Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

L'Ambiance Plaza Collapse

Caricato da

Krissalaine Capulong0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

91 visualizzazioni1 paginaSummary Sheet about L'Ambiance Plaza

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSummary Sheet about L'Ambiance Plaza

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

91 visualizzazioni1 paginaL'Ambiance Plaza Collapse

Caricato da

Krissalaine CapulongSummary Sheet about L'Ambiance Plaza

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 1

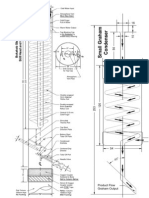

On April 23, 1987, the

L’Ambiance Plaza Building in

Bridgeport, Conneticut, collapsed

during construction. . This collapse

spurred a large scale, eight day,

rescue attempt and ultimately left 28

workers dead.(Moncarz, 1992) This

16 story building, 13 apartment levels

over 3 parking levels, was being CASE STUDY ON POSSIBLE

constructed using the lift-slab method. CONSTRUCTION FAILURES THAT CAUSED

THEORY 1:

The lift-slab method consists of

Instability of the wedges THE COLLAPSE

casting post-tensioned floor slabs,

supporting the 12th floor and roof package

one on-top of another, at ground level

-Thornton Tomasetti Engineers

and then hydraulically jacking each Thornton-Tomasetti Engineers' concluded the epicenter of the collapse was a core column, 3E, of

level into place. At approximately the west building. Wedges supporting the 12th floor and roof package at the column were unstable and

1:30pm on April 23rd a loud bang was started the collapse. They state in their "Collapse Scenario" that a wedge supporting the 12/R package rolled

heard and within the next 2-10 out leaving the shearhead at this level supported by a single wedge. The horizontal load from the jack used to

seconds the entire building crashed to plumb the building caused the remaining wedge to roll slightly as evidenced by rounding and bending in the

the ground. The collapse launched west weld block of the shearhead. Additional movement of the slabs may have caused the remaining wedge to

several investigations but was quickly roll completely out.

settled out of court ending all THEORY 2:

investigations and leaving the exact Jack rod and lifting nut slipped out due to a deformation of an overloaded steel angle

cause of the collapse unknown. welded to a shear head arm channel

Although the exact cause of the -National Bureau of Standards (NBS

collapse remains unknown, five viable The NBS concluded in their investigation that the failure began at the building's most heavily

theories have been proposed in the loaded column, E4.8 or the adjacent column, E3.8, as a result of a lifting assembly failure. At each column the

years since the collapse by various shearhead reinforces the concrete slab, transfers vertical load from the slab into the column, and provides a

experts on building failures. place of attachment for the lifting assembly. Steel channels are cast in the slab, allowing room for the lifting

angle. Lifting rods, raised by hydraulic jacks above them, are passed through holes in the lifting angle and

fastened with lifting nuts. (Scribner, 1988)

THEORY 3:

Improper design of post-tensioning tendons

-Schupack Suarez Engineers, Inc

The Schupack Suarez Engineers examined the unusual layout of the post-tensioning tendons in the

west building. The east building's tendons were run in a typical two-way banded layout, uniform tendons

running North - South carry the slab load to the East- West Column line, where the E-W banded tendons then

"pick up" the load and transfer it to the columns. However, at column 4.8E in the west building, the E-W

tendons split around the column line. The absence of tendons in Line E due to the split at the column added

increased load into the structure. The design details also did not include the location of the shear walls or the

openings for the walls at Columns 11A, 8A, and 2H. Finite-element analysis determined that the tensile

stresses along Column Line E, east of Column 4.8E, exceeded the cracking strength of the concrete. By this

reasoning once a crack was initiated it would spread immediately to Column 4.8E. The finite-element analysis

also showed that even under ideal lifting circumstances column 2H would have had unsuitably high

compressive and punching shear stresses.

THEORY 4:

Substandard welds and questionable weld details

-Occupational Safety and Health Administration (OSHA)

OSHA stated that two weld design details were questionable. These welds were the 1/2 in. single-

bevel-groove weld between the arm channel and the lifting angle in the shearheads, and the one-sided

square-groove weld connecting the header bar and header channel at the shearhead. Both welds were of

unknown and unspecified penetration depth and therefore had an unpredictable strength. The single-bevel-

groove weld could also have been further weakened from flush grinding. The one-sided square-groove welds

are even more questionable due to the fact that they were not among the American Welding Society

prequalified joints.

