Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

BS EN 124 Product Specification Guide

Caricato da

ZC47Descrizione originale:

Titolo originale

Copyright

Formati disponibili

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoCopyright:

Formati disponibili

BS EN 124 Product Specification Guide

Caricato da

ZC47Copyright:

Formati disponibili

……………………………………………………………………………………………………………………………………………………………..

……………………………………………

BS EN 124 – Standard Classification

• Access covers and gully grates installed in the UK should meet the

requirements of the European Standard BS EN 124.

• This applies to all situations, on and off-load and to all materials.

• Products designed to BS EN 124 are grouped and classified depending on their

place of installation.

• It is the responsibility of the engineer to ensure that the correct product is

specified.

• The appropriate class of manhole top or gully top to be used depends upon the

place of installation.

• The selection of the appropriate class is the responsibility of the designer.

• Where there is any doubt the stronger class should be selected.

• This standard divides access covers and gully grates into a number of classes by

static test load. It also categorises the various places where they may be

installed from Group 1, the least demanding environment, through to Group 6,

the most demanding environment. It provides guidance on the minimum class to

be used against each installation group.

• Group 1 – minimum Class A15 – Access covers and gratings capable of

withstanding a 15kN test load. For use in areas where only pedestrians have

access.

• Group 2 – minimum Class B125 – Access covers and gratings capable of

withstanding a 125kN test load. For use in car parks and pedestrian areas

where only occasional vehicular access is likely.

• Group 3 – minimum Class C250 – Access covers and gratings capable of

withstanding a 250kN test load. For use in car parks, forecourts, industrial sites

and areas with slow moving traffic also in highway locations up to 500mm from

the kerb and up to 200mm into the verge, excluding motorways.

• Group 4 – minimum Class D400 – Access covers and gratings capable of

withstanding a 400kN test load. For use in areas where cars and lorries have

access, including carriageways, hard shoulders and pedestrian areas.

• Group 5 – minimum Class E600 – Access covers and gratings capable of

withstanding a 600kN test load. For use in areas where high wheel loads are

imposed such as loading areas, docks or aircraft pavements.

• Group 6 – minimum Class F900 – Access covers and gratings capable of

withstanding a 900kN test load. For use in areas where particularly high wheel

loads are imposed such as aircraft pavements.

• All TD covers and gully g rates comply with BS EN 124:2015, However it is

accepted within the industry that the standard (due to both its lack of measure

for dynamic loading and its enforcement) has its limitations and can be

considered inadequate in ensuring that the in situ product is fit for purpose.

(Those areas are covered in more detail in our specification guide.

……………………………………………………………………………………………………………………………………………………………..……………………………………………

• In order to counter this TD (often uniquely within the sector) have introduced a

package of measures:

- D400 and above one standard range for all intensity of

traffic including HIGH INTENSITY

- Corner Testing of product as standard (most failures occur

in the corners as various importers concentrate solely on

passing centre pad load test required by standard and

reduce weight and strength in all other surface areas).

- Full transparency and suite of batch results available for

download online (and hard copies sent on every distributor

delivery).

- UK testing of all batches.

• Free UK testing and drop in for witnessing random testing of TD product and

incumbent supplier testing (again FREE).

BS EN 124 – Product Specification

The BS EN 124 standard provides a general guide to product stability and sets out test

load parameters for the various classes of products in terms of static load tests.

It does not provide specific information on dynamic loads imposed by the wide variety

of traffic conditions found on modern road systems. It therefore has its limitations with

regard making a truly informed specification decision in terms of the installed product

being fir for purpose.

The selection of product in the majority of cases is straightforward. However

increasingly road conditions make selecting a fit for purpose product more acute. In all

instances Thomas Dudley offer free to user specification / technical service (contact

details below).

……………………………………………………………………………………………………………………………………………………………..……………………………………………

In addition to this (in line with TD commitment to transparency and continuous

improvement) to simply the task for D400 loadings and above we offer 1 version of

the product that is suitable for any / all intensity of traffic at that load. (These have a

myriad of names within the sector but essentially are standard product is HIGH

INTENSITY). We do not offer low or medium intensity ranges.

