Documenti di Didattica

Documenti di Professioni

Documenti di Cultura

Spot Cooling

Caricato da

ocean2202200 valutazioniIl 0% ha trovato utile questo documento (0 voti)

174 visualizzazioni2 pagineSpot Cooling

Copyright

© © All Rights Reserved

Formati disponibili

PDF, TXT o leggi online da Scribd

Condividi questo documento

Condividi o incorpora il documento

Hai trovato utile questo documento?

Questo contenuto è inappropriato?

Segnala questo documentoSpot Cooling

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

0 valutazioniIl 0% ha trovato utile questo documento (0 voti)

174 visualizzazioni2 pagineSpot Cooling

Caricato da

ocean220220Spot Cooling

Copyright:

© All Rights Reserved

Formati disponibili

Scarica in formato PDF, TXT o leggi online su Scribd

Sei sulla pagina 1di 2

No.

111 / June 1999

Spot Cooling Applications

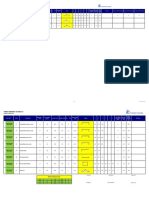

INTRODUCTION Table 1. Throw and Coverage at 40 CFM

This Technical Note provides basic guidelines for spot Distance, ft. Velocity, Coverage

cooling applications using the Unico System. This bulletin ft/min Diameter,

inch

does not discuss human comfort parameters. This is dis- 0 2000 2

cussed in great detail in the ASHRAE Fundamentals 7 200 6

Handbook and other sources. 10 150 8

Factory spot cooling. 12 100 12

20 50 18

Table 2. Throw and Coverage at 30 CFM

Distance, ft Velocity, Coverage

ft/min Diameter,

inch

0 1500 2

5 200 4

8 150 8

10 100 12

14 50 18

IL00211.CNV

erage by angling the outlets at a 45° angle rather than

In all the studies we conducted, worker productivity im-

from directly overhead.

proved, absenteeism and turnover was reduced, and the

employees generally had a better outlook on their job. If the person to be cooled moves about, it is necessary to

place an outlet at least every 3 feet in their work area;

Because spot cooling only cools personnel and not the

otherwise the airflow will not be felt.

surrounding space, it is not possible to calculate the load.

However, it is possible to obtain reasonable comfort by

following the guidelines presented in this Bulletin. DUCT DESIGN

• Use only Supply Tubing (without Sound Attenuator)

PLACEMENT • Use 9-inch metal plenum, insulated

• Locate outlets within 3 foot of work station • Use “flangeless” black terminator

• Aim at 45° • Use 100 percent outside return air

• For moving person, place every 3 foot Many applications for spot cooling will be in areas with

It is extremely important to position the outlets so that the significant background noise. Therefore, it is not impor-

person feels the stream of air. The outlets should always tant to use the Sound Attenuator. Unico recommends us-

be placed where the person can redirect the air stream.

Aluminum Supply Tubing

A00213.cnv

Normally, this means the duct is from 3 to 5 feet from the

(UPC-25)

person.

Plenum Takeoff

Table 1 and 2 lists the throw and coverage of a normal (UPC-28)

outlet at 40 and 30 CFM. Since the branch runs are very

short, the actual airflow and throw could be much higher.

Without any duct, an outlet can blow as much as 60 CFM.

Conversely, for very long duct (over 35 feet), the airflow

may be as only 20 CFM.

Aluminum Core Clamp

It is not necessary to completely cool the surrounding area (UPC-52)

or the full body of the individual. Normally, it is best to Outlet Terminator

cool the head and upper torso. You will get the most cov- (A00411-004)

© Copyright 1999 Unico, Inc.

Technote 111 — Page 2

ing only aluminum supply tubing as this has the added nozzles are considerably more expensive than using a

benefit of holding its shape when bent. short length of aluminum tubing and require a closer

mounted plenum but do have a more traditional “finished”

Using our aluminum supply tubing without a sound at-

look.

tenuator allows the person to reshape the duct so that the

points in the direction required.

