Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Aisc Lrfd-93 Example 002

Caricato da

Rodrigo PereiraCopyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

Aisc Lrfd-93 Example 002

Caricato da

Rodrigo PereiraCopyright:

Formati disponibili

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

AISC LRFD-93 Example 002

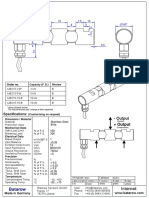

WIDE FLANGE MEMBER UNDER COMBINED COMPRESSION & BIAXIAL BENDING

EXAMPLE DESCRIPTION

A check of the column adequacy is checked for combined axial compression and

flexural loads. The column is 14 feet tall and loaded with an axial load,

Pu = 1400 kips and bending, M ux , M uy = 200k-ft and 70k-ft, respectively. It is

assumed that there is reverse-curvature bending with equal end moments about

both axes and no loads along the member. The column demand/capacity ratio is

checked against the results of Example 6.2 in the 3rd Edition, LRFD Manual of

Steel Construction, pages 6-6 to 6-8.

GEOMETRY, PROPERTIES AND LOADING

Member Properties Loading Geometry

W14X176 Pu = 1,400 kips H = 14.0 ft

E = 29000 ksi Mux = 200 kip-ft

Fy = 50 ksi Muy = 70 kip-ft

TECHNICAL FEATURES TESTED

Section compactness check (compression)

Member compression capacity

Member bending capacity

Demand/capacity ratio, D/C

AISC LRFD-93 Example 002 - 1

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

RESULTS COMPARISON

Independent results are hand calculated and compared with the results from

Example 6.2 in the 3rd Edition, LRFD Manual of Steel Construction, pages 6-6 to

6-8.

Percent

Output Parameter ETABS Independent Difference

Compactness Compact Compact 0.00%

φc Pn (kips) 1937.84 1937.84 0.00%

φb M nx (k-ft) 1200 1200 0.00%

φb M ny (k-ft) 600.478 600.478 0.00%

D/C 0.974 0.974 0.00%

COMPUTER FILE: AISC LRFD-93 EX002

CONCLUSION

The results show an exact comparison with the independent results.

AISC LRFD-93 Example 002 - 2

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

HAND CALCULATION

Properties:

Material: ASTM A992 Grade 50 Steel

Fy = 50 ksi, E = 29,000 ksi

Section: W14x176

A = 51.8 in2,

bf = 15.7 in, tf = 1.31 in, d = 15.2 in, tw = 0.83 in

hc = d − 2t f = 15.2 − 2 • 1.31 = 12.58 in

Ix = 2,140 in4, Iy = 838 in4, rx = 6.4275 in, ry = 4.0221 in

Sx = 281.579 in3, Sy = 106.7516 in3, Zx = 320.0 in3, Zy = 163.0 in3.

Member:

Kx = Ky = 1.0

L = Lb = 14 ft

Other

φc =0.85

φb =0.9

Loadings:

Pu = 1400 kips

Mux = 200 k-ft

Muy = 70 k-ft

Section Compactness:

Localized Buckling for Flange:

= λ

( b=

f / 2) (15.7 / 2)

= 5.99

tf 1.31

65 65

λ=

p = = 9.19

Fy 50

λ < λ p , No localized flange buckling

Flange is Compact.

AISC LRFD-93 Example 002 - 3

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

Localized Buckling for Web:

h 12.58

λ= c= = 15.16

tw 0.83

φb Py =φb Ag Fy =0.9 • 51.8 • 50 =

2331 kips

Pu 1400

= = 0.601

φb Py 2331

Pu

Since = 0.601 > 0.125

φb Py

191 P 253

=λp 2.33 − u ≥

Fy φb Py Fy

191 253

=

λp ( 2.33 − 0.601

= ) 46.714 ≥ = 35.780

50 50

λ < λ p , No localized web buckling

Web is Compact.

Section is Compact.

