Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

United States Patent (10) Patent No.: US 6,712,734 B1: Loeffler (45) Date of Patent: Mar. 30, 2004

Caricato da

pmurphTitolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

United States Patent (10) Patent No.: US 6,712,734 B1: Loeffler (45) Date of Patent: Mar. 30, 2004

Caricato da

pmurphCopyright:

Formati disponibili

USOO6712734B1

(12) United States Patent (10) Patent No.: US 6,712,734 B1

Loeffler (45) Date of Patent: Mar. 30, 2004

(54) GEARBOX FOR A MOTOR VEHICLE, 4,533,011 A * 8/1985 Heidemeyer et al. ...... 180/65.2

ESPECIALLY A GEARBOX WITH A DUAL 5,181,431 A 1/1993 Zaiser et al. .............. 74/664 X

CLUTCH AND METHOD FOR OPERATING 2 : - -2

sA : ::

le, et al... O.

OOO e a ----

SAID GEARBOX 5,730,675 A * 3/1998 Yamaguchi ..... ... 477/4 X

5,730,676 A * 3/1998 Schmidt ......... ... 477/5 X

(75) Inventor: Juergen Loeffler, Winnenden (DE) 6,019,698 A 2/2000 Lawrie et al. .............. 477/3 X

6,044,719 A * 4/2000 Reed, Jr. et al. .............. 74/330

(73) Assignee: Robert Bosch GmbH, Stuttgart (DE) 6,159,127 A 12/2000 Loeffler et al. ................ 477/5

6,341,541 B1 1/2002 Sakamoto et al. ........ 74/665 A

(*) Notice: Subject to any disclaimer, the term of this 6,409.623 B1 * 6/2002 E. - - - - - - - - - - - - - - - - 475/5

patent is extended or adjusted under 35

U.S.C. 154(b) by 0 days. FOREIGN PATENT DOCUMENTS

(21) Appl. No.: 09/830,953 EP O 724977 A 8/1996

EP O 845 618 A 6/1998

(22) PCT Filed: Oct. 16, 1999 FR 1 445 735 A 10/1966

FR 22 OO 800 4/1974

(86) PCT No.: PCT/DE99/03323 JP 406144020 A 5/1994 ................ 180/65.2

S371 (c)(1), sk -

(2), (4) Date: May 2, 2001 cited by examiner

(87) PCT Pub. No.: WO00/26559 Primary Examiner Roger Pang

(74) Attorney, Agent, or Firm Michael J. Striker

PCT Pub. Date: May 11, 2000

(57) ABSTRACT

(30) Foreign Application Priority Data

Nov. 3, 1998 (DE) ......................................... 198 SO 549 A multi-speed transmission has two input shafts and one

output shaft, each connected to a clutch and disconnectable

(51) Int. Cl." ................................................ B60K 41/02 by the clutch from the internal combustion engine of the

(52) U.S. Cl. ........................................................... 477/5 motor vehicle, and one or two electric machines are asso

(58) Field of Search ............................. 475/5; 477/5, 6; ciated with the two input shafts and connected to them by

74/664, 340; 180/65.2, 65.3, 65.6, 65.7 nonpositive engagement; the electric machines being

located on the Side of the clutches remote from the engine,

(56) References Cited So that it is possible to dispense with a starter and a generator

for the engine.

U.S. PATENT DOCUMENTS

4,335,429 A 6/1982 Kawakatsu ............ 180/65.2 X 10 Claims, 2 Drawing Sheets

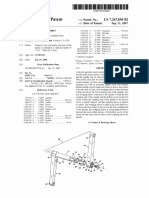

U.S. Patent Mar. 30, 2004 Sheet 1 of 2 US 6,712,734 B1

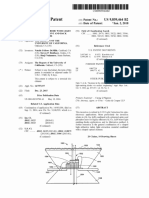

U.S. Patent Mar. 30, 2004 Sheet 2 of 2 US 6,712,734 B1

US 6,712,734 B1

1 2

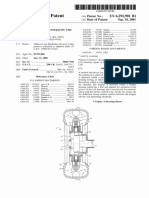

GEARBOXFOR A MOTOR VEHICLE, tion engine 11. The transmission 10 is embodied as a

ESPECIALLY A GEARBOX WITH A DUAL So-called twin-clutch manual transmission. To that end, the

CLUTCH AND METHOD FOR OPERATING transmission 10 has two input shafts 12, 13, which are each

SAID GEARBOX coupled, by means of a respective gear wheel 15, 16 Secured

to the input shaft 12, 13 in a manner fixed against relative

BACKGROUND OF THE INVENTION rotation, to a crown gear 14 Secured to the crankshaft of the

engine 11. Instead of a step-up by the gear wheels 15, 16 and

The invention relates to a transmission for a motor the crown gear 14, the two input shafts 12, 13 can also be

vehicle, in particular a twin-clutch manual transmission. driven directly by the crankshaft, however.

In Such known transmissions, for changing gears the Groups of gear wheels 17 and 18 are also disposed on the

rotary speeds of the members to be shifted are made to input shafts 12 and 13. The first gear wheel group 17

match one another by means of a Synchronizing device, includes the gear wheels 1E, 3E, 5E disposed on the input

which as a rule has Synchronizing rings. Furthermore, for shaft 12 in a manner capable of rotation, and the Second gear

Starting the internal combustion engine of the motor vehicle, wheel group 18 includes the gear wheels.2E and 4E, dis

a separate Starter is provided, which when the clutches are 15 posed on the Second input shaft 13 in a manner fixed against

disengaged rotates the crankshaft of the engine. The engine relative rotation. Two gear wheels 21, 22 are also disposed,

is Supplied with energy by the battery of the motor vehicle, in a manner fixed against relative rotation, on the first input

which in turn is charged constantly by a generator. The shaft 12; of these, one gear wheel 21 is located between the

known transmission and hence the motor vehicle thus two gear wheels 1E and 3E. A sliding cuff 23, 24 cooperates

require a number of coordinate devices for its operation, and with the respective gear wheels 21, 22 and causes the gear

the Synchronizing devices are more or leSS complex in wheel 21, 22 to engage the respective gear wheel 1E, 3E or

design. 5E.

