units to color the yarn and used in printing. The phthalocyanine induced caudal malformative syndrome

CPC pigments are broad-spectrum organic pigments. Beta in the chick embryo. Morphol Embryol (Bucur) 1985;

Blue is of a more stable crystal formulation than Alpha Blue 31(3): 173-81.

and is available as the non-crystallizing type and the non- 2. OECD SIDS. Copper Phthalocyanine. CAS N°:147-14-

crystallizing non-flocculating type. During manufacturing 8. 1990. Available online at http://www.inchem.org/

of organic pigments, major issue is hazardous water; it documents/sids/sids/147148.pdf.

should be properly handled. The life cycle analysis should 3. Rathoure AK, Aggarwal SG. Manufacturing process

be done before use of organic pigments. with chemical reactions and mass balance for 6

pharmaceutical drugs. J Durg Dis Dev 2017; 1(1): 54-64.

Conflict of Interest: None

Date of Submission: 2018-04-02

Date of Acceptance: 2018-04-16

Potrebbero piacerti anche

- Titan GelDocumento6 pagineTitan GelVladi Salas100% (1)

- Medical CodingDocumento5 pagineMedical CodingBernard Paul GuintoNessuna valutazione finora

- Psalm151 160Documento3 paginePsalm151 160Gina KristenNessuna valutazione finora

- Bomber JacketDocumento3 pagineBomber JacketLaura Carrascosa FusterNessuna valutazione finora

- Production of Emulsion House Paint Using PolyvinylDocumento5 pagineProduction of Emulsion House Paint Using PolyvinylOtegba GiftNessuna valutazione finora

- Diammonium PhosphateDocumento3 pagineDiammonium PhosphateJohannah Jane AbuelNessuna valutazione finora

- Design and Simulation of Hydrogen Peroxide Plant: Manufacturing ProcessesDocumento5 pagineDesign and Simulation of Hydrogen Peroxide Plant: Manufacturing Processesdfeor shenoyNessuna valutazione finora

- PNCB ManufacturingDocumento35 paginePNCB ManufacturingPrad1979100% (2)

- Macro PolymerDocumento30 pagineMacro PolymerAman Sinha100% (1)

- Pesticide Manufacturing Industy - CPCBDocumento37 paginePesticide Manufacturing Industy - CPCBSaurav Chatterjee100% (3)

- Terephthalic AcidDocumento8 pagineTerephthalic AcidWali AhsanNessuna valutazione finora

- Activated CarbonDocumento14 pagineActivated CarbonAbhisesh ThakurNessuna valutazione finora

- Sulfur and Hydrogen Sulfide RecoveryDocumento27 pagineSulfur and Hydrogen Sulfide RecoveryChemical.AliNessuna valutazione finora

- Terephthalic Acid Material Balance RevisedDocumento5 pagineTerephthalic Acid Material Balance RevisedsanketsdiveNessuna valutazione finora

- Dimethyl TerephthalateDocumento9 pagineDimethyl Terephthalatehung_metalNessuna valutazione finora

- Fatty Acid ProductsDocumento111 pagineFatty Acid Productspestott67% (3)

- D&C Act Schedule QDocumento5 pagineD&C Act Schedule QParthaNessuna valutazione finora

- Pthalic Anhydride Plant ProcessDocumento5 paginePthalic Anhydride Plant ProcesssandeepNessuna valutazione finora

- LAB ProductionDocumento37 pagineLAB ProductionAbdullah AzzamNessuna valutazione finora

- G 1 PDFDocumento199 pagineG 1 PDFKing HenryNessuna valutazione finora

- (NIIR) Industrial Chemicals Technology Hand BookDocumento9 pagine(NIIR) Industrial Chemicals Technology Hand BookNaveen KamatNessuna valutazione finora

- Manufacturing of Unsaturated Polymer ResinsDocumento49 pagineManufacturing of Unsaturated Polymer ResinsBurhaan Taskeen100% (3)

- Manufacture of Terepthalic AcidDocumento68 pagineManufacture of Terepthalic AcidAhmed Ali33% (3)

- 265 Tons Per Day Production of Terephthalic Acid by Amoco ProcessDocumento169 pagine265 Tons Per Day Production of Terephthalic Acid by Amoco ProcessTania Noor100% (1)

- Styrene Production From EthylbenzeneDocumento10 pagineStyrene Production From EthylbenzeneChegg ChemNessuna valutazione finora