Member Compression Capacity:

For braced frames, K = 1.0 and KxLx = KyLy = 14.0 ft, From AISC Table 4-2,

φc Pn =

1940 kips

Or by hand,

K y L Fy 1.0 • 14 • 12 50

=λc = = 0.552

ry π E 4.022 • π 29000

Since λ c < 1.5,

(

Fy 0.658λc

Fcr =

2

)=

50 • 0.658 0.5522

=

44.012 ksi

φc Pn =

φc Fcr Ag =

0.85 • 44.012 • 51.8

φc Pn =

1937.84 kips

AISC LRFD-93 Example 002 - 4

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

From LRFD Specification Section H1.2,

Pu 1400

= = 0.722 > 0.2

φc Pn 1937.84

Therefore, LRFD Specification Equation H1-1a governs.

Section Bending Capacity

50 • 310

=

M px F=

yZx = 1333.333 k-ft

12

M py = Fy Z y

Zy 163

However,= = 1.527 > 1.5,

S y 106.7516

So

Zy = 1.5 S y =1.5 • 106.7516 =

160.1274in 3

50 • 160.1274

=M py = 667.198 k-ft

12

Member Bending Capacity

From LRFD Specification Equation F1-4,

E

L p = 1.76ry

Fyf

29000 1

L= 1.76 • 4.02 • = 14.2 ft > L= 14 ft

p

50 12 b

φb M nx =

φb M px

φb M nx =0.9 • 1333.333

φb M nx =

1200 k-ft

φb M ny =

φb M py

φb M ny =

0.9 • 667.198

φb M ny =

600.478 k-ft

AISC LRFD-93 Example 002 - 5

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

Interaction Capacity: Compression & Bending

From LRFD Specification section C1.2, for a braced frame, Mlt = 0.

M ux = B1x M ntx , where M ntx = 200 kip-ft; and

M uy = B1 y M nty , where M nty = 70 kip-ft

Cm

B1 = ≥1

P

1 − u

Pe1

For reverse curvature bending and equal end moments:

M1

= +1.0

M2

M

C m = 0.6 − 0.4 1

M2

C m = 0.6 − 0.4(1.0 ) = 0.2

π2 EI

pe1 =

( KL )

2

π2 • 29000 • 2140

=pe1x = 21, 702 kips

(14.0 • 12 )

2

π2 • 29000 • 838

=pe1 y = 8, 498

(14.0 • 12 )

2

C mx

B1x = ≥1

Pu

1 −

Pe1x

0.2

=

B1x = 0.214 ≥ 1

1400

1 −

21702

AISC LRFD-93 Example 002 - 6

Software Verification

PROGRAM NAME: ETABS

REVISION NO.: 0

B1x = 1

C my

B1 y = ≥1

P

1 − u

P

e1 y

0.2

=

B1 y = 0.239 ≥ 1

1400

1 −

8498

B1 y = 1

M ux = 1.0 • 200 = 200 kip-ft;

and

M uy = 1.0 • 70 = 70 kip-ft

From LRFD Specification Equation H1-1a,

1400 8 200 70

+ + =0.974 < 1.0 , OK

1940 9 1200 600.478

D

= 0.974

C

AISC LRFD-93 Example 002 - 7

Potrebbero piacerti anche

- Solution Manual for an Introduction to Equilibrium ThermodynamicsDa EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNessuna valutazione finora

- Exercises in Electronics: Operational Amplifier CircuitsDa EverandExercises in Electronics: Operational Amplifier CircuitsValutazione: 3 su 5 stelle3/5 (1)

- Aisc Lrfd-93 Example 002Documento7 pagineAisc Lrfd-93 Example 002Antonius AjalahNessuna valutazione finora

- AISC LRFD-93 Example 001 PDFDocumento7 pagineAISC LRFD-93 Example 001 PDFDompu MengajiNessuna valutazione finora

- Aisc Lrfd-93 Example 001Documento7 pagineAisc Lrfd-93 Example 001Gerardo CordobaNessuna valutazione finora