SUMMARY OF THE INVENTION The two input shafts 12, 13 can be coupled to an output

The transmission of the invention for a motor vehicle, in 25

shaft 25, which forms the drive shaft of the motor vehicle or

particular a twin-clutch manual transmission has the advan leads to the drive shaft. The gear wheels 1A-5A correspond

tage over the prior art that because of the electric machine ing to the gear wheel groups 17, 18 are disposed on the

coupled to the at least one input shaft, a Starter and a output shaft 25, and of these the gear wheels 1A, 3A and 5A

generator for the engine can be dispensed with. Furthermore, are Secured to the output shaft 25 in a manner fixed against

easy synchronization of the members to be shifted of the relative rotation, while the gear wheels 2A and 4A are

various gears is possible without additional Synchronizing Secured to the output shaft in a manner capable of rotation.

devices. Also on the output shaft 25, between the gear wheels 2A and

4A, a gear wheel 27 is Secured in a manner fixed against

A relatively small size of the electric machines is neces relative rotation; it cooperates with a sliding cuff 28 in order

Sary if each of the two input Shafts is equipped with a to enable the power flow with the gear wheel 2A or 4A.

Separate electric machine. Furthermore, in that case a rela 35

To couple the engine 11 to the output shaft 25 by means

tively simple coupling to the input shafts can be attained. By of the input shaft 12 or 13, each input shaft 12, 13 is also

comparison, if a distributor transmission is used, it is poS assigned a respective clutch 29, 30 between the engine 11

Sible to employ merely a single electric machine, which can and the gear wheel groups 17, 18. If the two clutches 29, 30

be coupled to one or the other of the input shafts. are disengaged, then, for instance if the motor vehicle is on

40

Operating a motor Vehicle with a transmission of the a hill, the motor vehicle may roll backwards, which is

invention has the particular advantage that in the overrun unwanted. To prevent this, a so-called hill holder device 32

ning mode of the motor Vehicle, the rolling energy of the that acts as a parking brake is disposed in the region of the

vehicle can be converted into electrical energy that charges output shaft 25. In order to detect the aforementioned rolling

the on-board battery, if the electric machine or electric backward of the motor vehicle and to detect the rotary

machines function as generators in the overrunning mode. It 45

Speeds and optionally the angular positions of the gear

is also possible, for driving the motor vehicle in reverse, to wheels 1A-5A, 1E-5E, 21, 22, 27, sensors, not otherwise

dispense with a corresponding gear wheel Set in the shown, which are coupled to a control unit of the transmis

transmission, if an electric machine drives a forward gear in sion 10 are disposed in the region of the input shafts 12, 13

CWCSC.

50 and of the output shaft 25.

It is also possible to use the electric machine or electric It is essential to the invention that in the exemplary

machines as an additional drive mechanism which reinforces

the engine, So that greater total power can be furnished embodiment of FIG. 1, each of the input shafts 12, 13 is

briefly, for instance during passing. connected by positive engagement to a separate electric

machine 34, 35, which in turn is connected to the on-board

BRIEF DESCRIPTION OF THE DRAWINGS 55 battery of the motor vehicle. The nonpositive connection is

Two exemplary embodiments of the invention are shown achieved in the simplest case by the provision that each of

in the drawing and will be described in further detail below. the electric machines 34, 35 has an axially continuous rotor

Shown are: shaft, which is a constituent of the respective input shaft 12

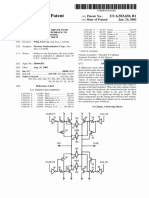

FIG. 1, a first drive train of a motor vehicle, shown and 13. However, other couplings, Such as a pinion of the

Schematically; and 60 electric machine 34, 35, which cooperates with a gear wheel

FIG. 2, a Second drive train of a motor Vehicle, again disposed on the input shaft 12, 13, are also conceivable.

shown Schematically. The electric machines 34, 35 can also each be connected

to the input shaft 12, 13 by nonpositive engagement via a

DESCRIPTION OF THE PREFERRED respective intermediate transmission. In the exemplary

EMBODIMENTS 65 embodiment, each of the electric machines 34, 35 is located

In FIG. 1, reference numeral 10 indicates a transmission between the clutches 29, 30 and the corresponding gear

of a motor Vehicle, which is coupled to an internal combus wheel groups 17, 18. In order to explain the function of the

US 6,712,734 B1

3 4

electric machines 34, 35 in the transmission 10, various without interrupting the tractive force. The sliding cuff 23 is

operating States will now be addressed: also put out of engagement with the gear wheel 1E.