With this the specifier and installer will have confidence that their chosen product will

be fit for purpose in all intensities of traffic at that loading.

Below we have highlighted those instances whereby higher intensity product is more

often than not required:

1. Dual carriageways

Higher speeds of traffic naturally increases the dynamic impact loading on castings. So

to can heavy braking zones towards traffic lights and roundabouts.

2. Traffic lights

Acceleration, deceleration and turning all increase the stress on ironwork

3. Roundabouts

Turning vehicles increase movement and torque between cover/grate and frame and

ultimate increase the stress.

4. Changes of Load Scenarios

Areas such as conversion to bus routes, one way, traffic calming, road maintenance,

temporary use of central reservation / hard shoulders can apply directional (and

clipping point), volume, and acceleration and deceleration stresses that original

specification was not envisaged.

Potrebbero piacerti anche

- BS en 00124-6-2015Documento42 pagineBS en 00124-6-2015myenas87Nessuna valutazione finora

- Bs 7263 Part 1 1994 SpecificationDocumento25 pagineBs 7263 Part 1 1994 Specificationmohamed samirNessuna valutazione finora

- MS ISO 6182-7-2009 (CONFIRMED 2015) Automatic Sprinkler Systems - Requirements and Test Method For Early SuppresionDocumento52 pagineMS ISO 6182-7-2009 (CONFIRMED 2015) Automatic Sprinkler Systems - Requirements and Test Method For Early SuppresionChung Yee Yong100% (1)

- BS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary BlocksDocumento10 pagineBS EN 772 Part 20-2000-Determination of Flatness of Faces of Masonary Blocksjerin sam kurianNessuna valutazione finora

- Aspen Uksrg GuidelinesDocumento32 pagineAspen Uksrg GuidelinesEshaan Awan100% (1)

- Malaysian Standards for Water SupplyDocumento6 pagineMalaysian Standards for Water SupplyalvinhamNessuna valutazione finora

- MS 628-2 2014 - Prepdf PDFDocumento9 pagineMS 628-2 2014 - Prepdf PDFzulkainiNessuna valutazione finora

- BS en 00040-1-1992 (2006) PDFDocumento14 pagineBS en 00040-1-1992 (2006) PDFShan Sandaruwan AbeywardeneNessuna valutazione finora

- BS 6375-1-2015 - (2015-05-18 - 09-55-44 PM)Documento26 pagineBS 6375-1-2015 - (2015-05-18 - 09-55-44 PM)MarcinNessuna valutazione finora

- (BS en 124) - Gully Tops and Manhole Tops For Vehicular and Pedestrian AreasDocumento78 pagine(BS en 124) - Gully Tops and Manhole Tops For Vehicular and Pedestrian Areasion ingenieria ion ingenieria100% (2)

- Standards For Pipes and FittingsDocumento11 pagineStandards For Pipes and FittingsMohammed sabatinNessuna valutazione finora

- BS en 124-2 - 2015Documento36 pagineBS en 124-2 - 2015Design Frame Cover100% (4)

- EN 295 - Part 4-95Documento20 pagineEN 295 - Part 4-95龙琦Nessuna valutazione finora

- Rain Water Piping SystemDocumento17 pagineRain Water Piping Systemerma ezdiani mokhy100% (1)

- BS en 845-2+a1-206Documento50 pagineBS en 845-2+a1-206Rajinda Bintang100% (1)

- Guide To SDRDocumento36 pagineGuide To SDRssarang100% (1)

- 12-Division 2-Section 02400 Pipeline by NDM-V 2.0Documento26 pagine12-Division 2-Section 02400 Pipeline by NDM-V 2.0Avaan IvaanNessuna valutazione finora

- Saso Gso 1438 2003 e PDFDocumento12 pagineSaso Gso 1438 2003 e PDFshafeeqm3086Nessuna valutazione finora

