Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

UT Inspection For Plate Lamination On Sample Supplied From Maui Pipeline Failure

Caricato da

bacabacabacaDescrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

UT Inspection For Plate Lamination On Sample Supplied From Maui Pipeline Failure

Caricato da

bacabacabacaCopyright:

Formati disponibili

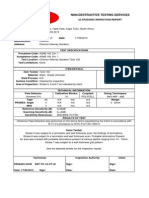

Quest Integrity NZL Limited

69 Gracefield Road

PO Box 38-096

Reference: 102274.08 Vector document 1166

Lower Hutt : New Zealand 5045

T +64 4 978 6630

Attention: A. Woodger, M. Webb, G. Wilson

F +64 4 978 9930

Organisation: Vector Gas Limited E info@QuestIntegrity.com

Private Bag

New Plymouth

Confidentiality: Confidential to Vector

E-Mail Address: Andrew Woodger [Andrew.Woodger@vector.co.nz]

Mark Webb [Mark.Webb@vector.co.nz]

Grant Wilson [Grant.Wilson@vector.co.nz]

From: David Firth

Checked by: Stephen Rowbotham

Date: 26 March 2012

Subject: UT inspection for plate lamination on sample supplied from Maui pipeline

failure at White Cliffs

1. Introduction

Quest Integrity NZL Limited (Quest Integrity) have been asked to provide Vector Gas Limited

(Vector) with expert advice concerning a linepipe which failed in service, in particular the

metallurgical properties of the linepipe, in order that Vector can assess the cause of the damage to

the pipeline. This work forms part of information being gathered by Vector and Maui Development

Limited (MDL).

Three samples of pipeline were supplied by Vector on 21 December 2011 for examination. The

three sections supplied were part of the samples removed from the failure of the Maui pipeline at

White Cliffs.

The pipe was reported to have been purchased in accordance with API 5LX for Grade X65

X:/102274.08 Report Issued 26 March 2012 Page 1 of 2

Ultrasonic Inspection

(19th Edition) with the additional requirements of Ministry of Works and Development (MWD)

specification “Maui Project Oaonui to Auckland pipeline supply of High test line pipe - Pipe

specification” section A530 “Ultrasonic Examination of Plate”.

API 5LX (20th Edition) covers the inspection for lamination in the areas adjacent to the ends of the

line pipe. It states in section 8.7 a “Laminations extending into the face or bevel of the pipe and

having a transverse dimension exceeding 1/4 in (6,35mm) are considered injurious defects.” The

inspection process is not defined.

Clause A530 of MWD specification covers ultrasonic examination of plate for laminations next to

the longitudinal edges prior to welding. This deemed the plate acceptable if there are no

laminations present > 15mm in length or width next to the longitudinal edge or no laminations away

from the longitudinal edge with a length >200mm or width >15mm.

A series of inspection and test plans were agreed, see Vector Document 1147. This report covers

the ultrasonic testing of the pipe base material for laminations as originally required by the MWD

specification.

2. Ultrasonic testing procedure and personnel

The following was used to complete the ultrasonic testing:

Panametric 36DL Plus UT thickness tester with A Scan.

Probe D790 SM 50MHZ 30/36 – 90 degrees to the surface.

The testing was completed on 19 March 2012, by David Firth (B Met). David has 30 years

experience as a consultant metallurgist.

3 Results of inspection

Two bands about 100-150mm wide along the length of the failed sample (1500 to 2100mm) were

scanned. These bands were either side of the seam weld in locations away from the buckled

region.

The possible presence of significant laminations in the pipe material was assessed by viewing the

“A” scan and detecting ultrasonic reflections other than “normal” back wall echo. No evidence of

any laminations was detected. As a result the section of line pipe examined met the requirements

of the MWD specification and the limits of the API 5LX code related to laminations.