For starting the engine 11, the input gear wheels 1E-5E The further gear changes in upshifting of the transmission

are decoupled from the output gear wheels 1A-5A on the 10 are logically done in Such a way that in each case the

output shaft 25; the transmission 10 is thus shifted to neutral. synchronized rpm of the input shaft 12, 13 of the next higher

This is accomplished in that the slide cuffs 23, 24, 28 are in target gear is Set by means of the electric machine 34, 35

their middle position, in which they each cover only the coupled to the applicable input shaft 12, 13. Once this has

corresponding gear wheels 21, 22, 27. To prevent the motor been done, the gear wheels 3E, 4A and 5E can be put into

vehicle from rolling backward, the hill holder device 32 is engagement with the gear wheels 21, 22, 27 by means of the

Simultaneously activated. Transmitting a starting torque to sliding cuffs 23, 24, 27. Next, the power flow between the

the crankshaft of the engine 11 is now no longer done as target gear and the engine 11 is established by closing the

usual by means of a separate Starter but instead by at least one clutch 29, 30 of the target gear and opening the other

one of the two electric machines 34, 35. To reduce the clutch 29, 30 of the gear originally selected, and the sliding

required power or size of the electric machines 34, 35, cuff 23, 24, 28 is displaced from the gear wheel 3E, 4A, 5E

however, the starting is preferably effected by both electric 15 that was originally in engagement.

machines 34, 35 jointly. In that case, the two clutches 29, 30

are engaged, So that a nonpositive connection is made Downshifting of the gears of the transmission 10 will be

between the electric machines 34, 35 and the crankshaft of described below, taking as an example changing from 3rd

the engine 11. Once this has happened, the two electric gear to 2nd gear: If the motor vehicle is being driven in 3rd

machines 34, 35 are driven synchronously and at the same gear, then the output shaft 25 and the input Shaft 12 are

rpm as electric motorS Supplied by the motor vehicle battery, driven by the engine 11, via the gear wheels 3E, 3A for the

and the rpm of the electric motorS is equivalent to the output shaft and the engaged clutch 29 for the input shaft.

requisite Starting rpm of the internal combustion engine 11. The clutch 30 is conversely disengaged, and the gear

It will additionally be noted at this point that in the event wheel 2A rotates loosely on the output shaft 25. The gear

that transmitting the Starting torque is to be done by only one 25 wheel 2A is now brought to the requisite rpm by driving of

of the two electric machines 34, 35, then the clutch 29, 30 the input shaft 13 by means of the electric machine 35; it

of the respectively other electric machine 35, 34 is prefer now rotates at the rpm of the gear wheel 27 on the output

ably disengaged, So that the input shaft 12, 13 of the electric shaft 25. The gear wheel 27 can now be coupled with the

machine 34, 35 not needed for starting will not also rotate. gear wheel 2A by means of the sliding cuff 28. Finally, the

Otherwise, this would mean an additional energy demand on clutch 30 is engaged, the clutch 29 is disengaged, and the

the part of the electric machine 34, 35 used for the starting. sliding cuff 23 located with the gear wheel 3E is put out of

Once the engine 11 has been started, one or both of the engagement with that gear wheel. Once again, further gear

previously engaged clutches 29, 30 is disengaged again. For changes in downshifting take place in a logically similar

Starting up in 1st gear, which is formed by the meshing pair way.

of gear wheels 1E and 1A, it is necessary that a power flow 35 In conclusion, various additional possibilities of the trans

from gear wheel 1E to gear wheel 1Abe made possible. This mission 10 will be described: In the version shown, the

is accomplished by displacing the sliding cuff 23 on the gear transmission 10 has no gear wheel set for travel of the motor

wheel 21 Such that this gear wheel is put into operative vehicle in reverse. Reverse travel can be effected by pro

connection with the gear wheel 1E. However, if the input Viding that when the clutches 29, 30 are disengaged, 1st gear

shaft 12 is in angular position Such that the sliding cuff 23 40 is put into engagement with the output shaft 25, and 1st gear

cannot be slipped over onto the gear wheel 1E, then by is driven by the electric machine 34 in the opposite direction

means of a brief pulse of the electric machine 34, the input of rotation. In that case, the rpm of the electric machine 34

shaft 12 is rotated into the angular position required for this is determined by the position of the accelerator pedal. Since

purpose. 1st gear is now Selected, and for Starting up the as a rule one drives in reverse for only a short distance, it

motor Vehicle the clutch 29 merely has to be engaged again, 45 should be possible for the vehicle battery to furnish the

and at the same time the hill holder device 32 is deactivated. requisite energy. However, to provide Security for driving far

A gear change will now be described, taking as an enough in reverse, the other clutch 30 can also be engaged

example upshifting from 1st gear to 2nd gear: This requires during the reverse travel, but then 2nd or 4th gear must not

that the gear wheel pair 2E, 2Abe Synchronized with the rpm be operatively connected with the output shaft 25. In that

of the output shaft 25, which is rotated by the gear wheel pair 50 state, the electric machine 35 is driven via the clutch 30 from

1E, 1A of 1st gear. The matching of the rotary Speeds is done the crankshaft of the engine 11. The electric machine 35 can

by driving the gear wheel 2A at an rpm that corresponds to therefore function as a generator, which feeds energy into

the rpm of the drive shaft 25 and of the gear wheel 27. To the battery.

that end, with the clutch 30 disengaged, the electric machine The feeding of the battery is typically done by a generator

35 is operated as an electric motor, which drives the input 55 that is constantly driven by the engine of the motor Vehicle,

shaft 13 and thus the gear wheel 2A at a rotary Speed Such and this accordingly increases the fuel consumption of the

that the gear wheel 2A rotates at the rpm of the output shaft motor vehicle. With the transmission 10, it is possible for the

25. The sliding cuff 28 can now be put into operative energy required for charging the battery to be at least partly

connection with the gear wheel 2A, and as a result a power recovered from the kinetic (rolling) energy of the motor

flow is established between the output shaft 25 and the input 60 vehicle. To that end, in the overrunning mode of the motor

shaft 13. After that, the electric machine 35 can be Switched vehicle, the clutch 29, 30 of whatever gear has just been

to be currentless. Since in this state both the gear wheels 1E, Selected is disengaged, and the electric machine 34, 35 is

1A of 1st gear and the gear wheels 2E, 2A of 2nd gear are driven as a generator by the rolling motor vehicle, via the

operatively connected to the output shaft 25, in the final output shaft 25. In addition, the engine 11 can also be

analysis it Suffices to disengage the one clutch 29 and at the 65 Stopped, So that even more fuel can be Saved. If the rolling