- BS 729-1971 Hot Ip Galvanized Coatings On Iron and Steel ArticlesDocumento15 pagineBS 729-1971 Hot Ip Galvanized Coatings On Iron and Steel Articlesjun005100% (1)

- British Standard: A Single Copy of This British Standard Is Licensed ToDocumento15 pagineBritish Standard: A Single Copy of This British Standard Is Licensed TopieremicheleNessuna valutazione finora

- BS 6263 - 2 Care and Maintenance of Floor Surfaces PDFDocumento16 pagineBS 6263 - 2 Care and Maintenance of Floor Surfaces PDFTom YeeNessuna valutazione finora

- Heat pump 50Hz installation and specifications guideDocumento408 pagineHeat pump 50Hz installation and specifications guideHải Trần Quốc100% (1)

- TMS 302 Sound STD Commentary UpdateDocumento15 pagineTMS 302 Sound STD Commentary UpdateHani Nemrawi100% (1)

- Bs 3600Documento12 pagineBs 3600Lucian ChituNessuna valutazione finora

- MS 1058 - Part 3 - 2006 PDFDocumento31 pagineMS 1058 - Part 3 - 2006 PDFNurul AkmaNessuna valutazione finora

- BS 1722-14-1992 Specification For Open Mesh Steel Panel FencesDocumento24 pagineBS 1722-14-1992 Specification For Open Mesh Steel Panel FencesAnoyNessuna valutazione finora

- Hydraulic Services DesignDocumento10 pagineHydraulic Services DesignSeenivasan GovindarajNessuna valutazione finora

- BS1881-131 1998Documento17 pagineBS1881-131 1998venkateswara rao PothinaNessuna valutazione finora

- As 4049.5-2007 Paints and Related Materials - Pavement Marking Materials Performance Assessment of Pavement MDocumento8 pagineAs 4049.5-2007 Paints and Related Materials - Pavement Marking Materials Performance Assessment of Pavement MSAI Global - APACNessuna valutazione finora

- MS 1183 5 1990Documento40 pagineMS 1183 5 1990Yeo WeizheNessuna valutazione finora

- Saso StandardsDocumento16 pagineSaso StandardsshafeeqmNessuna valutazione finora

- BS 1362 General Purpose Fuse Links For Domestic and Similar Purposes (Primarily For Use in Plugs)Documento24 pagineBS 1362 General Purpose Fuse Links For Domestic and Similar Purposes (Primarily For Use in Plugs)Mohamed987Nessuna valutazione finora

- Bsi-7263-1 Concrete Pre-Cast Unreinforced Concrete Paving F PDFDocumento42 pagineBsi-7263-1 Concrete Pre-Cast Unreinforced Concrete Paving F PDFAshraf TomizehNessuna valutazione finora

- Din 19537-1Documento19 pagineDin 19537-1FathyNessuna valutazione finora

- BS en 01253-4-2000 PDFDocumento10 pagineBS en 01253-4-2000 PDFsamNessuna valutazione finora

- MS 628-3 2014 - PrepdfDocumento7 pagineMS 628-3 2014 - PrepdfMay OngNessuna valutazione finora

- BS en 1453 1 2017Documento34 pagineBS en 1453 1 2017Mohamed Amdouni100% (1)

- BS en 13707-2013Documento44 pagineBS en 13707-2013Adel A. AbdelazizNessuna valutazione finora

- BS 13598Documento20 pagineBS 13598E Hammam El MissiryNessuna valutazione finora

- En 12977-1-2012Documento24 pagineEn 12977-1-2012PV DouzNessuna valutazione finora

- BSEN 50086 2 4 Conduit System Buried Underground PDFDocumento16 pagineBSEN 50086 2 4 Conduit System Buried Underground PDFSunil Devdutt Thakore100% (1)

- BS 437 - Cast Iron Spigot and Socket Drain Pipes and FittingsDocumento58 pagineBS 437 - Cast Iron Spigot and Socket Drain Pipes and FittingsSubhash Sharma100% (2)