X:/102274.08 Report Issued 26 March 2012 Page 2 of 2

Potrebbero piacerti anche

- Ut Contact Ultrasonics Angle BeamDocumento47 pagineUt Contact Ultrasonics Angle Beamtony blas cristobalNessuna valutazione finora

- 23 GinzelDocumento12 pagine23 Ginzelmusaismail8863Nessuna valutazione finora

- Formed Metal - Al Plate UT1 PictorialDocumento3 pagineFormed Metal - Al Plate UT1 PictorialSiggy LaiNessuna valutazione finora

- Welds Written ReportDocumento4 pagineWelds Written ReportChris Paulo100% (1)

- Ultrasonic Testing (Ut) : Level IiDocumento24 pagineUltrasonic Testing (Ut) : Level IiAhmed El MorsyNessuna valutazione finora

- Back Up Roll UTDocumento5 pagineBack Up Roll UTkinglordofatoNessuna valutazione finora

- UT3Documento115 pagineUT3Nikhil KashyapNessuna valutazione finora

- Nondestructive Examination (NDE) Technology and Codes Student Manual Introduction To Ultrasonic ExaminationDocumento78 pagineNondestructive Examination (NDE) Technology and Codes Student Manual Introduction To Ultrasonic ExaminationRaj KumarNessuna valutazione finora

- Ue Evaluation & InterpretationDocumento39 pagineUe Evaluation & InterpretationVaraGoudNessuna valutazione finora

- Lecture 18-UTDocumento50 pagineLecture 18-UTsamrn850% (2)

- TestingDocumento18 pagineTestingVivekanandan JNessuna valutazione finora

- Formed Metal - Al Extrusion UT1Documento3 pagineFormed Metal - Al Extrusion UT1Siggy LaiNessuna valutazione finora

- Formed Metal - Round Bar UT2Documento4 pagineFormed Metal - Round Bar UT2Siggy LaiNessuna valutazione finora

- Exit Point AngleDocumento1 paginaExit Point Anglenaiyar alamNessuna valutazione finora

- Introduction To Magnetic Particle TestingDocumento58 pagineIntroduction To Magnetic Particle TestingjerryceppyNessuna valutazione finora

- Line Pipe InspectionDocumento98 pagineLine Pipe InspectionBWQNessuna valutazione finora

- Nondestructive Examinations: Standard Terminology ForDocumento39 pagineNondestructive Examinations: Standard Terminology Forcatalina mazoNessuna valutazione finora

- STRUCTURE OF MATERIALS - The Key To Its Properties PDFDocumento66 pagineSTRUCTURE OF MATERIALS - The Key To Its Properties PDFRaafeymohammed khanNessuna valutazione finora

- Ultrasonic TestingDocumento36 pagineUltrasonic TestingMuhammad Rahim UsmanNessuna valutazione finora

- NDT Test Report NTP PDFDocumento6 pagineNDT Test Report NTP PDFwawan kusnandar100% (1)

- Ut Defect AssessementDocumento48 pagineUt Defect AssessementKarthikeyan Shanmugavel0% (1)

- Digital Ultrasonic Flaw Detectors For Curved SurfaceDocumento11 pagineDigital Ultrasonic Flaw Detectors For Curved Surfaceiprao0% (1)

- Handout Ultrasonic Testing Level II - Rev. 1 - 12 May 2010Documento185 pagineHandout Ultrasonic Testing Level II - Rev. 1 - 12 May 2010deari nur azisNessuna valutazione finora

- NDT Basic PresentationDocumento207 pagineNDT Basic PresentationIvan AgurtoNessuna valutazione finora

- Introduction of NDT UltrasonicDocumento8 pagineIntroduction of NDT Ultrasonicfarez77Nessuna valutazione finora

- 8.1 UT Lecture-Defect Sizing and EvaluationDocumento24 pagine8.1 UT Lecture-Defect Sizing and EvaluationNikhil KashyapNessuna valutazione finora

- Conventional UT (Pulse Echo)Documento15 pagineConventional UT (Pulse Echo)vcpNessuna valutazione finora

- UT LEVEL-2 Part-1Documento458 pagineUT LEVEL-2 Part-1கோகுல் இராNessuna valutazione finora

- Adapting CSA W59 Ultrasonic Inspections For Use With Distance Amplitude Techniques Holloway Crawford Keay VaidyaDocumento19 pagineAdapting CSA W59 Ultrasonic Inspections For Use With Distance Amplitude Techniques Holloway Crawford Keay VaidyaTerfaia NadjatNessuna valutazione finora

- Spacetec Certification Readiness Course: Materials and Processes I & IiDocumento68 pagineSpacetec Certification Readiness Course: Materials and Processes I & IiB.SATHISH KUMARNessuna valutazione finora