- AISC 360-10 Example 001Documento7 pagineAISC 360-10 Example 001Antonius AjalahNessuna valutazione finora

- Aisc Lrfd-93 Example 002Documento7 pagineAisc Lrfd-93 Example 002Anitha Hassan KabeerNessuna valutazione finora

- AISC 360-05 Example 001Documento7 pagineAISC 360-05 Example 001Ronald SotoNessuna valutazione finora

- Software Verification: AISC 360-10 Example 001Documento7 pagineSoftware Verification: AISC 360-10 Example 001Gerardo CordobaNessuna valutazione finora

- Software Verification: AISC 360-16 SFD Example 001Documento7 pagineSoftware Verification: AISC 360-16 SFD Example 001Dompu MengajiNessuna valutazione finora

- Software Verification: AISC 360-05 Example 001Documento7 pagineSoftware Verification: AISC 360-05 Example 001Gerardo CordobaNessuna valutazione finora

- AISC 360-05 Example 001 PDFDocumento7 pagineAISC 360-05 Example 001 PDFHendrik TaupanNessuna valutazione finora

- KBC 2009 Example 002Documento6 pagineKBC 2009 Example 002Mohamed Abo-ZaidNessuna valutazione finora

- AISC 360-05 Example 002Documento6 pagineAISC 360-05 Example 002Antonius AjalahNessuna valutazione finora

- AISC 360-16 Example 002Documento6 pagineAISC 360-16 Example 002Mohamed Abo-ZaidNessuna valutazione finora

- Software Verification: AISC-360-16 Example 003Documento5 pagineSoftware Verification: AISC-360-16 Example 003alejandro mantillaNessuna valutazione finora

- Aisc Lrfd-99 Example 002Documento7 pagineAisc Lrfd-99 Example 002Bùi Văn HợpNessuna valutazione finora

- Aisc Lrfd-99 Example 002Documento7 pagineAisc Lrfd-99 Example 002dilaislamiahnuruswahNessuna valutazione finora

- Aisc Asd-89 Example 001Documento5 pagineAisc Asd-89 Example 001gusla7Nessuna valutazione finora

- Software Verification: AISC 360-05 Example 002Documento6 pagineSoftware Verification: AISC 360-05 Example 002Gerardo CordobaNessuna valutazione finora

- KBC 2016 Example 002Documento6 pagineKBC 2016 Example 002C Y Lee (Keith)Nessuna valutazione finora

- SCBF Parallel NewDocumento156 pagineSCBF Parallel NewZarna ModiNessuna valutazione finora

- KBC 2009 Example 001 PDFDocumento7 pagineKBC 2009 Example 001 PDFMohamed Abo-ZaidNessuna valutazione finora

- Seismic For Special Plate Shear WallDocumento3 pagineSeismic For Special Plate Shear WallJheo TorresNessuna valutazione finora

- CSA S16-14 Example 002fgfDocumento7 pagineCSA S16-14 Example 002fgfBoby CuliusNessuna valutazione finora

- Design Criteria: Seismic Design For Special Plate Shear Wall Based On AISC 341-10/16 & AISC 360-10/16Documento4 pagineDesign Criteria: Seismic Design For Special Plate Shear Wall Based On AISC 341-10/16 & AISC 360-10/16innovativekarthiNessuna valutazione finora

- CSI IS 800-2007 Example 001Documento5 pagineCSI IS 800-2007 Example 001JESSIE B. GIRAYNessuna valutazione finora

- Software Verification: IS 800-2007 Example 001Documento5 pagineSoftware Verification: IS 800-2007 Example 001putra wiraNessuna valutazione finora

- Software Verification: AISC-360-16 Example 004Documento4 pagineSoftware Verification: AISC-360-16 Example 004alejandro mantillaNessuna valutazione finora

- EN 3-2005 Example 002Documento5 pagineEN 3-2005 Example 002dar.elhalNessuna valutazione finora