THEORY 5:

Global instability caused by lateral displacement

-Failure Analysis Associates, Inc. (FaAA)

FaAA consultants focused on the response of lateral loading and overall torsional instability. The shearhead

connection is rotationally stiff when the concrete slab is temporarily resting on the wedges and when it is

fully welded in its final position it becomes a rigid connection. However, when the slab is lifted off the wedge

it can rotate freely. In the absence of lateral loading the building would be completely stable. In the presence

of lateral loading or displacement, such as that from the horizontal jacking just after lunch, the slab could be

lifted off a wedge and the building would become laterally flexible. FaAA used 3D computer modeling (ANSYS)

and nonlinear stability modeling to investigate this possibility. Upon analysis of their modeling FaAA

concluded that lateral instability was the cause of collapse for both the west and east buildings.

Potrebbero piacerti anche

- Case Study - L'AMBIANCE PLAZA COLLAPSEDocumento27 pagineCase Study - L'AMBIANCE PLAZA COLLAPSEMirza Sajjad HussainNessuna valutazione finora

- L'ambianceDocumento17 pagineL'ambianceRome GentaNessuna valutazione finora

- School of Engineering & Technology M. Tech. Forensic Structural Engineering Semester - III, 2021-2022Documento38 pagineSchool of Engineering & Technology M. Tech. Forensic Structural Engineering Semester - III, 2021-2022Gandhi SagarNessuna valutazione finora

- Reinforced Concrete Eccentric Beam-Column Connections Subjected To Earthquake-Type LoadingDocumento11 pagineReinforced Concrete Eccentric Beam-Column Connections Subjected To Earthquake-Type LoadingUcok DedyNessuna valutazione finora

- Distortion of Steel Tanks Due To Settlement of Their WallsDocumento20 pagineDistortion of Steel Tanks Due To Settlement of Their WallsMiguel BenítezNessuna valutazione finora

- Cable StructureDocumento5 pagineCable StructureAshish ShettyNessuna valutazione finora

- Response of Reinforced Concrete Columns To Simulated Seismic LoadingDocumento10 pagineResponse of Reinforced Concrete Columns To Simulated Seismic LoadingpicottNessuna valutazione finora

- Airport Features A Seismic Retrofit During ConstructionDocumento5 pagineAirport Features A Seismic Retrofit During ConstructionJosimar OliveraNessuna valutazione finora

- Fatigue Cracking and Inspection of High-Mast Lighting TowersDocumento9 pagineFatigue Cracking and Inspection of High-Mast Lighting TowerskawallaceNessuna valutazione finora

- Shear Model 1Documento13 pagineShear Model 1yanimuhammadNessuna valutazione finora

- C F C L C: Onoidal Acade Asts Ight On OurthouseDocumento4 pagineC F C L C: Onoidal Acade Asts Ight On OurthouseTarik BosnoNessuna valutazione finora

- Cyclic Lateral Loading of Nonductile Slab-Column ConnectionsDocumento9 pagineCyclic Lateral Loading of Nonductile Slab-Column ConnectionsMishraq ul quraishNessuna valutazione finora

- Vanke CenterDocumento30 pagineVanke CenterSahil KaradNessuna valutazione finora

- Design of Self-Centering Moment Resisting Frame and Experimental Loading SystemDocumento17 pagineDesign of Self-Centering Moment Resisting Frame and Experimental Loading SystemAshwini TeegalaNessuna valutazione finora

- Seismic Demand Evaluation For A The Northridge Earthquake 4-Story Steel Frame Structure Damaged inDocumento27 pagineSeismic Demand Evaluation For A The Northridge Earthquake 4-Story Steel Frame Structure Damaged insanh137Nessuna valutazione finora

- Wellington Central Police Station Base Isolation Maintenance C. R. SmartDocumento16 pagineWellington Central Police Station Base Isolation Maintenance C. R. SmartAnkush BhartiNessuna valutazione finora

