Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

United States Patent (19) : Hermanns

Caricato da

Ivan Reyes0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni3 pagineTitolo originale

US3802743.pdf

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

31 visualizzazioni3 pagineUnited States Patent (19) : Hermanns

Caricato da

Ivan ReyesCopyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 3

United States Patent (19)

Hermanns (ii) 3,802,743

(45) Apr. 9, 1974

54) VARIABLE DIAMETER WHEEL 2,765, 199 10/1956 Partin........... r 301/47

76 Inventor: William H. Hermanns, clo George FOREIGN PATENTS OR APPLICATIONS

Spector 3615, Woolworth Building, 422,841 4/1925 Germany.............................. 301/46

233 Broadway, Tampa, Fla. 10007 9,385 10, 1912 Great Britain....... ... 52/55

22 Filed: Apr. 17, 1972 38,641 7/1902 . France................. ... 301/5 R

326,048 i? 1958 Switzerland............ . . . . . . . . . . . 301147

(21) Appl. No.: 244,456

Primary Examiner-Kenneth H. Betts

52 U.S. Cl....................... 301/5 R, 152/55, 30 1116 Assistant Examiner-Reinhard J. Eisenzopf

(5) Int. Cl............................................. B60b 19/04 Attorney, Agent, or Firm-Stein, Orman & Fisher

58) Field of Search........... 30 1/5 R, 16, 46, 47,50;

152/55 (57) ABSTRACT

A wheeled vehicle is provided with a plurality of

56) References Cited wheels, each wheel being provided with separately ac

UNITED STATES PATENTS tuatable means for varying the diameter between two

489.446 1/1893 Anderson............................ 301/5 R fixed values, one small, the other large. Through the

756,290 4/1904 Sayer.................................. 301/5 R use of separately adjustable wheels the vehicle can tra

3,358,634 121 1967. Pratt... ... 305/34 verse uneven surfaces such as steep hills and valleys

1,787,608 11193 l Ansell..... ... 301147 without tilting or tipping.

t,980,314 - 1 1/1934 Barreres................................ 301/16 4 Claims, 3 Drawing Figures

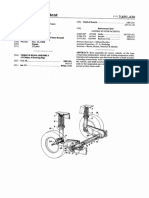

PATENTED PR 917 3,802,743

1.

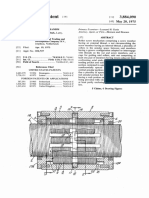

3,802,743 2

VARIABLE DIAMETER WHEEL plates 34 attached to an inner side of wheel rim seg

SUMMARY OF THE INVENTION ments 16.

Upon the outer side of the wheel rim segments 16,

Each wheel has a hub with a plurality of spokes ex there are bolted a plurality of rubber traction pads 36,

tending radially outward therefrom in a common verti in spaced apart relation, as shown in FIG. 3.

cal plane in equidistantly spaced positions. Each spoke The resulting wheel can have its diameter varied as

takes the form with a hydraulic cylinder with a piston previously described.

therein that can be moved between withdrawn and ex FIG. 2 shows a vehicle 26 having one wheel of large

tended positions. The pistons have free ends remotely diameter and an opposite wheel or smaller diameter

disposed from the hub and extending out of the cylin O whereby it can move in level position on a hill or the

ders. A plurality of circular segments are disposed pe like.

ripherally about the pistons and are secured either to I claim as follows:

the ends or to members connected to these ends. When 1. A variable diameter wheel of the type designed to

the pistons are fully extended the segments are spaced be incrementally retractable from a first diameter to a

from each other but are disposed along a circle having 15 second, concentric, smaller diameter and expandable

a first diameter. When the pistons are withdrawn, the from said second diameter to said first diameter, said

segments are spaced from each other but by smaller wheel comprising: a plurality of first spokes equidis

distances and are disposed along a circle having a sec tantly attached about the periphery of a hub and ex

ond and smaller diameter. Thus, the diameter of the tending radially outward therefrom in a common plane;

wheel can be adjusted as required. Hydraulic fluid, 20 a corresponding plurality of second spokes equidis

under the control of a manually operable valve, flows tantly attached in alternating arrangement with said

through the hub to the cylinders to determine the pis first spokes about said periphery of said hub and ex

ton positions and hence the wheel diameter. tending radially outward therefrom in said common

plane, said second spokes being of a predetermined les

BRIEF DESCRIPTION OF THE DRAWINGS 25 ser longitudinal dimension than said first spokes; sup