- BS en 12428-2013 PDFDocumento18 pagineBS en 12428-2013 PDFcoolkaisyNessuna valutazione finora

- As 1145.1-2001 Determination of Tensile Properties of Plastics Materials General PrinciplesDocumento6 pagineAs 1145.1-2001 Determination of Tensile Properties of Plastics Materials General PrinciplesSAI Global - APACNessuna valutazione finora

- 03-DG-Section 3 Sewerage System Design-Version 7.0Documento53 pagine03-DG-Section 3 Sewerage System Design-Version 7.0MMMSLOUHNessuna valutazione finora

- ADM Specs GRP Enclosures and KiosksDocumento3 pagineADM Specs GRP Enclosures and KiosksMahiBoumNessuna valutazione finora

- CP 00342-2-1974 (2007) PDFDocumento30 pagineCP 00342-2-1974 (2007) PDFStanislav PerevezentsevNessuna valutazione finora

- Astm-F1759 - Hdpe Mahole DesignDocumento12 pagineAstm-F1759 - Hdpe Mahole DesignSusanta PanigrahyNessuna valutazione finora

- BS en 10137-3-1996Documento14 pagineBS en 10137-3-1996Martijn GrootNessuna valutazione finora

- How to Create PDFs with pdfFactory Pro TrialDocumento12 pagineHow to Create PDFs with pdfFactory Pro Trialestabeja100% (1)

- Is 9523 (2000) - Ductile Iron Fittings For Pressure Pipes For Water, Gas and SewageDocumento38 pagineIs 9523 (2000) - Ductile Iron Fittings For Pressure Pipes For Water, Gas and SewageSainaveen Thota100% (2)

- BSI - CubesDocumento18 pagineBSI - CubesJay Musa0% (1)

- BS 00644 2009 (En) PDFDocumento28 pagineBS 00644 2009 (En) PDFMahendran MNessuna valutazione finora

- Commercial & Industrial: Product ManualDocumento87 pagineCommercial & Industrial: Product ManualjctroskieNessuna valutazione finora

- Spring SupportDocumento51 pagineSpring SupportYinka AkinkunmiNessuna valutazione finora

- Doleco Cargo ControlDocumento84 pagineDoleco Cargo Controlarcazulproveeduria16Nessuna valutazione finora

- Burndy Solar Solutions BrochureDocumento6 pagineBurndy Solar Solutions BrochureyesrtyNessuna valutazione finora

- Belt Conveyors, Stackers and Reclaimers and ReclaimersDocumento34 pagineBelt Conveyors, Stackers and Reclaimers and ReclaimersAndreNunesNessuna valutazione finora

- Norma Connect DCSDocumento24 pagineNorma Connect DCSAndy LuthorNessuna valutazione finora

- Selection Guide Fluid Coupling NewDocumento34 pagineSelection Guide Fluid Coupling NewIsaac Montero Barrera100% (1)

- MDCGS PDFDocumento12 pagineMDCGS PDFBrinleyNessuna valutazione finora

- Standardization of The Environmental Information For Asphalt TechnologiesDocumento10 pagineStandardization of The Environmental Information For Asphalt TechnologiesZC47Nessuna valutazione finora

- 7 Krishnaveni ArthiDocumento14 pagine7 Krishnaveni ArthiMahesh K sNessuna valutazione finora

- PA&D Lec 1Documento69 paginePA&D Lec 1ZC47Nessuna valutazione finora

- AggregatesDocumento47 pagineAggregatesZC47Nessuna valutazione finora

- Statistical Data PresentationDocumento39 pagineStatistical Data PresentationZC47Nessuna valutazione finora

- History PaperDocumento5 pagineHistory PaperZC47Nessuna valutazione finora

- Wasa Design CriteriaDocumento64 pagineWasa Design CriteriaZC47100% (1)