- Software Verification: AISC-360-10 Example 001Documento9 pagineSoftware Verification: AISC-360-10 Example 001Davico HernandezNessuna valutazione finora

- IS 800-2007 Example 002w321321weDocumento6 pagineIS 800-2007 Example 002w321321weputra wiraNessuna valutazione finora

- CSA S16-14 Example 001 PDFDocumento8 pagineCSA S16-14 Example 001 PDFMohamed Abo-ZaidNessuna valutazione finora

- EN 3-2005 Example 001Documento7 pagineEN 3-2005 Example 001dar.elhalNessuna valutazione finora

- AISC ASD-01 Example 001 PDFDocumento5 pagineAISC ASD-01 Example 001 PDFHendrik TaupanNessuna valutazione finora

- Software Verification: EN 3-2005 Example 002Documento5 pagineSoftware Verification: EN 3-2005 Example 002putra wiraNessuna valutazione finora

- Etabs 2016 16.2Documento6 pagineEtabs 2016 16.2kervinarmasNessuna valutazione finora

- BS 5950-2000 Example 002Documento5 pagineBS 5950-2000 Example 002Mohamed Abo-ZaidNessuna valutazione finora

- Aisc Lrfd-93 Example 001Documento7 pagineAisc Lrfd-93 Example 001Bùi Văn HợpNessuna valutazione finora

- NZS 3404-1997 Example 001 PDFDocumento5 pagineNZS 3404-1997 Example 001 PDFMohamed Abo-ZaidNessuna valutazione finora

- Software Verification: AISC-360-16 Example 006Documento5 pagineSoftware Verification: AISC-360-16 Example 006alejandro mantillaNessuna valutazione finora

- Software Verification: AISC-360-16 Example 003Documento4 pagineSoftware Verification: AISC-360-16 Example 003alejandro mantillaNessuna valutazione finora

- Software Verification: ACI 318-14 Example 002Documento4 pagineSoftware Verification: ACI 318-14 Example 002yudhi putraNessuna valutazione finora

- Aisc Asd-89 Example 002Documento5 pagineAisc Asd-89 Example 002Antonius AjalahNessuna valutazione finora

- Didactic DC/DC Buck Converter: With Discrete PID ControllerDocumento14 pagineDidactic DC/DC Buck Converter: With Discrete PID ControllerJuan DetemNessuna valutazione finora

- ACI 318-14 ColumnaDocumento4 pagineACI 318-14 ColumnaMoy ReapNessuna valutazione finora

- ACI 318-11 Ex001Documento5 pagineACI 318-11 Ex001Antonius AjalahNessuna valutazione finora

- Software Verification: AISC-360-05 Example 001Documento8 pagineSoftware Verification: AISC-360-05 Example 001Zakir KhanNessuna valutazione finora

- Meinnen Holltrop MethodDocumento17 pagineMeinnen Holltrop Methodvenkat krishnaNessuna valutazione finora

- Column Supporting DiscontinuousDocumento40 pagineColumn Supporting DiscontinuousRohan JaiswalNessuna valutazione finora

- ACI 318-08 Ex002Documento4 pagineACI 318-08 Ex002Antonius AjalahNessuna valutazione finora

- Connection Design: B104-CJ: ETABS 2016 16.0.3 License # 15QT3R6KGWUL9HRDocumento4 pagineConnection Design: B104-CJ: ETABS 2016 16.0.3 License # 15QT3R6KGWUL9HReffan f gultomNessuna valutazione finora

- Software Verification: CSA S16-09 Example 001Documento8 pagineSoftware Verification: CSA S16-09 Example 001putra wiraNessuna valutazione finora

- Bolted Moment ConnectionDocumento18 pagineBolted Moment ConnectionAlpha50% (2)

- Basement Column Supporting Lateral Resisting Frame Based On ACI 318-08 Input Data & Design SummaryDocumento3 pagineBasement Column Supporting Lateral Resisting Frame Based On ACI 318-08 Input Data & Design SummaryAnonymous fLgaidVBhzNessuna valutazione finora