Same time to engage the other clutch 30, and as a result a Speed of the motor vehicle decreases to Such an extent that

gear change from 1st gear to 2nd gear can be attained the rpm of the input shaft 12, 13 of the gear selected, on the

US 6,712,734 B1

S 6

side of the engine 11 remote from the clutch 29, 30, threatens putting the electric machine 40 into operative connection

to drop below the idling rpm of the engine 11, then the with the input shaft 12 or the input shaft 13 via the shifting

applicable clutch 29, 30 is engaged again, and as a result the cuffs 46, 47. With the clutch 29 or 30 engaged, and with the

crankshaft of the engine 11 is rotated again and the engine output shaft 25 in neutral, the Starting torque of the electric

is thus started. machine 40 is thus transmitted via either one of the two input

By coupling the electric machines 34, 35 to the input shafts 12, 13 or via both input shafts 12, 13.

shafts 12, 13 and because it is possible to decouple them The other operating States, Such as driving in reverse,

from the engine 11 by means of the clutches 29, 30, the power assist mode, or charging of the battery, can be realized

possibility is afforded in a simple way of operating the motor in the transmission 10a in a logically similar way to the

vehicle as a hybrid vehicle. In this case, for driving in transmission 10. It is evident that the electric machine 40 is

downtown areas, for instance, the vehicle is driven Solely by designed to be larger or more powerful than the electric

the two electric machines 34,35, while the engine 11 is shut machines 34, 35, with the power of the electric machine 40

off. It is understood that for use as a hybrid vehicle, the size determined especially by the power required to Start the

and power of the electric machines should be adapted engine 11. The reduced expense from having only one

accordingly, Since in that case the requisite power is no 15

longer oriented to the process of Starting the engine 11. electric machine is counteracted, however, by an additional

A separate generator can be dispensed with whenever, in engineering expense because of the Selective coupling of the

cases when just then there is no imminent gear change and electric machine 40 to the input shaft 12, 13 (additional gear

the Voltage Status of the battery necessitates it, for the wheels 41–45, sliding cuffs 46, 47).

particular one of the two electric machines 34, 35 that is not The exemplary embodiments shown in FIGS. 1 and 2 are

jointly rotating, because it is force-free, to be into operative merely examples and are therefore shown Structurally quite

connection with the engine 11 via the clutch 29, 30, so that Simply. In a structural conversion, for instance, it is appro

the electric machine 34, 35 then functions as a generator. priate particularly for Space reasons not to dispose the two

Finally, the possibility will be mentioned of temporarily input shafts 12, 13 parallel to one another but instead to

using one or both electric machines 34, 35 as an additional 25

embody one of the two input shafts 12, 13 as a hollow shaft,

drive mechanism for the motor vehicle, in that the electric within which the other input shaft 12, 13 rotates.

machines reinforce the propulsion by the engine 11 (“power The transmission 10, 10a can also have a conventional

assist mode”). To that end, via one or both electric machines reverse gear with a corresponding pair of gear wheels on the

34, 35, a torque is transmitted to the output shaft 25 and acts input shaft 12, 13 and the output shaft 25. In that case,

in the same direction as the torque generated by the engine reverse travel takes place Solely via a nonpositive coupling

11. In the event that both electric machines 34, 35 are to to the engine 11.

transmit an additional torque to the output shaft 25, there are Moreover, the invention should not be limited to trans

two options for the electric machine 34, 35 25 whose missions that have one output shaft and two input shafts.

asSociated clutch 29, 30 is disengaged first, because the Transmissions in which the groups of gear wheels are

Selected gear was Selected via the other input shaft 12, 13: 35 disposed for example on one input shaft and one output shaft

first, it is preferably provided that the applicable clutch 29, or on an intermediate shaft are also covered by the concept

30 be engaged, so that the applicable electric machine 34,35 of the invention. Versions with multiple output shafts are

will transmit its torque via the gear wheel 15, 16 to the also conceivable.

crown gear 14, Second, however, it is also conceivable to Both transmissions 10 and 10a can be embodied as or be

leave the applicable clutch 29, 30 open, and to transmit the 40 a component of manual transmissions or automatic trans

additional torque directly to the output shaft 25 via a gear missions. In either case, however, because of the Sometimes

wheel pair 1E, 1A through 5E, 5A. To that end, however, as quite complex events, it is necessary that an electronic

in a gear change, the rpm of one gear wheel pair 1E, 1A Switchgear be used for open- or closed-loop control of the

through 5E, 5A of the applicable input shaft 12, 13 must be various events; this Switchgear processes the measurement

Synchronized with the rpm of whichever gear wheel pair 1E, 45 values detected by the Sensors mentioned and in turn triggers

1A through 5E, 5A is in engagement at the moment, and then actuators, for example for displacing the sliding cuffs, or

the nonpositive engagement with the output Shaft 25 must be Selects various modes of operation.

established. What is claimed is:

In contrast to the exemplary embodiment of FIG. 1, in the 1. A transmission for a motor vehicle having an internal

transmission 10a of FIG. 2 only a single electric machine 10 50 combustion engine, comprising at least two transmission

40 is required, which is disposed between the input shafts input shafts and at least one transmission output shaft having