FIG. 1 is a side view of my wheel; and port means comprising a circle attached to said first

FIG. 2 is an end view of a vehicle in use employing and second spokes at a predetermined distance from

my wheels. FIG. 3 is an enlarged detail of the structure said hub, whereby said first and second spokes are sup

shown in FIG. 1 and shown in the same plane. ported in fixed equidistant relation to one another; a

DETAILED DESCRIPTION OF PREFERRED 30 plurality of circular segments including wear plates at

EMBODIMENT tached to the concave sides thereof disposed in spaced

apart relation along a circle of said first diameter and

Referring now to FIG. 1, a plurality of hydraulic cyl attached at their midpoints to the outer extremity of

inders 10 extend radially outward from a central hub said first spokes; a plurality of reinforcing means at

12 in a common vertical plane in equidistantly spaced 35 tached to the outer extremity of said second spokes and

positions. These cylinders each contain a separate pis abutting the concave surfaces of two of said wear plates

ton. Each cylinder and piston defines a spoke in a adjacent each other; and hydraulic means connected to

wheel. Each piston has a free end extending out of its said first and second spokes to vary the length of said

cylinder remote from the hub. Each piston has a with first and second spokes, whereby the length of said

drawn position (shown in solid line of FIG. 1) and an 40 spokes determines which of said diameters is defined

extended position (shown in phantom in FIG. 1). These by said segments.

spokes have two different lengths as shown at 14A 2. A wheel as in claim 1 wherein said first and second

(first spoke) and 14B (second spoke) and alternate in spokes comprise an hydraulic cylinder including a pis

position with each adjacent pair of spokes of one length ton mounted therein, said piston including a free end

being separated by a spoke of the other length. The 45 comprising said outer extremity of said first and second

spokes are supported by circle 24. spokes extending out of said cylinder remotely from

A plurality of circular segments 16 lie along the path said hub.

of either a first diameter circle shown in phantom at 18 3. A wheel as in claim 2 wherein said reinforcing

or a second diameter circle shown in solid line at 20. means comprise substantially triangular gussets at

In both cases the segments are separated from each 50 tached at their apex to said free ends of said second

other, the separation decreasing with decreasing circle spokes, said gussets further including a rolled plate se

S2. cured to the convex outer edge thereof and a checker

Each second piston extends into a space between ad type plate fastened to the convex outer face of said

jacent segments 16. Each first piston is connected di rolled plate, whereby said checker type plate abuts the

rectly to the center of a corresponding segment. 55 concave surfaces of two of said wear plates adjacent

As shown in greater detail in FIG. 3, it is to be noted each other.

that the spokes 14A are at their outward ends con 4. A wheel as in claim 2 wherein said circular seg

nected to gussets 28 welded to rolled plates 30. A ments further include traction treads formed of elastic

checker type wear plate 32 is bolted to plate 30; the material attached to the convex surface thereof.

wear plate 32 being in face to face alignment with wear 60 k k k :

65

Potrebbero piacerti anche

- Scientific American Supplement, No. 441, June 14, 1884.Da EverandScientific American Supplement, No. 441, June 14, 1884.Nessuna valutazione finora

- US2099314Documento3 pagineUS2099314Jhonnatan E Avendaño Florez100% (1)

- Us 3601426 RearDocumento4 pagineUs 3601426 Rearanup tiwariNessuna valutazione finora

- Dec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetDocumento6 pagineDec. 5, 1967 Hiroshi Utashiro Eta.L 3,355,922: Filed Sept. 28, 1965 2 Sheets-SheetEstebanPortilloNessuna valutazione finora

- United States PatentDocumento10 pagineUnited States PatentАлександр ПалюNessuna valutazione finora

- US4335764Documento7 pagineUS4335764Jorge ArbelaezNessuna valutazione finora

- My Attorneys: Feb. 18, 1969 J. Britt EtalDocumento4 pagineMy Attorneys: Feb. 18, 1969 J. Britt EtalBa1313yNessuna valutazione finora

- Us 2543888Documento5 pagineUs 2543888Juan Sebastian PrietoNessuna valutazione finora

- US Patent 3884090Documento5 pagineUS Patent 3884090sthollanderNessuna valutazione finora

- US5186686Documento11 pagineUS5186686雷黎明Nessuna valutazione finora

- United States Patent: (45) July 4, 1972Documento4 pagineUnited States Patent: (45) July 4, 1972Lidya SimatupangNessuna valutazione finora