- Software Verification: AISC-360-10 Example 002Documento9 pagineSoftware Verification: AISC-360-10 Example 002Mohamed Abo-ZaidNessuna valutazione finora

- Department of Mechanical EngineeringDocumento4 pagineDepartment of Mechanical EngineeringNihar RoyNessuna valutazione finora

- Economical Testing of Large Induction Motors by JEC 37, 1979Documento18 pagineEconomical Testing of Large Induction Motors by JEC 37, 1979N. T. DadlaniNessuna valutazione finora

- ACI 318-08 Example 001Documento5 pagineACI 318-08 Example 001RMM100% (1)

- Cantoneira Perfis Abas IguaisDocumento20 pagineCantoneira Perfis Abas IguaisRogerio Salarini JabbourNessuna valutazione finora

- Specifications Page 1 of 2 UCT-300 7 Ft. Tri-Pod: Model#: 8513158Documento2 pagineSpecifications Page 1 of 2 UCT-300 7 Ft. Tri-Pod: Model#: 8513158Rodrigo PereiraNessuna valutazione finora

- Bro 9700107 Side Entry Rev00Documento4 pagineBro 9700107 Side Entry Rev00Rodrigo PereiraNessuna valutazione finora

- Mb215 Loadpin Bs Rev BDocumento2 pagineMb215 Loadpin Bs Rev BRodrigo PereiraNessuna valutazione finora

- SPC 8513700 Tank PodDocumento2 pagineSPC 8513700 Tank PodRodrigo PereiraNessuna valutazione finora

- Bro 9700107 Side Entry Rev00Documento4 pagineBro 9700107 Side Entry Rev00Rodrigo PereiraNessuna valutazione finora

- Ifu 8900276 Ak105a TripodDocumento5 pagineIfu 8900276 Ak105a TripodRodrigo PereiraNessuna valutazione finora

- SPC 8513700 Tank PodDocumento2 pagineSPC 8513700 Tank PodRodrigo PereiraNessuna valutazione finora

- Bro 9700107 Side Entry Rev00Documento4 pagineBro 9700107 Side Entry Rev00Rodrigo PereiraNessuna valutazione finora

- Bro 9700104 Winches Rev00Documento16 pagineBro 9700104 Winches Rev00Rodrigo PereiraNessuna valutazione finora

- Bro 9700111 Basic Hoists Rev00Documento4 pagineBro 9700111 Basic Hoists Rev00Rodrigo PereiraNessuna valutazione finora

- Bro 9700101 Adv Hoist Rev00Documento12 pagineBro 9700101 Adv Hoist Rev00Rodrigo PereiraNessuna valutazione finora

- Custom Autodesk Inventor 2013 Material LibraryDocumento10 pagineCustom Autodesk Inventor 2013 Material LibraryRodrigo PereiraNessuna valutazione finora

- A252 PDFDocumento4 pagineA252 PDFRodrigo PereiraNessuna valutazione finora

- SplineDocumento22 pagineSplinekshripNessuna valutazione finora

- Wear Resistant Steel: Material Data Sheet, Edition April 2016Documento6 pagineWear Resistant Steel: Material Data Sheet, Edition April 2016Zoltán PálfyNessuna valutazione finora

- Rate ListDocumento13 pagineRate ListUsamaQadirNessuna valutazione finora

- Fit Up ReportDocumento5 pagineFit Up ReportAkash Singh Tomar100% (1)

- ProValve Cast SteelDocumento12 pagineProValve Cast SteelHarry HonchoNessuna valutazione finora

- Ducting Handbook 4th Ed FinalDocumento56 pagineDucting Handbook 4th Ed FinalamitkdewNessuna valutazione finora

- FD72 Technical Manual 28.10.09Documento74 pagineFD72 Technical Manual 28.10.09cavgsi16vNessuna valutazione finora

- Start-Up Checklist: Safety WarningsDocumento3 pagineStart-Up Checklist: Safety WarningsNorman CanlasNessuna valutazione finora