12, 13. If possible, the same reference numerals have been a plurality of pairs of gear wheels that form different ratioS

used otherwise in FIG. 2 for identical components of the between said at least two transmission input shafts and Said

transmissions 10 and 10a. The electric machine 40 is at least one transmission output shaft; two clutch devices for

coupled with a gear wheel 41, which drives two further gear 55 connecting the internal combustion engine of the motor

wheels 42, 43 that are disposed loosely on the respective vehicle to Said at least one output Shaft by nonpositive

input shaft 12 and 13. Additional gear wheels 44 and 45, engagement, at least one of Said transmission input Shafts is

secured firmly to the respective input shaft 13 and 13, via coupleable to at least one electrical machine which, for

sliding cuffs 46 and 47, furnish the requisite nonpositive Starting the internal combustion engine, drives at least one of

engagement with the electric machine 40. The gear changes 60 Said transmission input shafts connectable le by nonpositive

take place analogously to the first exemplary embodiment; engagement to the engine, and for driving the motor vehicle

the electric machine 40 sets the synchronized rpm of the in reverse with Said clutch devices disengaged drives Said at

input shaft 12, 13 of the target gear, and this shaft is in this least one transmission output shaft.

case coupled to the electric machine 40 by means of the 2. A transmission for a motor Vehicle as defined in claim

sliding cuff 46 or 47. 65 1, wherein the two transmission input Shafts which each

In contrast to the first exemplary embodiment, Starting of cooperate with a respective electrical machine and one

the engine 11 by means of the transmission 10a is done by transmission output shaft are provided, and the electrical

US 6,712,734 B1

7 8

machines being disposed on Sides of Said clutch devices 7. A transmission for a motor Vehicle as defined in claim

remote from the internal combustion engine. 1; and further comprising a device for blocking Said trans

3. A transmission for a motor vehicle as defined in claim mission output Shaft and disposed on Said at least one

1, wherein the two transmission input shafts, one transmis transmission output shaft.

Sion output Shaft and one electrical machine are provided, 8. The transmission of claim 1, characterized in that for

and the electrical machine is coupleable to one of the driving the motor vehicle in reverse, while at least one of the

transmission input Shafts. clutch devices disengaged, at least one of the electric

4. A transmission for a motor vehicle as defined in claim machines drives the at least one transmission output shaft.

1, wherein the two transmission input shafts, one transmis 9. The transmission of claim 1, characterized in that to

Sion output Shaft and one electrical machine are provided, reinforce the torque induced by the engine to the at least one

and the electrical machine is coupleable to both the trans transmission output shaft, at least one electric machine

mission input shafts. introduces an additional torque to the at least one transmis

5. A transmission for a motor vehicle as defined in claim Sion output shaft, in the same direction of rotation as the

1, wherein the nonpositive engagement between the at least engine.

one electrical machine and at least one of Said transmission 15 10. A method for operating a transmission for a motor

input shafts is effected directly. vehicle, in particular a twin-clutch manual transmission of

6. A transmission for a motor vehicle as defined in claim claim 1, characterized in that for energy recovery in the

1; and further comprising an intermediate transmission overrunning mode of the motor vehicle, with at least one of

which effects the nonpositive engagement between the at the clutch devices disengaged, at least one electric machine

least one electrical machine and at least one of Said trans is driven by its input Shaft and functions as a generator.

mission input shafts. k k k k k

Potrebbero piacerti anche

- Transormer For HV X RayDocumento24 pagineTransormer For HV X RayArmando LopezNessuna valutazione finora

- Contactless Electromechanical Actuator With Coupled Electronic Motor Commutation and Output Position SensorsDocumento18 pagineContactless Electromechanical Actuator With Coupled Electronic Motor Commutation and Output Position SensorsHassanNessuna valutazione finora

- United States Patent (10) Patent No.: US 7,188.478 B2: Bourgeois (45) Date of Patent: Mar. 13, 2007Documento10 pagineUnited States Patent (10) Patent No.: US 7,188.478 B2: Bourgeois (45) Date of Patent: Mar. 13, 2007Mateus GaygerNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,634,175 B1: Kawata Et Al. (45) Date of Patent: Oct. 21, 2003Documento22 pagineUnited States Patent (10) Patent No.: US 6,634,175 B1: Kawata Et Al. (45) Date of Patent: Oct. 21, 2003RohitNessuna valutazione finora

- Compact FusionDocumento7 pagineCompact Fusionpaperoni iNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002Documento10 pagineUnited States Patent (10) Patent No.: US 6,367,365 B1: Weickert Et Al. (45) Date of Patent: Apr. 9, 2002back1949Nessuna valutazione finora

- SKX (E.g. As: (12) United States Patent (10) Patent No.: US 6,626,712 B1Documento9 pagineSKX (E.g. As: (12) United States Patent (10) Patent No.: US 6,626,712 B1shruti kapseNessuna valutazione finora

- 59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Documento22 pagine59 0f1-,-,,é - 1,, M 13,553 $525113ei Iiii?if III Fifit 21811101511121.1118Qwerty UiopNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,327,954 B1: Medlin (45) Date of Patent: Dec. 11, 2001Documento29 pagineUnited States Patent (10) Patent No.: US 6,327,954 B1: Medlin (45) Date of Patent: Dec. 11, 2001Mary HullNessuna valutazione finora

- Bubbler InkDocumento25 pagineBubbler Inkhoax008Nessuna valutazione finora

- US6840311Documento11 pagineUS6840311Pardeep SharmaNessuna valutazione finora

- United States Patent: Gaydos Et AlDocumento8 pagineUnited States Patent: Gaydos Et AlHugo Mauricio Echeverry HerreraNessuna valutazione finora

- Segmented Bearing BushingDocumento12 pagineSegmented Bearing BushingAnonymous 2k25WMLY0Nessuna valutazione finora

- 2008 - US007461707B2 - Electric HDD Machine SystemDocumento12 pagine2008 - US007461707B2 - Electric HDD Machine SystemCường Nguyễn QuốcNessuna valutazione finora

- US6804943Documento6 pagineUS6804943Abdullah KhanNessuna valutazione finora

- Us6944575Documento49 pagineUs6944575Anonymous KiraNessuna valutazione finora

- Mold CastingDocumento22 pagineMold CastingDicky MadikatamaNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,773,818 B2: Cretekos Et Al. (45) Date of Patent: Aug. 10, 2004Documento10 pagineUnited States Patent (10) Patent No.: US 6,773,818 B2: Cretekos Et Al. (45) Date of Patent: Aug. 10, 2004Arif QA AresNessuna valutazione finora