- History PaperDocumento5 pagineHistory PaperZC47Nessuna valutazione finora

- Descriptive Statistics (Central Tendency)Documento33 pagineDescriptive Statistics (Central Tendency)ZC47Nessuna valutazione finora

- QA Assignment # 1Documento5 pagineQA Assignment # 1ZC47Nessuna valutazione finora

- Tem-515: Statistical Analyses With Computer Application: Department of Transportation Engineering and ManagementDocumento23 pagineTem-515: Statistical Analyses With Computer Application: Department of Transportation Engineering and ManagementZC47Nessuna valutazione finora

- NCCADocumento7 pagineNCCAZC47Nessuna valutazione finora

- NCCADocumento7 pagineNCCAZC47Nessuna valutazione finora

- Tem-515: Statistical Analyses With Computer Application: Lecture Series 1: Introduction To Data CollectionDocumento37 pagineTem-515: Statistical Analyses With Computer Application: Lecture Series 1: Introduction To Data CollectionZC47Nessuna valutazione finora

- Introduction to Statistics Lecture 1Documento30 pagineIntroduction to Statistics Lecture 1AdnanNessuna valutazione finora

- GDHS Spring 2017 - Design Controls and Criteria (1) (For Class)Documento21 pagineGDHS Spring 2017 - Design Controls and Criteria (1) (For Class)ZC47Nessuna valutazione finora

- LEC 03 - Descriptive StatisticsDocumento42 pagineLEC 03 - Descriptive StatisticsZC47Nessuna valutazione finora

- A Study of Food Handlers in Public FoodDocumento5 pagineA Study of Food Handlers in Public FoodZC47Nessuna valutazione finora

- Airport Runway Designation and PlacementDocumento8 pagineAirport Runway Designation and PlacementZC47Nessuna valutazione finora

- SACA - 5 - Linear Regression (Compatibility Mode)Documento15 pagineSACA - 5 - Linear Regression (Compatibility Mode)ZC47Nessuna valutazione finora

- LEC 03 - Descriptive StatisticsDocumento42 pagineLEC 03 - Descriptive StatisticsZC47Nessuna valutazione finora

- SACA - 5 - CORRELATION - 2 (Compatibility Mode)Documento41 pagineSACA - 5 - CORRELATION - 2 (Compatibility Mode)ZC47Nessuna valutazione finora

- Food Safety KAP AnalysisDocumento6 pagineFood Safety KAP AnalysisZC47Nessuna valutazione finora

- Disruptive Innovation Risk-Shifting and Precarity in The Age of UberDocumento20 pagineDisruptive Innovation Risk-Shifting and Precarity in The Age of UberZC47Nessuna valutazione finora

- Transportation Network Companies and Paratransit.Documento14 pagineTransportation Network Companies and Paratransit.ZC47Nessuna valutazione finora

- An Exploratory Study On Uber, GrabCar, and Conventional Taxis in Metro Manila.Documento15 pagineAn Exploratory Study On Uber, GrabCar, and Conventional Taxis in Metro Manila.ZC47Nessuna valutazione finora

- A Study On Factors Influencing-3700Documento5 pagineA Study On Factors Influencing-3700Saras AgrawalNessuna valutazione finora

- 09 - Chapter 1 PDFDocumento45 pagine09 - Chapter 1 PDFZC47Nessuna valutazione finora

- Vehicle Operations MaintenanceDocumento49 pagineVehicle Operations MaintenanceZC47Nessuna valutazione finora

- Public Awareness Campaign ManualDocumento29 paginePublic Awareness Campaign ManualPadma ShahiNessuna valutazione finora

- 08 Stopping Sight DistanceDocumento39 pagine08 Stopping Sight Distancegetachew ambayeNessuna valutazione finora

- Solution To Traffic AccidentDocumento2 pagineSolution To Traffic AccidentPham Thi Nhung QP3145Nessuna valutazione finora

- Accident Scene ChecklistDocumento3 pagineAccident Scene ChecklistAbdelhamid SadNessuna valutazione finora