- BP 07 Roofing and Waterproofing Scope ofDocumento6 pagineBP 07 Roofing and Waterproofing Scope ofjacksondcplNessuna valutazione finora

- Catálogo de Abraçadeiras - STAUFFDocumento96 pagineCatálogo de Abraçadeiras - STAUFFLuiz Carlos NicolaNessuna valutazione finora

- Effect of Casting Speed On Continuous Casting of Steel Slab: January 2014Documento12 pagineEffect of Casting Speed On Continuous Casting of Steel Slab: January 2014Prakash SarangiNessuna valutazione finora

- Digital Viriable-Capacity DX Air Handling Unit Installation and Maintenance ManualDocumento58 pagineDigital Viriable-Capacity DX Air Handling Unit Installation and Maintenance ManualAbyan TaufikNessuna valutazione finora

- Dossier Teca A BDocumento20 pagineDossier Teca A Bpeter2002Nessuna valutazione finora

- Service Handleiding Hisense LC VloermodelDocumento204 pagineService Handleiding Hisense LC VloermodelMichel ZreikNessuna valutazione finora

- AS 1379 - 1997 - Specification and Supply of ConcreteDocumento38 pagineAS 1379 - 1997 - Specification and Supply of Concretekevin kurnia marpaungNessuna valutazione finora

- Mechanical Properties of High-Strength Lightweight ConcreteDocumento8 pagineMechanical Properties of High-Strength Lightweight ConcreteAdán Cogley CantoNessuna valutazione finora

- Thesis RawDocumento74 pagineThesis RawBryan YuNessuna valutazione finora

- Shopping Center-Construction GuidelinesDocumento14 pagineShopping Center-Construction GuidelinesRoy PersonalNessuna valutazione finora

- Is417 Ettringite Formation and The Performance of ConcreteDocumento16 pagineIs417 Ettringite Formation and The Performance of ConcreteMayank Singh100% (1)

- Epoxy Painting & Sand Blasting JobDocumento11 pagineEpoxy Painting & Sand Blasting JobStrategic ThinkingNessuna valutazione finora

- 10.0 Innovative Turbulence Modeling - SST Model in ANSYS CFXDocumento2 pagine10.0 Innovative Turbulence Modeling - SST Model in ANSYS CFXกี้ บางพระNessuna valutazione finora

- Vitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenDocumento50 pagineVitus Bering, Centre For Higher Education: Jens Bertelsen & Jens Peder PedersenAnca IscruNessuna valutazione finora

- Fem Assignment 2 and 3Documento7 pagineFem Assignment 2 and 3Aravind PhoenixNessuna valutazione finora

- EcogenDocumento2 pagineEcogenBelle CervantesNessuna valutazione finora

- Min FlowDocumento4 pagineMin FlowashrafNessuna valutazione finora

- Welding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFDocumento11 pagineWelding Metallurgy of Stainless Steels During Resistance Spot Welding Part I - Fusion Zone PDFKhalid HafezNessuna valutazione finora

- Studies On Cement and Mortar Containing Low-Calcium y Ash, Limestone, and Dolomitic LimestoneDocumento8 pagineStudies On Cement and Mortar Containing Low-Calcium y Ash, Limestone, and Dolomitic LimestoneIsha PatelNessuna valutazione finora

- Number:: Evaluation SubjectDocumento22 pagineNumber:: Evaluation SubjectKevin ChanNessuna valutazione finora

- POINPRE66L - Pressure Switch POINPRE - Rv05Documento1 paginaPOINPRE66L - Pressure Switch POINPRE - Rv05EMMA VIDALNessuna valutazione finora

- Sihp3wg4 Product ManualDocumento2 pagineSihp3wg4 Product ManualPál HústalzNessuna valutazione finora

- Vivre Louvers by Vivre PanelsDocumento83 pagineVivre Louvers by Vivre PanelsAnkit JaiswalNessuna valutazione finora