- United States Patent (10) Patent No.: Us 6,197,264 B1: Korhonen Et Al. (45) Date of Patent: Mar. 6, 2001Documento13 pagineUnited States Patent (10) Patent No.: Us 6,197,264 B1: Korhonen Et Al. (45) Date of Patent: Mar. 6, 2001yamakunNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,382,646 B1: Shaw (45) Date of Patent: May 7, 2002Documento10 pagineUnited States Patent (10) Patent No.: US 6,382,646 B1: Shaw (45) Date of Patent: May 7, 2002Eric Manuel Mercedes AbreuNessuna valutazione finora

- US7156267Documento7 pagineUS7156267Efabind OtNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,767,161 B1: 107, Pasadena, CA (US) 91105 Janet E. A: 19: Taberg OSRDocumento12 pagineUnited States Patent (10) Patent No.: US 6,767,161 B1: 107, Pasadena, CA (US) 91105 Janet E. A: 19: Taberg OSRSpring SuperbNessuna valutazione finora

- United States Patent: Al-HawajDocumento23 pagineUnited States Patent: Al-Hawaj임학진Nessuna valutazione finora

- United States Patent (10) Patent N0.2 US 6,583,656 B1Documento10 pagineUnited States Patent (10) Patent N0.2 US 6,583,656 B1SaurabhABCNessuna valutazione finora

- US8567791 Head GasketDocumento7 pagineUS8567791 Head Gaskethamed soleymaniNessuna valutazione finora

- Sizii: (12) United States PatentDocumento10 pagineSizii: (12) United States PatentrakkaNessuna valutazione finora

- United States Patent: (10) Patent No.: (45) Date of PatentDocumento21 pagineUnited States Patent: (10) Patent No.: (45) Date of PatentRicardo Jimenez SNessuna valutazione finora

- US7743601Documento4 pagineUS7743601Alien GmpNessuna valutazione finora

- Us8261906 - SBRDocumento8 pagineUs8261906 - SBRLOAN PHẠM THỊ PHƯƠNGNessuna valutazione finora

- Wheel PWR GenerationDocumento8 pagineWheel PWR GenerationAsad Ahmed KhanNessuna valutazione finora

- US6522106 AVR Generator Patent HondaDocumento8 pagineUS6522106 AVR Generator Patent HondaBruno LambertNessuna valutazione finora

- 7.3/123,125,129,865,6,146 303,122 122.5 TCE"C. F Rhen. Pontani. LiebDocumento7 pagine7.3/123,125,129,865,6,146 303,122 122.5 TCE"C. F Rhen. Pontani. LiebNamelezz ShadowwNessuna valutazione finora

- Tesla Patent2 PDFDocumento26 pagineTesla Patent2 PDFatirinaNessuna valutazione finora

- United States Patent: US 7,574,795 B2 Aug. 18,2009Documento17 pagineUnited States Patent: US 7,574,795 B2 Aug. 18,2009amd mhmNessuna valutazione finora

- United States Patent (10) Patent No.: US 9,080,720 B2Documento16 pagineUnited States Patent (10) Patent No.: US 9,080,720 B2sfjhsakjfhNessuna valutazione finora

- Us 6758544Documento16 pagineUs 6758544norbertscribdNessuna valutazione finora

- United States Patent: (10) Patent No.: (45) Date of PatentDocumento20 pagineUnited States Patent: (10) Patent No.: (45) Date of PatentzhenyupanNessuna valutazione finora

- United States Patent (10) Patent No.: US 7489,225 B2: Dadafshar (45) Date of Patent: Feb. 10, 2009Documento24 pagineUnited States Patent (10) Patent No.: US 7489,225 B2: Dadafshar (45) Date of Patent: Feb. 10, 2009Jie99Nessuna valutazione finora

- Adsorption 5ADocumento9 pagineAdsorption 5ANguyễn Thị Kim PhượngNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,599,476 B1: Watson Et Al. (45) Date of Patent: Jul. 29, 2003Documento38 pagineUnited States Patent (10) Patent No.: US 6,599,476 B1: Watson Et Al. (45) Date of Patent: Jul. 29, 2003Jie99Nessuna valutazione finora

- Compressor Casing Gas Turbine JournalDocumento9 pagineCompressor Casing Gas Turbine JournalRaditya IqbalNessuna valutazione finora

- United States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009Documento11 pagineUnited States Patent (10) Patent No.: US 7.587,842 B2: Tajiri Et Al. (45) Date of Patent: Sep. 15, 2009emre yıldırımNessuna valutazione finora

- United States Patent: (12) (10) Patent N0.: US 7,259,469 B2Documento10 pagineUnited States Patent: (12) (10) Patent N0.: US 7,259,469 B2Floyd PriceNessuna valutazione finora

- United States Patent (10) Patent No.: US 8,794,651 B2Documento29 pagineUnited States Patent (10) Patent No.: US 8,794,651 B2swapnil kaleNessuna valutazione finora

- US9360082Documento11 pagineUS9360082kippcamNessuna valutazione finora

- United States Patent: (10) Patent No.: US 7,605,347 B2Documento20 pagineUnited States Patent: (10) Patent No.: US 7,605,347 B2Mihail AvramovNessuna valutazione finora

- Us 6964501Documento12 pagineUs 6964501alchjunkmailNessuna valutazione finora

- Flat Glass Annealing LehrsDocumento7 pagineFlat Glass Annealing LehrsHồng ĐàoNessuna valutazione finora