- Ultrasonic Test Procedure1Documento8 pagineUltrasonic Test Procedure1MHDNessuna valutazione finora

- UT Testing Add01a Equipment CalibrationsDocumento97 pagineUT Testing Add01a Equipment CalibrationsdebduttamallikNessuna valutazione finora

- Ultrasonic Testing (UT) : The Engineers Edge Institute of NDTDocumento83 pagineUltrasonic Testing (UT) : The Engineers Edge Institute of NDTThe Engineers EDGE, CoimbatoreNessuna valutazione finora

- Inspection Trends (January 2013 Vol. 16 No. 1)Documento28 pagineInspection Trends (January 2013 Vol. 16 No. 1)Patrick DominguezNessuna valutazione finora

- Supervisory Development Programme-I (SDP-I) Topic: Non Destructive Testing (NDT) Faculty: Naveen SethDocumento20 pagineSupervisory Development Programme-I (SDP-I) Topic: Non Destructive Testing (NDT) Faculty: Naveen SethvcpNessuna valutazione finora

- Weld - Tee Weld Csa w59 Aws d1Documento5 pagineWeld - Tee Weld Csa w59 Aws d1Siggy LaiNessuna valutazione finora

- NDT Xl-Ut-05.1 Babbit QualityDocumento7 pagineNDT Xl-Ut-05.1 Babbit QualityRon KentNessuna valutazione finora

- Ut 2Documento7 pagineUt 2Akhilesh KumarNessuna valutazione finora

- RT Pratical Exam FormulasDocumento2 pagineRT Pratical Exam FormulasKartik SharmaNessuna valutazione finora

- Whitepaper NDT Pulsed Eddy Current Whitepaper TUV Rheinland PDFDocumento9 pagineWhitepaper NDT Pulsed Eddy Current Whitepaper TUV Rheinland PDFMohammed HassanNessuna valutazione finora

- Compilation of UT TestDocumento34 pagineCompilation of UT TestAlex RaleighNessuna valutazione finora

- Ut of Austenitic WeldsDocumento46 pagineUt of Austenitic Weldslinhcdt3100% (1)

- Ultrasonic Crack Depth Measurement of Surface Bracking Cracks in PipingDocumento8 pagineUltrasonic Crack Depth Measurement of Surface Bracking Cracks in Pipingcal2_uniNessuna valutazione finora

- Ruukki Hot Rolled Steels Ultrasonic Testing 2011 PDFDocumento5 pagineRuukki Hot Rolled Steels Ultrasonic Testing 2011 PDFpvdang8453Nessuna valutazione finora

- What Is NDT ?: Detection of Damage Before BreakdownDocumento40 pagineWhat Is NDT ?: Detection of Damage Before BreakdownAnik hasan BadhonNessuna valutazione finora

- 6dB SizingDocumento1 pagina6dB SizingJeevanandam ShanmugasundaramNessuna valutazione finora

- Weld DiscontinuityDocumento61 pagineWeld DiscontinuityEKKACHAI PRABNAKORN0% (1)

- Solution of 5817 Standard PDFDocumento37 pagineSolution of 5817 Standard PDFRajesh KumarNessuna valutazione finora

- ATT MT-2.0 Rev. 1 ProcedureDocumento13 pagineATT MT-2.0 Rev. 1 ProcedurewalitedisonNessuna valutazione finora

- Formed Metal - Round Bar UT2Documento4 pagineFormed Metal - Round Bar UT2Siggy LaiNessuna valutazione finora

- Srut GWDocumento2 pagineSrut GWNour MasmoudiNessuna valutazione finora

- Ultrasound Basic: Manual UT Principal & WorkingDocumento65 pagineUltrasound Basic: Manual UT Principal & WorkingVarun DubeyNessuna valutazione finora

- Ultrasonic Examination ProcedureDocumento10 pagineUltrasonic Examination ProcedureJake SparrowNessuna valutazione finora

- Chap 9-SMAW Beads Fillet WeldsDocumento47 pagineChap 9-SMAW Beads Fillet WeldsSally Java SenayoNessuna valutazione finora

- Formulas For Ultrasonic Nondestructive TestingDocumento3 pagineFormulas For Ultrasonic Nondestructive TestingdhasdjNessuna valutazione finora