- Bartley Smith Greenway Trail MapDocumento1 paginaBartley Smith Greenway Trail MapMenandro AmbanlocNessuna valutazione finora

- AMB Vehicle For Hire Fillable Forms - Zoom PDFDocumento8 pagineAMB Vehicle For Hire Fillable Forms - Zoom PDFVedant SharmaNessuna valutazione finora

- Pavement Design & Traffic Census WorkshopDocumento38 paginePavement Design & Traffic Census WorkshopJK HallNessuna valutazione finora

- Geometric Design of HighwaysDocumento94 pagineGeometric Design of HighwaysNatukunda NathanNessuna valutazione finora

- Hearing Handout Packet: Environmental AssessmentDocumento41 pagineHearing Handout Packet: Environmental AssessmentWBAYNessuna valutazione finora

- Volvo S60 ANCAP PDFDocumento2 pagineVolvo S60 ANCAP PDFcarbasemyNessuna valutazione finora

- Safe Load Securing ChecklistDocumento2 pagineSafe Load Securing ChecklistIRU100% (3)

- Tennessee 2011Documento61 pagineTennessee 2011drivershandbooksNessuna valutazione finora

- Road Markings k53 Learners Licence Test Website PDFDocumento4 pagineRoad Markings k53 Learners Licence Test Website PDFClassic DeepNessuna valutazione finora

- Florida Traffic Crash Report ManualDocumento67 pagineFlorida Traffic Crash Report ManualRabie AlzifiteNessuna valutazione finora

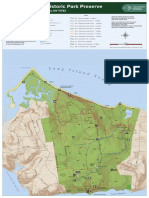

- Caumsett State Historic Park Preserve: Isla ND SoDocumento1 paginaCaumsett State Historic Park Preserve: Isla ND SoJosh WexlerNessuna valutazione finora

- Loksabhaquestions Annex 1712 AU684Documento27 pagineLoksabhaquestions Annex 1712 AU684Amit ChitwarNessuna valutazione finora

- The Federal Democratic Republic of Ethio PDFDocumento68 pagineThe Federal Democratic Republic of Ethio PDFVõ Quang KiệtNessuna valutazione finora

- National Highway of IndiaDocumento16 pagineNational Highway of IndiaBhupendra Singh100% (1)

- Guidelines For Traffic ControllersDocumento36 pagineGuidelines For Traffic ControllersAli AbdurrahmanSungkar0906631036Nessuna valutazione finora

- Work Progress-Bar ChartDocumento20 pagineWork Progress-Bar ChartLakmal JayashanthaNessuna valutazione finora

- 17 5 2019 12 21 56 Janrat-FinalDocumento73 pagine17 5 2019 12 21 56 Janrat-FinalMG WARISNessuna valutazione finora

- Lto Exam Set CDocumento3 pagineLto Exam Set CDanica Joy PaasaNessuna valutazione finora

- Nairobi Expressway Route Map 120522Documento1 paginaNairobi Expressway Route Map 120522Theodore Teddy KahiNessuna valutazione finora

- Feasibility Report DPRDocumento14 pagineFeasibility Report DPRbijendraNessuna valutazione finora

- Lesson 5 Traffic Law Enforcement PDFDocumento20 pagineLesson 5 Traffic Law Enforcement PDFmattlovrjyNessuna valutazione finora

- Manila - Cavite Toll Expressway Project (Cavitex) : VAT Inclusive Toll FeesDocumento6 pagineManila - Cavite Toll Expressway Project (Cavitex) : VAT Inclusive Toll FeesChoy De VillaNessuna valutazione finora

- RoadwayDocumento40 pagineRoadwaymanikandanNessuna valutazione finora

- Company ListDocumento5 pagineCompany ListarvindNessuna valutazione finora

- Civil Engineering Summit 2k20Documento1 paginaCivil Engineering Summit 2k20VeeNessuna valutazione finora

- Public Arrest Report For 05jun2015Documento5 paginePublic Arrest Report For 05jun2015api-214091549Nessuna valutazione finora