- Experimental StudyDocumento12 pagineExperimental StudyAyush GargNessuna valutazione finora

- Performance of Practical Beam To SHS Column Connections 2016 Engineering STDocumento16 paginePerformance of Practical Beam To SHS Column Connections 2016 Engineering STAnonymous SXPgzGNessuna valutazione finora

- Formwork Failure Course PDFDocumento24 pagineFormwork Failure Course PDFwhellyNessuna valutazione finora

- The Design of Steel Plate Girder Bridges Using Sliding Isolation BearingsDocumento6 pagineThe Design of Steel Plate Girder Bridges Using Sliding Isolation BearingsAayush AggarwalNessuna valutazione finora

- Five Useful Stability ConceptsDocumento11 pagineFive Useful Stability ConceptsPokiri VedavaNessuna valutazione finora

- 8884 PDFDocumento10 pagine8884 PDF081382991318Nessuna valutazione finora

- Cyclic Performance of Lower Stories of Mid-Rise Reinforced Concrete Frame BuildingsDocumento9 pagineCyclic Performance of Lower Stories of Mid-Rise Reinforced Concrete Frame BuildingsJitendraNessuna valutazione finora

- Jack Arch RetrofitDocumento13 pagineJack Arch RetrofitDebendra Dev KhanalNessuna valutazione finora

- Seismic Design Strategy of The New East Bay Bridge Suspension Span Marwan NaderDocumento8 pagineSeismic Design Strategy of The New East Bay Bridge Suspension Span Marwan Naderjuho jungNessuna valutazione finora

- TacomaDocumento16 pagineTacomaJhon OrjuelaNessuna valutazione finora

- OL-1 Failure of Steel StructureDocumento0 pagineOL-1 Failure of Steel StructureSunil PulikkalNessuna valutazione finora

- 2004 Monotonic LateralLoad 13WCEEDocumento9 pagine2004 Monotonic LateralLoad 13WCEEJANMESHNessuna valutazione finora

- Arch 323 - Theory of StructureDocumento29 pagineArch 323 - Theory of StructureSam garcuaNessuna valutazione finora

- Failure of Chauras BridgeDocumento8 pagineFailure of Chauras BridgeRitesh ChaurasiaNessuna valutazione finora

- Zeinoddini 2004 SpaceStructure3Documento18 pagineZeinoddini 2004 SpaceStructure3Johnny VillarroelNessuna valutazione finora

- Live Load Deflections in A Prestressed Steel Beam Bridge: Aisc Engineering JournalDocumento8 pagineLive Load Deflections in A Prestressed Steel Beam Bridge: Aisc Engineering JournalcmkohNessuna valutazione finora

- Performance Based Analysis and Modeling of A Dual Seismic Force-Resisting SystemDocumento7 paginePerformance Based Analysis and Modeling of A Dual Seismic Force-Resisting SystemjcvalenciaNessuna valutazione finora

- 2002 12 TaipeiDocumento4 pagine2002 12 TaipeiElvis GrayNessuna valutazione finora

- Slip Track Design Tn-W100-08aDocumento4 pagineSlip Track Design Tn-W100-08aZebNessuna valutazione finora

- Damage Analysis of Xiaoyudong Bridge Affected by Wenchuan Earthquake, ChinaDocumento12 pagineDamage Analysis of Xiaoyudong Bridge Affected by Wenchuan Earthquake, Chinaanne marieNessuna valutazione finora

- Lift Slab ConstructionDocumento17 pagineLift Slab ConstructionMartinez, Khrisha Mae B.Nessuna valutazione finora

- 1 s2.0 S0263823108001973 MainDocumento13 pagine1 s2.0 S0263823108001973 MainWaleed MohamedNessuna valutazione finora

- Unit - Iii: Srividya College of Engineering and Technology Question BankDocumento8 pagineUnit - Iii: Srividya College of Engineering and Technology Question BankAravindNessuna valutazione finora

- Lateral Load Response of Strengthened and Repaired Reinforced Concrete ColumnsDocumento10 pagineLateral Load Response of Strengthened and Repaired Reinforced Concrete ColumnsCiro AscioneNessuna valutazione finora