- United States Patent (10) Patent No.: US 6,692,544 B1: Grillenzoni (45) Date of Patent: Feb. 17, 2004Documento20 pagineUnited States Patent (10) Patent No.: US 6,692,544 B1: Grillenzoni (45) Date of Patent: Feb. 17, 2004rianne nabilahNessuna valutazione finora

- Us 7665468Documento13 pagineUs 7665468moustafahamod9Nessuna valutazione finora

- Mte CutawayDocumento14 pagineMte CutawayMujeres Virglius PabliusNessuna valutazione finora

- United States Patent: Shepard (45) Date of Patent: Sep. 13, 2016Documento11 pagineUnited States Patent: Shepard (45) Date of Patent: Sep. 13, 2016Budo Gold CoastNessuna valutazione finora

- United States Patent: (12) (10) Patent N0.: US 7,267,030 B2Documento15 pagineUnited States Patent: (12) (10) Patent N0.: US 7,267,030 B2cirno9Nessuna valutazione finora

- United States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Documento20 pagineUnited States Patent (10) Patent No.: US 7,681,342 B2: Choi (45) Date of Patent: Mar. 23, 2010Ronan RojasNessuna valutazione finora

- ConstrctivoDocumento9 pagineConstrctivobrandon padillaNessuna valutazione finora

- United States Patent (10) Patent No.: US 8,970,075 B2Documento14 pagineUnited States Patent (10) Patent No.: US 8,970,075 B2Sanjay SharmaNessuna valutazione finora

- US9212603Separate-type Rotary EngineDocumento12 pagineUS9212603Separate-type Rotary Engine임학진Nessuna valutazione finora

- 2002 - Us6491115 - Directional Drilling Machine and Method of Directional DrillingDocumento42 pagine2002 - Us6491115 - Directional Drilling Machine and Method of Directional DrillingCường Nguyễn QuốcNessuna valutazione finora

- United States Patent (10) Patent N0.: US 8,899,217 B2Documento7 pagineUnited States Patent (10) Patent N0.: US 8,899,217 B2Teleson MarquesNessuna valutazione finora

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PDa EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNessuna valutazione finora

- Us 7151027Documento11 pagineUs 7151027pmurphNessuna valutazione finora

- Us 6996461Documento12 pagineUs 6996461pmurphNessuna valutazione finora

- Us 6900124Documento11 pagineUs 6900124pmurphNessuna valutazione finora

- Us 5567207Documento7 pagineUs 5567207pmurphNessuna valutazione finora

- Us 6369416Documento8 pagineUs 6369416pmurphNessuna valutazione finora

- Us 7018922Documento11 pagineUs 7018922pmurphNessuna valutazione finora

- Us 7092801Documento11 pagineUs 7092801pmurphNessuna valutazione finora

- Us 5591678Documento8 pagineUs 5591678pmurphNessuna valutazione finora

- Patent Application Publication (10) Pub - No .: US 2020/0027096 A1Documento92 paginePatent Application Publication (10) Pub - No .: US 2020/0027096 A1pmurphNessuna valutazione finora

- United States Patent: Wardenburg (45) Date of Patent: Jul. 22, 2003Documento14 pagineUnited States Patent: Wardenburg (45) Date of Patent: Jul. 22, 2003pmurphNessuna valutazione finora

- IND INI: Patent Application Publication (10) Pub - No .: US 2019/0373472 A1Documento94 pagineIND INI: Patent Application Publication (10) Pub - No .: US 2019/0373472 A1pmurphNessuna valutazione finora

- United States Patent (10) Patent No.: US 8,209,912 B2Documento14 pagineUnited States Patent (10) Patent No.: US 8,209,912 B2pmurphNessuna valutazione finora

- United States Patent: (10) Patent No .: US 11,234,891 B2 (45) Date of Patent: Feb - 1, 2022Documento60 pagineUnited States Patent: (10) Patent No .: US 11,234,891 B2 (45) Date of Patent: Feb - 1, 2022pmurphNessuna valutazione finora

- United States Patent: Related U.S. Application Data Split It. Other, Printout Als N ArDocumento17 pagineUnited States Patent: Related U.S. Application Data Split It. Other, Printout Als N ArpmurphNessuna valutazione finora

- United States Patent: Nakamura Et AlDocumento32 pagineUnited States Patent: Nakamura Et AlpmurphNessuna valutazione finora

- Vannanen: (12) United States PatentDocumento11 pagineVannanen: (12) United States PatentpmurphNessuna valutazione finora

- US20180273642A1Documento63 pagineUS20180273642A1pmurphNessuna valutazione finora

- United States Patent: (10) Patent No .: US 10,949,429 B1Documento37 pagineUnited States Patent: (10) Patent No .: US 10,949,429 B1pmurphNessuna valutazione finora

- United States Patent: (10) Patent No .: US 9, 859, 464 B2 (45) Date of Patent: Jan - 2, 2018Documento21 pagineUnited States Patent: (10) Patent No .: US 9, 859, 464 B2 (45) Date of Patent: Jan - 2, 2018pmurphNessuna valutazione finora

- Joooool: 000000 LogoodDocumento16 pagineJoooool: 000000 LogoodpmurphNessuna valutazione finora

- United: States PatentDocumento37 pagineUnited: States PatentpmurphNessuna valutazione finora

- United States Patent: Nakamura Et AlDocumento32 pagineUnited States Patent: Nakamura Et AlpmurphNessuna valutazione finora

- Pada:: (12) United States PatentDocumento33 paginePada:: (12) United States PatentpmurphNessuna valutazione finora

- United States Patent: Nakamura Et AlDocumento32 pagineUnited States Patent: Nakamura Et AlpmurphNessuna valutazione finora