SIZING

The plenum should be made of metal as it is sturdier and

the takeoffs are much more secure. It is important, The size of the system is based on the number of outlets.

though, to seal the metal duct and to insulate the duct with The system should be sized for 5 outlets per ton for

at least 1.5 inches of blanket fiberglass or insulation maximum performance. The number of outlets is depend-

ent on three things:

Split before installing

Aluminum Core

• The ambient temperature

• The return air temperature

IL00212.CVN

• Personal comfort level

To maximize performance, we recommend using 100

605

percent outside air. If the outside air temperature drops

below 70°F, you can turn off the condensing unit for

Clamp

economy. For these lower outdoor temperatures, we also

Jacket and Insulation

Part No. UPC-52

(Black)

Spot Cooling Terminator

Part No. A00411-004

recommend using a head pressure control on the con-

(Black) densing unit to reduce possible freeze-ups.

sleeve. Also, be sure to use a foam saddle under the duct Table 3 lists recommended number of outlets for station-

wherever it is supported by a strap. ary workers depending on the application.

Since sound levels are not a concern, only a short length If 100 percent outside air of 95°F is pulled into the return,

of supply tubing is required. There is no requirement for the discharge temperature will be approximately 65-70°F

an outlet other than for aesthetics. We have a special for refrigeration or chilled water systems. For chilled with

black outlet similar to our terminator that does not have a water temperature between 40 and 45°F.

flange specifically for the spot cooling applications. We

highly recommend its use as it makes the job much more The air mixes rapidly so it is important to keep the duct

professional looking. discharge as close the person to be cooled as possible.

Note — When connecting the supply tubing

to the outlet, it is necessary to slit the tube Table 3. Recommended Number of Outlets

end so it fits over the stub. Then use the

Number

clamp and seal the connection as you would Ambient

of Out-

for all outlets. Application Tempera-

lets per

ture, °F

As an alternative, special nozzles such as the Seiho PK-4 worker

“eyeball” can be mounted directly to the plenum. These Warehouse, Assembly 85 – 95 1 –2

lines, Light Industry

Non-ventilated Ware- 90 – 100 2–4

house, Hot factory

Dry Cleaners, Foundries, 100 – 130 4-8

Welding areas

© Copyright 1998 Unico, Inc.

Potrebbero piacerti anche

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDa EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceValutazione: 4 su 5 stelle4/5 (895)

- SPKinney Product Catalog New LiteratureDocumento12 pagineSPKinney Product Catalog New Literatureocean220220Nessuna valutazione finora

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDa EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeValutazione: 4 su 5 stelle4/5 (5794)

- DamperDocumento20 pagineDamperJay SuguitanNessuna valutazione finora

- The Yellow House: A Memoir (2019 National Book Award Winner)Da EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Valutazione: 4 su 5 stelle4/5 (98)

- ANDRITZ Split Case Pump: Highest Efficiencies and Sturdy DesignDocumento6 pagineANDRITZ Split Case Pump: Highest Efficiencies and Sturdy Designocean220220Nessuna valutazione finora

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDa EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureValutazione: 4.5 su 5 stelle4.5/5 (474)

- Guia Diseño RejasDocumento10 pagineGuia Diseño RejasJose Alberto Muñoz FloresNessuna valutazione finora

- Shoe Dog: A Memoir by the Creator of NikeDa EverandShoe Dog: A Memoir by the Creator of NikeValutazione: 4.5 su 5 stelle4.5/5 (537)

- Nebb T&CDocumento118 pagineNebb T&Cbabmech6007100% (3)

- The Little Book of Hygge: Danish Secrets to Happy LivingDa EverandThe Little Book of Hygge: Danish Secrets to Happy LivingValutazione: 3.5 su 5 stelle3.5/5 (399)

- Plane and Principal Stress - 2Documento32 paginePlane and Principal Stress - 2adnankhan1988Nessuna valutazione finora

- TIA-942 Addendum 2Documento40 pagineTIA-942 Addendum 2ocean220220100% (1)

- On Fire: The (Burning) Case for a Green New DealDa EverandOn Fire: The (Burning) Case for a Green New DealValutazione: 4 su 5 stelle4/5 (73)

- Anti CondensationDocumento2 pagineAnti Condensationocean220220Nessuna valutazione finora

- Never Split the Difference: Negotiating As If Your Life Depended On ItDa EverandNever Split the Difference: Negotiating As If Your Life Depended On ItValutazione: 4.5 su 5 stelle4.5/5 (838)

- Balancing ValveDocumento2 pagineBalancing Valveocean220220Nessuna valutazione finora

- Grit: The Power of Passion and PerseveranceDa EverandGrit: The Power of Passion and PerseveranceValutazione: 4 su 5 stelle4/5 (588)