- Tay Bridge DisasterDocumento20 pagineTay Bridge DisasterCameron BreakellNessuna valutazione finora

- Study On The Design of Chirajara BridgeDocumento8 pagineStudy On The Design of Chirajara Bridgepaul ostepNessuna valutazione finora

- C StructuralRehab StuartDocumento3 pagineC StructuralRehab StuartimadNessuna valutazione finora

- Static and Seismic Design of One-Way and Two-Way Jack Arch Masonry SlabsDocumento16 pagineStatic and Seismic Design of One-Way and Two-Way Jack Arch Masonry SlabsDoğan ArslanNessuna valutazione finora

- Hyatt Regency Collapse - NASA ArticleDocumento4 pagineHyatt Regency Collapse - NASA Articlealum_91Nessuna valutazione finora

- Active Confinement of Reinforced Concrete Bridge CDocumento9 pagineActive Confinement of Reinforced Concrete Bridge Cnoor ayaadNessuna valutazione finora

- Steel Orthotropic Decks: Developments in The 1990sDocumento8 pagineSteel Orthotropic Decks: Developments in The 1990sMARIONessuna valutazione finora

- 16-Analysis of A Flexible Concrete ArchDocumento8 pagine16-Analysis of A Flexible Concrete Archirmreza68Nessuna valutazione finora

- Pre-Stressed Elective EngineeringDocumento7 paginePre-Stressed Elective EngineeringJonas FernandezNessuna valutazione finora

- A Guide to Some of the Equations used in Constructing a Suspension BridgeDa EverandA Guide to Some of the Equations used in Constructing a Suspension BridgeNessuna valutazione finora

- Report Example ColumnDocumento46 pagineReport Example ColumnvirgoknNessuna valutazione finora

- A Study of Reinforced Concrete Bridge Columns RetrDocumento11 pagineA Study of Reinforced Concrete Bridge Columns Retrnattanai kuangmiaNessuna valutazione finora

- Structure Structure: Magazine MagazineDocumento4 pagineStructure Structure: Magazine MagazinershaghayanNessuna valutazione finora

- 102 s45 PDFDocumento10 pagine102 s45 PDFCesarRicaldiMirandaNessuna valutazione finora

- Suspension BridgesDocumento16 pagineSuspension Bridgesramanplahas100% (1)

- A Review of The Effect of Corner LoadsDocumento4 pagineA Review of The Effect of Corner LoadsATSNessuna valutazione finora

- Basic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionDa EverandBasic Theory of Structures: The Commonwealth and International Library: Mechanical Engineering DivisionValutazione: 4 su 5 stelle4/5 (4)

- Structural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionDa EverandStructural Concrete: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionNessuna valutazione finora

- Some Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Da EverandSome Mooted Questions in Reinforced Concrete Design American Society of Civil Engineers, Transactions, Paper No. 1169, Volume LXX, Dec. 1910Nessuna valutazione finora

- A Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsDa EverandA Short Guide to the Types and Details of Constructing a Suspension Bridge - Including Various Arrangements of Suspension Spans, Methods of Vertical Stiffening and Wire Cables Versus Eyebar ChainsNessuna valutazione finora

- The Capital Gate TowerDocumento1 paginaThe Capital Gate TowerKrissalaine CapulongNessuna valutazione finora

- Post Tension SystemsDocumento1 paginaPost Tension SystemsKrissalaine CapulongNessuna valutazione finora

- A Review of Human Disturbance Impacts On Waterbirds PDFDocumento23 pagineA Review of Human Disturbance Impacts On Waterbirds PDFKrissalaine CapulongNessuna valutazione finora

- Chapter 13: Cities and Cultures - The Hidden Dimension by Edward HallDocumento5 pagineChapter 13: Cities and Cultures - The Hidden Dimension by Edward HallKrissalaine CapulongNessuna valutazione finora

- CHAPTER 1 FINAL YEAR ProjectDocumento5 pagineCHAPTER 1 FINAL YEAR ProjectdejayzNessuna valutazione finora

- Dieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HilleryDocumento6 pagineDieless Wire Drawing-An Experimental and Numerical Analysis: P. Tiernan, M.T. HillerycostytzuNessuna valutazione finora