- United States Patent (10) Patent No.: US 7,051,539 B2: A. Schmidt, Newburgh, IN (US) 3. A. E. E. A. O. 3.87Documento27 pagineUnited States Patent (10) Patent No.: US 7,051,539 B2: A. Schmidt, Newburgh, IN (US) 3. A. E. E. A. O. 3.87pmurphNessuna valutazione finora

- TEPZZ 64969ZB - T: European Patent SpecificationDocumento17 pagineTEPZZ 64969ZB - T: European Patent SpecificationpmurphNessuna valutazione finora

- Patent Application Publication (10) Pub. No.: US 2016/0161167 A1Documento17 paginePatent Application Publication (10) Pub. No.: US 2016/0161167 A1pmurphNessuna valutazione finora

- United States Patent: Demille Et Al. (45) Date of Patent: Jan. 19, 2016Documento21 pagineUnited States Patent: Demille Et Al. (45) Date of Patent: Jan. 19, 2016pmurphNessuna valutazione finora

- United States Patent: (10) Patent No.: (45) Date of PatentDocumento25 pagineUnited States Patent: (10) Patent No.: (45) Date of PatentpmurphNessuna valutazione finora

- TEPZZ Z - 688B - T: European Patent SpecificationDocumento25 pagineTEPZZ Z - 688B - T: European Patent SpecificationpmurphNessuna valutazione finora

- Ce Licensure Examination Problems Rectilinear Translation 6Documento2 pagineCe Licensure Examination Problems Rectilinear Translation 6Ginto AquinoNessuna valutazione finora

- DR Afwan Fajri - Trauma - Juli 2023Documento82 pagineDR Afwan Fajri - Trauma - Juli 2023afwan fajriNessuna valutazione finora

- 4BT3 9-G2 PDFDocumento5 pagine4BT3 9-G2 PDFNv Thái100% (1)

- Gics-In-India Getting Ready For The Digital WaveDocumento81 pagineGics-In-India Getting Ready For The Digital Wavevasu.gaurav75% (4)

- Motion To Dismiss Guidry Trademark Infringement ClaimDocumento23 pagineMotion To Dismiss Guidry Trademark Infringement ClaimDaniel BallardNessuna valutazione finora

- MikoritkDocumento6 pagineMikoritkChris Jonathan Showip RouteNessuna valutazione finora

- Approved College List: Select University Select College Type Select MediumDocumento3 pagineApproved College List: Select University Select College Type Select MediumDinesh GadkariNessuna valutazione finora

- 0409 Book About Minoru Yamasaki, ReviewDocumento4 pagine0409 Book About Minoru Yamasaki, RevieweviannNessuna valutazione finora

- Vertical Cutoff WallsDocumento18 pagineVertical Cutoff WallsMark LaiNessuna valutazione finora

- Book of IQ TestsDocumento124 pagineBook of IQ TestsFox Mango100% (4)

- MotorsDocumento116 pagineMotorsAmália EirezNessuna valutazione finora

- 04 Task Performance 1Documento2 pagine04 Task Performance 1mart arvyNessuna valutazione finora

- Net Pert: Cable QualifierDocumento4 pagineNet Pert: Cable QualifierAndrés Felipe Fandiño MNessuna valutazione finora

- Purposive Communication Preliminary DiscussionDocumento2 paginePurposive Communication Preliminary DiscussionJohn Mark100% (1)

- Department of Education: Republic of The PhilippinesDocumento1 paginaDepartment of Education: Republic of The PhilippinesKlaribelle VillaceranNessuna valutazione finora

- Paper 4 Material Management Question BankDocumento3 paginePaper 4 Material Management Question BankDr. Rakshit Solanki100% (2)

- Jordan CVDocumento2 pagineJordan CVJordan Ryan SomnerNessuna valutazione finora

- NJEX 7300G: Pole MountedDocumento130 pagineNJEX 7300G: Pole MountedJorge Luis MartinezNessuna valutazione finora

- Different Principles Tools and Techniques in Creating A BusinessDocumento5 pagineDifferent Principles Tools and Techniques in Creating A BusinessLuna LedezmaNessuna valutazione finora

- Internship Report PDFDocumento71 pagineInternship Report PDFNafiz FahimNessuna valutazione finora

- State Farm Claims: PO Box 52250 Phoenix AZ 85072-2250Documento2 pagineState Farm Claims: PO Box 52250 Phoenix AZ 85072-2250georgia ann polley-yatesNessuna valutazione finora

- 5 - Perception and Individual Decision Making in Organizational BehaviorDocumento25 pagine5 - Perception and Individual Decision Making in Organizational BehaviorJanaVrsalovićNessuna valutazione finora

- Piping Class Spec. - 1C22 (Lurgi)Documento9 paginePiping Class Spec. - 1C22 (Lurgi)otezgidenNessuna valutazione finora

- SAP HCM Case StudyDocumento17 pagineSAP HCM Case StudyRafidaFatimatuzzahraNessuna valutazione finora

- AWS Compete CustomerDocumento33 pagineAWS Compete CustomerSergeyNessuna valutazione finora

- Distance SortDocumento6 pagineDistance SortAI Coordinator - CSC JournalsNessuna valutazione finora

- M.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanDocumento43 pagineM.Sc. Steel Structures LEC. #7 Plastic Analysis and Design: Dr. Qasim Shaukat KhanSSNessuna valutazione finora

- 2 Calculation ProblemsDocumento4 pagine2 Calculation ProblemsFathia IbrahimNessuna valutazione finora

- TABEL Sifat Uap Jenuh Tabel Suhu Dan TekananDocumento8 pagineTABEL Sifat Uap Jenuh Tabel Suhu Dan Tekanan21-002 Alditua sinabaribaNessuna valutazione finora

- China's Military UAV Industry - 14 June 2013Documento21 pagineChina's Military UAV Industry - 14 June 2013Deep Kanakia100% (1)