- United States Patent (191: Sullivan Et A1Documento21 pagineUnited States Patent (191: Sullivan Et A1fghdfjerNessuna valutazione finora

- Reverse Energy Bow Patent US 7743760 B2Documento8 pagineReverse Energy Bow Patent US 7743760 B2DoukhoborNessuna valutazione finora

- US4893426Documento7 pagineUS4893426Jean DelaronciereNessuna valutazione finora

- Patent USPTO 4098523 Traction DeviceDocumento5 paginePatent USPTO 4098523 Traction Devicexeron7126Nessuna valutazione finora

- US3782337Documento7 pagineUS3782337Mustafa Umut SaracNessuna valutazione finora

- United States Patent (19) : Primary Examiner-Samuel ScottDocumento7 pagineUnited States Patent (19) : Primary Examiner-Samuel ScottRockerss RockerssNessuna valutazione finora

- BY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Documento2 pagineBY 4W1?" Mal/MM : July 4, 1957 A. Roque V 3,329,192Namelezz ShadowwNessuna valutazione finora

- Honing ToolDocumento3 pagineHoning ToolKyle YsitNessuna valutazione finora

- Nov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Documento3 pagineNov. 18, 1969 H, I, Hans EN 3,478,972: Filed Aug. 27, 1965Karin AndersonNessuna valutazione finora

- Us 3075777Documento8 pagineUs 3075777Vijayakumar G VNessuna valutazione finora

- (12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Documento13 pagine(12 Ulllted States Patent (10) Patent No.: US 6,860,188 B2Selvaraji MuthuNessuna valutazione finora

- Sept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetDocumento4 pagineSept. 16, 1969 J. Marcovc-3,466,911: Filed Day L, 1967 2 Sheets-SheetLucas RaithsNessuna valutazione finora

- Us4173933 PDFDocumento10 pagineUs4173933 PDFRizki Fajar NovantoNessuna valutazione finora

- US1952501 Drum WeirDocumento12 pagineUS1952501 Drum WeirSlađana RadovanovićNessuna valutazione finora

- Get. 15, 1968 J. A. Gregoire 3,405,901: Filed July 5, 1966 3 Sheets-Sheet LDocumento6 pagineGet. 15, 1968 J. A. Gregoire 3,405,901: Filed July 5, 1966 3 Sheets-Sheet LFercon DocenciaNessuna valutazione finora

- Project ASSEMBLYDocumento5 pagineProject ASSEMBLYfachrifadlurrohman8Nessuna valutazione finora

- A. E. Jones: Filed March 20, 1924 2 Sheets-SheetDocumento5 pagineA. E. Jones: Filed March 20, 1924 2 Sheets-SheetRinnoNessuna valutazione finora

- Us4252504 PDFDocumento7 pagineUs4252504 PDFAhmed EltemsahNessuna valutazione finora

- US2125697Documento3 pagineUS2125697davarniyaalirezasepehrelectricNessuna valutazione finora

- "A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Documento7 pagine"A1.h.. May,: June 4, 1929. A. B. Kerr 1,715,929Guillermo Avila RiveraNessuna valutazione finora

- Us 3090578Documento3 pagineUs 3090578mohamad zareNessuna valutazione finora

- Patented May 27, 1919.: S. H. GarstDocumento4 paginePatented May 27, 1919.: S. H. GarstKrozeNessuna valutazione finora

- Nun M.: BC BM 0000Documento12 pagineNun M.: BC BM 0000shdhsjkNessuna valutazione finora

- Us1955360 PDFDocumento8 pagineUs1955360 PDFRodrigoPomaNessuna valutazione finora

- Benelli B76 US3893369Documento4 pagineBenelli B76 US3893369apoorva singhNessuna valutazione finora

- WWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANDocumento6 pagineWWW VMQ, I07: Feb. 12, 1963 v. C. BOWMANRodrigoPomaNessuna valutazione finora

- FLEX BEAM Bell 206Documento7 pagineFLEX BEAM Bell 206Lewis MarcvsNessuna valutazione finora

- United States PatentDocumento7 pagineUnited States Patentmohammad dehghanfarsiNessuna valutazione finora

- Berthier Us1366863Documento9 pagineBerthier Us1366863cll1968Nessuna valutazione finora

- Us 4909638Documento7 pagineUs 4909638Rohan KulkarniNessuna valutazione finora

- United States Patent (19) : TinkerDocumento12 pagineUnited States Patent (19) : TinkerJoel AndradeNessuna valutazione finora

- EP000001582377A1Documento10 pagineEP000001582377A1임학진Nessuna valutazione finora