- Manufacturing of Phosphoric Acid - FinalDocumento54 pagineManufacturing of Phosphoric Acid - FinalPawan SuvarnaNessuna valutazione finora

- Kinetics of The Catalytic Oxidation of Phthalic AnhydrideDocumento214 pagineKinetics of The Catalytic Oxidation of Phthalic Anhydrideannisa plNessuna valutazione finora

- Catalytic Methanol CarbonylationDocumento27 pagineCatalytic Methanol CarbonylationMartin Dubois100% (1)

- EpichlorohydrinDocumento36 pagineEpichlorohydrinCharles Amiel DionisioNessuna valutazione finora

- AlkydDocumento5 pagineAlkydHasan Tariq SahiNessuna valutazione finora

- Preliminary Design Chemical Plant LAB PDFDocumento9 paginePreliminary Design Chemical Plant LAB PDFgeorge cabreraNessuna valutazione finora

- Chemistry of Synthetic Dyes, 8 Volumes SetDocumento2 pagineChemistry of Synthetic Dyes, 8 Volumes SetDinesh22Nessuna valutazione finora

- Alkyd Resin PlantDocumento1 paginaAlkyd Resin PlantVarun MalhotraNessuna valutazione finora

- Zinc Stearate FinalDocumento93 pagineZinc Stearate FinalSyedMeherAli100% (1)

- CPCB - Grain Based DistilleriesDocumento37 pagineCPCB - Grain Based Distilleriesmyself_riteshNessuna valutazione finora

- CPC Blue Manufacturing ProcessDocumento21 pagineCPC Blue Manufacturing ProcessKaran Kothia100% (1)

- Siloxane DX-1708 and 1709Documento45 pagineSiloxane DX-1708 and 1709jones32Nessuna valutazione finora

- Alkyd GBDocumento2 pagineAlkyd GBAhmad HamoudaNessuna valutazione finora

- Niir Complete Technology Book On Dyes Dye IntermediatesDocumento9 pagineNiir Complete Technology Book On Dyes Dye IntermediatesAmit Kanani100% (1)

- The Earth's SubsystemsDocumento17 pagineThe Earth's SubsystemsAndevie Balili Iguana100% (1)

- Shreyas Intermediates: Key HighlightsDocumento8 pagineShreyas Intermediates: Key Highlightsnitin2khNessuna valutazione finora

- StyreneDocumento22 pagineStyreneMohd Masri A. Razak100% (1)

- Pilot Scale Fertilizer CoatingDocumento2 paginePilot Scale Fertilizer CoatingĐoàn TrangNessuna valutazione finora

- LURGI ZIMMER PolyesterPackagingTechnologyDocumento12 pagineLURGI ZIMMER PolyesterPackagingTechnologyGeorge Markas100% (1)

- Cativa BPDocumento12 pagineCativa BPGhaya Bani Rushaid100% (1)

- Carbon BlackDocumento15 pagineCarbon BlackBoonyarit Lurdgrienggraiying100% (1)

- Steam Cracking of Naphtha in Packed Bed ReactorsDocumento6 pagineSteam Cracking of Naphtha in Packed Bed Reactorscandidater100% (1)

- Fydp - Final Report - G6Documento185 pagineFydp - Final Report - G6Sanika TalathiNessuna valutazione finora

- Drum Granulator 30000TDocumento4 pagineDrum Granulator 30000TShahid LatifNessuna valutazione finora

- Fuels and Combustion 3rd EditionDocumento2 pagineFuels and Combustion 3rd EditionSajal sinha100% (1)

- OM For MES Sulfonation Plant Rev 0Documento184 pagineOM For MES Sulfonation Plant Rev 0Harits Eka FebriyantoNessuna valutazione finora

- What Are Acrylic Polymers?: MonomerDocumento8 pagineWhat Are Acrylic Polymers?: MonomerShivani UpadhyayNessuna valutazione finora

- Preliminary Report CompletedDocumento28 paginePreliminary Report CompletedJacky100% (1)

- Titanium Dioxide SynthesisDocumento204 pagineTitanium Dioxide SynthesisArif Yavuz AkartepeNessuna valutazione finora

- GFL ReportDocumento43 pagineGFL Reportmanoj singhNessuna valutazione finora

- Thesis Autosaved XDocumento77 pagineThesis Autosaved XDaniel Setyadi100% (1)