- RITC (Pty) LTD: Non-Destructive Testing ServicesDocumento1 paginaRITC (Pty) LTD: Non-Destructive Testing Servicesjacobus_louw4329Nessuna valutazione finora

- 13 - Piping Sample ReportDocumento5 pagine13 - Piping Sample ReportS Surya Dharma100% (3)

- Wallis Earthing & Lightning Protection Systems CatalogueDocumento120 pagineWallis Earthing & Lightning Protection Systems CatalogueRelief_EngineerNessuna valutazione finora

- Negotino Cable Factory CatalogueDocumento125 pagineNegotino Cable Factory CatalogueRejnald ZyfiNessuna valutazione finora

- Matest C380Documento1 paginaMatest C380bacabacabacaNessuna valutazione finora

- General Services Brochure PDFDocumento2 pagineGeneral Services Brochure PDFbacabacabacaNessuna valutazione finora

- EEMUA 159 Reading ChecklistDocumento3 pagineEEMUA 159 Reading ChecklistbacabacabacaNessuna valutazione finora

- Alarm Management KPI Utilizing IMS in Offshore PlatformsDocumento91 pagineAlarm Management KPI Utilizing IMS in Offshore PlatformsbacabacabacaNessuna valutazione finora

- ASME Guide For ReviewsDocumento13 pagineASME Guide For Reviewsbacabacabaca100% (1)

- API 1104 Reading ChecklistDocumento2 pagineAPI 1104 Reading Checklistbacabacabaca100% (2)

- EN 14015 Reading ChecklistDocumento4 pagineEN 14015 Reading ChecklistbacabacabacaNessuna valutazione finora

- THE FIELD GUIDE TO TYPOGRAPHY Prev PDFDocumento32 pagineTHE FIELD GUIDE TO TYPOGRAPHY Prev PDFbacabacabacaNessuna valutazione finora

- Scaffolder: Construction Job Description 5Documento1 paginaScaffolder: Construction Job Description 5bacabacabacaNessuna valutazione finora

- API 652 Reading ChecklistDocumento1 paginaAPI 652 Reading ChecklistbacabacabacaNessuna valutazione finora

- BS 10500 Anti-Bribery Management It's Your ReputationDocumento16 pagineBS 10500 Anti-Bribery Management It's Your ReputationbacabacabacaNessuna valutazione finora

- API 651 Reading ChecklistDocumento1 paginaAPI 651 Reading ChecklistbacabacabacaNessuna valutazione finora

- API 582 Reading ChecklistDocumento1 paginaAPI 582 Reading ChecklistbacabacabacaNessuna valutazione finora

- API 580 Reading ChecklistDocumento2 pagineAPI 580 Reading ChecklistbacabacabacaNessuna valutazione finora

- Calcium Cyanide: Hydrogen Cyanide. CONSULT THE NEW JERSEYDocumento6 pagineCalcium Cyanide: Hydrogen Cyanide. CONSULT THE NEW JERSEYbacabacabacaNessuna valutazione finora

- API 510 Reading ChecklistDocumento2 pagineAPI 510 Reading Checklistbacabacabaca100% (2)

- 3M Respirator Selection Guide 2018 PDFDocumento127 pagine3M Respirator Selection Guide 2018 PDFbacabacabacaNessuna valutazione finora

- Dacon PAUT PresentationDocumento20 pagineDacon PAUT Presentationbacabacabaca100% (1)

- ToFD Nuclear Power PlantDocumento8 pagineToFD Nuclear Power PlantbacabacabacaNessuna valutazione finora

- Analisis Kapasitas Daya Dukung Cerucuk Pada Tanah Gambut Dan Lunak Di Kabupaten SiakDocumento17 pagineAnalisis Kapasitas Daya Dukung Cerucuk Pada Tanah Gambut Dan Lunak Di Kabupaten SiakbacabacabacaNessuna valutazione finora

- WP 100 Instruction ManualDocumento19 pagineWP 100 Instruction ManualbacabacabacaNessuna valutazione finora

- SNT-TC-1A Certification SchemeDocumento1 paginaSNT-TC-1A Certification Schemebacabacabaca100% (1)

- API 577 Reading ChecklistDocumento1 paginaAPI 577 Reading ChecklistbacabacabacaNessuna valutazione finora

- Chapter 2Documento8 pagineChapter 2Fahmia MidtimbangNessuna valutazione finora

- Data StructuresDocumento4 pagineData StructuresBenjB1983Nessuna valutazione finora