- BE YK EngineeringGuide HDocumento88 pagineBE YK EngineeringGuide Hocean220220100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDa EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryValutazione: 3.5 su 5 stelle3.5/5 (231)

- 1200 Buildings Program BMS Seminar 1Documento37 pagine1200 Buildings Program BMS Seminar 1HayanJanakatNessuna valutazione finora

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDa EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaValutazione: 4.5 su 5 stelle4.5/5 (266)

- 056-075 Taylor PDFDocumento20 pagine056-075 Taylor PDFJuanolivares ReynaNessuna valutazione finora

- BMS FaqDocumento5 pagineBMS Faqocean220220Nessuna valutazione finora

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDa EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersValutazione: 4.5 su 5 stelle4.5/5 (344)

- Trane Chiller Plant Admapn014en - 0105Documento4 pagineTrane Chiller Plant Admapn014en - 0105a_salehiNessuna valutazione finora

- The Emperor of All Maladies: A Biography of CancerDa EverandThe Emperor of All Maladies: A Biography of CancerValutazione: 4.5 su 5 stelle4.5/5 (271)

- Variable Inlet Guide VaneDocumento3 pagineVariable Inlet Guide Vaneocean220220Nessuna valutazione finora

- CHP Clean Energy SolutionDocumento24 pagineCHP Clean Energy SolutionFrank MtetwaNessuna valutazione finora

- Team of Rivals: The Political Genius of Abraham LincolnDa EverandTeam of Rivals: The Political Genius of Abraham LincolnValutazione: 4.5 su 5 stelle4.5/5 (234)

- Energy Policies of Korea IEA 2016Documento140 pagineEnergy Policies of Korea IEA 2016ocean220220Nessuna valutazione finora

- Policy Framework and The Promotion of Cogeneration in MalaysiaDocumento13 paginePolicy Framework and The Promotion of Cogeneration in Malaysiaocean220220Nessuna valutazione finora

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDa EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreValutazione: 4 su 5 stelle4/5 (1090)

- Review of The Distributed Generation Concept - Attempt of UnificationDocumento4 pagineReview of The Distributed Generation Concept - Attempt of Unificationocean220220Nessuna valutazione finora

- The Unwinding: An Inner History of the New AmericaDa EverandThe Unwinding: An Inner History of the New AmericaValutazione: 4 su 5 stelle4/5 (45)

- Singapore: 1. Goals For Efficiency Improvement Overall Energy Efficiency Improvement GoalsDocumento11 pagineSingapore: 1. Goals For Efficiency Improvement Overall Energy Efficiency Improvement Goalsocean220220Nessuna valutazione finora

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDa EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyValutazione: 3.5 su 5 stelle3.5/5 (2259)

- Regulations VSPP Renew 10 MW EngDocumento10 pagineRegulations VSPP Renew 10 MW EngSébastien WagemansNessuna valutazione finora

- 01 District Energy Chapter 1 - PrintDocumento26 pagine01 District Energy Chapter 1 - Printocean220220Nessuna valutazione finora

- Fcsi CKV White PaperDocumento39 pagineFcsi CKV White PaperSasa NackovicNessuna valutazione finora

- Investors Look Again at CHPDocumento8 pagineInvestors Look Again at CHPocean220220Nessuna valutazione finora

- Ozone Mitigation TestDocumento23 pagineOzone Mitigation Testocean220220Nessuna valutazione finora

- Radon EngDocumento110 pagineRadon EngEjder KenanNessuna valutazione finora

- Water Treatment For Cooling TowersDocumento57 pagineWater Treatment For Cooling TowersKiran Duggaraju100% (3)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)Da EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Valutazione: 4.5 su 5 stelle4.5/5 (120)

- Kitchen Ventilation Design Guide 2Documento14 pagineKitchen Ventilation Design Guide 2palindapcNessuna valutazione finora

- ED600Documento5 pagineED600Mohamed TahounNessuna valutazione finora

- Flash CalcinationDocumento4 pagineFlash CalcinationalulatekNessuna valutazione finora

- Eutectic Cell and Nodule Count in Cast Irons: International Journal of Cast Metals ResearchDocumento8 pagineEutectic Cell and Nodule Count in Cast Irons: International Journal of Cast Metals ResearchKhairul MuzafarNessuna valutazione finora

- Causes and Prevention of Cracks in BuildingDocumento34 pagineCauses and Prevention of Cracks in Buildingvatika100% (2)