- Prediction of Forming Limits and Parameter in TheDocumento17 paginePrediction of Forming Limits and Parameter in TheĐặng Quốc ĐạiNessuna valutazione finora

- Ar710 (T2) - Door ScheduleDocumento1 paginaAr710 (T2) - Door ScheduleErwin ObenzaNessuna valutazione finora

- Testing & Commissioning of Chilled Water Pumps - Method Statement HQDocumento6 pagineTesting & Commissioning of Chilled Water Pumps - Method Statement HQMirajul IslamNessuna valutazione finora

- Pipeline Integrity Management MSC (Penspen)Documento7 paginePipeline Integrity Management MSC (Penspen)Majeed Rumani0% (2)

- ATR Ata - 21 - Air - ConditioningDocumento115 pagineATR Ata - 21 - Air - ConditioningJesús Montalvo Fernández100% (5)

- ThermoDocumento219 pagineThermoIkhlas KittaNessuna valutazione finora

- Pre Engineering BuildingDocumento6 paginePre Engineering BuildingHowo4DieNessuna valutazione finora

- MeCaTeC MeCaCorr 710 Surface Polymer Ceramic CoatingDocumento1 paginaMeCaTeC MeCaCorr 710 Surface Polymer Ceramic CoatingjaviermvsNessuna valutazione finora

- Oguni DomeDocumento5 pagineOguni DomeShubham PatidarNessuna valutazione finora

- Luminarias Glamox para Areas DeportivasDocumento2 pagineLuminarias Glamox para Areas DeportivasAlberto PopushoyNessuna valutazione finora

- Fasani Pressure Seal Check ValveDocumento5 pagineFasani Pressure Seal Check Valvegm_revankar3942Nessuna valutazione finora

- Notes For - Process Level GaugesDocumento8 pagineNotes For - Process Level GaugesDavid BaughNessuna valutazione finora

- Cvp68 - Mini Project Synopsis: Title of The Project: Analysis and Design of Multistoried FrameDocumento3 pagineCvp68 - Mini Project Synopsis: Title of The Project: Analysis and Design of Multistoried FrameSHAHBAZ M MAINUDDINNessuna valutazione finora

- Durafit Installation GuideDocumento3 pagineDurafit Installation GuideBrian EnderwitzNessuna valutazione finora

- Moglix Material PendencyyDocumento12 pagineMoglix Material Pendencyylucky sharmaNessuna valutazione finora

- Lecture-7-Part 1-Strength of Materials - Bending StressesDocumento41 pagineLecture-7-Part 1-Strength of Materials - Bending Stressesarno assassinNessuna valutazione finora

- VCCT For Abaqus PDFDocumento14 pagineVCCT For Abaqus PDFFelipe Dornellas SilvaNessuna valutazione finora

- General NotesDocumento1 paginaGeneral Notesjayr.catapangNessuna valutazione finora

- Structural Design and AnalysisDocumento11 pagineStructural Design and AnalysisJames GarciaNessuna valutazione finora

- Crystal DefectsDocumento75 pagineCrystal DefectsAshok PradhanNessuna valutazione finora

- ASME P-Numbers 1Documento2 pagineASME P-Numbers 1SH1961Nessuna valutazione finora

- SRS-UK Silk A4Documento2 pagineSRS-UK Silk A4Jacinto alvaresNessuna valutazione finora

- Bokakob No VMDocumento1 paginaBokakob No VM2depicNessuna valutazione finora

- ABS Fire and Safety Features For MODU - Part5Documento40 pagineABS Fire and Safety Features For MODU - Part5Eyoma Etim100% (1)

- 1 - Hill Yield CriterionDocumento5 pagine1 - Hill Yield CriterionsililloNessuna valutazione finora

- HF 725 Series: in Line High Pressure FiltersDocumento16 pagineHF 725 Series: in Line High Pressure FilterssitnikovsNessuna valutazione finora

- Energy Recovery Atlas CopcoDocumento3 pagineEnergy Recovery Atlas CopcoSergio LinNessuna valutazione finora

- A New Approach With Prepregs For ReinforcingDocumento8 pagineA New Approach With Prepregs For ReinforcingRajesh Kumar SNessuna valutazione finora