- 2016 IT - Sheilding Guide PDFDocumento40 pagine2016 IT - Sheilding Guide PDFlazarosNessuna valutazione finora

- Advertising II Marathi VersionDocumento91 pagineAdvertising II Marathi VersionHarsh Sangani100% (1)

- Draft PDFDocumento166 pagineDraft PDFashwaq000111Nessuna valutazione finora

- Math Review CompilationDocumento9 pagineMath Review CompilationJessa Laika CastardoNessuna valutazione finora

- Chapter 4 - Basic ProbabilityDocumento37 pagineChapter 4 - Basic Probabilitynadya shafirahNessuna valutazione finora

- Bacacay South Hris1Documento7.327 pagineBacacay South Hris1Lito ObstaculoNessuna valutazione finora

- Stentofon Pulse: IP Based Intercom SystemDocumento22 pagineStentofon Pulse: IP Based Intercom SystemCraigNessuna valutazione finora

- Gracie Warhurst WarhurstDocumento1 paginaGracie Warhurst Warhurstapi-439916871Nessuna valutazione finora

- 3 Diversion&CareDocumento2 pagine3 Diversion&CareRyan EncomiendaNessuna valutazione finora

- TraceDocumento5 pagineTraceNorma TellezNessuna valutazione finora

- CLG418 (Dcec) PM 201409022-EnDocumento1.143 pagineCLG418 (Dcec) PM 201409022-EnMauricio WijayaNessuna valutazione finora

- Switching Simulation in GNS3 - GNS3Documento3 pagineSwitching Simulation in GNS3 - GNS3Jerry Fourier KemeNessuna valutazione finora

- Report FinalDocumento48 pagineReport FinalSantosh ChaudharyNessuna valutazione finora

- Google Tools: Reggie Luther Tracsoft, Inc. 706-568-4133Documento23 pagineGoogle Tools: Reggie Luther Tracsoft, Inc. 706-568-4133nbaghrechaNessuna valutazione finora

- EAC Inquiry SDCDocumento9 pagineEAC Inquiry SDCThe Sustainable Development Commission (UK, 2000-2011)Nessuna valutazione finora

- Roxas City For Revision Research 7 Q1 MELC 23 Week2Documento10 pagineRoxas City For Revision Research 7 Q1 MELC 23 Week2Rachele DolleteNessuna valutazione finora

- E-Versuri Ro - Rihana - UmbrelaDocumento2 pagineE-Versuri Ro - Rihana - Umbrelaanon-821253100% (1)

- A Medium-Rise Residential Building: A B C E D F G HDocumento3 pagineA Medium-Rise Residential Building: A B C E D F G HBabyjhaneTanItmanNessuna valutazione finora

- Civ Beyond Earth HotkeysDocumento1 paginaCiv Beyond Earth HotkeysExirtisNessuna valutazione finora

- Basic Econometrics Questions and AnswersDocumento3 pagineBasic Econometrics Questions and AnswersRutendo TarabukuNessuna valutazione finora

- Chinese Paper Cutting Work SheetDocumento4 pagineChinese Paper Cutting Work Sheet黃梓Nessuna valutazione finora

- Importance of Communications 05sept2023Documento14 pagineImportance of Communications 05sept2023Sajib BhattacharyaNessuna valutazione finora

- 1995 Biology Paper I Marking SchemeDocumento13 pagine1995 Biology Paper I Marking Schemetramysss100% (2)

- User Manual PM3250Documento80 pagineUser Manual PM3250otavioalcaldeNessuna valutazione finora

- Feed-Pump Hydraulic Performance and Design Improvement, Phase I: J2esearch Program DesignDocumento201 pagineFeed-Pump Hydraulic Performance and Design Improvement, Phase I: J2esearch Program DesignJonasNessuna valutazione finora

- Syllabus PDFDocumento3 pagineSyllabus PDFBibin Raj B SNessuna valutazione finora

- 07 GDL Web-Site 04 (2021-2022) For 15284Documento2 pagine07 GDL Web-Site 04 (2021-2022) For 15284ABCDNessuna valutazione finora

- Multimodal Essay FinalDocumento8 pagineMultimodal Essay Finalapi-548929971Nessuna valutazione finora