- T Red.: 3. Sheets-Sheet LDocumento6 pagineT Red.: 3. Sheets-Sheet LThyagaraj A HNessuna valutazione finora

- 枪炮声抑制器 PDFDocumento11 pagine枪炮声抑制器 PDFJin SongNessuna valutazione finora

- Us 2120533asfafafDocumento5 pagineUs 2120533asfafafankitsarvaiyaNessuna valutazione finora

- Us5221379 PDFDocumento8 pagineUs5221379 PDFdfus603Nessuna valutazione finora

- US3982767Documento6 pagineUS3982767takanobu ouraNessuna valutazione finora

- US3404552Documento4 pagineUS3404552Prabal JindalNessuna valutazione finora

- Filed Oct. 22, 1951: P. C. HuttonDocumento5 pagineFiled Oct. 22, 1951: P. C. HuttonGalo YambayNessuna valutazione finora

- US2228469Documento4 pagineUS2228469George AcostaNessuna valutazione finora

- United States Patent (19) : Filed: July 27, 1976 57Documento3 pagineUnited States Patent (19) : Filed: July 27, 1976 57Alexandre Magno Bernardo FontouraNessuna valutazione finora

- US20110274550A1Documento9 pagineUS20110274550A1雷黎明Nessuna valutazione finora

- Siled Sept. 8, 1966: T, N. NccomeDocumento5 pagineSiled Sept. 8, 1966: T, N. NccomeliNessuna valutazione finora

- Multi-Vane Expanders-Geometry and Vane Kinematics - BadrDocumento24 pagineMulti-Vane Expanders-Geometry and Vane Kinematics - BadrTodd StevensNessuna valutazione finora

- US4707035Documento5 pagineUS4707035aungkyawzoreNessuna valutazione finora

- NOV-9, 1943. A. Ca. Schneider: Planetary Turbine TransmissionDocumento6 pagineNOV-9, 1943. A. Ca. Schneider: Planetary Turbine Transmissionbelchior alvaroNessuna valutazione finora

- July 4, 1950 E. L. Masters 2,53,810: Filed April 10, 1946 2 Sheets-SheetDocumento5 pagineJuly 4, 1950 E. L. Masters 2,53,810: Filed April 10, 1946 2 Sheets-SheetVijayakumar G VNessuna valutazione finora

- Berthier Us1446635Documento12 pagineBerthier Us1446635cll19680% (1)

- March 26, 1957:1. - RUSSELL 2,786,361 Gimbal MechanismsDocumento2 pagineMarch 26, 1957:1. - RUSSELL 2,786,361 Gimbal MechanismsjemanuelvNessuna valutazione finora

- Us6821294 PDFDocumento30 pagineUs6821294 PDFIvan ReyesNessuna valutazione finora

- Us8678520 PDFDocumento18 pagineUs8678520 PDFIvan ReyesNessuna valutazione finora

- Us3128829 PDFDocumento13 pagineUs3128829 PDFIvan ReyesNessuna valutazione finora

- Us3006208 PDFDocumento4 pagineUs3006208 PDFIvan ReyesNessuna valutazione finora

- RoemheldDocumento20 pagineRoemheldIvan ReyesNessuna valutazione finora

- United States: (12) Patent Application Publication (10) Pub. No.: US 2013/0299636 A1Documento8 pagineUnited States: (12) Patent Application Publication (10) Pub. No.: US 2013/0299636 A1Ivan ReyesNessuna valutazione finora

- Solution Document For Link LoadBalancerDocumento10 pagineSolution Document For Link LoadBalanceraralNessuna valutazione finora

- Sultan Omar Ali Saifuddin IIIDocumento14 pagineSultan Omar Ali Saifuddin IIISekolah Menengah Rimba100% (3)

- ESS Revision Session 2 - Topics 5-8 & P1 - 2Documento54 pagineESS Revision Session 2 - Topics 5-8 & P1 - 2jinLNessuna valutazione finora

- Odisha Block Summary - NUAGAONDocumento8 pagineOdisha Block Summary - NUAGAONRohith B.NNessuna valutazione finora

- AFI 90-901 Operational Risk ManagementDocumento7 pagineAFI 90-901 Operational Risk ManagementJohan Lai100% (1)

- Baixar Livro Draw With Jazza Creating Characters de Josiah Broo PDFDocumento5 pagineBaixar Livro Draw With Jazza Creating Characters de Josiah Broo PDFCarlos Mendoza25% (4)