- Group Acetic Acid PresentationDocumento24 pagineGroup Acetic Acid PresentationNatko47Nessuna valutazione finora

- Flexible Low - Cost SSP TechnologyDocumento17 pagineFlexible Low - Cost SSP TechnologyQuadrant727Nessuna valutazione finora

- Chloro AlkalisDocumento20 pagineChloro AlkalisPrabhdeep Singh VirdiNessuna valutazione finora

- Aluminium SulphateDocumento21 pagineAluminium SulphateSarang BondeNessuna valutazione finora

- AosDocumento20 pagineAosHari Om Kumar VNessuna valutazione finora

- 2014 Isocyanate and Phosgene Free Routes PDFDocumento17 pagine2014 Isocyanate and Phosgene Free Routes PDFPilar MayaNessuna valutazione finora

- IT ReportDocumento29 pagineIT ReportKingsley OgbavwuduNessuna valutazione finora

- Thyrotoxic Periodic Paralysis As A Presentation of Thyrotoxicosis: A Case ReportDocumento4 pagineThyrotoxic Periodic Paralysis As A Presentation of Thyrotoxicosis: A Case ReportAdvanced Research PublicationsNessuna valutazione finora

- Multiple Symmetrical Lipomatosis With Involvement of TongueDocumento3 pagineMultiple Symmetrical Lipomatosis With Involvement of TongueAdvanced Research PublicationsNessuna valutazione finora

- Celiac Disease With Balanced TranslocationDocumento3 pagineCeliac Disease With Balanced TranslocationAdvanced Research PublicationsNessuna valutazione finora

- Turmeric - Its Applications in DentistryDocumento4 pagineTurmeric - Its Applications in DentistryAdvanced Research PublicationsNessuna valutazione finora

- Pancytopenia in Cytophagic Histiocytic PanniculitisDocumento3 paginePancytopenia in Cytophagic Histiocytic PanniculitisAdvanced Research PublicationsNessuna valutazione finora

- Different Faces of HIV in A Single Patient: Case StudyDocumento3 pagineDifferent Faces of HIV in A Single Patient: Case StudyAdvanced Research PublicationsNessuna valutazione finora

- Complete Remission in Newly Diagnosed Type 1 Diabetes Mellitus PatientDocumento3 pagineComplete Remission in Newly Diagnosed Type 1 Diabetes Mellitus PatientAdvanced Research Publications100% (1)

- An Epidemiological Cross - Sectional Comparative Study of Morbidity Profile in An Automobile Manufacturing UnitDocumento5 pagineAn Epidemiological Cross - Sectional Comparative Study of Morbidity Profile in An Automobile Manufacturing UnitAdvanced Research PublicationsNessuna valutazione finora

- Vitamin D Supplementation Improves Bone Mineral Density in Patients With HyperthyroidismDocumento7 pagineVitamin D Supplementation Improves Bone Mineral Density in Patients With HyperthyroidismAdvanced Research PublicationsNessuna valutazione finora

- Bilateral Ptosis in An Adult Following Wasp Sting With Spontaneous RecoveryDocumento3 pagineBilateral Ptosis in An Adult Following Wasp Sting With Spontaneous RecoveryAdvanced Research PublicationsNessuna valutazione finora

- Health Status Among Biscuit Factory Workers in Greater Noida, Uttar Pradesh: A Cross Sectional StudyDocumento5 pagineHealth Status Among Biscuit Factory Workers in Greater Noida, Uttar Pradesh: A Cross Sectional StudyAdvanced Research PublicationsNessuna valutazione finora

- Ultrasonography: A Cost - Effective Modality For Diagnosis of Rib Tuberculosis - A Case ReportDocumento3 pagineUltrasonography: A Cost - Effective Modality For Diagnosis of Rib Tuberculosis - A Case ReportAdvanced Research PublicationsNessuna valutazione finora

- Disaster Relief Workers: Health IssuesDocumento4 pagineDisaster Relief Workers: Health IssuesAdvanced Research PublicationsNessuna valutazione finora

- Personal Hygiene and Self-Reported Handwashing Practices Among Food Handlers of A Medical College in DelhiDocumento6 paginePersonal Hygiene and Self-Reported Handwashing Practices Among Food Handlers of A Medical College in DelhiAdvanced Research PublicationsNessuna valutazione finora