- W11 Normal and Higher Strength Hull Structural Steels W11Documento45 pagineW11 Normal and Higher Strength Hull Structural Steels W11Fernando ReyesNessuna valutazione finora

- Full Report of Structure G2Documento46 pagineFull Report of Structure G2Farah ArishaNessuna valutazione finora

- 4130-2009 (A1)Documento37 pagine4130-2009 (A1)Vardhan100% (1)

- DVM S Technical Bulletins - DVM S System Refrigerant Pump Down Guideline PDFDocumento2 pagineDVM S Technical Bulletins - DVM S System Refrigerant Pump Down Guideline PDFDavid AlmeidaNessuna valutazione finora

- Procedure of CrossingDocumento68 pagineProcedure of Crossingrizalbaso100% (4)

- 2017 LATBSDC CRITERIA - Final - 06 08 17 PDFDocumento72 pagine2017 LATBSDC CRITERIA - Final - 06 08 17 PDFRannie IsonNessuna valutazione finora

- Modelling of Negative Skin Friction On Bored Piles in ClayDocumento64 pagineModelling of Negative Skin Friction On Bored Piles in ClayLordM00nNessuna valutazione finora

- Welding Questions 1Documento26 pagineWelding Questions 1dselvakuuNessuna valutazione finora

- Her Body and Other Parties: StoriesDa EverandHer Body and Other Parties: StoriesValutazione: 4 su 5 stelle4/5 (821)

- 3 WO Copper NickelDocumento78 pagine3 WO Copper NickelAnonymous Kr13NEBNessuna valutazione finora

- Thermal ComfortDocumento25 pagineThermal Comfortshahzadali0786Nessuna valutazione finora

- Columns and StrutsDocumento10 pagineColumns and StrutsamitsagaNessuna valutazione finora

- Alloy Steels - Engineering Materials & Metallurgy Questions and Answers - SanfoundryDocumento6 pagineAlloy Steels - Engineering Materials & Metallurgy Questions and Answers - SanfoundrySample UseNessuna valutazione finora

- Monitoring Pekerjaan Dan MaterialDocumento3 pagineMonitoring Pekerjaan Dan MaterialHarits Angga KusumaNessuna valutazione finora

- Control Valve Interview Questions and AnswersDocumento11 pagineControl Valve Interview Questions and Answersakmal100% (2)

- AC018KN4DCH - WBMF Front Wind Baffle SubmittalDocumento2 pagineAC018KN4DCH - WBMF Front Wind Baffle SubmittalChin Heng LimNessuna valutazione finora

- Bar Bending Batching PlantDocumento3 pagineBar Bending Batching PlantAnonymous 5OUozYNessuna valutazione finora

- Sikaplast® 204: Product DatasheetDocumento2 pagineSikaplast® 204: Product DatasheetTiger CageNessuna valutazione finora

- Split Type Air Conditioner Ceiling Type (60Hz) : Indoor Unit Outdoor UnitDocumento11 pagineSplit Type Air Conditioner Ceiling Type (60Hz) : Indoor Unit Outdoor UnitThiago FrazãoNessuna valutazione finora

- On Base PlateDocumento20 pagineOn Base PlateHemant SonawadekarNessuna valutazione finora

- Service Cabinet and Transformer Breaker Sizing 1082004Documento49 pagineService Cabinet and Transformer Breaker Sizing 1082004Hazem HassanNessuna valutazione finora

- Project: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedDocumento2 pagineProject: 1x950 TDS/Day Soda Recovery Boiler Customer: ITC LTD., - PSPD Enmas Engenius Projects LimitedV U P RaoNessuna valutazione finora

- Lecture02 Slides ME382 UofMDocumento13 pagineLecture02 Slides ME382 UofMCasey HollowayNessuna valutazione finora

- Glass and Glazing Products IIDocumento46 pagineGlass and Glazing Products IIKArthik AustinNessuna valutazione finora

- WG 325 PDFDocumento1 paginaWG 325 PDFمحمد مقلدNessuna valutazione finora

- Strategies in LightDocumento32 pagineStrategies in Lightsang_halNessuna valutazione finora

- 2 Plastic DeformationDocumento33 pagine2 Plastic DeformationpremquilonNessuna valutazione finora

- Cere 131.2 EditedDocumento3 pagineCere 131.2 EditedMary Elizabeth SolasNessuna valutazione finora