- 2011 06 13-DI-PER8-Acoustic Insulation Catalogue-Rev 01Documento12 pagine2011 06 13-DI-PER8-Acoustic Insulation Catalogue-Rev 01Tien PhamNessuna valutazione finora

- Laws and Policies of Fertilizers SectorDocumento12 pagineLaws and Policies of Fertilizers Sectorqry01327Nessuna valutazione finora

- Air Microbiology 2018 - IswDocumento26 pagineAir Microbiology 2018 - IswOktalia Suci AnggraeniNessuna valutazione finora

- DB - Empirically Based TheoriesDocumento3 pagineDB - Empirically Based TheoriesKayliah BaskervilleNessuna valutazione finora

- PEDIA OPD RubricsDocumento11 paginePEDIA OPD RubricsKylle AlimosaNessuna valutazione finora

- Harlem Renaissance LiteratureDocumento2 pagineHarlem Renaissance LiteratureSylvia Danis100% (1)

- DODGER: Book Club GuideDocumento2 pagineDODGER: Book Club GuideEpicReadsNessuna valutazione finora

- 2-Emotional Abuse, Bullying and Forgiveness Among AdolescentsDocumento17 pagine2-Emotional Abuse, Bullying and Forgiveness Among AdolescentsClinical and Counselling Psychology ReviewNessuna valutazione finora

- Mythologia: PrologueDocumento14 pagineMythologia: ProloguecentrifugalstoriesNessuna valutazione finora

- Steps For Copyright ApplicationDocumento7 pagineSteps For Copyright ApplicationLeah MedenillaNessuna valutazione finora

- PDF - Unpacking LRC and LIC Calculations For PC InsurersDocumento14 paginePDF - Unpacking LRC and LIC Calculations For PC Insurersnod32_1206Nessuna valutazione finora

- Trainee'S Record Book: Technical Education and Skills Development Authority (Your Institution)Documento17 pagineTrainee'S Record Book: Technical Education and Skills Development Authority (Your Institution)Ronald Dequilla PacolNessuna valutazione finora

- Lunch Hour Meetings: Kiwanis Mission:: - Officers & Directors, 2018-2019Documento2 pagineLunch Hour Meetings: Kiwanis Mission:: - Officers & Directors, 2018-2019Kiwanis Club of WaycrossNessuna valutazione finora

- Directory of Schools For The Deaf in The PhilippinesDocumento6 pagineDirectory of Schools For The Deaf in The PhilippinesVERA Files100% (1)

- Determination of Physicochemical Pollutants in Wastewater and Some Food Crops Grown Along Kakuri Brewery Wastewater Channels, Kaduna State, NigeriaDocumento5 pagineDetermination of Physicochemical Pollutants in Wastewater and Some Food Crops Grown Along Kakuri Brewery Wastewater Channels, Kaduna State, NigeriamiguelNessuna valutazione finora

- Student Management System - Full DocumentDocumento46 pagineStudent Management System - Full DocumentI NoNessuna valutazione finora

- Comparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Documento12 pagineComparing Effect of Adding LDPE, PP, PMMA On The Mechanical Properties of Polystyrene (PS)Jawad K. OleiwiNessuna valutazione finora

- University of Engineering & Management, Jaipur: (A) Production (B) Quality (C) Product Planning (D) All of The AboveDocumento4 pagineUniversity of Engineering & Management, Jaipur: (A) Production (B) Quality (C) Product Planning (D) All of The AboveSupriyo BiswasNessuna valutazione finora

- Tutorial Class 4: Finders As Bailee Right of A Bailee General LienDocumento26 pagineTutorial Class 4: Finders As Bailee Right of A Bailee General Lienchirag jainNessuna valutazione finora

- Sycip v. CA (Sufficient Funds With The Drawee Bank)Documento15 pagineSycip v. CA (Sufficient Funds With The Drawee Bank)Arnold BagalanteNessuna valutazione finora

- Sleep and Dreams PDFDocumento16 pagineSleep and Dreams PDFMarina Los100% (1)

- The Rescue Agreement 1968 (Udara Angkasa)Documento12 pagineThe Rescue Agreement 1968 (Udara Angkasa)Rika Masirilla Septiari SoedarmoNessuna valutazione finora

- Modul9 VPNDocumento34 pagineModul9 VPNDadang AbdurochmanNessuna valutazione finora

- Forensic BallisticsDocumento23 pagineForensic BallisticsCristiana Jsu DandanNessuna valutazione finora