- A Study On Needle Sticks Injury Among Nursing Staff of A Tertiary Care Hospital of HaryanaDocumento5 pagineA Study On Needle Sticks Injury Among Nursing Staff of A Tertiary Care Hospital of HaryanaAdvanced Research PublicationsNessuna valutazione finora

- Quality Traits in Cultivated Mushrooms and Consumer AcceptabilityDocumento40 pagineQuality Traits in Cultivated Mushrooms and Consumer AcceptabilityShivendra SinghNessuna valutazione finora

- Need For Advanced Suspension SystemsDocumento10 pagineNeed For Advanced Suspension SystemsIQPC GmbHNessuna valutazione finora

- Topik 3 - Hazard Di Air Selangor, Penilaian Risiko Langkah Kawalan Rev1 2020 090320Documento59 pagineTopik 3 - Hazard Di Air Selangor, Penilaian Risiko Langkah Kawalan Rev1 2020 090320Nuratiqah SmailNessuna valutazione finora

- North Central Mindanao College: Maranding, Lala, Lanao Del NorteDocumento8 pagineNorth Central Mindanao College: Maranding, Lala, Lanao Del NorteAnalyn FielNessuna valutazione finora

- Neuropsychological Performance in Neurofibromatosis Type 1: Original ArticleDocumento5 pagineNeuropsychological Performance in Neurofibromatosis Type 1: Original ArticleRaquel DuarteNessuna valutazione finora

- Feasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofDocumento9 pagineFeasibility Study On The Seaweed Kappaphycus Alvarezii Cultivation Site in Indari Waters ofUsman MadubunNessuna valutazione finora

- Joseph Conrad - Heart of DarknessDocumento86 pagineJoseph Conrad - Heart of DarknessCaztor SscNessuna valutazione finora

- DUPIXENT Doctor Discussion GuideDocumento4 pagineDUPIXENT Doctor Discussion GuideTAP THANH CHAUNessuna valutazione finora

- MetDocumento41 pagineMetadityaNessuna valutazione finora

- Etl 213-1208.10 enDocumento1 paginaEtl 213-1208.10 enhossamNessuna valutazione finora

- ZW250-7 BROCHURE LowresDocumento12 pagineZW250-7 BROCHURE Lowresbjrock123Nessuna valutazione finora

- Video Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabDocumento1 paginaVideo Tutorials of Read and Write Seagate F3 Series HDDs by MRT - MRT LabBusur DataNessuna valutazione finora

- BCSL 058 Previous Year Question Papers by IgnouassignmentguruDocumento45 pagineBCSL 058 Previous Year Question Papers by IgnouassignmentguruSHIKHA JAINNessuna valutazione finora

- DLP Physical Science Week1Documento2 pagineDLP Physical Science Week1gizellen galvezNessuna valutazione finora

- Spina 2002Documento10 pagineSpina 2002hasantapNessuna valutazione finora

- BiPAP ST Clinical ManualDocumento37 pagineBiPAP ST Clinical ManualEng. Edelson Martins100% (2)

- EU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Documento60 pagineEU - Guidance On GMP For Food Contact Plastic Materials and Articles (60p)Kram NawkNessuna valutazione finora

- Introduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesDocumento65 pagineIntroduction: Science and Environment: Brgy - Pampang, Angeles City, PhilippinesLance AustriaNessuna valutazione finora

- Chapter 5 TEstDocumento18 pagineChapter 5 TEstJeanneau StadegaardNessuna valutazione finora

- Problem-Based Learning ReportDocumento24 pagineProblem-Based Learning Reporterdayu86Nessuna valutazione finora

- Practical 3.1 Determining The Specific Heat CapacityDocumento3 paginePractical 3.1 Determining The Specific Heat CapacityiAlex11Nessuna valutazione finora

- ESM-4810A1 Energy Storage Module User ManualDocumento31 pagineESM-4810A1 Energy Storage Module User ManualOscar SosaNessuna valutazione finora

- Unemployment in IndiaDocumento9 pagineUnemployment in IndiaKhushiNessuna valutazione finora

- DoomsdayDocumento29 pagineDoomsdayAsmita RoyNessuna valutazione finora

- Biochem Acids and Bases Lab ReportDocumento4 pagineBiochem Acids and Bases Lab ReportShaina MabborangNessuna valutazione finora